What is Positive Temperature Coefficient?

Discover What is Positive Temperature Coefficient thermistor in DXM's latest article. Explore how PTC thermistors work, offering reliable and efficient temperature control solutions. Ideal for various applications, these Thermistors enhance safety and performance. Dive into the details with DXM and understand why choosing Positive temperature coefficient thermistors can make a significant difference in your projects.

- What is a Positive Temperature Coefficient (PTC) Thermistor?

- Types of Positive Temperature Coefficient Thermistors

- 1. Silistor (Silicon-based PTC Thermistor)

- 2. Switching Type PTC Thermistor

- Applications of Positive Temperature Coefficient (PTC) Thermistors

- Overcurrent Protection with Positive Temperature Coefficient Thermistors

- Temperature Sensing with PTC Thermistors

- Self-Regulating Heating Applications in PTC Thermistors

- Motor Protection and Inrush Current Limiting with Thermal Resistor

- Liquid Level Sensing with Positive Temperature Coefficient Thermistor

- Inrush Current Limiting with PTC Thermistors

- Overcurrent Protection in DC Motors and Solenoids Using Positive Temperature Coefficient Thermistor

- Telecom Applications with Positive Temperature Coefficient Device

- Conclusion

- Benefits of Positive Temperature Coefficient Thermistors

- Operating Principles of Positive Temperature Coefficient Thermistors

- Resistance-Temperature Relationship

- Self-Heating Mode

- Sensing Mode

- Current Limiting Functionality

- Material Composition of Positive Temperature Coefficient (PTC) Thermistors

- Ceramic PTC Thermistors

- Polymer PTC Thermistors

- Silicon PTC Thermistors (Silistors)

- Future Developments in Positive Temperature Coefficient (PTC) Thermistor

- Emerging Applications

- Advancements in Materials

- Miniaturization

- Smart PTC Systems

- Biomedical and Energy Applications

- FAQs

- 1.What is a positive temperature coefficient?

- 2. What is positive negative and zero temperature coefficient?

- 3.What does a thermistor with a positive temperature coefficient mean?

- 4.What is PTC thermistor used for?

- Conclusion: The Future of Positive Temperature Coefficient (PTC) Thermistors

What is a Positive Temperature Coefficient (PTC) Thermistor?

Positive Temperature Coefficient thermistors are type of PTC thermistors that increase resistance with rising temperature. This Positive Temperature Coefficient behavior makes these thermistors ideal for temperature sensing and circuit protection. Positive temperature coefficient thermistor plays a crucial role in modern electronics by preventing overheating and overcurrent. Their reliability and safety features are essential in various applications, ensuring optimal device performance. By incorporating PTC thermistors, manufacturers enhance product longevity and user safety. The Positive Temperature Coefficient ensures efficient operation in diverse environments.

Types of Positive Temperature Coefficient Thermistors

There are two main types of PTC thermistors:

1. Silistor (Silicon-based PTC Thermistor)

- Made from silicon with impurities.

- Resistance increases linearly with temperature.

- Ideal for precise temperature sensing and compensation.

2. Switching Type PTC Thermistor

- Composed of polycrystalline ceramic (commonly barium titanate).

- Sharp resistance rise at a specific temperature threshold.

- Used for overcurrent protection and self-regulating heating elements.

-

Applications of Positive Temperature Coefficient (PTC) Thermistors

- Used in power supplies, batteries, and motor circuits.

- Reliable protection for sensitive components.

- Positive Temperature Coefficient (PTC) thermistors are critical components in modern electronics. Their unique properties make them ideal for overcurrent protection, temperature sensing, and self-regulating heating systems.Details are as below:

Overcurrent Protection with Positive Temperature Coefficient Thermistors

PTC thermistors act as resettable fuses, protecting circuits from excessive current. When current exceeds a threshold, the thermistor’s resistance increases, limiting current flow. After the fault is resolved, it automatically resets.

- Used in power supplies, batteries, and motor circuits

- Reliable protection for sensitive components

-

-

-

-

-

-

Temperature Sensing with PTC Thermistors

Positive Temperature Coefficient thermistor is widely used in temperature sensing systems. Its resistance changes with temperature, providing precise temperature readings.

- Ideal for thermostats, alarms, and thermal management systems

- Ensures accurate temperature monitoring for heating and cooling systems

-

Self-Regulating Heating Applications in PTC Thermistors

PTC thermistors serve as self-regulating heating elements. As current flows, the thermistor heats up and its resistance rises, preventing overheating.

- Commonly found in automotive seat heaters and defrosters

- Used in household devices like hair dryers and space heaters

-

-

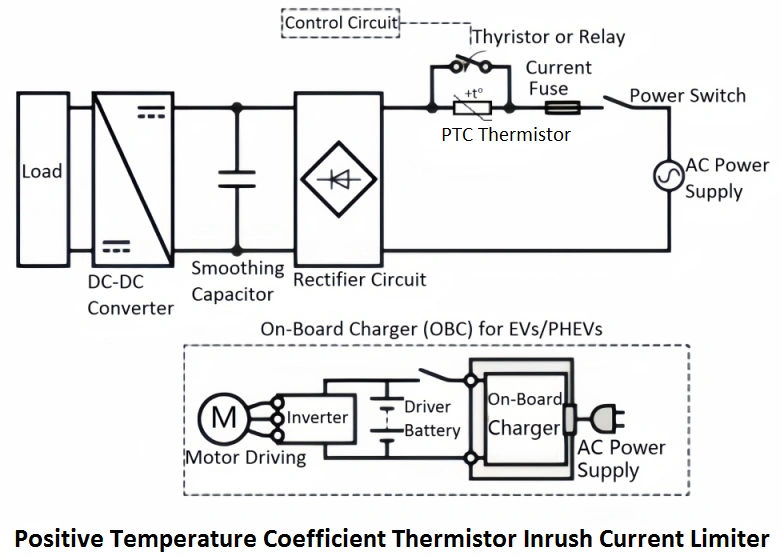

Motor Protection and Inrush Current Limiting with Thermal Resistor

Thermal Resistor protects motors from overheating by limiting current at high temperatures. It also reduces inrush current during startup, safeguarding motor components.

- Essential in motor starters and power supplies

- Protects motor windings from excessive startup currents

-

-

- Positive Temperature Coefficient (PTC) thermistors are critical components in modern electronics. Their unique properties make them ideal for overcurrent protection, temperature sensing, and self-regulating heating systems.Details are as below:

-

Liquid Level Sensing with Positive Temperature Coefficient Thermistor

Thermal Resistor can detect liquid levels by altering resistance in response to varying liquid exposure. This capability makes them effective for liquid level control systems.

- Used in industrial and automotive applications for accurate level detection

Inrush Current Limiting with PTC Thermistors

PTC Thermistors protect sensitive components by managing inrush currents during startup.

- On-Board Chargers (OBC): In electric vehicles, Thermal Resistor safeguards onboard chargers by limiting high peak currents during activation.

- Industrial Inverters: In systems like Variable Frequency Drives (VFDs), PTC thermistors protect capacitors and semiconductors from damage during startup.

Overcurrent Protection in DC Motors and Solenoids Using Positive Temperature Coefficient Thermistor

PTC thermistors prevent overcurrent conditions in motors and solenoids by increasing resistance during excessive current flow, avoiding thermal damage.

- DC Motors: Prevents motor windings from overheating.

- Solenoids: Ensures safe operation by limiting overcurrent during continuous use.

Telecom Applications with Positive Temperature Coefficient Device

PTC thermistors play a vital role in protecting sensitive communication systems from overcurrent and voltage surges.

- Surge Protective Devices (SPDs): In telecommunications, PTC devices safeguard equipment by limiting surge currents.

- Overcurrent Protection: Protects network devices, signal processing modules, and user terminals from damage.

Conclusion

PTC thermistor offers versatile solutions for current regulation, temperature sensing, and heating applications. Its self-resetting capabilities ensures reliable protection and enhanced safety across consumer and industrial applications. These features make Positive Temperature Coefficient Thermistors essential components in modern electronics.

-

Benefits of Positive Temperature Coefficient Thermistors

- Reliable temperature protection.

- Energy-efficient regulation.

- High durability and long service life.

In summary, PTC thermistors are critical for both safety and efficiency in electronics. Their self-regulating nature allows them to prevent overheating, control temperatures, and enhance the longevity of devices.

Operating Principles of Positive Temperature Coefficient Thermistors

PTC thermistors increase their resistance with temperature, providing reliable overcurrent protection and temperature sensing. These thermistors operate in two primary modes: self-heating and sensing, depending on their application.

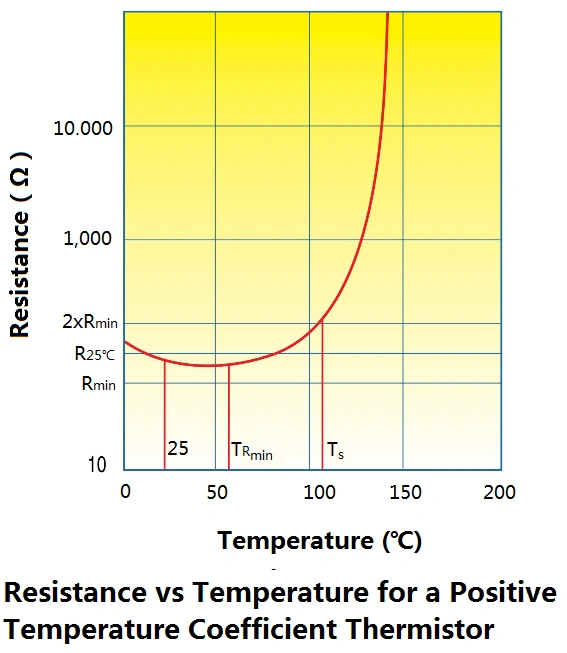

Resistance-Temperature Relationship

PTC thermistors rely on the resistance-temperature relationship. For silistors, the resistance gradually increases in a linear fashion. For switching-type Thermal Resistor, resistance remains stable until reaching the Curie point. At this temperature, resistance increases rapidly, limiting current flow.

Self-Heating Mode

In self-heating mode, the PTC thermistor heats up when current flows through it. As temperature rises, its resistance increases sharply at a specific switching temperature, limiting current and preventing overheating. This self-regulating feature makes it ideal for overcurrent protection.

Sensing Mode

In sensing mode, the PTC thermistor's resistance changes based on external temperature variations. This provides a reliable way to measure temperature, making Thermal Resistor useful for temperature control systems.

Current Limiting Functionality

When resistance increases due to temperature, current flow decreases, creating a self-regulating effect. This behavior makes Thermal Resistor essential for protecting circuits from excessive current. In summary, the Positive Temperature Coefficient property allows PTC thermistors to serve as overcurrent protectors and temperature sensors, ensuring device safety and performance in various applications.

Material Composition of Positive Temperature Coefficient (PTC) Thermistors

PTC thermistors are composed of materials that affect their performance and reliability. These materials determine their resistance behavior, response time, and durability in various applications.

Ceramic PTC Thermistors

Ceramic PTC thermistors are commonly made from barium titanate (BaTiO₃), doped with rare earth elements such as lanthanum or yttrium. This material provides a sharp resistance increase near its Curie point, making it ideal for switching-type Thermal Resistor used in overcurrent protection.

- High stability and reliability in harsh environments

- Suitable for circuit protection applications

Polymer PTC Thermistors

Polymer PTC (PPTC) thermistors are created from conductive polymer composites. These thermistors offer a more gradual resistance rise compared to ceramic types and can reset after tripping, making them reusable.

- Faster response times but lower maximum operating temperatures

- Ideal for resettable overcurrent protection

Silicon PTC Thermistors (Silistors)

Silistors are made from doped silicon and provide linear resistance changes with temperature. This material composition allows for precise temperature sensing and compensation.

- Accurate temperature control

- Suitable for applications requiring stable temperature measurements

In summary, the material composition of Positive Temperature Coefficient thermistors—whether ceramic, polymer, or silicon—directly influences their performance, stability, and application range, making them versatile components in temperature sensing and protection systems.

Future Developments in Positive Temperature Coefficient (PTC) Thermistor

The demand for Thermal Resistor is expected to rise as industries continue to adopt automation and smart technologies. With advancements in material science, manufacturing, and miniaturization, PTC thermistors are becoming more precise and reliable, expanding their applications across various sectors.

Emerging Applications

- Overcurrent protection: Thermal Resistor will play a key role in electric vehicles and infotainment systems, offering efficient circuit protection.

- Temperature regulation: Industrial automation and IoT devices will rely on Thermal Resistor for precise temperature control.

- Medical equipment: High-precision sensing applications will emerge in healthcare, enhancing the accuracy of medical devices.

Advancements in Materials

- Nanomaterials: Future developments in nanotechnology will create PTC thermistor with faster response times and greater sensitivity.

- Enhanced ceramics and polymers: Research into new ceramic and polymer blends will lead to more durable and efficient thermistors.

Miniaturization

- Smaller PTC devices: Compact electronics, wearables, and semiconductor devices will benefit from smaller, more efficient Thermal Resistor

- On-chip thermal management: Integration of PTC thermistor directly into chips will improve temperature regulation in modern electronics.

Smart PTC Systems

- IoT integration: PTC thermistors will be crucial in IoT devices, enabling remote temperature monitoring and control.

- Self-diagnostic systems: Future PTC Thermistor may feature self-diagnostic capabilities to predict and report potential failures.

Biomedical and Energy Applications

- Wearable technology: Thermal Resistor in wearables will offer reliable temperature monitoring for health applications.

- Energy harvesting: PTC thermistors could be used in thermoelectric energy harvesting systems, enhancing waste heat recovery.

As Positive Temperature Coefficient thermistor technology advances, these devices will continue to contribute to improved safety, energy efficiency, and functionality across numerous industries, driving innovation in temperature sensing and protection systems.

FAQs

1.What is a positive temperature coefficient?

A Positive Temperature Coefficient (PTC) thermistor is a type of resistor that increases its resistance as temperature rises.

This characteristic is commonly observed in metals like platinum and nickel, as well as in specific semiconductor materials known as PTC thermistors.Commonly used in temperature measurement, circuit protection, and motor starting. PTC thermistors ensure safe operation by limiting current flow, making them essential in electronics and thermal management.

2. What is positive negative and zero temperature coefficient?

3.What does a thermistor with a positive temperature coefficient mean?

4.What is PTC thermistor used for?

Positive Temperature Coefficient (PTC) thermistors are essential in various applications due to their unique properties.

- Overcurrent Protection: PTC thermistors act as resettable fuses, limiting current during overloads.

- Temperature Sensing: They provide accurate measurements by varying resistance with temperature changes.

- Self-Regulating Heating: Commonly found in hair dryers and seat heaters, they generate heat as current flows.

- Motor Startup Protection: They limit inrush current to protect motor components.

- Liquid Level Sensing: PTC thermistors detect liquid levels by changing resistance.

These uses demonstrate the reliability of Positive temperature coefficient thermistors in enhancing safety and efficiency.

Conclusion: The Future of Positive Temperature Coefficient (PTC) Thermistors

Recommended for you

Water Temperature Sensor: The Key to Engine Health and Efficiency

Lightning Surge Protection Varistor: Essential for Protecting Your Electrical Systems

Water Temp Sensor: How to Test it for Reliable Performance?

Capacitor Impedance: Calculation Guide & FAQs

Temperature Probe Sensor: A Comprehensive Guide

Termistor NTC: What Does a Thermistor Do?

Logistics

Does it support express delivery?

Yes, we support express delivery services. You can choose different delivery methods according to your needs, including ordinary express delivery and expedited express delivery.

Shipment

1)Small order quantity and small packing:cargo may be arranged by courier;

2)Bulk order and big volume:shipment may be arranged by sea or by air as per customer’s requirements on FOB, C&F,CIF or LCL terms and do prompt shipment which is very important for our customers, so we do this matter seriously and we may arrange our shipment in time due to our rich experiences in this line. We may also accept the shipment on the term of freight prepaid or freight collect.

Can I change my shipping address?

Yes, you can contact our customer service team to modify the delivery address before order confirmation to ensure that the order can be accurately delivered to the address you specify.

Customized Services

Free sample availability

You can contact our representative via email, fax or phone to specify the sample you need and provide your courier's account number (such as UPS, FedEx, DHL, TNT, etc.).. And we’ll send you samples free of charge through your courier by freight collection.

Price and Payment

How are the prices of your products determined?

Our product prices are based on a variety of factors, including order quantity, customization requirements, and market competition.

You may also like

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd