Resistance Temperature Detector Price: A Comprehensive Guide

Discover the best prices for Resistance Temperature Detectors with our comprehensive guide. DXM offers top-quality Resistance Temperature Detector at competitive rates. Learn about the factors affecting resistance temperature detector prices and make an informed decision for your needs. Trust DXM for reliable and affordable solutions.

- What Is Resistance Temperature Detector (RTD)?

- Why Choose a Resistance Temperature Detector?

- Types of Resistance Temperature Detectors

- 1. Wirewound Resistance Temperature Detector

- 2. Thin-Film Resistance Temperature Detector

- 3. Surface Mount Resistance Temperature Detectors

- Factors That Influence the Price of Resistance Temperature Detector

- 1. Material

- 2. Accuracy and Tolerance

- 3. Construction and Packaging

- 4. Calibration and Certification

- How to Choose the Right Resistance Temperature Detector

- 1. Temperature Range

- 2. Response Time

- 3. Accuracy

- 4. Environmental Conditions

- Key Applications of Resistance Temperature Detector (RTD) in Industry

- Industrial Applications of Resistance Temperature Detectors

- Other Notable Resistance Temperature Detector Applications

- Laboratory & Research

- Frequently Asked Questions of Resistance Temperature Detector

- Q: What is the difference between an RTD and a thermocouple?

- Q: How often should I calibrate my RTD?

- Q: How can I extend the lifespan of my RTD?

- Conclusion: Make an Informed Decision with the Right Resistance Temperature Detector (RTD)

A Resistance Temperature Detector (RTD) is an essential component in industrial temperature measurement. Known for its high accuracy and stability, it offers precise temperature control. Understanding the types of Resistance Temperature Detectors(RTDs), the factors influencing Resistance Temperature Detector price, and how to choose the right one can make a big difference in your application. This guide will walk you through everything you need to know to make an informed decision.

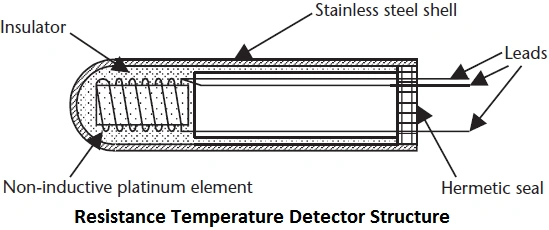

What Is Resistance Temperature Detector (RTD)?

Resistance Temperature Detector (RTD) is a type of temperature sensor that operates by correlating the resistance of a material (usually platinum) with temperature. As the temperature increases, the electrical resistance of the material also increases, providing an accurate measurement of temperature changes. Resistance Temperature Detectors are often used in precision temperature measurement applications where stability and accuracy are paramount.

One of the key benefits of RTDs is their high accuracy and stability compared to other temperature sensors such as thermocouples. Due to their predictable behavior, Resistance Temperature Detectors are widely used in industries such as chemical processing, automotive, aerospace, and HVAC systems, among others. Understanding how these sensors work and the factors that influence the Resistance Temperature Detector price is important when selecting the right RTD for your needs.

Why Choose a Resistance Temperature Detector?

Resistance Temperature Detectors are preferred in high-precision applications because they offer several advantages over other temperature measurement technologies. These advantages include:

- High Accuracy: Resistance Temperature Detector can achieve accuracy levels of up to 0.1°C, which is essential for processes requiring precise control.

- Long-Term Stability: Unlike thermocouples, which can drift over time, Resistance Temperature Detectors maintain their accuracy over extended periods, reducing the need for frequent recalibration.

- Wide Temperature Range: RTDs can operate in a broad temperature range, typically from -200°C to 850°C, making them suitable for diverse industrial environments.

Types of Resistance Temperature Detectors

The term "Resistance Temperature Detector" refers to a category of sensors, but there are different types, each designed to suit specific needs. Below are the most common types of Resistance Temperature Detectors:

1. Wirewound Resistance Temperature Detector

Wirewound Resistance Temperature Detector is the most traditional type of RTDs. It consists of a thin wire of platinum wound around a core material. This Resistance Temperature Detector offers high accuracy and stability, making it ideal for industrial environments that require reliable temperature measurements. However, it has slower response times compared to other types of Resistance Temperature Detectors, making it less suitable for dynamic applications where rapid changes in temperature occur.

The price of wirewound Resistance Temperature Detector varies depending on the configuration and materials used. For example, standard platinum wirewound RTD is generally more affordable than those with higher accuracy or specialized coatings for extreme environments.

2. Thin-Film Resistance Temperature Detector

Thin-film Resistance Temperature Detector is made by depositing a thin layer of platinum onto a ceramic or glass substrate. This construction results in a more compact and faster-responding sensor compared to wirewound Resistance Temperature Detectors. This RTD is often used in applications where space is limited or where fast temperature changes need to be detected quickly.

Thin-film Resistance Temperature Detector is typically more expensive than wirewound model because of its manufacturing process. The increased cost is often justified by their faster response times and small size, which make it ideal for applications in electronics and precision instrumentation.

3. Surface Mount Resistance Temperature Detectors

Surface mount Resistance Temperature Detectors are designed to be easily integrated into printed circuit boards (PCBs). These sensors are popular in the electronics industry and other applications where space-saving designs are critical. Surface mount RTDs can offer high accuracy and rapid response times, similar to thin-film RTDs, but they tend to be more affordable due to their integration into standard PCB designs.

Factors That Influence the Price of Resistance Temperature Detector

The Resistance Temperature Detector price can vary significantly depending on several key factors. Understanding these factors will help you determine which Resistance Temperature Detector is best suited for your needs, while also ensuring that you get the best value for your investment.

1. Material

The most common material used in RTDs is platinum, due to its excellent stability and predictable resistance behavior over a wide temperature range. Platinum-based Resistance Temperature Detectors, especially those classified as Pt100 (with a nominal resistance of 100 ohms at 0°C), are the most widely used and tend to have a higher price due to the cost of platinum. Other materials, such as nickel or copper, can be used for RTDs in less demanding applications, and these models are typically more affordable.

2. Accuracy and Tolerance

The accuracy and tolerance of an Resistance Temperature Detector play a significant role in its price. RTDs with tighter tolerance and higher accuracy specifications are more expensive because they require higher manufacturing standards and additional calibration steps. For instance, an RTD with an accuracy of ±0.1°C will generally cost more than one with an accuracy of ±1°C. The choice of tolerance depends on the precision required in your specific application.

3. Construction and Packaging

The construction and packaging of the Resistance Temperature Detector can also impact its price. Resistance Temperature Detectors designed for harsh environments, such as those with special coatings or protective sheaths, are more expensive than those designed for less demanding conditions. Additionally, RTDs with specialized connectors or extended lead wires for easier integration into systems can also increase the price.

4. Calibration and Certification

Factory calibration and certification, which ensure that the RTD meets specific accuracy standards, add to the cost of the sensor. Calibration is particularly important in industries where regulatory compliance or stringent temperature control is required. Certified RTDs provide added assurance of measurement accuracy, which is why they tend to be priced higher than non-certified models.

How to Choose the Right Resistance Temperature Detector

When selecting the appropriate RTD for your application, several key considerations should guide your decision:

1. Temperature Range

It is crucial to ensure that the RTD you choose can operate within the required temperature range for your application. While most RTDs can handle temperatures between -200°C and 850°C, certain specialized Resistance Temperature Detectors can measure even more extreme temperatures. Select an RTD that can cover the expected operating temperatures of your process.

2. Response Time

If your application involves rapid temperature changes, you may need an RTD with a fast response time. Thin-film and surface-mount Resistance Temperature Detectors generally offer faster response times than wirewound Resistance Temperature Detectors, which is an important consideration for high-speed applications such as electronics testing or rapid process control.

3. Accuracy

For applications that require precise temperature control, accuracy is a key factor. High-accuracy RTDs may be more expensive, but they provide the precision needed for critical measurements. Ensure that the RTD’s accuracy is aligned with the requirements of your process.

4. Environmental Conditions

The environmental conditions in which the RTD will operate must also be considered. For example, if the RTD is exposed to high pressure, vibration, or corrosive chemicals, you may need a rugged, custom-designed RTD with protective sheaths and coatings.

Key Applications of Resistance Temperature Detector (RTD) in Industry

Resistance Temperature Detectors (RTDs) are highly valued across industries for their accuracy, stability, and ability to operate across a wide temperature range. These characteristics make them ideal for precise temperature measurements in various industrial applications. Below are some of the most common uses of RTDs:

Industrial Applications of Resistance Temperature Detectors

- Chemical Processing: RTDs help maintain precise temperature control in chemical reactors, ensuring safe and efficient processes.

- Power Plants: Resistance Temperature Detectors are essential for monitoring temperatures in boilers and turbines, optimizing efficiency and safety.

- Food Processing: Ensuring food is processed at the right temperature is crucial for quality and safety. RTDs are used in this process to maintain standards.

- Pharmaceuticals: Accurate temperature control is critical in pharmaceutical manufacturing, with RTDs used to monitor and control production processes.

- Industrial Boilers: RTDs ensure efficient temperature monitoring in industrial boilers, preventing overheating and system failure.

Other Notable Resistance Temperature Detector Applications

- Automotive: RTDs are used to measure engine temperature and intake air temperature, helping optimize performance and prevent damage.

- Aerospace & Military: These temperature sensors are essential for precise measurements in aerospace and military systems where accuracy is vital.

- Medical Electronics: Resistance Temperature Detectors play a key role in medical devices, offering accurate temperature monitoring in sensitive applications like patient care equipment.

- Semiconductor Manufacturing: Resistance Temperature Detectors ensure precise temperature control during semiconductor fabrication, ensuring high-quality production standards.

- Maritime: RTDs are used in shipbuilding to monitor engine temperatures and manage cargo temperatures effectively.

Laboratory & Research

- In laboratory settings, RTDs are utilized for high-accuracy measurements, supporting scientific experiments and research that require precision.

Resistance Temperature Detectors are preferred in all these applications due to their high accuracy, reliability, and stability under various operating conditions. Whether it's for industrial, automotive, medical, or scientific use, Resistance Temperature Detectors deliver the precision needed for critical temperature monitoring.

Frequently Asked Questions of Resistance Temperature Detector

Q: What is the difference between an RTD and a thermocouple?

A: Resistance Temperature Detectors offer higher accuracy and stability compared to thermocouples, but thermocouples typically have a faster response time. The choice between an RTD and a thermocouple depends on the specific application and measurement requirements.

Q: How often should I calibrate my RTD?

A: Calibration frequency depends on the criticality of your application and the level of accuracy required. Regular calibration ensures the RTD continues to provide precise measurements over time.

Q: How can I extend the lifespan of my RTD?

A: Proper installation, careful handling, and adherence to environmental limits can significantly prolong the lifespan of your RTD. Additionally, regular maintenance is essential to ensure long-term performance.

Conclusion: Make an Informed Decision with the Right Resistance Temperature Detector (RTD)

Understanding the Resistance Temperature Detector (RTD) and the factors influencing its price is key to making the best purchase. Selecting the right RTD requires considering factors like temperature range, accuracy, and environmental conditions. The resistance temperature detector price can vary based on these factors, so it's important to choose an RTD that fits your specific needs. With the right RTD, you can optimize your temperature measurement processes and improve overall efficiency.

If you're ready to buy or need expert advice, contact us today for personalized assistance and competitive Resistance Temperature Detectors (RTDs) pricing.

Recommended for you

Water Temperature Sensor: The Key to Engine Health and Efficiency

Lightning Surge Protection Varistor: Essential for Protecting Your Electrical Systems

Water Temp Sensor: How to Test it for Reliable Performance?

Capacitor Impedance: Calculation Guide & FAQs

Temperature Probe Sensor: A Comprehensive Guide

Termistor NTC: What Does a Thermistor Do?

Logistics

How to track my order?

You can track your order through our official website or the order number provided and learn about the logistics status and delivery progress of your order at any time.

Can I change my shipping address?

Yes, you can contact our customer service team to modify the delivery address before order confirmation to ensure that the order can be accurately delivered to the address you specify.

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

Price and Payment

How are the prices of your products determined?

Our product prices are based on a variety of factors, including order quantity, customization requirements, and market competition.

Customized Services

Free sample availability

You can contact our representative via email, fax or phone to specify the sample you need and provide your courier's account number (such as UPS, FedEx, DHL, TNT, etc.).. And we’ll send you samples free of charge through your courier by freight collection.

You may also like

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd