Definition of PTC: Positive Temperature Coefficient Explained

This article provides a detailed explanation of the definition of PTC (Positive Temperature Coefficient), covering its physics, applications, material selection, and practical considerations. It's a valuable resource for professionals needing a thorough understanding of PTC thermistors.

- Understanding the Definition of PTC, Positive Temperature Coefficient

- What is a Positive Temperature Coefficient (PTC)?

- The Physics Behind the Definition Of PTC ( Positive Temperature Coefficient)

- Common Materials Exhibiting a PTC Effect

- Applications of PTC Thermistors

- Choosing the Right PTC Thermistor

- FAQs about PTC Thermistors

- Q: What is the difference between PTC and NTC thermistors?

- Q: How does a PTC thermistor self-reset?

- Q: Can PTC thermistors be used for precise temperature measurement?

- Q: What are the limitations of PTC thermistors?

- Conclusion of Definition Of PTC

- Call to Action:

Understanding the Definition of PTC, Positive Temperature Coefficient

The definition of PTC, Positive Temperature Coefficient, is crucial for professionals working with thermistors and temperature-sensitive devices. This article will delve into the core concepts of PTC thermistors, exploring their characteristics, applications, and the significance of understanding their positive temperature coefficient. We will examine the relationship between resistance and temperature, common PTC materials, and the practical implications of this technology.

What is a Positive Temperature Coefficient (PTC)?

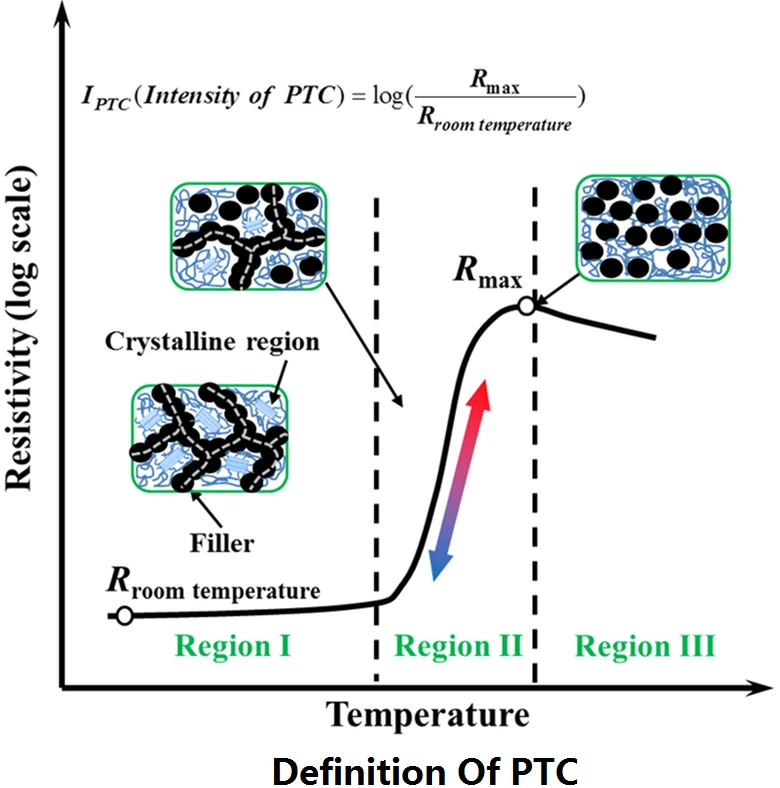

A Positive Temperature Coefficient (PTC) describes the behavior of a material whose electrical resistance increases with increasing temperature. This is in contrast to a Negative Temperature Coefficient (NTC), where resistance decreases with rising temperature. The definition of PTC hinges on this fundamental relationship: a predictable, positive correlation between temperature and resistance. This characteristic is exploited in various applications where temperature-dependent switching or sensing is required. Understanding the precise definition of PTC is paramount for selecting the appropriate components for specific applications.

The Physics Behind the Definition Of PTC ( Positive Temperature Coefficient)

The definition of PTC is rooted in the physics of materials. As temperature increases, the lattice vibrations within the material intensify. These increased vibrations interfere with the flow of electrons, leading to higher resistance. The magnitude of this increase varies depending on the material's composition and structure. For PTC thermistors, the material is engineered to exhibit a sharp, pronounced increase in resistance at a specific temperature – often referred to as the Curie temperature. This characteristic is central to the functionality of many PTC devices. Precisely defining the PTC effect involves understanding this transition.

Common Materials Exhibiting a PTC Effect

Several materials exhibit a PTC effect, but those most commonly used in commercial applications are ceramic materials containing barium titanate (BaTiO3). These materials are formulated to optimize the PTC effect within a specific temperature range. The precise composition and manufacturing process profoundly impact the resulting characteristics of the PTC thermistor. We need to consider the specific definition of PTC when discussing different material compositions and their respective properties.

Applications of PTC Thermistors

The unique properties defined by the definition of PTC make these devices invaluable across a wide range of applications. Some of the most common include:

* Overcurrent Protection: PTC thermistors are frequently used as self-resetting fuses. When excessive current flows, the temperature rises, increasing the resistance and limiting the current flow. Once the fault is cleared and the temperature drops, the resistance returns to its original low value. This functionality is directly related to the core definition of PTC.

* Temperature Sensing: While often associated with switching applications, PTC thermistors can also function as temperature sensors, providing a straightforward way to measure temperature based on their resistance. The definition of PTC enables this sensing capability.

* Motor Protection: PTC thermistors offer a reliable method for protecting motors from overheating. They act as a safety mechanism, shutting down the motor if temperatures exceed safe limits. This application again relies heavily on the precise definition of PTC.

* Heating Elements: In some specialized applications, the PTC effect is leveraged to create self-limiting heating elements. The increase in resistance with temperature prevents overheating. The inherent safety provided by the PTC is a key benefit here.

* Automotive Applications: The automotive industry uses PTC thermistors extensively in various applications, such as engine cooling, battery management, and cabin heating. Here, the reliability and predictable behavior defined by the definition of PTC are crucial.

Choosing the Right PTC Thermistor

Selecting the appropriate PTC thermistor requires careful consideration of various factors including:

* Operating Temperature Range: The definition of PTC dictates the operating temperature range, and choosing a thermistor outside of this range will lead to inaccurate results or device failure.

* Resistance-Temperature Curve: Understanding the specific resistance-temperature profile of the chosen PTC thermistor is crucial for accurate applications.

* Power Dissipation: The maximum power that the PTC thermistor can safely dissipate without damage is a critical parameter.

* Size and Package: The physical size and package type of the PTC thermistor should be compatible with the application’s space constraints.

FAQs about PTC Thermistors

Q: What is the difference between PTC and NTC thermistors?

A: PTC thermistors exhibit an increase in resistance with increasing temperature, while NTC thermistors exhibit a decrease in resistance. This fundamental difference in their response to temperature dictates their suitability for different applications. The definition of PTC contrasts sharply with that of NTC.

Q: How does a PTC thermistor self-reset?

A: Once the fault condition causing the PTC thermistor to heat up is removed, the thermistor cools down and its resistance returns to its original low value, allowing current to flow again. This self-resetting capability is a key advantage.

Q: Can PTC thermistors be used for precise temperature measurement?

A: While they can be used for temperature sensing, PTC thermistors might not provide the same level of precision as other temperature sensors, such as RTDs or thermocouples. However, their simplicity and robustness often make them the preferred choice.

Q: What are the limitations of PTC thermistors?

A: PTC thermistors have a limited operating temperature range and their response time might not be as fast as some other temperature sensors. Moreover, their resistance-temperature curve is non-linear, requiring careful calibration for precision applications.

Conclusion of Definition Of PTC

Understanding the definition of PTC, Positive Temperature Coefficient, is essential for effectively utilizing PTC thermistors in various applications. Their unique properties, including their self-resetting characteristic and predictable resistance-temperature relationship, make them invaluable components in many industrial and consumer products. By carefully selecting the appropriate PTC thermistor and understanding its limitations, engineers and designers can leverage the benefits of this technology to create reliable and efficient systems. We hope this comprehensive explanation has helped you to grasp the nuances of the definition of PTC, its implications, and its practical applications.

Call to Action:

Improve your designs and enhance your products' reliability by integrating the predictable and reliable performance of PTC thermistors. Contact us today to discuss your specific applications and find the perfect PTC (Positive Temperature Coefficient) solution for your needs.

© 2025 DXM Blog. All rights reserved.

Author: Ivan Huang

Recommended for you

Water Temperature Sensor: The Key to Engine Health and Efficiency

Lightning Surge Protection Varistor: Essential for Protecting Your Electrical Systems

Water Temp Sensor: How to Test it for Reliable Performance?

Capacitor Impedance: Calculation Guide & FAQs

Temperature Probe Sensor: A Comprehensive Guide

Termistor NTC: What Does a Thermistor Do?

Logistics

Can I change my shipping address?

Yes, you can contact our customer service team to modify the delivery address before order confirmation to ensure that the order can be accurately delivered to the address you specify.

Customized Services

Free sample availability

You can contact our representative via email, fax or phone to specify the sample you need and provide your courier's account number (such as UPS, FedEx, DHL, TNT, etc.).. And we’ll send you samples free of charge through your courier by freight collection.

Custom-made sample/order

SHENZHEN DXM TECHNOLOGY CO., LTD. are structured by high-tech talents from famous university

in China and accompanied with a batch of ceramic-sensitive components experts and technology

specialist, have powerful R&D and technology capabilities.DXM is one of a few manufacturers

master core production technology of ceramic-sensitive components in the world.

Samples and orders can be custom-made per customer’s requirements, as below:

1. Application environment of product

2. Required specifications or technical parameters

3. Reference sample

4. Reference drawing

Price and Payment

Are invoices provided?

Yes, we provide legal invoices that can be used for reimbursement and accounting records.

Do you offer bulk purchase discounts?

Yes, we offer bulk purchase discounts; the specific discount rate depends on the order quantity and cooperation method.

You may also like

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd