Glass Thermistors MF58E for High-Precision Applications

Introducing DXM's Glass Thermistors for High-Precision Applications. Our glass encapsulated thermistor provides reliable temperature sensing with unmatched NTC resistor precision. Ideal for demanding environments, DXM's glass thermistors ensure optimal performance and durability. Enhance your systems with the industry-leading choice for accurate temperature control.

Why Glass Thermistors Are Crucial for Reliable Temperature Control

Glass thermistors, are vital in temperature control systems. Our MELF-333H3950F NTC resistor meets the strict needs of automotive, aerospace, and electronics industries. With an impressive operating range of -40°C to 300°C, this glass encapsulated thermistor ensures reliability under extreme conditions. Glass thermistors are indispensable where precision and safety matter, providing consistent and accurate temperature sensing, making them ideal for critical systems.

Key Features of Glass Thermistors for Reliable Performance

Our glass thermistors offer strong protection against environmental impacts. This glass encapsulated thermistor ensures long-term stable performance. Key features include:

Technical Specifications of the MF58E-333H3950F Glass Thermistors

The MF58E-333H3950 glass thermistors provide precise resistance-temperature characteristics. Below are the technical specifications to help you better understand its performance metrics:

Model Number: MF58E-333H3950F

| Item | Description | Electrical Parameters |

| 1 | Product Type | NTC Glass Thermistors |

| 2 | Resistance at 25°C (R25) | 33 kΩ ± 3% |

| 3 | Thermistor B Value (B25/50): | 3950K±1% |

| 4 | High Insulation Resistance | minimum 100MΩ @ 500VDC |

| 5 | Thermal time constant ( τ ) | 8~12 sec in still air |

| 6 | Thermal dissipation constant ( δ ) | minimum 1.4 mw/°C in still air |

| 7 | Operating temperature range | -40~+300°C |

- Reliable under thermal shock and vibration.

This NTC resistor is essential for stability and accuracy in critical conditions, ensuring consistent and reliable temperature control.

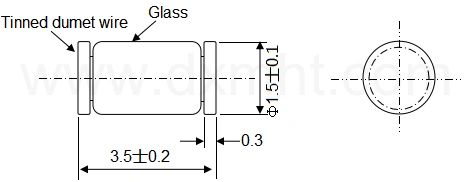

Dimensions and Outlooks of MF58E Glass Encapsulated Thermistor

Applications of Glass Thermistors

The versatility of glass encapsulated thermistor makes them ideal for various applications. From automotive systems that demand accurate temperature readings to industrial equipment requiring high thermal stability, these thermistors deliver unmatched performance. Specific applications include:

Automotive Industry

Glass thermistors are used to monitor engine temperatures, battery management, and other critical parameters. Their stability under high temperatures ensures that automotive systems operate safely and efficiently. The NTC resistor in these thermistors provides rapid and accurate temperature sensing, which is crucial for maintaining optimal engine performance and safety. Modern vehicles are increasingly relying on glass encapsulated thermistor due to its reliability in the face of temperature fluctuations.

Consumer Electronics

With growing demands for smarter and more energy-efficient devices, NTC resistor is an essential component in managing heat dissipation in smartphones, computers, and home appliances. The use of glass thermistors in these applications helps prevent overheating, ensuring that the electronics function reliably. In consumer electronics, where space is limited and thermal management is critical, glass encapsulated thermistor offers compact and effective solutions.

Industrial Equipment

Glass encapsulated thermistor is also extensively used in industrial machinery, where accurate temperature measurement is required to maintain equipment efficiency and longevity. By incorporating glass thermistors into monitoring systems, industries can achieve precise control over processes, leading to better productivity and reduced downtime. The durability and precision of NTC resistor makes it ideal for harsh industrial environments, where both reliability and accuracy are paramount.

Why Choose Our Glass Thermistors?

Our glass thermistors are designed with precision and reliability in mind, providing consistent resistance readings even under extreme conditions. They are manufactured to meet high standards of quality, making them ideal for use in demanding applications where accuracy and reliability are essential. The use of glass encapsulated thermistor ensures that each unit is protected against moisture and mechanical damage, extending the operational life of the thermistor.

Additionally, the glass encapsulation provides excellent protection against moisture and mechanical damage, extending the lifespan of the thermistor. With a commitment to quality and rigorous testing, our thermistors ensure that your applications run smoothly and without interruptions. The precise construction of NTC resistor allows for accurate temperature sensing, a crucial requirement in many industrial, automotive, and consumer electronics applications.

Reliability Testing for Glass Thermistors

Our glass thermistors undergo extensive reliability testing to ensure durability. Each glass encapsulated thermistor and NTC resistor is tested under challenging conditions to verify its performance.

- High-Temperature Storage: Stored at 250°C for 1000 hours, ensuring thermal resilience.

- Low-Temperature Storage: Stored at -40°C for 1000 hours, verifying low-temperature reliability.

- High Temperature and Humidity: Stored at 60°C, 95% RH for 1000 hours.

- Thermal Shock: 100 cycles of following sequence:-40°C 10min.---5min. room temp. ---200°C 10min.---5 min. room temp.Ensuring stability.Vibration Test: Frequency 10-500Hz, amplitude 1.5 mm for 15 minutes in X and Y directions.

- Pulling Test: Force of 5N applied axially for 60 seconds.

- Drop Test: Dropped from 1 meter onto a wooden surface 10 times, ensuring no visible damage.

These tests guarantee the reliability of our glass thermistors under demanding conditions, providing consistent performance in critical applications.

Quality Assurance for Glass Thermistors: Outgoing Inspection Process

All glass thermistors undergo thorough inspection before delivery. Each batch of glass ntc resistor is tested to ensure quality. Our outgoing inspection process for NTC resistor and glass encapsulated thermistor includes:

- Resistance Value: Sample size N=20, Ac=0, Re=1.

- B-value: Sample size N=10, Ac=0, Re=1.

- Insulation Resistance: Sample size N=5, Ac=0, Re=1.

- Shape & Dimensions: Sample size N=5, Ac=0, Re=1.

- Appearance: Sample size N=5, Ac=0, Re=1.

Inspection data is available upon request, ensuring transparency and confidence in the quality of our glass ntc resistor.

Benefits of Using Glass Encapsulated Thermistor

The use of glass encapsulated thermistor offers numerous benefits that make them superior to other types of thermistors. The encapsulation provides protection against contaminants such as dust and moisture, which can affect the accuracy and performance of thermistors without proper encapsulation. Here are some key benefits:

- Longer Lifespan: Glass encapsulation enhances the longevity of the thermistor by protecting it from environmental factors that cause wear and tear.

- High Precision: The NTC resistor element within the glass thermistor provides highly accurate temperature readings, essential for applications where precision is critical.

- Wide Temperature Range: Our glass thermistors operate effectively across a broad temperature range, making them versatile for various industrial, automotive, and consumer applications.

- Reliability in Harsh Environments: The glass encapsulation protects the thermistor from extreme conditions, ensuring stable performance under both high and low temperatures.

How Glass Thermistors Enhance Product Safety

Product safety is a paramount concern in all industries. Using glass thermistors enhances the safety of products by providing accurate temperature control, which helps in preventing overheating or thermal runaway. This is especially important in the automotive and consumer electronics sectors, where temperature regulation is directly related to product safety. The glass encapsulated thermistor offers a reliable solution for temperature monitoring, minimizing the risk of component failure due to thermal stress.

Comparing Glass Thermistors with Other Types of Thermistors

There are several types of thermistors available, each with its specific advantages and disadvantages. Compared to other types, such as epoxy-coated thermistor, glass encapsulated thermistor provides superior protection and longevity. The glass thermistors have higher resistance to environmental factors, making them a preferred choice for applications where long-term reliability is required. The NTC resistor used in these thermistors are optimized for stability, ensuring that the performance remains consistent even after prolonged use.

Epoxy-Coated vs. Glass Encapsulated Thermistor

While epoxy-coated thermistor may be more economical, it lacks the durability of glass encapsulated thermistor. Epoxy coatings can degrade over time when exposed to moisture, leading to variations in resistance and reduced accuracy. In contrast, glass thermistors maintain their integrity even under challenging conditions, providing a more stable and reliable temperature measurement solution.

Installation and Handling Guidelines for Glass Thermistors

Proper installation and handling are crucial for ensuring the optimal performance of glass thermistors. Here are some guidelines to follow:

- Avoid Mechanical Stress: Do not apply excessive force when handling or installing the thermistor, as this can damage the glass encapsulation.

- Ensure Proper Soldering: When soldering glass encapsulated thermistor, ensure that the temperature and duration are controlled to avoid damaging the thermistor.

- Protect from Contaminants: Keep the thermistor free from contaminants such as grease and dust, as these can affect its performance.

Following these guidelines will help maintain the accuracy and reliability of the NTC resistor used in your applications, ensuring consistent performance.

Safe Packing Practices for Glass Thermistors

Proper packing is essential to protect our glass thermistors during delivery. Each glass encapsulated thermistor is carefully packed to avoid any damage or contamination. This ensures that NTC resistor and other products maintain their quality and integrity. By using secure and contamination-free packaging, we guarantee that our glass ntc resistor reaches you in perfect condition, ready for use in sensitive applications.

FAQs - Frequently Asked Questions

1. What is the primary use of glass thermistors?

Glass thermistors are primarily used for temperature sensing and control in various industries, including automotive, aerospace, and consumer electronics. Their robust design ensures reliable operation in harsh environments.

2. How does the B-value affect the performance of the thermistor?

The B-value represents the relationship between resistance and temperature for an NTC resistor. A higher B-value indicates a more significant change in resistance with temperature, enabling more precise temperature measurements.

3. What are the benefits of using glass encapsulated thermistor?

Glass encapsulated thermistor offers enhanced protection against environmental factors such as humidity and mechanical stress, resulting in greater reliability and a longer service life.

4. Can glass thermistors be used in extreme temperatures?

Yes, glass thermistors are designed to operate effectively in extreme temperatures, ranging from -40°C to 300°C. This wide operating range makes them suitable for various demanding applications.

5. How does NTC resistor help in temperature control?

NTC resistor decreases its resistance as the temperature rises, which makes them ideal for temperature sensing and control. They are widely used in circuits that require precise temperature monitoring.

6. Why is glass encapsulation important for thermistor?

Glass encapsulation protects the thermistor from external factors such as moisture, dust, and mechanical damage, ensuring reliable performance and extending the component's lifespan. This makes glass encapsulated thermistor highly reliable for long-term use.

To learn more about our full range of glass thermistors, please visit our product page for detailed specifications and to explore other temperature sensor solutions that we offer.

Conclusion

In conclusion, glass thermistors are an essential component for applications requiring precise temperature measurement and control. Their robust design, high reliability, and wide temperature range make them ideal for use in various industries, from automotive to consumer electronics. The glass encapsulated thermistor we provide are manufactured to the highest standards, ensuring that your applications perform reliably under even the most challenging conditions. By using our NTC resistor, you can achieve precise and consistent temperature control, enhancing both the safety and efficiency of your systems. For more information on our products, please visit our product page.

© 2024 DXM Product. All rights reserved.

Author: Ivan Huang

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd