Ceramic PTC Thermistor 15P 101R for Reliable Overload Protection

Introducing the DXM Ceramic PTC Thermistor 15P 101R, your essential solution for reliable overload protection.

-

● Reliable Overload Protection: Ceramic PTC Thermistor protects welding machines from damage.

- ● Fast Reaction: 15P shifts quickly to high resistance for safety.

- ● Durable & Self-Resetting: Auto-resets after overloads for long-term use.

- ● Compact Design: Fits easily into space-limited circuits.

- ● Cost-Effective & Comprehensive Support: Check the 15P 101R Datasheet for optimal use with great value.

Choose DXM for superior quality and safety!

Introducing Ceramic PTC Thermistor 15P for Reliable Overload Protection

Reliable Overload Protection: The Ceramic PTC Thermistor 15P, detailed in the PTC 15P Datasheet and 15P-101R Datasheet, is specifically designed for overload protection in welding machines. The 15P 101R model safeguards your equipment from damage by quickly transitioning to a high-resistance state to prevent overheating.

Fast Reaction Time: The PTC 15P ensures safety with its rapid response, extending the lifespan of your welding machines. Its durable design eliminates the need for manual resets after overload events.

Durable and Stable: Engineered for long-term stability, the Ceramic PTC Thermistor is built to last. The self-resetting fuse, also known as an "auto restore fuse" or "ten-thousand-time fuse," automatically returns to a low-resistance state once the fault is resolved.

Compact Design: The small size of the PTC 15P allows easy integration into space-constrained circuits without compromising performance. This makes it ideal for various applications, especially in welding machines.

Comprehensive Technical Support: Detailed technical information is available in the 15P-101R Datasheet and other PTC 15P Datasheets, helping you select the right thermistor for your needs. Access these datasheets to ensure optimal performance and compatibility with your circuits.

Enhancing Welding Machine Safety with Ceramic PTC Thermistor

Ceramic PTC Thermistor 15P is crucial for overload protection in welding machines. The 15P 101R model, in particular, ensures consistent performance. It offers durability and recovers after multiple overloads. This makes 15P a reliable choice for welding equipment.

Refer to the 15P-101R Datasheet for detailed specifications. PTC 15P components enhance safety and extend machine lifespan. Using data from the PTC 15P Datasheet, engineers can optimize protection circuits. Ceramic PTC Thermistors maintain stable operation under stress.

Incorporating 15P 101R into designs improves reliability. Ceramic PTC Thermistors safeguard against current surges. This ensures welding machines operate efficiently over time.

Key Advantages of Ceramic PTC Thermistor

Ceramic PTC Thermistor 15P provides automatic circuit protection with steady recovery. Its contactless, noiseless, and flameless operation ensures safety. With fast reaction time, it prevents damage efficiently.

It offers enhanced performance in overvoltage protection. It operates over a wide voltage range. Small steady resistance and low rated current make it energy-efficient.

Compact size allows for easy assembly. The Ceramic PTC Thermistors 15P 101R model ensure stable long-term performance. No need for reset supply after overload protection.

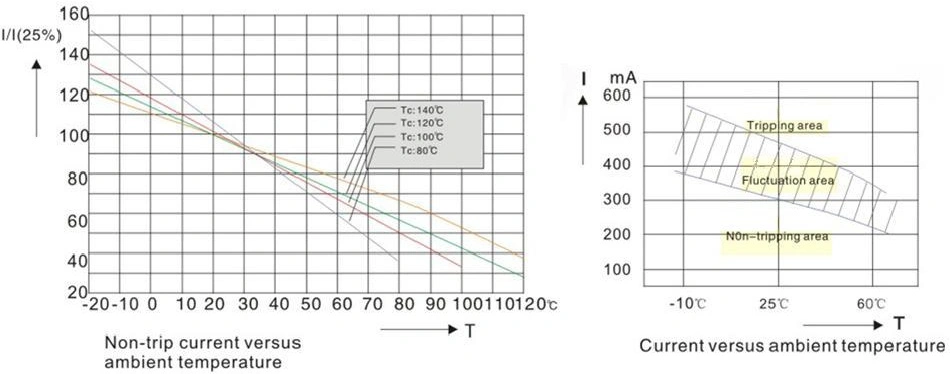

It has a wide operating temperature range:

- 0 ~ +60°C (V=Vmax)

- -25 ~ +125°C (V=0)

Refer to the 15P-101R Datasheet and PTC 15P Datasheet for detailed specifications. The product is RoHS compliant.

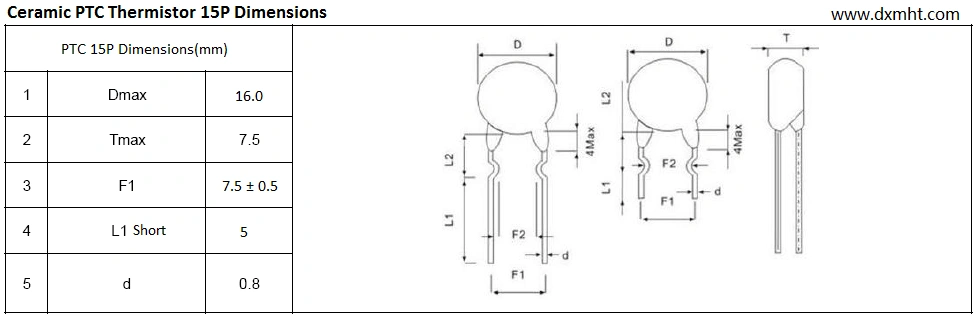

Key Product Features of 15P Thermistor

Optimized Electrical Performance Specifications of Ceramic PTC Thermistor 15P 101R

| Item | Description | Electrical Parameters |

| 1 | Resistance at 25°C (R25): | 100Ω±30% |

| 2 | Curie Temperature: | 120℃ |

| 3 | Maximum Operating Voltage (TA=25°C, Vmax): | 400V |

| 4 | Rated Voltage (TA=25°C, VN): | 270V |

| 5 | Operating Voltage: | 220Vrms |

| 6 | Maximum Allowable Current (Imax): | 200mA |

| 7 | Maximum Continuous Current at 25°C (Imax): | 50mA |

| 8 | Minimum It Current at 25°C (Imin): | 100mA |

| 9 | Operating Temperature Range (V=Vmax): | -10~+170°C |

| 10 | Storage Temperature Range (V=0): | -10~+60°C |

Materials:

- Lead Type: Internal bend

- Lead Material: CP wire

- Encapsulation Color: Green

- Encapsulation Material: Silicone rubber

Main 15P Datasheet

| Item | Model Number | Nominal Resistance | Allowable Deviation | Rated Power | Thermistor PTC Function |

| 1 | 15P-101R | 100Ω | ±30% | 0.5W | 15P 101R Special for over current,overload protection of welding machines. |

| 2 | 15P-390R | 39Ω | ±25% | 0.5W | |

| 3 | 15P-470R | 47Ω | ±25% | 0.5W | |

| 4 | 15P-500R | 50Ω | ±25% | 0.5W | |

| 5 | 15P-121R | 120Ω | ±25% | 0.5W |

Working Principle of Ceramic PTC Thermistors

The Ceramic PTC Thermistor operates by maintaining low resistance under normal conditions. This allows the circuit to function smoothly. Models like 15P 101R are designed for this purpose. When a fault occurs and the current exceeds the rated limit, the thermistor heats up rapidly. It transitions to a high-resistance state, effectively disconnecting the circuit. This action provides overload current protection and prevents damage. Once the fault is resolved, the thermistor PTC automatically returns to a low-resistance state, allowing normal operation to resume.

User Evaluations and Conclusion on Ceramic PTC Thermistor

User Feedback of Ceramic PTC Thermistors

Customers consistently praise the PTC 15P Thermistor for its reliability in overload protection. Its quick recovery after fault conditions is highly valued. Users in the welding industry highlight its effectiveness in maintaining equipment safety and longevity.

Conclusion

The Ceramic PTC Thermistor 15P series, offers a robust solution for overload current protection in welding machines. With a durable design, fast reaction time, and consistent performance, this thermistor PTC series ensures reliable operation under varying conditions. For detailed information, refer to the 15P-101R Datasheet and other relevant PTC 15P Datasheet. Whether you need PTC thermistors for overload protection or to ensure long-term circuit stability, the PTC 15P series is a proven choice.

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd