How Does a PTC Thermistor Work? Understanding Key Functions

Discover how does a ptc thermistor work, its principles, applications, and key functions in thermal management. This detailed guide offers insights for professionals seeking to boost their understanding and implementation efficiency.

PTC thermistor, or Positive Temperature Coefficient thermistor, is intriguing component essential in numerous applications for effective temperature sensing and control. If you've ever wondered, "how does a PTC thermistor work?" you're in the right spot. In this comprehensive guide, we will break down the complexity surrounding these small yet powerful devices.

What is a PTC Thermistor?

Before we dive deeper into how does a ptc thermistor work, it's essential to understand what a PTC thermistor is. A PTC thermistor is a type of resistor whose resistance increases with an increase in temperature. Unlike typical resistors that aim for constant resistance, PTC thermistors provide a dynamic response to temperature changes, making them invaluable for applications where current and temperature regulation are critical.

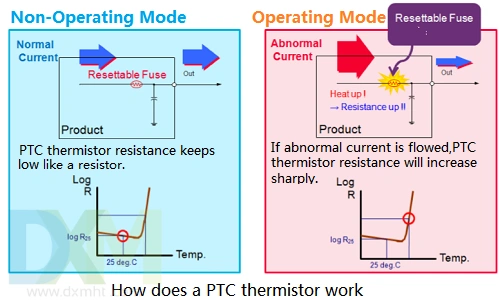

How Does a PTC Thermistor Work?

At the heart of a PTC thermistor's function is its resistive property, which relies on the temperature coefficient. So, how does a PTC thermistor work in practical terms? As the temperature around the thermistor increases, so does its resistance. This characteristic is beneficial in automatic reset switches and circuit protection. When the current passing through the thermistor exceeds a specific threshold, the resultant heat will increase the temperature, thereby increasing the resistance sharply. This limits the current flow through the circuit, protecting it from potential damage.

Applications of PTC Thermistor

1. Overcurrent Protection: One of the most common applications is in overcurrent protection. When circuits face excessive current, PTC thermistors respond by reducing the current flow.

2. Temperature Sensing and Control: PTC thermistors are crucial in systems that require temperature monitoring and control, such as HVAC systems, to ensure optimal performance.

3. Timer Circuits: The delay feature in how does a ptc thermistor work is often employed in creating timer circuits. This is particularly useful in household appliances like hairdryers and toasters, where timed shutoff is a safety feature.

4. Motor Start: In motor applications, PTC thermistors can regulate the power supply during startup, thereby safeguarding the motor against damage due to overheating.

Benefits of Using PTC Thermistor

Understanding how a ptc thermistor works reveals its myriad benefits:

- Self-Regulating Properties: Once the maximum resistance is reached, the thermistor can actively regulate the current without needing external control circuits.

- Compact and Cost-Effective: Compact design and cost-efficiency make PTC thermistors a favorite in intricate circuit designs and mass production environments.

- Reliability and Durability: Due to their robust design, PTC thermistors offer long-term reliability and are resilient to frequent temperature fluctuations.

How to Integrate PTC Thermistor in Designs

Integrating PTC thermistors into your designs requires understanding their operation within specific circuit conditions. Ensuring proper placement for optimal thermal interaction and selecting the right specifications tailored to your application are key success factors. Simulation and incremental testing help ensure that the manufacturer’s characteristics align with your system requirements.

FAQs

1. What distinguishes PTC thermistors from an NTC thermistors?

- PTC thermistors' resistance increases with rising temperature, whereas an NTC thermistors’ resistance decreases as temperature rises.

2. Can PTC thermistors be used for precise temperature measurement?

- While excellent for temperature regulation, PTC thermistors are generally used for broad applications rather than precise temperature measurements due to their non-linear response.

3. What factors should be considered when selecting PTC thermistors?

- Consider operating temperature range, resistance range, tolerance levels, and the nature of the environment (e.g., humidity, exposure to chemicals).

Conclusion

In our dynamic world of electronics, understanding how does a ptc thermistor work enhances our ability to design robust, efficient, and reliable systems. Employing PTC thermistors can lead to innovations in safety, efficiency, and cost-effectiveness across numerous applications. We invite you to take what you've learned here, explore the numerous benefits, and implement these components in your next project for better performance and protection.

Call to Action

Ready to integrate PTC thermistors into your designs? Enhance your projects’ performance with our range of high-quality PTC thermistors, optimized for various applications. Contact us to discover more about PT thermistor solutions that can transform your thermal management strategies.

© 2025 DXM Blog. All rights reserved.

Author: Ivan Huang

Recommended for you

What Are NTC Thermistors Made Of ? Discover the Secrets

NTC Thermistors: A Deep Dive for Professionals

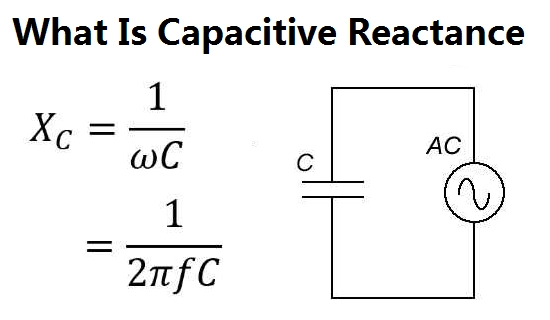

What is Capacitive Reactance? Unveiling its Role in Electrical Circuits

Surface-Mount Device - A Comprehensive Guide

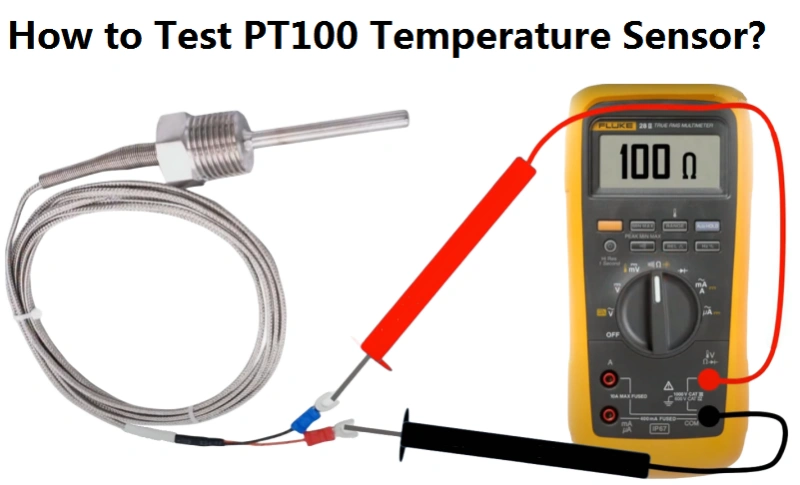

PT100 temperature sensor Testing Guide

Understanding Varistors: What is a Varistor?

Logistics

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

Price and Payment

How are the prices of your products determined?

Our product prices are based on a variety of factors, including order quantity, customization requirements, and market competition.

Payment Terms

There are a number of different payment methods that can be used when you deal with us. Two are mostly used: T/T payment in advance for small values and irrevocable L/C at sight for large values.

Do you offer bulk purchase discounts?

Yes, we offer bulk purchase discounts; the specific discount rate depends on the order quantity and cooperation method.

What’s the Minimum Order Quantity (MOQ) and Minimum Order Amount (MOA)

MOQ: 10000PCS

You may also like

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd