MOVs: Comprehensive Guide to Metal Oxide Varistors for Reliable Surge Protection

Discover how DXM's comprehensive guide on Metal Oxide Varistors (MOVs) can enhance your understanding of reliable overvoltage protection. This article delves into the critical role MOVs play in safeguarding electrical and electronic devices from voltage surges. Perfect for professionals seeking to optimize their systems, our guide offers insightful strategies and best practices. Explore how DXM's expertise in MOV technology can help you ensure electrical safety and longevity. Read now for pivotal MOV insights.

- MOVs: Definition and Function of Metal Oxide Varistors

- Key Functions of Metal Oxide Varistors

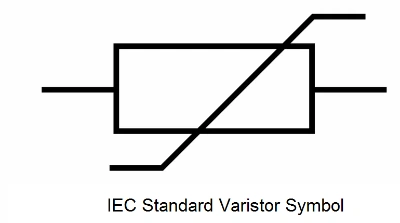

- Varistor Symbol

- MOVs: The Working Principle of Metal Oxide Varistors

- Key Stages of Varistor Operation

- Voltage-Dependent Resistance and Material Composition

- MOVs: Types and Materials of Metal Oxide Varistors

- MOVs: Applications and Importance of Metal Oxide Varistors

- Key Applications of MOVs

- Importance of Metal Oxide Varistors

- MOVs: Key Considerations for Effective Use of Metal Oxide Varistors

- 1. Proper Selection

- 2. Placement

- 3. Thermal Management

- 4. Failure Modes

- 5. Lifetime Considerations

- Key Features of MOVs: Metal Oxide Varistors

- 1. Fast Response Time

- 2. High Surge Current Capability

- 3. Compact and Cost-Effective

- 4. Bidirectional Protection

- Advantages of Using MOVs: Metal Oxide Varistors

- 1. High Reliability

- 2. Versatility Across Applications

- 3. Cost Efficiency

- 4. Easy Integration

- 5. Thermal Protection and Failure Modes

- FAQs About MOVs: Metal Oxide Varistors

- Conclusion: The Essential Role of MOVs in Circuit Protection

MOVs: Types and Materials of Metal Oxide Varistors

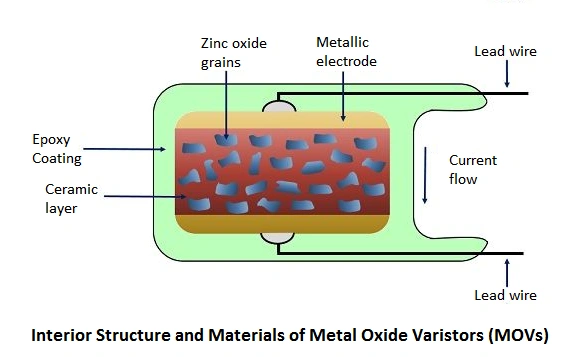

MOVs (Metal Oxide Varistors) are the most widely used type of varistor. They are made from a sintered matrix of zinc oxide grains, forming a structure similar to a diode junction. When exposed to high voltages, MOVs undergo avalanche breakdown, absorbing excess energy to protect the circuit.

The metal oxide varistor design enables it to quickly react to voltage spikes, making it an essential varistor resistor for safeguarding sensitive electronic components. This combination of materials ensures reliable protection against transient surges.

By utilizing the properties of Metal Oxide Varistors, circuits are effectively shielded from high-voltage events, ensuring system longevity and stability.

MOVs: Applications and Importance of Metal Oxide Varistors

MOVs (Metal Oxide Varistors) are essential in protecting electronic systems from transient voltage spikes. Their ability to absorb excess energy makes them invaluable across various applications, ensuring equipment safety and longevity.

Key Applications of MOVs

-

1.Power Supply Protection: MOVs protect power supply circuits from voltage spikes, safeguarding sensitive components from damage caused by overvoltage events.

-

2.Communication Line Protection: Telecommunication systems are vulnerable to lightning-induced surges. MOVs provide effective protection against these high-voltage transients.

-

3.Industrial Equipment: MOVs are crucial in industrial environments where large motors and switches can create harmful voltage spikes. They protect control systems and sensitive electronics, improving system reliability.

-

4.Consumer Electronics: From televisions to computers, MOVs protect household devices from power surges, prolonging their lifespan and ensuring safe operation.

-

5.Automotive Systems: In modern vehicles, MOVs protect intricate electronic systems from electrical transients caused by alternators and ignition systems.

-

6.Lightning Protection: While not a standalone solution, MOVs are part of broader lightning protection systems, helping absorb voltage spikes caused by lightning strikes.

Importance of Metal Oxide Varistors

- 1.Equipment Longevity: MOVs protect against cumulative damage from transient voltages, significantly extending the life of electronic components.

- 2.Safety: In critical systems, MOVs prevent voltage spikes from causing failures, enhancing safety.

- 3.Cost Savings: The low cost of integrating MOVs is minimal compared to the savings from prevented damage and downtime.

- 4.System Reliability: Especially in industries where continuous operation is essential, MOVs help ensure system reliability by preventing transient-induced failures.

- 5.Regulatory Compliance: MOVs are often required for compliance with electrical safety standards, making them critical for regulatory adherence.

By incorporating Metal Oxide Varistors, industries and consumers alike benefit from enhanced protection, reliability, and cost efficiency in their electronic systems.

MOVs: Key Considerations for Effective Use of Metal Oxide Varistors

To maximize the protective capabilities of MOVs (Metal Oxide Varistors), several critical factors must be considered when incorporating them into electronic systems. Ensuring the proper selection and placement of varistors helps maintain reliability and safety.

1. Proper Selection

Choosing the correct varistor resistor involves understanding the circuit’s operating voltage and potential transient magnitudes. Key parameters to consider include:

- Clamping voltage: The voltage at which the varistor begins to conduct.

- Peak current: The maximum current the varistor can safely handle.

- Maximum pulse energy: The energy the varistor can absorb during transient events.

- Rated AC/DC voltage: The normal operating voltage range.

- Standby current: The minimal current flowing under normal conditions.

2. Placement

MOVs should be placed as close as possible to the protected components to minimize lead inductance, ensuring maximum efficiency in diverting transient surges.

3. Thermal Management

Proper thermal design is crucial as Metal Oxide Varistors can generate significant heat during transient events. Ensuring adequate heat dissipation prevents degradation and potential failure.

4. Failure Modes

Varistors can fail in a short-circuit mode, so it is essential to incorporate protective measures, such as fuses, to avoid catastrophic damage in the event of a failure.

5. Lifetime Considerations

Repeated exposure to transients can degrade varistor performance over time. Regular assessment and replacement of varistors in critical systems ensure long-term protection and reliability.

By considering these factors, engineers can effectively utilize MOVs to protect electronic systems from transient voltage spikes, ensuring both safety and longevity of the components.

Key Features of MOVs: Metal Oxide Varistors

MOVs (Metal Oxide Varistors) are essential components in protecting electronic systems from transient voltage spikes. Their unique features make them a popular choice for overvoltage protection in various industries.

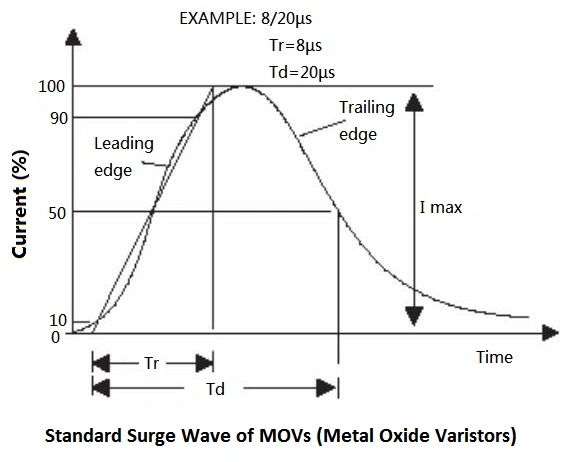

1. Fast Response Time

MOVs offer an extremely fast response, typically within nanoseconds. This quick reaction is critical for minimizing damage to sensitive electronics during voltage surges.

2. High Surge Current Capability

Metal Oxide Varistors can absorb large amounts of energy and handle multiple surge events without degrading. Their robust construction ensures reliable protection over time.

3. Compact and Cost-Effective

Varistors are compact, making them ideal for space-constrained designs. Additionally, they are a cost-effective solution for manufacturers looking to implement reliable overvoltage protection.

4. Bidirectional Protection

MOVs provide bidirectional protection, safeguarding circuits from both positive and negative voltage spikes, which is particularly important in AC power systems.

By incorporating varistor resistors, engineers can ensure that their designs are well-protected from voltage spikes, offering both reliability and efficiency in various applications.

Advantages of Using MOVs: Metal Oxide Varistors

MOVs (Metal Oxide Varistors) provide reliable and versatile overvoltage protection, making them a popular choice for safeguarding electronics in a wide range of applications.

1. High Reliability

MOVs offer superior protection and long-term stability compared to other devices. Their consistent performance ensures electronics remain protected over extended periods.

2. Versatility Across Applications

The ability of varistor resistors to function in both AC and DC circuits makes them adaptable to various industries, including automotive, telecommunications, and industrial systems.

3. Cost Efficiency

Thanks to their durability and high protection capabilities, Metal Oxide Varistors provide a cost-effective solution by reducing the need for frequent replacements or repairs.

4. Easy Integration

Due to their compact size and simple functionality, MOVs are easy to integrate into existing circuits without requiring extensive redesign or additional components.

5. Thermal Protection and Failure Modes

Over time, varistors can degrade due to repeated exposure to transient events. To ensure safe operation, varistor resistors should be paired with thermal fuses, which protect against overheating and reduce fire risks in the event of failure.

By incorporating MOVs into circuit designs, engineers can ensure both cost-effective protection and reliability, enhancing system safety and longevity.

FAQs About MOVs: Metal Oxide Varistors

1. How do MOVs differ from traditional resistors?

Unlike traditional resistors that maintain constant resistance, MOVs (Metal Oxide Varistors) change their resistance based on the applied voltage, allowing them to provide surge protection.

2. Can MOVs handle continuous overvoltage?

No, MOVs are designed to protect against short-term voltage transients. Continuous overvoltage exposure can degrade their performance over time.

3. What should be considered when selecting a varistor?

When selecting a varistor resistor, key factors include maximum working voltage, energy rating, response time, and physical size. The choice depends on the specific application and required protection.

4. Do varistors have a lifespan?

Yes, varistor resistors have a finite lifespan, influenced by the frequency and magnitude of surges they encounter. Regular inspection and replacement are necessary for maintaining protection.

By understanding these aspects, engineers can effectively select and maintain MOVs for optimal performance in surge protection.

Conclusion: The Essential Role of MOVs in Circuit Protection

MOVs (Metal Oxide Varistors) are crucial for protecting electronic systems from transient voltage spikes, ensuring both safety and functionality. Their ability to rapidly absorb and divert surges makes them indispensable in a variety of applications, from consumer electronics to industrial equipment.

By understanding the operational principles of varistor resistors, engineers can design more reliable systems that prevent potential damage from voltage surges. Whether used in AC or DC circuits, MOVs provide a cost-effective, reliable solution for overvoltage protection.

In summary, MOVs and their unique properties, such as fast response time, high surge capability, and bidirectional protection, are vital in ensuring the longevity and safety of modern electronic systems. As technology evolves, the importance of these components continues to grow, making them an essential part of any robust circuit design.

Recommended for you

Degausser and Degaussing TV Resistor: A Complete Guide

Temperature Probe: A Comprehensive Guide

Resistance Temperature Detector Price: A Comprehensive Guide

Electrical Components International: Top Electrical Component Manufacturer DXM

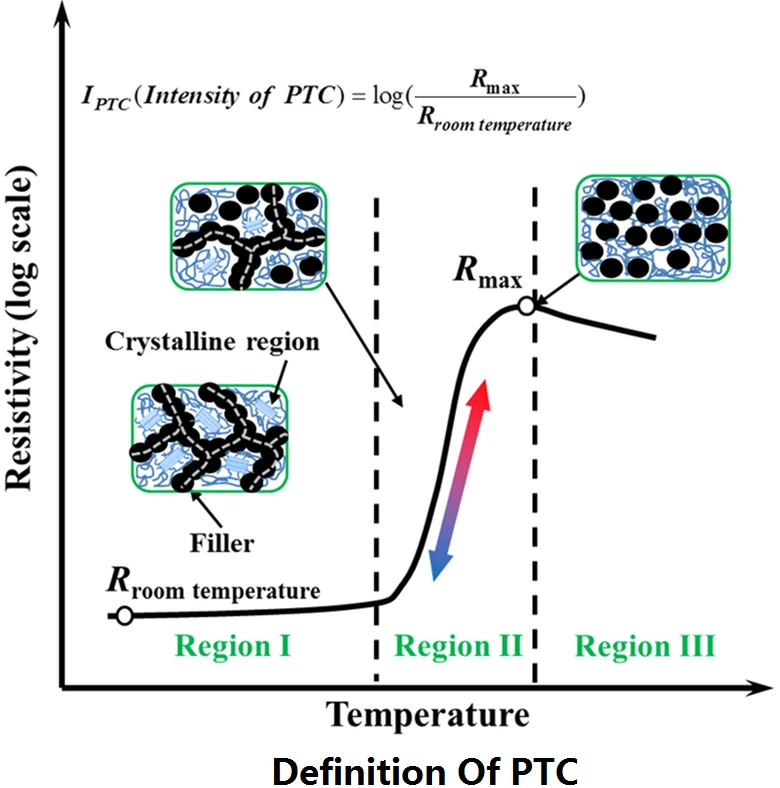

PTC Sensor: Understanding & Applications

Definition of PTC: Positive Temperature Coefficient Explained

Logistics

How to track my order?

You can track your order through our official website or the order number provided and learn about the logistics status and delivery progress of your order at any time.

Does it support express delivery?

Yes, we support express delivery services. You can choose different delivery methods according to your needs, including ordinary express delivery and expedited express delivery.

Shipment

1)Small order quantity and small packing:cargo may be arranged by courier;

2)Bulk order and big volume:shipment may be arranged by sea or by air as per customer’s requirements on FOB, C&F,CIF or LCL terms and do prompt shipment which is very important for our customers, so we do this matter seriously and we may arrange our shipment in time due to our rich experiences in this line. We may also accept the shipment on the term of freight prepaid or freight collect.

Customized Services

Custom-made sample/order

SHENZHEN DXM TECHNOLOGY CO., LTD. are structured by high-tech talents from famous university

in China and accompanied with a batch of ceramic-sensitive components experts and technology

specialist, have powerful R&D and technology capabilities.DXM is one of a few manufacturers

master core production technology of ceramic-sensitive components in the world.

Samples and orders can be custom-made per customer’s requirements, as below:

1. Application environment of product

2. Required specifications or technical parameters

3. Reference sample

4. Reference drawing

Free sample availability

You can contact our representative via email, fax or phone to specify the sample you need and provide your courier's account number (such as UPS, FedEx, DHL, TNT, etc.).. And we’ll send you samples free of charge through your courier by freight collection.

You may also like

Varistor Perfet MOV Surge Protection

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd