Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Experience precision with the DXM Bracket Type NTC Thermal Sensor MF52X. Ideal for accurate temperature measurement, these high-quality NTC temperature sensors ensure reliability and efficiency. Enhance your systems with this state-of-the-art NTC sensor. Keywords: Thermal Sensor, NTC Sensor, NTC temperature sensors.

The Thermal Sensor model MF52X-104H4100FAL25 is a bracket type of NTC temperature sensors, designed for precise temperature measurement, delivering reliable and stable performance under varying environmental conditions. This thermal sensor is part of a broader category of NTC sensor that is recognized for its high accuracy and dependability in measuring temperature across a range of applications, making them ideal for both industrial and consumer use.

Overview of Bracket Type NTC Thermal Sensor

The Bracket Type NTC Sensor, model MF52X-104H4100FAL25, is a high-quality thermal sensor featuring an NTC thermistor that provides consistent performance for temperature measurement. This product is ideal for applications requiring reliable thermal monitoring capabilities, from home appliances to industrial devices. NTC temperature sensors are crucial for maintaining system safety and efficiency, and the MF52X-104H4100FAL25 delivers on this front by providing consistent and precise readings.

Key Features of MF52X-104H4100FAL25 Thermal Sensor

The NTC sensor provides several key advantages that make it a preferred choice for applications requiring accurate thermal sensing. The key features of this thermal sensor include:

- Highly precise resistance values at 25°C: 100 KΩ with a tolerance of ±3%.

- Operating temperature range: -30°C to 105°C, making it suitable for a wide variety of applications, including extreme environmental conditions.

- Compact bracket type construction, enabling easy mounting and stability, which is crucial for environments requiring vibration resistance and secure placements.

- Robust construction using high-quality materials such as epoxy resin for durability in challenging conditions.

The MF52X-104H4100FAL25 thermal sensor is manufactured with a special focus on reliability, precision, and ease of integration. Its NTC thermistor offers an accurate and predictable response to temperature changes, which is essential for both safety and efficiency in various systems.

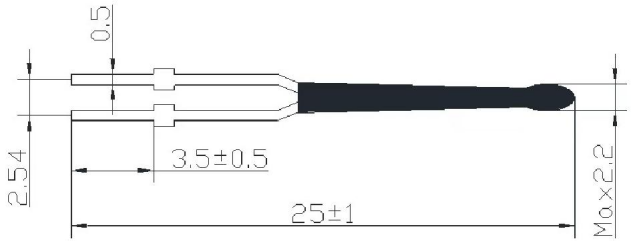

Dimensions of NTC Thermal Sensor MF52X-104H4100FAL25

Technical Specifications

Components of the Thermal Sensor Product

The Thermal Sensor components include the NTC sensor, a bracket, casing, and epoxy resin. Each part is designed to ensure high performance and durability. Below is a detailed list of the product's components:

| Item Number | Material Name | Specifications / Models | Quantity |

|---|---|---|---|

| 2-1 | NTC Thermistor | 104H4100FA | 1 PCS |

| 2-2 | Bracket | MF52X Tinned Bracket | 1 PCS |

| 2-3 | Casing | φ0.8 Black Heat Shrink Tubing | 1 PCS |

| 2-4 | Epoxy Resin | Black Epoxy Resin | -- |

Key Components Explained

-

NTC Thermistor (NTC Sensor)

This ntc temperature sensor (104H4100FA) provides temperature measurement with high accuracy and reliability. -

Bracket (MF52X Tinned Bracket)

The MF52X bracket offers structural stability and protection for the sensor. -

Heat Shrink Tubing

The φ0.8 black tubing is used to insulate the thermistor for added safety. -

Epoxy Resin

The black epoxy resin covers and protects the thermistor, ensuring durability. -

Electrical Characteristics of the Thermal Sensor

The Thermal Sensor has specific electrical properties that ensure accuracy and reliability. The details include values such as resistance at 25℃, dissipation factor, and thermal time constant. Below is a detailed table summarizing these properties.

| Item | Items | Measure Methods | Min | Nominal | Max | Unit |

|---|---|---|---|---|---|---|

| 3-1 | Resistance at 25℃ (R25) | Ta=25±0.05℃, PT ≤ 0.1mW | 97 | 100 | 103 | KΩ |

| 3-2 | Thermistor B Value (B25/50) |

|

4059 | 4100 | 4141 | K |

| 3-3 | Dissipation (σ) | Ta=25±0.5℃ | 3 | / | / | mW/℃ |

| 3-4 | Thermal Time Constant (t) | 25℃ air to 85℃ water, resistance change 63.2% | / | / | 5 | sec |

| 3-5 | Insulation Resistance | 100VDC/60S | 100 | / | / | MΩ |

| 3-6 | Operating Temperature Range | -30 to 105℃ | -30 | / | 105 | ℃ |

Detailed Electrical Parameters

-

Resistance at 25℃ (R25)

- The Thermal Sensor has a nominal resistance of 100 KΩ at 25℃.

- Ensures stable temperature readings.

-

B Value (B25/50)

- B value for NTC temperature sensors ranges between 4059 and 4141 K.

- Higher B values indicate greater sensitivity.

-

Dissipation Factor

- Shows the sensor’s power dissipation.

- The dissipation factor is 3 mW/℃ at 25℃.

-

Thermal Time Constant

- Response time from 25℃ air to 85℃ water is 5 seconds.

- Indicates fast temperature response.

-

Insulation Resistance

- Minimum insulation resistance is 100 MΩ at 100VDC for safety.

-

Operating Temperature Range

- Works effectively between -30℃ and 105℃.

- Suitable for diverse environments.

-

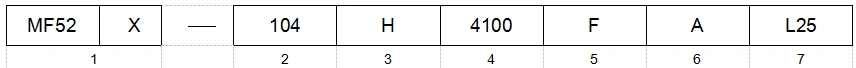

NTC Thermal Sensor Naming Rule

- The Thermal Sensor follows a structured naming convention that describes its key characteristics, such as resistance and B value. Each part of the model name provides information about the sensor's specifications, ensuring clarity for both engineers and users. Here is the detailed breakdown of the naming method:

-

Detailed Naming Structure

-

1.Series (MF52)

Indicates the sensors type, which is the Bracket type NTC temperature sensors. -

2.Resistance at 25℃ (104)

The NTC temperature sensors have a resistance value of 100 KΩ at 25℃. -

3.Resistance Tolerance Code (F, G, H, J)

The code H stands for a tolerance of ±3%. Other codes include F (±1%), G (±2%), and J (±5%). -

4.Thermistor B Value (4100)

The B value of the Thermal Sensor is 4100 K. -

5.B value of thermistor Tolerance (F, G)

Code F represents a tolerance of ±1%. Code G indicates a ±2% tolerance. -

6.ntc thermistor b value Calculating Methods (A, B)

Code A means the B value is calculated between 25/50℃.Code B means the B value is calculated between 25/85℃.

-

7.Wire Length (L25)

L25 refers to a product length of 25 mm.

-

Applications of NTC Temperature Sensors

The NTC temperature sensors are highly versatile and used in a variety of applications due to their accuracy and reliability. Below are some of the common use cases where NTC thermal sensor, like the MF52X-104H4100FAL25, are employed:

- Temperature sensing for home appliances like air conditioners, refrigerators, and water heaters. The thermal sensor helps maintain the desired temperature by providing accurate readings.

- Temperature monitoring for battery packs and electric vehicles. NTC temperature sensors ensure that battery packs operate within safe temperature limits to avoid overheating and potential damage.

- Environmental temperature control for industrial machines. Using an NTC thermal sensor ensures that the temperature within the machines stays within optimal operating ranges, preventing any malfunctions caused by overheating.

- Medical devices: NTC temperature sensors are used in medical devices for precise body temperature measurement and control, ensuring patient safety and comfort.

These applications underscore the versatility of NTC temperature sensors. The MF52X-104H4100FAL25 thermal sensor's reliability makes it suitable for these demanding environments where precision is non-negotiable. For instance, in electric vehicle battery management systems, precise temperature sensing ensures safe operation, prevents thermal runaway, and enhances the overall longevity of the batteries.

Why Choose MF52X-104H4100FAL25 Thermal Sensor?

Choosing the right thermal sensor is critical for ensuring the safety, reliability, and efficiency of your application. The MF52X-104H4100FAL25 thermal sensor stands out due to the following reasons:

- Durable Construction: The sensor is constructed using high-quality materials, including a durable epoxy resin that protects the NTC thermistor. The tinned bracket design ensures easy installation and provides corrosion resistance.

- Precision in Temperature Measurement: The NTC thermistor used in this thermal sensor has a resistance value with a tight tolerance, ensuring high precision in temperature measurement. This level of accuracy is crucial for applications that demand precise thermal control.

- Wide Operating Temperature Range: The sensor can operate from -30°C to 105°C, which makes it suitable for a variety of environments, from household appliances to industrial machinery.

- Extensive Testing: The MF52X-104H4100FAL25 has undergone rigorous reliability tests, including high-temperature tests, low-temperature tests, humidity tests, and vibration tests. This ensures that the sensor performs consistently under various conditions.

With its durable build and precise measurements, the MF52X-104H4100FAL25 sensor is perfect for applications that require accurate temperature readings. The use of high-quality materials like epoxy resin and tinned brackets makes it highly reliable in harsh environments. The thermal sensor is also equipped with a robust NTC thermistor to ensure longevity and stability, giving you peace of mind that your application will function optimally with accurate temperature control.

Reliability Tests for the MF52X-104H4100FAL25

Mechanical Properties Test of the Thermal Sensor

The Thermal Sensor undergoes rigorous mechanical testing to ensure its reliability and quality. These tests evaluate aspects such as solderability and heat resistance during soldering, making sure the NTC temperature sensors meet high standards.

Solderability Test

The solderability of the NTC temperature sensors were tested as per the IEC60068-2-20 (GB2423.28) standard.

The procedure involved dipping the sensor's terminal into flux and then immersing it into a 235±5℃ tin bath for 2±0.5 seconds. The tin surface was kept 2 to 2.5 mm away from the NTC body during the immersion.

Upon completion, the sensor's appearance was checked. The result demonstrated that tin flowed freely, and the wetting was excellent, with a solder coverage of 95% or more.

Soldering Heat Resistance Test

The Thermal Sensor was also tested for its heat resistance during soldering.

In this test, the terminal was dipped into flux and then immersed in a 260±5℃ tin bath for 10±1 seconds, according to IEC60068-2-20 (GB2423.28).

After this, the sensor was allowed to recover at normal temperature and humidity for 1 to 2 hours. Following recovery, its appearance was inspected and the resistance at 25℃ (R25) was remeasured. The results confirmed that there were no visible damages, and the resistance change (△R/R25) was within ±3%.

Reliability Testing of the Thermal Sensor

The Thermal Sensor is subjected to a series of reliability tests to ensure its consistent performance and durability. Each test examines different aspects of the NTC temperature sensors under varied environmental conditions. Here is a detailed overview of these tests.

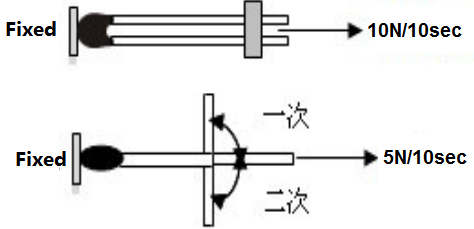

Terminal Strength Test

The Thermal Sensor terminal strength was evaluated according to the IEC60068-2-21 (GB2423.29) standard.

Two tests were performed:

- Test 1: A tensile force of 10N was applied for 10 seconds.

- Test 2: The terminal was bent 90 degrees twice, under a 5N load, for 10 seconds.

After testing, the sensor was left at normal temperature and humidity for 1 to 2 hours before inspection. Results showed no visible damage, and the resistance change (△R/R25) remained within ±3%.

High Temperature Test

The Thermal Sensor was tested at a high temperature of 125℃ for 1000 hours, according to IEC60068-2-2 (GB2423.2).

After the test, the sensor was allowed to recover at room temperature for 1 to 2 hours. The resistance change (△R/R25) was within ±3%, ensuring reliability at high temperatures.

Low Temperature Test

The NTC sensor was also exposed to a low temperature of -40℃ for 1000 hours as per IEC60068-2-1 (GB2423.1).

After recovery at normal temperature for 1 to 2 hours, the resistance change remained within ±3%.

Constant Temperature Test

The Thermal Sensor was powered at 25℃ for 1000 hours, with a DC current of 0.2mA. The resistance change (△R/R25) remained within ±3%, indicating good stability during prolonged operation.

Damp Heat Test

The ntc temperature sensors were tested under damp conditions at 40℃ with 90% to 95% humidity for 1000 hours, according to IEC60068-2-3 (GB2423.3).

After recovery, the resistance change was found to be within ±3%.

Thermal Shock Test

The Thermal Sensor underwent thermal shock testing between -30℃ and 125℃, with a transition time of less than 30 seconds.

Each temperature was maintained for 3 minutes, with a total of 100 cycles. After the test, the sensor's resistance change (△R/R25) stayed within ±3%, proving its robustness under rapid temperature changes.

Installation and Integration Tips for NTC Sensor

The MF52X-104H4100FAL25 thermal sensor is designed for ease of integration, thanks to its bracket type construction and standard wiring. Here are a few tips for installing and integrating this thermal sensor into your system:

- Ensure the sensor is securely mounted to prevent movement, which could affect the accuracy of the temperature readings. The bracket design makes mounting simple and secure, even in environments subject to vibration.

- Use compatible wiring and follow the electrical guidelines to maintain the accuracy of the sensor. Proper wiring will ensure the correct transfer of temperature readings from the sensor to your control system.

- Avoid direct exposure to chemicals or corrosive substances, which could damage the protective epoxy casing. This will extend the life of the sensor and ensure long-term reliability.

Following these guidelines will help maximize the performance and lifespan of the NTC temperature sensors. The MF52X-104H4100FAL25 is designed to integrate seamlessly with most control systems, making it an ideal choice for those looking for a robust and accurate solution for temperature sensing needs.

Storage Conditions for the Thermal Sensor

Proper storage is crucial to maintain the performance of the Thermal Sensor. Below are the recommended storage conditions to ensure reliability and longevity for NTC sensor.

1.Temperature and Humidity Requirements

The Thermal Sensor should be stored at a temperature between -10℃ and +40℃. The relative humidity should not exceed 75% RH. These conditions help preserve the stability and functionality of the NTC temperature sensors.

2.Environmental Precautions

Avoid storing the Thermal Sensor in environments exposed to corrosive substances or direct light. Such exposure can degrade the quality of the NTC sensor over time.

3.Packaging and Sealing

Both bulk and individual packaging should be sealed to maintain quality. For best results, the NTC temperature sensors should be used within one year of storage. If stored for more than a year, assess the solderability of the lead terminals before use.

FAQs about MF52X-104H4100FAL25 NTC Sensor

Q1: What is the primary use of an NTC thermal sensor?

A: The primary use of an NTC thermal sensor is for measuring temperature accurately, using the predictable change in resistance with temperature. The MF52X-104H4100FAL25 is ideal for applications requiring stability in temperature readings.

Q2: How reliable is the MF52X-104H4100FAL25 in extreme temperatures?

A: The MF52X-104H4100FAL25 has been tested to withstand extreme temperatures, ranging from -30°C to 105°C, ensuring consistent performance in demanding environments.

Q3: How do I integrate the MF52X-104H4100FAL25 into my application?

A: The sensor's bracket type design makes it easy to mount, and it comes with standard wiring that allows straightforward integration into most systems. Detailed specifications are available to assist with system compatibility.

Q4: What makes NTC temperature sensorss suitable for battery management systems?

A: NTC temperature sensors, such as the MF52X-104H4100FAL25, are well-suited for battery management systems due to their precision in measuring temperature. Accurate temperature monitoring is critical in preventing overheating and ensuring the safe and efficient operation of batteries, especially in electric vehicles.

Q5: Can the MF52X-104H4100FAL25 be used in medical devices?

A: Yes, the MF52X-104H4100FAL25 thermal sensor is suitable for use in medical devices. Its high accuracy and reliable temperature measurement make it ideal for applications like patient temperature monitoring and thermal control in medical equipment.

Q6: What is the significance of the B value in NTC temperature sensors?

A: The B value in NTC temperature sensors, such as the MF52X-104H4100FAL25, indicates the sensitivity of the thermistor to temperature changes. A higher B value generally means greater sensitivity, allowing for more precise temperature monitoring.

For more information about integrating NTC sensor and purchasing details, please visit our official product page.

The MF52X-104H4100FAL25 thermal sensor provides the reliability and precision needed for a wide range of applications. Whether you need to measure temperature in consumer electronics, automotive systems, or industrial machines, this thermal sensor is a reliable solution. Its high-quality build and tested performance make it an excellent choice for those seeking durability and accuracy in their temperature sensing components.

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2025 DXM | All Rights Reserved.

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd