Negative Temp Coefficient Thermistor: Precision in Temperature Sensing and Control

Discover precision in temperature sensing and control with DXM's Negative Temp Coefficient Thermistor. Our expertly engineered NTC thermistor provides unmatched accuracy and reliability, making them ideal for diverse applications. Leveraging advanced Negative Temperature Coefficient technology, DXM ensures optimal performance in demanding environments. Enhance your systems with our cutting-edge solutions designed for superior thermal management. Trust DXM for innovation and quality in NTC thermistors. Explore excellence in temperature regulation today.

- Understanding Negative Temp Coefficient Thermistor

- How Does a Negative Temp Coefficient Thermistor Work?

- Negative Temp Coefficient Thermistor Applications

- 1. Temperature Sensing and Control

- 2. Automotive Industry

- 3. Consumer Electronics

- 4. Medical Equipment

- 5. Household Appliances

- Advantages of Negative Temp Coefficient Thermistor

- 1. High Sensitivity

- 2. Wide Temperature Range

- 3. Quick Response Time

- 4. Compact Size

- 5. Cost-Effective Solution

- 6. High Accuracy

- 7. Wide Range of Resistance Values

- 8. Non-Linear Response

- 9. Durability and Reliability

- 10. Versatility

- Benefits of Using Negative Temp Coefficient Thermistor

- Delving Deeper: What Does Negative Temperature Coefficient Mean?

- NTC vs PTC Thermistors: Understanding the Difference

- Real-World Applications of Negative Temp Coefficient Thermistor

- Automotive Industry: using Negative Temp Coefficient Thermistor

- Consumer Electronics: Protecting Devices with NTC Thermistor

- Medical Equipment: Precision with Negative Temp Coefficient Thermistor

- Challenges and Considerations

- 1. Non-Linear Response

- 2. Self-Heating Effects

- 3. Environmental Factors

- 4. Calibration Requirements

- Technical Insights on Negative Temp Coefficient Thermistor

- Installation and Usage Tips for Negative Temperature Coefficient Thermistor

- Maintenance and Calibration of Negative Temp Coefficient Thermistor

- Future Trends in Negative Temp Coefficient Thermistor Technology

- 1. Miniaturization

- 2. Improved Accuracy and Stability

- 3. Integration with IoT and Smart Systems

- 4. High-Temperature Applications

- 5. Enhanced Environmental Resistance

- Best Practices for Implementing Negative Temp Coefficient Thermistor

- QA: Common Questions About Negative Temp Coefficient Thermistor

- 1. What is the key advantage of NTC thermistors?

- 2. Can NTC thermistor be used in harsh environments?

- 3. What is the lifespan of an NTC thermistor?

- 4. How do NTC thermistors help in energy efficiency?

- 5. How does the Beta value affect the performance of an NTC thermistor?

The Negative Temp Coefficient Thermistor (NTC thermistor) is a vital component in various electronic systems. It plays a key role in temperature sensing and control. Negative Temp Coefficient means that as temperature increases, resistance decreases. This unique property makes NTC thermistors ideal for temperature sensing and control applications, especially in environments requiring precise temperature management.

But what does negative temperature coefficient mean, and why is it significant?Let's explore the world of Negative Temp Coefficient Thermistor and uncover its properties, uses, and importance in today's technology.

Understanding Negative Temp Coefficient Thermistor

The Negative Temp Coefficient Thermistor is a key component used in various applications. It has a Negative Temperature Coefficient property, meaning its resistance decreases as temperature rises. This property makes NTC thermistor ideal for temperature sensing and circuit protection across various fields.. In contrast, a positive temperature coefficient (PTC) means resistance increases with temperature.

Specifically, materials with a negative temperature coefficient experience a decrease in resistance as temperatures increase. This property is vital in semiconductors and thermistors used in temperature sensors, circuit protection, and various systems.

Understanding What does Negative Temperature Coefficient Mean is crucial. It describes how a material's physical property - in this case, electrical resistance - decreases when temperature increases. This principle is the foundation of NTC thermistor operation, which can help in selecting the right thermistor for your application.

How Does a Negative Temp Coefficient Thermistor Work?

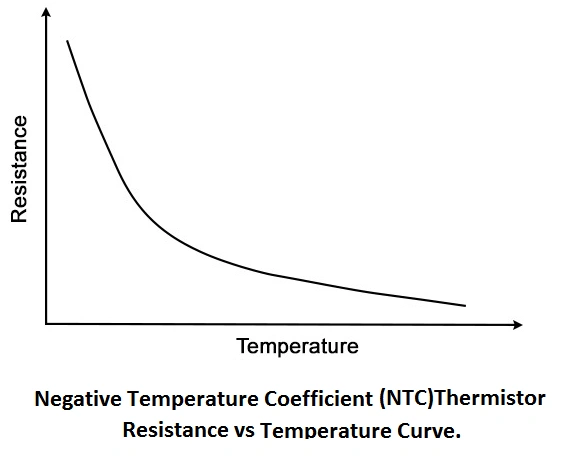

The operating principle of an Negative Temp Coefficient Thermistor is grounded in negative temperature coefficient behavior based on semiconductor material property. As the temperature rises, the semiconductor material within the thermistor generates more charge carriers, such as electrons and holes. This increase in charge carriers reduces the resistance because thermal energy propels more carriers into the conduction band, enhancing conductivity.This allowing the thermistor to provide accurate measurements and circuit protection.

The relationship between temperature and resistance in a Negative Temp Coefficient Thermistor follows the Steinhart-Hart equation:

1/T = A + B(ln R) + C(ln R)³

Where T is temperature, R is resistance, and A, B, and C are thermistor-specific coefficients.

An Negative Temp Coefficient Thermistor decreases its resistance as temperature increases.This enhancing conductivity and makes it effective for accurate temperature measurement and circuit protection in various sensitive applications. The Negative Temp Coefficient property of these thermistors ensures they respond effectively to even small changes in temperature, providing reliable and precise data for control systems.

The Negative Temperature Coefficient Thermistor functions by having its resistance change inversely to temperature changes. This characteristic allows it to be used in circuits where temperature sensitivity is necessary. When the temperature increases, the resistance of the NTC thermistor drops, enabling more current to pass through.

This is particularly useful in devices that require constant monitoring of temperature for safety and efficiency. The thermistor’s behavior is governed by its composition of semiconducting materials, which ensures consistent performance across a wide range of temperatures. Understanding what does Negative Temperature Coefficient mean helps to grasp why these thermistors are preferred in specific applications over other types of temperature sensors.

Negative Temp Coefficient Thermistor Applications

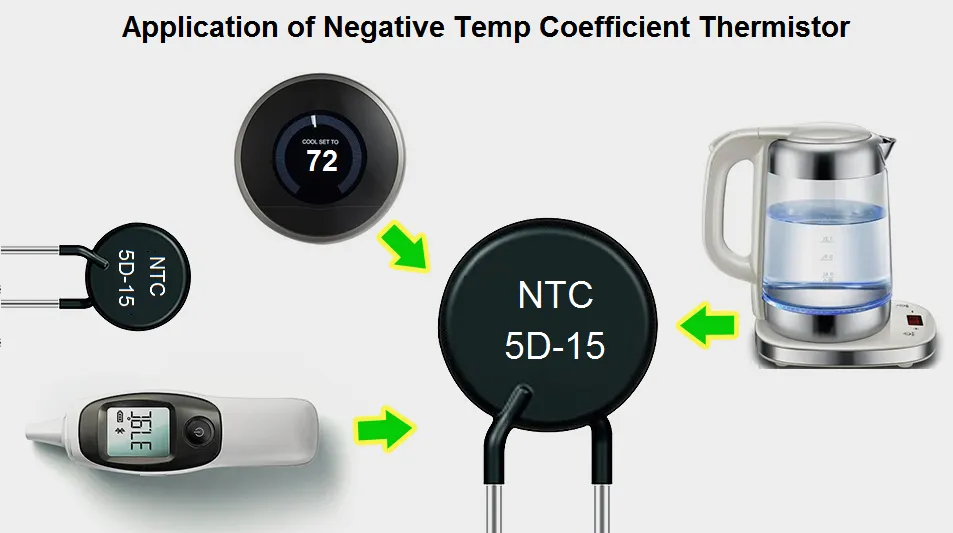

Negative Temp Coefficient Thermistors are widely used across many industries for their high precision in temperature measurement.Key application areas include:

1. Temperature Sensing and Control

NTC thermistors excel in temperature measurement. Their high sensitivity to temperature changes makes them ideal for:

- Digital thermometers

- HVAC systems

- Industrial process control

- Food processing equipment

2. Automotive Industry

In automotive applications, precise temperature sensing of NTC Thermistors are crucial for:

- Engine temperature monitoring

- Battery pack temperature monitoring systems.

- Climate control systems

- Oil temperature sensing

- Coolant temperature sensors

- Air intake sensors

3. Consumer Electronics

NTC thermistors protect and optimize various electronic devices:

- Smartphones and tablets

- Laptops and computers

- Power supplies

- LCD displays

4. Medical Equipment

In medicine, Negative Temp Coefficient Thermistor provides reliable temperature control to enhance the accuracy of:

-

- MRI machines

- Diagnostic equipment.

- Incubators

- Blood analyzers

5. Household Appliances

In Household Appliances,negative temp coefficient thermistor enhances the accuracy of:

-

-

-

- Digital thermostats for controlling heating and cooling systems

- Air conditioners

- Washing machines

- Water kettles and coffee makers

NTC thermistor in air conditioners helps regulate the room temperature by sensing changes and adjusting the cooling cycle accordingly.Use NTC thermistor to maintain optimal water temperature of washing machines during different washing cycles.

-

-

Advantages of Negative Temp Coefficient Thermistor

Negative Temp Coefficient Thermistor provides several critical features that make it a reliable option for temperature management. It is widely used in various industries due to its unique characteristics. Understanding What does Negative Temperature Coefficient Mean helps in selecting the right component for specific applications. Below are the main advantages:

1. High Sensitivity

The Negative Temp Coefficient Thermistor changes resistance by 1% to 5% per degree Celsius as temperature fluctuates. This high sensitivity allows for fine-tuned monitoring and control, especially in critical applications where even slight temperature variations could have significant impacts.

2. Wide Temperature Range

Most NTC thermistors operate effectively from -55°C to +200°C. Specialized models can withstand up to +300°C. This wide range of operation makes NTC thermistors versatile for applications in harsh environments, such as automotive exhaust systems and industrial machinery.

3. Quick Response Time

Negative Temp Coefficient Thermistor responds quickly to temperature fluctuations, which can be as short as a few seconds, depending on the thermistor's size and the surrounding medium. The fast response time of NTC Thermistor is crucial for systems that require immediate action, such as fire detection systems or temperature regulation in power electronics.Ensuring precise temperature control.

4. Compact Size

NTC thermistors are small, allowing integration into tight spaces. This compact form factor makes them suitable for portable devices and miniaturized electronics.

5. Cost-Effective Solution

Compared to other temperature sensing technologies, Negative Temp Coefficient Thermistor is an effective solution for precise temperature measurement and control. Its features, including a wide temperature range, high sensitivity, and cost-effectiveness without compromising accuracy or reliability.This makes it attractive for both industrial applications and consumer electronics.

6. High Accuracy

NTC thermistor provides precise temperature measurements, with some models achieving accuracies of ±0.1°C or better. This high accuracy is crucial in medical equipment and scientific instruments.

7. Wide Range of Resistance Values

Negative Temp Coefficient Thermistor is available in a broad range of resistance values, typically from a few ohms to several megohms. This variety allows flexibility in circuit design and application-specific optimization.

8. Non-Linear Response

The non-linear resistance-temperature relationship of NTC thermistor can be advantageous in certain applications. It provides higher sensitivity in specific temperature ranges, which can be leveraged for improved performance in targeted applications.

9. Durability and Reliability

Negative Temp Coefficient Thermistor is known for its robust construction and long-term stability. When properly selected and implemented, they provide reliable temperature sensing over extended periods, even in harsh environments.

10. Versatility

The wide range of available sizes, shapes, and packaging options makes NTC thermistor suitable for diverse applications. From surface-mount devices for compact electronics to rugged probes for industrial use, there's a Negative Temp Coefficient Thermistor for almost every need.

The Negative Temp Coefficient Thermistor is a versatile, cost-effective, and reliable option for temperature sensing. Its high sensitivity, wide temperature range, and quick response make it suitable for many applications, from automotive to medical devices. Understanding the advantages of Negative Temperature Coefficient thermistors ensures better selection and use for effective temperature control.

Benefits of Using Negative Temp Coefficient Thermistor

The main benefit of Negative Temperature Coefficient Thermistor is their ability to detect small temperature changes with high accuracy. They are widely used in industrial applications where precise temperature monitoring is crucial. The high sensitivity and quick response make them effective in both control systems and overload protection. Negative Temp Coefficient Thermistors are used to prevent overheating by detecting temperature increases and either adjusting the current or triggering shutdown protocols to protect sensitive components.

Another significant advantage of using Negative Temp Coefficient Thermistor is their cost-effectiveness. Compared to other temperature sensing technologies, NTC thermistors are relatively inexpensive while still providing accurate and reliable performance. This cost efficiency, coupled with their versatility, makes them an attractive choice for a wide range of applications. Moreover, the compact size of NTC thermistors allows for easy integration into complex electronic systems without taking up much space, which is a critical factor in the design of modern electronic devices.

Delving Deeper: What Does Negative Temperature Coefficient Mean?

The concept of negative temperature coefficient is fundamental to NTC thermistor operation. But what does negative temperature coefficient mean in practical terms? Let's break it down:

Negative Temperature Coefficient: A property where a material's electrical resistance decreases as temperature increases.

In Negative Temp Coefficient Thermistor, this behavior stems from semiconductor materials, typically metal oxides. As temperature rises, more charge carriers generate within the material, increasing conductivity and decreasing resistance.

This unique property makes Negative Temp Coefficient Thermistor invaluable in applications requiring precise temperature measurement and control. By leveraging the negative temperature coefficient, these devices provide accurate and reliable temperature feedback in diverse environments.

NTC vs PTC Thermistors: Understanding the Difference

Understanding these differences is crucial when selecting the appropriate thermistor. While Negative Temp Coefficient Thermistor excels in temperature sensing and continuous monitoring, PTC thermistors are often preferred for protection circuits and self-regulating heating elements.Detailed main differences are as below:

-

-

- Temperature Behavior: Negative Temp Coefficient Thermistor decreases resistance with temperature, while PTC thermistor does the opposite. This makes NTC suitable for continuous temperature monitoring and control.The behavior of Negative Temp Coefficient Thermistor is especially useful in systems where a decrease in resistance correlates with a need for increased current flow, such as in temperature regulation circuits.

- Material Composition: Both thermistors are made from semiconductor materials, but their specific material composition varies, impacting their performance and application suitability. Negative Temp Coefficient Thermistor is typically made from materials such as metal oxides, including manganese, nickel, and cobalt. The choice of material affects the thermistor’s resistance-temperature relationship, making it vital to select the right composition for the intended application.

- Applications: NTC is used for temperature sensing, while PTC is often used for overcurrent protection. Negative Temp Coefficient Thermistor finds its applications in devices requiring precise temperature measurement, while PTC thermistor is preferred for use as resettable fuses in electronic circuits where overcurrent protection is necessary.

-

The distinct properties of Negative Temp Coefficient Thermistor make them an ideal choice for applications where temperature monitoring and fast response are crucial. Their behavior, where resistance drops with increasing temperature, ensures that they can provide accurate readings in real time. This is why they are commonly used in HVAC systems, battery management, and safety devices, offering a reliable solution for maintaining optimal temperatures and protecting systems from thermal damage.

Knowing the differences between Positive and Negative Temp Coefficient Thermistor is essential for choosing the right component for your application.

Real-World Applications of Negative Temp Coefficient Thermistor

NTC thermistors have practical uses across multiple industries due to their accuracy and reliability:

The practical uses of negative temp coefficient thermistors span multiple industries due to their accuracy and high sensitivity to temp changes.

Automotive Industry: using Negative Temp Coefficient Thermistor

In automotive applications, Negative Temp Coefficient Thermistor ensures safe engine operation by monitoring engine temperatures, ensuring efficient and safe engine operation. The thermistor’s sensitivity helps detect temperature variations in the engine coolant and the air intake, which directly affect engine efficiency and emissions. NTC thermistors are also used in electric vehicles to monitor battery temperature, helping to optimize battery life and performance.

Consumer Electronics: Protecting Devices with NTC Thermistor

Devices like smartphones and laptops use NTC thermistor to protect circuits from overheating, optimizing performance and preventing damage. For instance, when charging a smartphone, the NTC thermistor monitors the battery temperature to prevent overheating and potential damage. This protective feature is crucial in maintaining the safety and longevity of consumer electronics.

Medical Equipment: Precision with Negative Temp Coefficient Thermistor

In medical diagnostics,, NTC thermistor maintains precise temperature control, ensuring sensitive instruments maintain accurate and reliable operation. For example, incubators that care for premature infants must maintain a stable temperature, and NTC thermistors are used to provide accurate temperature readings to ensure the incubator environment remains within safe limits. Similarly, NTC thermistors are used in autoclaves to monitor and regulate sterilization temperatures effectively.

By leveraging the negative temperature coefficient, these thermistors deliver critical temperature management in diverse applications.

Challenges and Considerations

While Negative Temp Coefficient Thermistors offer numerous advantages, it's important to be aware of potential challenges:

1. Non-Linear Response

The non-linear resistance-temperature relationship, while advantageous in some cases, can complicate circuit design and require additional linearization techniques in others.

2. Self-Heating Effects

The current flowing through an NTC thermistor can cause self-heating, potentially affecting measurement accuracy. Proper circuit design and current limiting are essential to mitigate this effect.

3. Environmental Factors

Factors such as humidity, vibration, and chemical exposure can influence the performance and lifespan of Negative Temp Coefficient Thermistors. Proper encapsulation and protection are crucial in harsh environments.

4. Calibration Requirements

To achieve high accuracy, NTC thermistors often require individual calibration, which can add to the overall cost and complexity of the system.

Technical Insights on Negative Temp Coefficient Thermistor

Delving deeper into the technical aspects, a Negative Temp Coefficient Thermistor operates based on the principle that as temperature rises, the thermistor's semiconducting material produces more charge carriers. This increase in charge carriers, such as electrons and holes, results in a decrease in resistance, allowing more current to pass through the thermistor. The specific resistance-temperature relationship of an NTC thermistor is defined by the Steinhart-Hart equation, which is often used to calculate the temperature based on the resistance measured at a given time.

Another important factor in the operation of negative temperature coefficient thermistor is the Beta (β) value, which represents the material constant that defines the sensitivity of the thermistor over a particular temperature range. A higher Beta value indicates a higher sensitivity, meaning that the thermistor will have a more significant change in resistance for a given temperature change. This makes selecting an NTC thermistor with an appropriate Beta value essential for accurate temperature measurement in specific applications.

Installation and Usage Tips for Negative Temperature Coefficient Thermistor

When using a Negative Temp Coefficient Thermistor, proper installation is essential to ensure accurate temperature measurements. The placement of the thermistor should be in a location where it can effectively sense the temperature of the desired medium. For example, when used in HVAC systems, the NTC thermistor should be placed where air passes over it to provide real-time data for temperature adjustments.

Another critical consideration is the connection method. NTC thermistors can be connected in series or parallel depending on the application requirements. In a series configuration, the thermistor can be used to monitor and control the flow of current based on temperature changes. In parallel configurations, they can provide average temperature readings across multiple points, which is useful in applications like battery packs where even temperature distribution is needed to prevent overheating.

Maintenance and Calibration of Negative Temp Coefficient Thermistor

To maintain the accuracy of Negative Temp Coefficient Thermistors, regular calibration is recommended. Calibration ensures that the resistance values correspond accurately to the temperature readings over time. Factors such as aging, thermal cycling, and exposure to harsh environments can affect the accuracy of thermistors. Using a reference thermometer and following the manufacturer's calibration guidelines can help maintain the precision of the thermistor throughout its lifespan.

Future Trends in Negative Temp Coefficient Thermistor Technology

As technology advances, so does the field of negative temperature coefficient thermistor. Emerging trends include:

1. Miniaturization

The trend towards smaller devices is driving the development of increasingly miniaturized NTC thermistors. These smaller components enable temperature sensing in even the most space-constrained applications.

2. Improved Accuracy and Stability

Advancements in materials science and manufacturing techniques are leading to negative temperature coefficient thermistor with enhanced accuracy and long-term stability. This improvement benefits precision applications such as medical diagnostics and scientific research.

3. Integration with IoT and Smart Systems

As IoT grows, NTC thermistors are playing a crucial role in enabling smart, connected temperature sensing solutions. Integration with wireless technologies and cloud-based analytics is opening new possibilities for remote monitoring and predictive maintenance.

4. High-Temperature Applications

Research into new materials and manufacturing processes is expanding the temperature range of Negative Temp Coefficient Thermistors, making them suitable for more extreme environments. This development is particularly relevant in aerospace and industrial processing.

5. Enhanced Environmental Resistance

Improved encapsulation techniques and materials are increasing NTC thermistor resistance to environmental factors such as moisture, chemicals, and mechanical stress. This enhancement is expanding their applicability in harsh industrial and outdoor environments.

Best Practices for Implementing Negative Temp Coefficient Thermistor

To maximize the performance and reliability of NTC thermistors in your applications, consider these best practices:

1. Proper Selection

Choose a Negative Temp Coefficient Thermistor with the appropriate resistance range, accuracy, and temperature coefficient for your specific application. Consider factors such as operating temperature range, response time, and environmental conditions.

2. Accurate Calibration

For high-precision applications, individual calibration of NTC thermistors is often necessary. Develop a robust calibration process and maintain proper documentation to ensure long-term accuracy.

3. Circuit Design Optimization

Design your measurement circuit to minimize self-heating effects and optimize signal-to-noise ratio. Consider using a Wheatstone bridge or constant current source for improved measurement accuracy.

4. Environmental Protection

Properly protect your Negative Temp Coefficient Thermistor from environmental factors that could affect its performance or lifespan.

QA: Common Questions About Negative Temp Coefficient Thermistor

1. What is the key advantage of NTC thermistors?

NTC thermistors have rapid response times and high sensitivity, which makes them perfect for precise temperature monitoring and control. Their ability to quickly react to temperature changes ensures that systems remain within safe operational limits.

2. Can NTC thermistor be used in harsh environments?

Yes, Negative Temperature Coefficient Thermistor can be engineered to withstand harsh environments, including extreme temperatures and high humidity. Specialized coatings and encapsulation techniques allow them to operate reliably in demanding applications such as automotive and industrial settings.

3. What is the lifespan of an NTC thermistor?

The lifespan of an NTC thermistor depends on usage conditions but is generally designed for long-term reliability and performance. Proper installation, avoiding mechanical stress, and following the recommended temperature range help prolong the lifespan of an NTC thermistor.

4. How do NTC thermistors help in energy efficiency?

NTC thermistors contribute to energy efficiency by providing precise temperature monitoring and control, which allows systems to operate at optimal conditions. In HVAC systems, for instance, accurate temperature sensing ensures that heating and cooling cycles are efficient, reducing energy consumption.

5. How does the Beta value affect the performance of an NTC thermistor?

The Beta value of a Negative Temp Coefficient Thermistor represents its sensitivity over a temperature range. A higher Beta value means the thermistor has a more significant resistance change for a given temperature change, which enhances accuracy in temperature measurement applications.

For more information on selecting the right Negative Temp Coefficient Thermistor for your application, check out our detailed products guide on ntc thermistors.

Recommended for you

Water Temperature Sensor: The Key to Engine Health and Efficiency

Lightning Surge Protection Varistor: Essential for Protecting Your Electrical Systems

Water Temp Sensor: How to Test it for Reliable Performance?

Capacitor Impedance: Calculation Guide & FAQs

Temperature Probe Sensor: A Comprehensive Guide

Termistor NTC: What Does a Thermistor Do?

Logistics

How to track my order?

You can track your order through our official website or the order number provided and learn about the logistics status and delivery progress of your order at any time.

Shipment

1)Small order quantity and small packing:cargo may be arranged by courier;

2)Bulk order and big volume:shipment may be arranged by sea or by air as per customer’s requirements on FOB, C&F,CIF or LCL terms and do prompt shipment which is very important for our customers, so we do this matter seriously and we may arrange our shipment in time due to our rich experiences in this line. We may also accept the shipment on the term of freight prepaid or freight collect.

Does it support express delivery?

Yes, we support express delivery services. You can choose different delivery methods according to your needs, including ordinary express delivery and expedited express delivery.

Can I change my shipping address?

Yes, you can contact our customer service team to modify the delivery address before order confirmation to ensure that the order can be accurately delivered to the address you specify.

Price and Payment

Payment Terms

There are a number of different payment methods that can be used when you deal with us. Two are mostly used: T/T payment in advance for small values and irrevocable L/C at sight for large values.

You may also like

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd