How to choose ntc thermistor

Selecting the right NTC thermistor involves careful consideration of the maximum working current, nominal resistance value, ntc thermistor beta value and thermal characteristics. Understanding these factors ensures optimal performance and longevity of the NTC thermistor in various applications. By considering additional factors like maximum rated voltage, filter capacitor value, allowable startup current, and environmental conditions, engineers can make informed decisions to enhance the reliability and efficiency of their electronic designs.

- What is NTC?

- How NTC thermistor works

- NTC thermistor applications

- How to choose a NTC thermistor

- Factor 1: Maximum Working Current

- Calculation Example

- Key Points:

- Factor 2: Nominal Resistance Value

- Example Calculation:

- Key Points:

- Factor 3: NTC thermistor B value and Thermal Characteristics

- Thermal Characteristics:

- Additional Considerations

- Maximum Rated Voltage and Filter Capacitor Value

- Allowable Startup Current and Long-Term Load

- Environmental Factors

- Conclusion

What is NTC?

An NTC thermistor, or Negative Temperature Coefficient thermistor, is a type of resistor whose resistance decreases as temperature increases. This characteristic makes NTC thermistors ideal for temperature sensing and control applications. Widely used in various industries, these thermistors are valued for their precision, reliability, and fast response time.

How NTC thermistor works

NTC thermistors are made from ceramic materials that exhibit significant changes in resistance with temperature variations. As the temperature rises, the semiconductor material's resistance drops, allowing more current to flow through the circuit. This predictable change in resistance with temperature makes thermistors NTC a critical component in many electronic devices.

NTC thermistor applications

NTC thermistors are used in a broad range of applications. Common uses include temperature monitoring in HVAC systems, battery packs, and medical devices. Additionally, they are essential in automotive temperature sensors, household appliances, and industrial equipment, where precise temperature control is crucial.

How to choose a NTC thermistor

Table: Summary of Key Factors for Selecting NTC Thermistors

| Factor | Description | Example Calculation |

| Maximum Working Current | Must exceed the circuit's operating current | If operating current is 5A, select > 5A |

| Nominal Resistance Value | Determines inrush current limiting capability | For 220V line, 50A inrush: ≥ 6.2Ω |

| ntc thermistor b value | higher b value of thermistor results in lower residual resistance and smaller temperature rise | B-value selection based on application |

| Maximum Rated Voltage | Affects the allowable filter capacitor value; inverse relationship between voltage and capacitance | For higher voltage, use smaller capacitance |

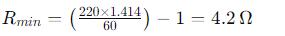

| Allowable Startup Current | Must handle the maximum startup current and continuous load | For 60A startup, minimum resistance = 4.2Ω |

| Environmental Factors | Consider ambient temperature, humidity, and mechanical stress | High humidity accelerates aging |

Factor 1: Maximum Working Current

The maximum working current of an NTC thermistor must be greater than the actual operating current of the circuit. This ensures the NTC thermistor can handle the electrical load without overheating or failing.

When selecting a power type NTC thermistor, the maximum operating current is a critical factor. The NTC thermistor's maximum operating current must be greater than the actual operating current of the power circuit to prevent overheating and ensure reliable performance.

Calculation Example

For instance, consider a power circuit with an operating current of 10 A. The selected NTC thermistor should have a maximum operating current significantly higher than 10A to handle potential current surges without degradation.

Key Points:

- Ensure the NTC thermistor's maximum current rating exceeds the circuit's operating current.

- Account for potential inrush currents which can be significantly higher than steady-state currents.

Factor 2: Nominal Resistance Value

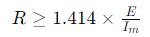

The nominal resistance value of the NTC thermistor, denoted as R, is another crucial factor. This value should be selected based on the line voltage E and the expected inrush current Im.

The resistance value determines how effectively the negative temperature coefficient ntc thermistor can limit the current when the device is powered on.

Formula:

Where:

· R: Nominal resistance

· E: Line voltage

· Im: Inrush current

For conversion power supply, inverter power supply, switching power supply, UPS power supply, Im=100 times the operating current

For filament, heater and other circuits Im=30 times the operating current

Example Calculation:

For a power supply with a line voltage of 220V and an inrush current of 60A:

Key Points:

- Calculate the minimum resistance based on line voltage and inrush current.

- Ensure the selected NTC thermistor's resistance value meets or exceeds this minimum requirement.

Factor 3: NTC thermistor B value and Thermal Characteristics

The B value of thermistor indicates its sensitivity to temperature changes. A higher B value means a greater change in resistance with temperature, which can be beneficial for certain applications.

Thermal Characteristics:

· Thermal Dissipation Coefficient (δ): Indicates how much power the thermistors ntc can dissipate per degree of temperature rise.

· Time Constant (τ): Represents the ntc thermistor's thermal response time.

The product of the time constant and the thermal dissipation coefficient gives an indication of the NTC thermistor's thermal capacity and its ability to suppress inrush currents.

Additional Considerations

Maximum Rated Voltage and Filter Capacitor Value

The maximum rated voltage and the value of the filter capacitor are crucial for selecting the appropriate NTC thermistor. The size of the filter capacitor determines the size of the NTC thermistor needed. In power applications, the inrush current results from the capacitor charging, and the NTC thermistor must handle this current.

Allowable Startup Current and Long-Term Load

The maximum startup current and the continuous current load on the NTC thermistor must be within the specified limits. For example, if an electronic device allows a maximum startup current of 60A and the thermistor has a minimum resistance of 4.2 ohms at startup, it must be selected to handle these conditions.

Environmental Factors

The operating environment significantly affects the performance of NTC thermistors. Factors such as ambient temperature, humidity, and mechanical stress must be considered. For instance, high humidity can accelerate the aging process of the thermistor, reducing its effectiveness over time.

Ensure the NTC thermistor operates within the specified temperature , humidity, and mechanical stress range to avoid accelerated aging or failure.

Conclusion

Selecting the right NTC thermistor involves careful consideration of the maximum working current, nominal resistance value, ntc thermistor beta value and thermal characteristics. Understanding these factors ensures optimal performance and longevity of the NTC thermistor in various applications. By considering additional factors like maximum rated voltage, filter capacitor value, allowable startup current, and environmental conditions, engineers can make informed decisions to enhance the reliability and efficiency of their electronic designs.

You may also like

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd