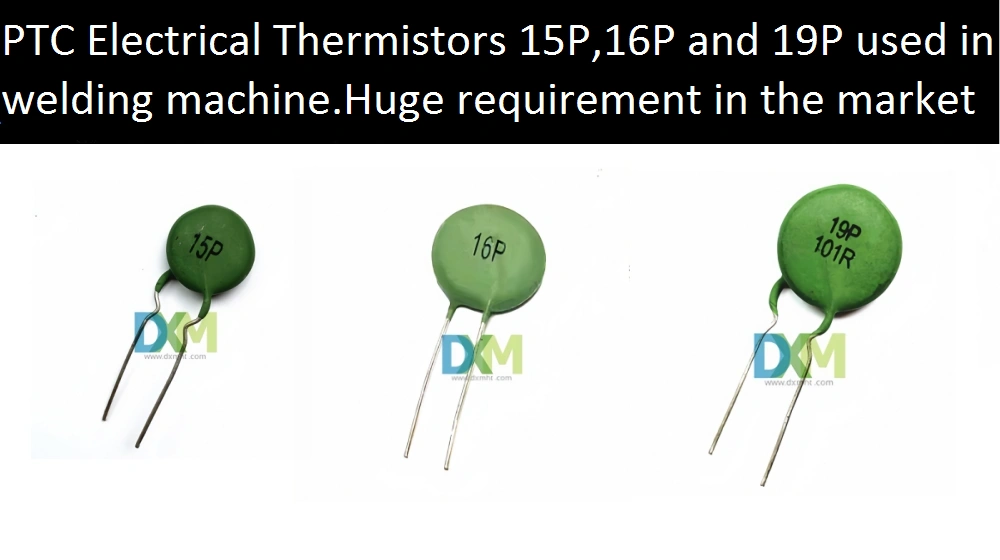

PTC Electrical Thermistors for Welding Machines: huge requirement in the market

Discover the high demand for PTC Electrical Thermistors 15P,16P,19P from DXM, designed specifically for welding machines. Our cutting-edge PTC Thermistors offer superior temperature regulation, enhancing safety and efficiency in welding applications. With robust performance and reliability, DXM's thermistors are essential components for modern welding equipment. Explore how our products meet industry standards and boost operational excellence. Trust DXM for quality and innovation in PTC Electrical solutions tailored to your welding needs.

- Understanding PTC Electrical Thermistors: The Heart of Welding Technology

- The Market Demand for PTC Electrical Thermistor

- Comparing PTC Thermistors 15P, 16P, and 19P: Key Differences

- 1. PTC Electrical 15P Thermistor

- 2. PTC 16P Thermistor

- 3. PTC Thermistors 19P

- Applications and Benefits of PTC Electrical Thermistor in Welding

- Manufacturing Excellence: Our Approach to PTC Electrical Production

- Market Insights: The Growing Demand for PTC Thermistors

- PTC 16P: A Closer Look at Our Best-Seller

- Choosing the Right PTC Electrical Thermistors for Your Welding Machine

- The Future of PTC Electrical Technology in Welding

- Conclusion: Elevating Welding Performance with PTC Thermistors

- Frequently Asked Questions

- Q: What is the main difference between PTC 15P, 16P, and 19P thermistors?

- Q: Can PTC Electrical Thermistor improve the efficiency of welding machines?

- Q: How often should PTC thermistor be replaced in welding machines?

- Q: Are your PTC Electrical products customizable?

- Q: How do PTC thermistors contribute to welding machine safety?

Welcome to our comprehensive guide on PTC thermistors, specifically focusing on the PTC Electrical technology used in welding machines. As experts in PTC 15P, PTC 16P, PTC 19P and related components, we'll dive deep into the world of these essential devices that play a crucial role in modern welding equipment.which have huge requirement in the market.

Understanding PTC Electrical Thermistors: The Heart of Welding Technology

PTC thermistors, or Positive Temperature Coefficient thermistors, are fundamental components in welding machines. These small but mighty elements help regulate temperature, ensuring optimal performance and safety in welding operations. Let's explore the most popular models: PTC 15P, PTC 16P, and PTC 19P.

The Market Demand for PTC Electrical Thermistor

The welding industry has seen a surge in demand for high-quality PTC thermistors. Our manufacturing facility has been at the forefront, supplying PTC Electrical products to customers across China and Southeast Asia. The robust market requirements underscore the critical role these components play in modern welding equipment.

Comparing PTC Thermistors 15P, 16P, and 19P: Key Differences

While all three models are designed for welding machines, they cater to different specifications and machine sizes. Let's break down their unique characteristics:

1. PTC Electrical 15P Thermistor

- Finished product diameter: 15.5-16.0 mm

- Mold size: 16mm

- Foot distance: 7.5 ± 0.5 mm

- Foot length (cut): 5mm

- Resistance: 70-130 ohm

2. PTC 16P Thermistor

- Finished product diameter: 17-17.5 mm

- Mold size: 20 mm

- Foot distance: 5 ± 0.5 mm

- Foot length (cut): 8mm

- Resistance: 4-8 ohm

- Curie temperature: 120°C

- Voltage rating: 400V

3. PTC Thermistors 19P

- Finished product diameter: 17.5-18.0 mm

- Mold size: 20mm

- Foot distance: 7.5 ± 0.5 mm

- Foot length (cut): 6mm

- Resistance: 70-130 ohm

Applications and Benefits of PTC Electrical Thermistor in Welding

PTC Electrical Thermistor offers several advantages in welding applications:

- Temperature regulation for consistent weld quality

- Overheating protection, enhancing equipment longevity

- Energy efficiency through self-regulating properties

- Compact design for integration into various welding machine sizes

Manufacturing Excellence: Our Approach to PTC Electrical Production

As a leading manufacturer of PTC thermistors, we pride ourselves on producing high-quality PTC Electrical components. Our production process ensures consistency and reliability, crucial for the demanding welding industry. We offer customization options, including printing 15P, 16P, or 19P directly on the products as per customer requirements.

Market Insights: The Growing Demand for PTC Thermistors

The welding industry's rapid growth has driven an unprecedented demand for PTC thermistors. Our customer base, spanning China and Southeast Asia, continually places large orders for these essential components. This trend reflects the expanding welding sector and the critical role of PTC Electrical technology in modern manufacturing.

PTC 16P: A Closer Look at Our Best-Seller

Among our range, the PTC 16P has emerged as a particularly popular model. Let's examine its packaging specifications:

- 250 pieces per bag

- 3 bags per small box (750 pieces total)

- 5000 pieces per large carton

This efficient packaging system allows for easy handling and distribution, catering to both small-scale operations and large industrial needs.

Choosing the Right PTC Electrical Thermistors for Your Welding Machine

Selecting the appropriate PTC Electrical thermistor for your welding equipment is crucial. Consider these factors:

- Welding machine size and power requirements

- Specific temperature regulation needs

- Voltage and current specifications of your equipment

- Physical dimensions and integration requirements

Our team of experts is always ready to assist you in choosing the perfect PTC thermistor for your application.

The Future of PTC Electrical Technology in Welding

As welding technology advances, so does the potential of PTC thermistors. We're seeing trends towards:

- Higher precision temperature control

- Miniaturization for more compact welding equipment

- Integration with smart welding systems for Industry 4.0

- Enhanced durability for extreme welding environments

Conclusion: Elevating Welding Performance with PTC Thermistors

PTC thermistors, particularly our PTC Electrical thermistor series including PTC 15P, PTC 16P, and PTC 19P, are indispensable components in modern welding technology. Their role in temperature regulation, safety, and efficiency cannot be overstated. As the welding industry continues to evolve, these small but mighty components will play an increasingly crucial role in shaping the future of welding operations worldwide. For inquiries about our PTC thermistor products or to discuss your specific welding machine needs, don't hesitate to contact our expert team. We're committed to providing top-quality PTC Electrical solutions at competitive prices, backed by unparalleled customer service.

Frequently Asked Questions

Q: What is the main difference between PTC 15P, 16P, and 19P thermistors?

A: The main differences lie in their physical dimensions, resistance values, and specific applications in different welding machine sizes. PTC 16P stands out with its lower resistance (4-8 ohm) compared to 15P and 19P (70-130 ohm).Q: Can PTC Electrical Thermistor improve the efficiency of welding machines?

A: Yes, PTC Electrical thermistor can significantly improve welding machine efficiency by providing accurate temperature regulation, which leads to consistent weld quality and reduced energy consumption.Q: How often should PTC thermistor be replaced in welding machines?

A: The lifespan of PTC thermistor depends on usage conditions, but generally, they can last several years. Regular inspection and replacement as part of routine maintenance is recommended to ensure optimal performance.Q: Are your PTC Electrical products customizable?

A: Yes, we offer customization options, including specific markings (like PTC 15P, 16P, or 19P) printed directly on the products to meet our customers' unique requirements.Q: How do PTC thermistors contribute to welding machine safety?

A: PTC thermistors enhance safety by providing overheating protection. Their self-regulating properties help prevent excessive temperatures, reducing the risk of equipment damage and potential hazards.

Discover the high demand for PTC Electrical Thermistors 15P,16P,19P from DXM, designed specifically for welding machines. Our cutting-edge PTC Thermistors offer superior temperature regulation, enhancing safety and efficiency in welding applications. With robust performance and reliability, DXM's thermistors are essential components for modern welding equipment. Explore how our products meet industry standards and boost operational excellence. Trust DXM for quality and innovation in PTC Electrical solutions tailored to your welding needs.

Recommended for you

Water Temperature Sensor: The Key to Engine Health and Efficiency

Lightning Surge Protection Varistor: Essential for Protecting Your Electrical Systems

Water Temp Sensor: How to Test it for Reliable Performance?

Capacitor Impedance: Calculation Guide & FAQs

Temperature Probe Sensor: A Comprehensive Guide

Termistor NTC: What Does a Thermistor Do?

Price and Payment

Do you offer bulk purchase discounts?

Yes, we offer bulk purchase discounts; the specific discount rate depends on the order quantity and cooperation method.

Price

The price will be quoted in US dollars.

1) For small order quantities and small packing, normally our quotation is based on the ex-works price. The cargo will be delivered by courier after being finished normally.

2) For bulk orders and large volumes, normally our quotation is based on the FOB price. Please inform us of your destination seaport and estimated quantity, and our representative will quote you the C&F or CIF price accordingly. If you feel our freight is higher than your expectation, you can recommend your shipping company to us. Our principal is looking for a shipping company with a good reputation that offers competitive freight costs and can deliver your cargo promptly.

Logistics

How to track my order?

You can track your order through our official website or the order number provided and learn about the logistics status and delivery progress of your order at any time.

Does your product support global logistics and distribution?

Yes, our products support global logistics and distribution services, and you can receive our products anytime and anywhere.

Customized Services

Free sample availability

You can contact our representative via email, fax or phone to specify the sample you need and provide your courier's account number (such as UPS, FedEx, DHL, TNT, etc.).. And we’ll send you samples free of charge through your courier by freight collection.

You may also like

Ceramic PTC Thermistor 15P 101R for Reliable Overload Protection

Termisor PTC 16P: Reliable Overload Protection for Welding machine

PTC Thermal Resistor 19P for Overcurrent and Overload Protection

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd