PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Key Features of PTC thermistors MZ12 series:

● Intelligent Preheat Start: Extending lamp life by up to 10 times.

● Competitive Price, Small size.

● Energy Efficient: Contributing to long-term energy savings.

● High Reliability: With over 100,000 switching cycles.

● Environmentally Friendly,Versatile Compatibility.

● Combination of PTC Resistor and Varistor,no temperature-increasing or power-consuming after preheating.

-

MZ12 Series PTC Thermistors: Advanced Solution for Energy-Efficient Lighting

The MZ12 series PTC Thermistors are a groundbreaking advancement in green lighting technology. These state-of-the-art PTC resistor offers an intelligent preheat start for Ballast Electronic and Energy Saving Lighting. They operate without raising temperature or consuming extra power post-preheat. This technology greatly extends on-off cycles and the lifespan of lighting systems.

The MZ12 PTC Termistor is crucial for energy-efficient lighting, offering reliable performance and durability. Their innovative design ensures they are an indispensable component in modern lighting systems.

- Our PTC Thermistors MZ12 series for ballast electronic and energy saving lighting intelligent preheat start.Combination of PTC Resistor and Varistor,no temperature-increasing or power-consuming after preheating.

-

Key Features

- Smart preheat start with no temperature increase

- Zero additional power usage after preheat

- Extends lighting system lifespan

- Critical for energy-saving solutions

PTC Thermistor Price: The MZ12 series provides a cost-effective and efficient option for sustainable lighting solutions.

-

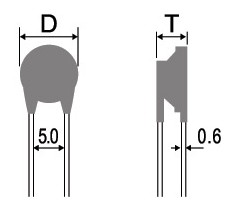

Technical drawing showing the dimensions of a PTC thermistors used for intelligent preheat starting in Ballast Electronic and Energy Saving Lighting.

- Prevents Filament Damage: Ensures proper preheating, reducing filament wear.

- Extends Lamp Life: Protects against high starting voltages, extending lamp life by up to 10 times.

- Energy Efficiency: Lower resistance and optimized switch temperature reduce energy consumption.

-

Advantages of Using Our PTC Thermistors

1. Reliability and Efficiency

Our PTC Thermistors ensure efficiency by not increasing power consumption after preheating. This enhances reliability and reduces energy costs.2. Extended Lamp Life

The MZ12 PTC Termistor reduces thermal and electrical stress during startup, prolonging lamp life by up to ten times.3. High Switching Capability

With a switching capability of over 100,000 cycles, our PTC Thermistors guarantee long-lasting performance and durability.4. Resistance Stabilization

PTC Resistor maintain stable resistance at normal temperatures, ensuring consistent performance over time.5. Environmental Compliance

Our PTC Thermistors are fully RoHS-compliant, prioritizing environmental safety and meeting strict regulatory standards.Choosing our PTC Termistor, you benefit from high reliability, extended product lifespan, and reduced environmental impact. For PTC Thermistor price and specifications, contact us to find the best solution for your needs.

Key Features of PTC Termistor

Working Principle

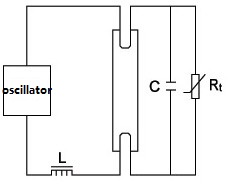

PTC Thermistors play a crucial role in energy-saving lamps by regulating the preheating and starting process. Initially, when the high-frequency shaking circuit is activated, the PTC Thermistor is in a cold state, resulting in low resistance. The resistance value of the PTC is much lower than that of the capacitor (C2), allowing minimal voltage across the lamp. The current flows through the capacitor (C1) and the PTC Thermistor, forming a loop to preheat the filament.

Meanwhile, PTC Termistor is heated to above the Curie temperature, Rt heating temperature exceeding the switch temperature TSW and leaping to the state of high resistance too. Its resistance value is far higher than that of C2, and the current goes through C1, C2, forming the return circuit and causing LC resonance and producing high pressure and lighting the tube.

Optimizing Energy-Saving Lamps

Selecting a higher resistance PTC Resistor, smaller ceramic body, and lower switch temperature reduces power consumption and preheating time. Conversely, a lower resistance and higher switch temperature increase power consumption and extend preheating time. For extended preheating, choose a PTC Thermistor with lower resistance, a higher Curie point, and a larger size.

Filament material will be sputtered seriously if the filament of energy-saving lamps starting with high voltage without preheating anymore,cause lamp tubes black and scrap in advance! Use PTC thermistors MZ12 type, the filament will be preheated around 1 second in starting, and then add high voltage to lit the lamp, can prevent black of the tube ends effectively,can also prevent components of lamps and lanterns lines such as audion from impact of starting instant large current and high back voltage,can prolong lamp life 10 times more.

Benefits of PTC Thermistors in Lamps

-

By selecting the appropriate PTC Termistor, you can optimize lamp performance, reduce maintenance, and achieve energy savings.

For more information on PTC Thermistor prices and specifications, consult the latest PTC Thermistor models to find the best fit for your energy-saving needs.

-

Circuit schematic showing the application of a PTC thermistor in the preheat start process of an Ballast Electronic for energy-saving lamps.

Guidelines for Choosing the Right PTC Thermistors

Selecting the correct PTC Thermistors is crucial for optimal performance and compatibility in energy-saving lamps. Consider the following factors:

1. Curie Temperature

Choose a PTC Thermistor with a Curie temperature above 100°C to handle high operating temperatures effectively.2. Voltage Requirements

Ensure the PTC Termistor can withstand voltages above 800V, especially in circuits with single capacitors.3. High-Resistance for Reliability

High-resistance PTC Thermistors provide better reliability during startup, reducing failure rates.4. Low-Temperature Start Consideration

For low-temperature starts, select PTC Resistor with balanced heat resistance to prevent startup failures.5. Switching Life

Opt for PTC Thermistors with a switch life of over 100,000 cycles for enhanced durability and reduced maintenance.6. Preheat Time

Ensure the PTC Resistor’s preheat time is not less than 0.4 seconds to allow proper filament preheating.7. Power Consumption Compliance

Select PTC Termistor that meet relevant power consumption standards to ensure efficiency and compliance.For the best PTC Thermistor price and detailed specifications, contact us to find the ideal match for your energy-saving solutions.

Understanding PTC Termistor Model Number Marking

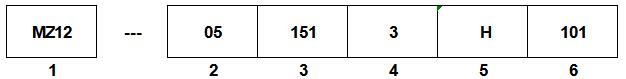

Our detailed model number system helps you select the perfect PTC Resistor for your needs, with specifications on varistor chip size, voltage, and resistance clearly marked.Details are as below:

-

Detailed breakdown of model numbers for the MZ12 series PTC thermistors, indicating specifications for use in Ballast Electronic and energy-saving lamps.

Our PTC Thermistors come with detailed model number markings to help you choose the right component for your application. Below is the breakdown of model numbers for the MZ12 series, designed for Ballast Electronic and energy-saving lamps.

1. PTC Termistor Series

The MZ12 Series features intelligent preheat starting PTC Thermistors for Ballast Electronic and energy-saving lamps.2. Varistor Chip Size

Marked as "05," indicating a varistor chip diameter of 5mm (Φ5mm).3. Varistor Voltage

Indicated by "151," representing a varistor voltage of 150V ±10%.4. Thermistor Chip Size

Marked as "3," indicating a thermistor chip diameter of 3mm (Φ3mm).5. PTC Resistor Curie Temperature

Curie temperatures are denoted by letters: "F" for 55°C, "H" for 75°C, and "N" for 105°C.6. PTC Thermistors Resistance

Resistance values are marked as "101" for 100Ω or "332" for 3300Ω.Our clear model number system ensures that you select the ideal PTC Termistor with precise specifications for your energy-saving needs. For detailed PTC Thermistor price and further assistance, reach out to us.Part

Customization Options for PTC Thermistors in Ballast Electronics

Using PTC Thermistors in Ballast Electronic and energy-saving lamp preheating systems offers intelligent start-up capabilities. The number and specifications can be customized based on application needs.

Key Customization Options:

-

Resistance Tolerance

R25 resistance tolerance can be customized to meet specific customer requirements for optimal performance. -

Encapsulation Mode

PTC Termistor can be encapsulated in various modes as per customer needs, enhancing compatibility with different applications. -

Wire Shape

Kinked wire forms are available for selection, allowing for tailored connection options in circuit designs.

Our PTC Thermistors offer exceptional design flexibility, providing a precise fit and optimal functionality for Ballast Electronics and energy-saving lamps. To explore the best options tailored to your needs, including detailed PTC Thermistor prices and customization options, please refer to our comprehensive specifications and part numbers guide.

For further inquiries or to discuss your specific requirements, contact us directly. Our expert team is ready to assist you in selecting the ideal PTC Termistor solution for your application, ensuring top performance and reliability.

-

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd