NTC Thermistor Applications

Comprehensive Guide to NTC Thermistor Applications What is ntc thermistor? (Negative Temperature Coefficient) NTC thermistors are essential components in many electronic circuits and devices due to their unique temperature-sensitive resistance properties. U……

Comprehensive Guide to N TC Thermistor Applications

W hat is ntc thermistor?

(Negative Temperature Coefficient) NTC thermistors are essential components in many electronic circuits and devices due to their unique temperature-sensitive resistance properties. Unlike other resistors, NTC thermistor decreases in resistance as temperature increases, making them ideal for various applications such as temperature measurement, control, and compensation. In this article, we will explore the various applications of NTC thermistors, highlighting their roles in surge current suppression, temperature compensation, temperature measurement and control, and temperature sensing.

How does ntc thermistor work?

When the device is powered on, the NTC thermistor’s high resistance restricts the surge current. As the thermistor heats up due to the current flow, its resistance decreases, allowing normal current to pass through with minimal voltage drop. This self-regulating behavior makes NTC thermistors ideal for protecting power supplies, transformers, and other electronic circuits from surge damage.

Surge Current Suppression

Role of NTC Thermistors in Surge Current Suppression

Surge currents, also known as inrush currents, occur when an electrical device is initially powered on, causing a momentary spike in current. This surge can damage components or reduce the lifespan of the device. NTC thermistors are effective in suppressing these surges due to their high initial resistance, which limits the inrush current.

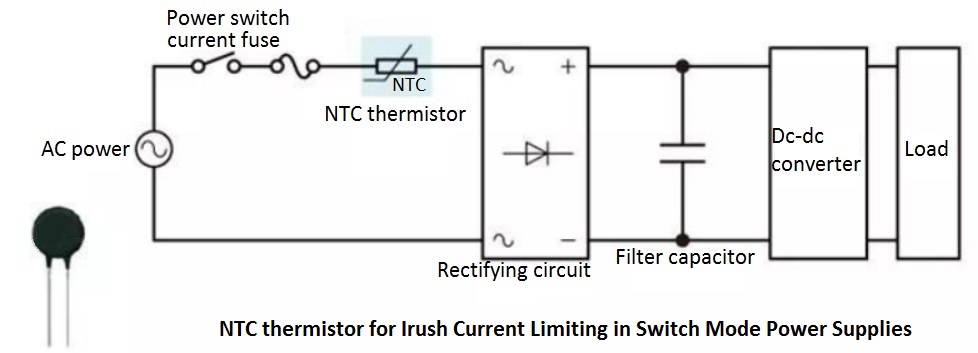

As shown in the circuit below, negative temperature coefficient ntc thermistor is widely used in limiting the inrush current of SMPS,that is a low-cost and simple circuit method. The same result can be obtained even if the NTC thermistor is connected after the rectifier circuit.

Figure 1: NTC thermistor for I rush Current Limiting in Switch Mode Power Supplies

Temperature Compensation

Importance in Electronic Circuits

Electronic components such as transistors, diodes, and integrated circuits can exhibit changes in performance due to temperature variations. NTC thermistor is used to stabilize and compensate for these changes, ensuring consistent operation.

Applications

- Crystal Oscillators : NTC thermistor helpsmaintain the frequency stability of crystal oscillators in temperature-sensitive environments.

- Battery Packs : In rechargeable battery packs, NTC thermistors monitor and manage temperature to prevent overheating and ensure safe operation.

- Precision Instruments : In high-precision measurement instruments, NTC thermistors compensate for ambient temperature variations, maintaining accuracy.

Temperature Measurement and Control

Precision and Reliability

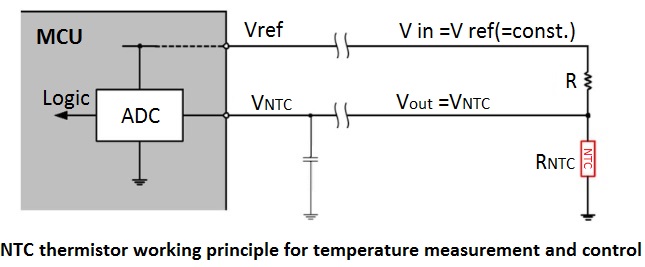

NTC thermistors are widely used in temperature measurement and control applications due to their high sensitivity and accuracy over a wide temperature range. Their rapid response to temperature changes makes them suitable for real-time monitoring and control.The working principle diagram is as follows:

Specific Uses

- HVAC Systems : NTC thermistors are integral in heating, ventilation, and air conditioning systems for accurate temperature regulation and energy efficiency.

- Medical Devices : In medical equipment, such as incubators and dialysis machines, NTC thermistors ensure precise temperature control, critical for patient safety.

- Consumer Electronics : Devices like smartphones, laptops, and wearable technology use thermistors ntc for thermal management, preventing overheating and optimizing performance.

Temperature Sensing

Versatility in Applications

NTC thermistors are commonly used as temperature sensors due to their durability, small size, and cost-effectiveness. They can be embedded in various environments to provide accurate temperature readings.

Examples

- Automotive Industry : NTC thermistors are used in engine management systems to monitor coolant and oil temperatures, ensuring optimal engine performance.

- Home Appliances : Refrigerators, ovens, and dishwashers use NTC thermistors to regulate temperature and enhance efficiency.

- Industrial Processes : In industrial automation, NTC thermistors monitor temperatures in processes such as chemical manufacturing and food production to maintain quality and safety standards.

Other Applications of NTC Thermistors

In Renewable Energy Systems

NTC thermistors play a crucial role in the efficiency and safety of renewable energy systems. In solar power systems, they monitor and manage the temperature of solar panels and inverters, preventing overheating and ensuring optimal energy conversion.

In Aerospace Technology

The aerospace industry relies on NTC thermistors for temperature monitoring in critical systems such as avionics and environmental control systems. Their reliability and precision are vital for maintaining safety and performance in harsh conditions.

In Telecommunication

NTC thermistors are used in telecommunication equipment to stabilize the temperature of electronic circuits, ensuring reliable data transmission and preventing thermal-related failures.

In Consumer Goods

From household appliances to personal gadgets, thermistors ntc is integral in managing and controlling temperatures. This includes use in coffee makers, electric kettles, and even hairdryers, where precise temperature control is essential for functionality and safety.

Conclusion

NTC thermistors are indispensable components across a wide range of applications due to their unique temperature-sensitive resistance properties. Their roles in surge current suppression, temperature compensation, temperature measurement and control, and temperature sensing highlight their versatility and importance in modern technology. By incorporating NTC thermistors, engineers and designers can enhance the performance, safety, and reliability of various electronic devices and systems.

You may also like

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd