Surge Protection: Mastering Varistor Technology

This article provides a comprehensive guide to surge protection, focusing on the role of varistor. We cover its function, selection, limitations, and maintenance, equipping professionals with the knowledge to effectively protect its equipment.

- What are Surge Protection Devices (SPDs) and Why are They Necessary?

- Understanding Varistor: The Heart of Many SPDs

- How Varistor Provides Surge Protection

- Types of Varistors and Their Applications

- Selecting the Right Varistor for Your Application

- Limitations and Failure Mechanisms of Varistor

- Testing and Maintenance of Surge Protection Systems

- The Future of Surge Protection and Varistor Technology

- Frequently Asked Questions of Surge Protection (FAQs)

- Conclusion

Surge protection is essential for safeguarding electronics from power surges. Varistor plays a crucial role in this protection device, offering reliable and cost-effective solutions. A varistor absorbs excess voltage, preventing damage to sensitive components. Commonly used in power strips, circuit boards, and appliances, varistor is key to maintaining the longevity of electrical systems. When selecting a varistor, consider factors like voltage rating, energy absorption capacity, and response time. Though highly effective, varistor does have limitations, such as wear over time. Understanding these factors ensures better surge protection for your electronic devices.

What are Surge Protection Devices (SPDs) and Why are They Necessary?

Transient voltage surges, often caused by lightning strikes, power grid switching, or electrostatic discharge (ESD), can wreak havoc on sensitive electronic equipment. These surges can lead to malfunctions, data loss, and even permanent damage. Surge protection devices (SPDs) act as the first line of defense, diverting excess energy away from protected equipment. They're essential for safeguarding everything from delicate instrumentation to industrial power systems. Effective surge suppression minimizes downtime and protects valuable investments.

Understanding Varistor: The Heart of Many SPDs

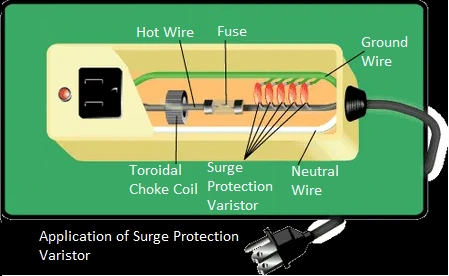

Metal oxide varistors (MOVs) are the most common type of varistor used in surge suppression applications. These devices are voltage-dependent resistors that exhibit a highly non-linear current-voltage characteristic. Under normal operating voltages, their resistance is high, allowing current to flow unimpeded to the protected equipment. However, when a surge occurs, their resistance drastically decreases, shunting the surge current to ground and protecting the load. The effectiveness of surge protection greatly depends on the varistor's ability to absorb and dissipate this energy.

How Varistor Provides Surge Protection

Varistors provide surge protection through their unique voltage-current characteristic. When a voltage exceeding their clamping voltage is applied, the varistor's resistance drops sharply, allowing a large surge current to flow. This current is then diverted to ground, limiting the voltage reaching the protected equipment. The energy from the surge is dissipated as heat within the varistor itself. Proper selection of a varistor is crucial; it must be capable of handling the expected surge energy without failing.

Types of Varistors and Their Applications

Various varistors types exist, each suited for specific applications. For instance, some are designed for high-energy surges, while others are optimized for fast response times. The choice of varistor depends on several factors, including the expected surge energy, the response time requirements, and the operating voltage. We often see them in power supplies, telecom systems, and industrial control equipment, showcasing their versatility in providing comprehensive surge protection.

Selecting the Right Varistor for Your Application

Choosing the correct varistor is crucial for effective surge protection. Several factors influence this selection, including the maximum clamping voltage, the energy absorption capacity, and the response time. Understanding the specific characteristics of your application is essential to choose a varistor that will provide adequate protection without compromising performance or reliability. Incorrect selection can lead to insufficient protection or premature varistor failure. Thorough analysis of your application’s requirements is crucial.

Limitations and Failure Mechanisms of Varistor

While varistors provide excellent surge protection, they have limitations. Repeated exposure to large surges can degrade their performance, leading to eventual failure. This is often characterized by a decrease in clamping voltage and an increase in leakage current. Regular inspection and preventative maintenance are crucial to ensure continued effectiveness of the surge suppression system. Understanding these limitations is critical in designing a robust and reliable system.

Testing and Maintenance of Surge Protection Systems

Regular testing and maintenance of surge protection systems are vital for ensuring their continued effectiveness. Testing methodologies vary depending on the type of SPD and application. We commonly recommend visual inspection for signs of damage, such as discoloration or physical damage. Furthermore, periodic testing of the SPD's clamping voltage and leakage current is essential to determine its operational status. Maintenance ensures the longevity and reliability of your surge suppression system.

The Future of Surge Protection and Varistor Technology

Ongoing research and development continually improve varistor technology. New materials and designs are constantly being explored, leading to improvements in energy absorption capacity, response time, and overall reliability. As electronic systems become more sensitive and sophisticated, the need for advanced surge protection solutions will only increase, driving innovation in this critical field.

Frequently Asked Questions of Surge Protection (FAQs)

Q: How often should I replace my varistors?

A: The lifespan of a varistor depends on the number and magnitude of surges it experiences. Regular inspection and testing are crucial to determine when replacement is necessary.

Q: Can I use a varistor of a higher voltage rating than my application requires?

A: While it might seem safer, using a higher voltage rating varistor could lead to slower response times and reduced effectiveness.

Q: What happens if a varistor fails?

A: A failed varistor may no longer provide adequate surge protection, potentially leading to damage to connected equipment.

Q: Are there alternative technologies to varistor for surge protection?

A: Yes, other technologies exist, but varistor remains the most widely used and cost-effective solution for many applications due to its robust capabilities.

Conclusion

Surge protection using varistor is essential for protecting valuable equipment from the damaging effects of transient voltage surges. Understanding the principles of operation, selection criteria, limitations, and maintenance procedures is crucial for ensuring the reliability and longevity of your system. By properly integrating surge protection into your designs, we can safeguard valuable electronics and minimize costly downtime. Invest in reliable surge protection; it is a cost-effective measure to protect your investments.

© 2025 DXM Blog. All rights reserved.

Author: Ivan Huang

Recommended for you

Water Temperature Sensor: The Key to Engine Health and Efficiency

Lightning Surge Protection Varistor: Essential for Protecting Your Electrical Systems

Water Temp Sensor: How to Test it for Reliable Performance?

Capacitor Impedance: Calculation Guide & FAQs

Temperature Probe Sensor: A Comprehensive Guide

Termistor NTC: What Does a Thermistor Do?

Customized Services

Custom-made sample/order

SHENZHEN DXM TECHNOLOGY CO., LTD. are structured by high-tech talents from famous university

in China and accompanied with a batch of ceramic-sensitive components experts and technology

specialist, have powerful R&D and technology capabilities.DXM is one of a few manufacturers

master core production technology of ceramic-sensitive components in the world.

Samples and orders can be custom-made per customer’s requirements, as below:

1. Application environment of product

2. Required specifications or technical parameters

3. Reference sample

4. Reference drawing

Free sample availability

You can contact our representative via email, fax or phone to specify the sample you need and provide your courier's account number (such as UPS, FedEx, DHL, TNT, etc.).. And we’ll send you samples free of charge through your courier by freight collection.

Logistics

Does it support express delivery?

Yes, we support express delivery services. You can choose different delivery methods according to your needs, including ordinary express delivery and expedited express delivery.

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

Price and Payment

Do you offer bulk purchase discounts?

Yes, we offer bulk purchase discounts; the specific discount rate depends on the order quantity and cooperation method.

You may also like

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd