SMD Sensors: Advanced Temperature Sensing Excellence

Discover unparalleled precision with DXM's Advanced SMD Sensors, the next-generation solution for temperature sensing excellence. Crafted for optimal performance, this SMD sensor ensures accurate and reliable measurements in diverse applications. Trust DXM's expertise in NTC SMD sensors to elevate your projects with cutting-edge technology and unmatched efficiency. Experience the future of temperature monitoring today.

SMD sensors like the SMDNTS-0805X104F4250FA are designed for precise temperature measurement. This advanced ntc smd sensor integrates seamlessly into high-density PCB layouts, making it ideal for applications such as battery management, HVAC, and consumer electronics.

Our specialized smd sensors ensure accurate and reliable temperature control, meeting the high demands of modern industries. With a compact 0805 package, this sensor excels in space-constrained environments, providing engineers with efficient ntc smd solutions.Discover how our SMD sensors offer unmatched stability and sensitivity, revolutionizing temperature monitoring in critical applications.

Versatile Industrial Applications of High-Performance SMD Sensors

Our SMD sensors are essential for precise temperature monitoring across various industries.Such as:

Temperature Measurement and Compensation

SMD sensors are used in battery management, HVAC systems, and consumer electronics to measure and control temperature accurately. In circuit applications, these sensors also compensate for temperature variations, ensuring stable performance.

Industrial Automation

SMD sensor technology is crucial for temperature control in automated manufacturing. The compact design enables easy integration into production equipment, while NTC SMD components ensure reliability in harsh conditions.

Medical Equipment

Our SMD sensors provide the accuracy and stability needed for critical temperature monitoring in medical devices. Advanced NTC SMD technology ensures dependable patient and equipment temperature control.

Automotive Systems

Modern vehicles rely on SMD sensors for comprehensive temperature monitoring. From engine management to battery systems, these sensors deliver vital thermal data, enhancing performance and safety.

Key Technology Advantages of High-Performance SMD Sensors

Our high-performance SMD sensors provide unparalleled precision and reliability, utilizing advanced NTC SMD technology for optimal temperature monitoring.

Proprietary Manufacturing Process

Our proprietary NTC SMD manufacturing process ensures consistent thermal characteristics, essential for stable and accurate temperature sensing. Each smd sensor is engineered for precise applications across industries.

Reliable Surface-Mount Technology

We utilize advanced surface-mount technology, enabling reliable integration at the board level. This ensures that each SMD sensor is securely positioned, maximizing performance in high-density PCB layouts.

Specialized Protective Coating

A specialized coating shields each SMD sensor from environmental factors, enhancing durability. This protective layer is crucial for applications in harsh environments where reliability is essential.

Innovative Thermal Interface Design

Our unique thermal interface design maximizes heat transfer, boosting sensor response time. This innovation ensures accurate readings, especially in critical applications requiring real-time data.

Precision Calibration and Compact Design

Each SMD sensor undergoes rigorous calibration for accuracy across the full temperature range. The compact 0805 package allows high-density mounting, perfect for space-constrained applications.

Additional Key Features

- High Stability: Maintains resistance stability post-soldering for consistent circuit performance.

- Heat and Moisture Resistant: Delivers reliable results in demanding environments.

- High Sensitivity and Low Power Consumption: Ideal for precise temperature monitoring.

- B-Value: Around 4250K, indicating strong sensitivity to temperature changes.

- Quick Response: Ensures real-time monitoring.

- Eco-Friendly: RoHS-compliant, lead-free, and halogen-free.

Our SMD sensors provide advanced, reliable solutions, making them ideal for industrial, automotive, and medical applications.

Comprehensive Technical Specifications of SMD Sensors

Our SMD sensors are engineered to meet the most demanding requirements across various industries. The integration of advanced NTC SMD technology ensures superior performance in all applications.Main specifications of popular models are as below:

MAIN ELECTRICAL PARAMETER OF SMDNTS-0805X104F4250FA

| Item | Description | Unit | Spec | Condition | |

| 1 | Type | SMD NTC Sensor | |||

| 2 | Package Size | 0805 | 2.0×1.2mm | Leadless Chip size | |

| 3 | Resistance Value(R25) | 100 | kΩ | at 25°C | |

| 4 | Tolerance of R25 Resistance | ±1% | |||

| 5 | B25/50 Constant Value | 4250 | K | (25/50℃) | |

| 6 | B25/85 Constant Value | 4310 | K | (25/85℃) | |

| 7 | Tolerance of B Value | ±1% | |||

| 8 | Rated Electric Power (Prated) | 100 | mW | at 25℃ | |

| 9 | Dissipation Factor | 1.0 | (mW/℃) | ||

| 10 | Permissible Operating Current | 0.14 | (mA) | ( 25℃) | |

| 11 | Thermal Time Constant | <5 | (s) | ||

| 12 | Operating ambient temperature | -40~+125 | (℃) | ||

MAIN ELECTRICAL PARAMETER OF SMDNTS-0805X474F4500FA

| Item | Description | Unit | Spec | Condition | |

| 1 | Type | SMD NTC Sensor | |||

| 2 | Package Size | 0805 | 2.0×1.2mm | Leadless Chip size | |

| 3 | Resistance Value(R25) | 470 | kΩ | at 25°C | |

| 4 | Tolerance of R25 Resistance | ±1% | |||

| 5 | B25/50 Constant Value | 4500 | K | (25/50℃) | |

| 6 | B25/85 Constant Value | 4512 | K | (25/85℃) | |

| 7 | Tolerance of B Value | ±1% | |||

| 8 | Rated Electric Power (Prated) | 100 | mW | at 25℃ | |

| 9 | Dissipation Factor | 2.0 | (mW/℃) | ||

| 10 | Permissible Operating Current | 0.05 | (mA) | ( 25℃) | |

| 11 | Thermal Time Constant | <5 | (s) | ||

| 12 | Operating ambient temperature | -40~+125 | (℃) | ||

Notes: When measured at 25°C in still air, as a single unit without mounting.

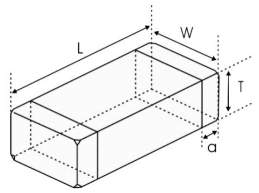

Product outlook and dimension:

Dimension (unit: inch[mm])

| Product size | L | W | T | a | |

| 0805 [2012] |

0.079±0.008 [2.0±0.2] |

0.049±0.008 [1.25±0.2] |

0.033±0.008 [0.85±0.2] |

0.020±0.012 [0.5±0.3] |

|

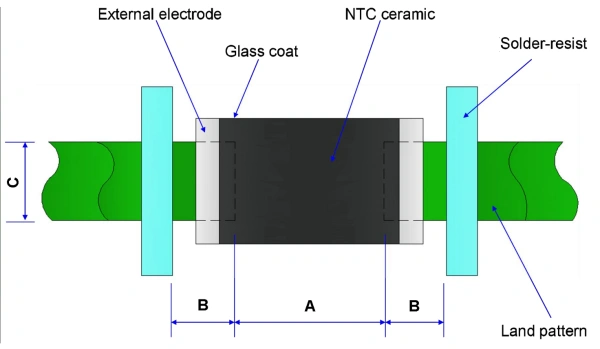

Recommended PCB pattern for reflow soldering:

| Product size | A | B | C | |

| 0805[2012] | [1.0-1.1] | [0.6-0.7] | [1.0-1.2] | |

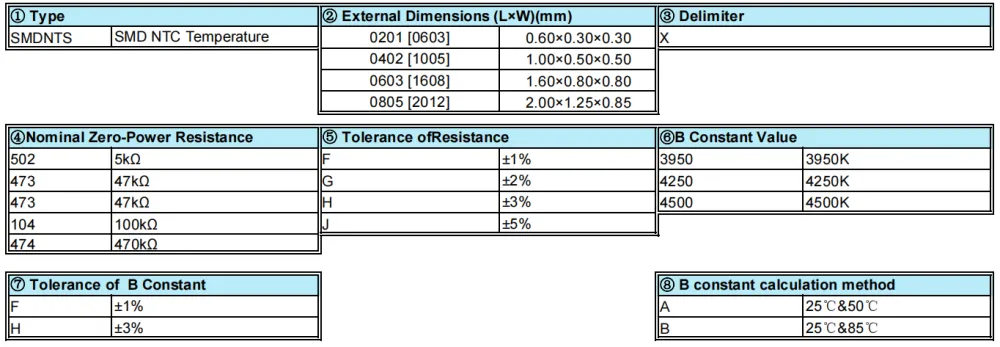

NTC SMD Sensors Marking of Part Number:

| SMDNTS | |

X 104 | F 4250 | F | A |

| ① | ② | ③ ④ | ⑤ ⑥ | ⑦ | ⑧ |

Test and Measurement Procedures of SMD Sensors

→ Test Conditions

Unless otherwise specified, the standard atmospheric conditions for measurement/test as:

a. Ambient Temperature: 20±15℃.

b. Relative Humidity: 65±20%.

c. Air Pressure: 86kPa to 106kPa.

If any doubt on the results, measurements/tests should be made within the following limits:

a. Ambient Temperature: 25±2℃.

b. Relative Humidity: 65±5%.

c. Air Pressure: 86kPa to 106kPa.

→ Inspection Equipment

Visual Examination: 20×magnifier

Resistance value test: Thermistor resistance tester

Advanced SMD Sensors: Features and Core Technologies

Our SMD sensors incorporate multiple advanced features that set them apart in the temperature sensing market:

NTC SMD Key Technology Advantages

- Proprietary NTC SMD manufacturing process ensuring uniform thermal characteristics

- Advanced surface-mount technology for reliable board-level integration

- Specialized coating technology protecting each SMD sensor from environmental factors

- Innovative thermal interface design maximizing heat transfer efficiency

- Precision calibration procedures ensuring accuracy across the full temperature range

Implementation Guidelines of NTC SMD sensors

Successful integration of SMD sensors requires attention to several key factors:

PCB Design Considerations

- Optimal placement of SMD sensor components for accurate temperature measurement

- Proper thermal isolation techniques for enhanced accuracy

- Recommended pad layouts for different SMD sensor packages

- Guidelines for thermal relief patterns in PCB design

Environmental Considerations

- Protection measures for harsh environmental conditions

- Temperature compensation techniques for extreme environments

- Moisture protection strategies for sensitive applications

- Thermal management in high-temperature applications

SMD Sensor Quality Assurance and Reliability

Every SMD sensor undergoes comprehensive testing and validation:

- 100% functional testing of all SMD sensor units

- Environmental stress screening for reliability verification

- Thermal cycling tests ensuring stability

- Long-term drift analysis for aging characteristics

- Statistical process control throughout manufacturing

Frequently Asked Questions of NTC SMD

Our SMD sensors provide superior accuracy, faster response times, and easier integration into modern electronics. The advanced NTC SMD technology enables precise temperature measurement in a compact form factor.

Each SMD sensor is designed with built-in protection against environmental factors. The specialized coating and packaging ensure reliable operation even in challenging conditions.

Under normal operating conditions, our SMD sensors demonstrate exceptional longevity, typically exceeding 10 years of reliable service. Regular calibration checks ensure continued accuracy throughout the sensor's lifetime.

Yes, we offer customization options for our SMD sensor products, including specialized calibration ranges, custom packaging, and application-specific modifications.

© 2024 DXM Product. All rights reserved.

Author: Ivan Huang

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2025 DXM | All Rights Reserved.

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd