Thermistor NTC Applications for Effective Inrush Current Limiting

NTC (Negative Temperature Coefficient) thermistors are crucial components in many electronic devices, known for their ability to effectively manage inrush current. This article will explore various applications of thermistor ntc in inrush current limiting, particularly in Switch Mode Power Supplies (SMPS), AC-DC power modules, DC-DC converters, and industrial inverters.

Thermistor NTC Applications in Inrush Current Limiting

Introduction

NTC (Negative Temperature Coefficient) thermistors are crucial components in many electronic devices, known for their ability to effectively manage inrush current. This article will explore various applications of thermistor ntc in inrush current limiting, particularly in Switch Mode Power Supplies (SMPS), AC-DC power modules, DC-DC converters, and industrial inverters.

Application s :

1. Inrush Current Limiting in Switch Mode Power Supplies (SMPS)

Switch Mode Power Supplies (SMPS) are popular due to their compact size, lightweight design, and high performance. When an SMPS is powered on, it experiences a high peak inrush current as the filter capacitor charges. This inrush current can reduce the lifespan of the capacitor, damage the power switch contacts, or destroy rectifying diodes, necessitating effective countermeasures.

NTC thermistors are widely used to limit the inrush current in SMPS, offering a low-cost and straightforward solution. Connecting an NTC thermistor even after the rectifier circuit yields similar benefits.

2. Inrush Current Limiting in AC-DC Power Modules

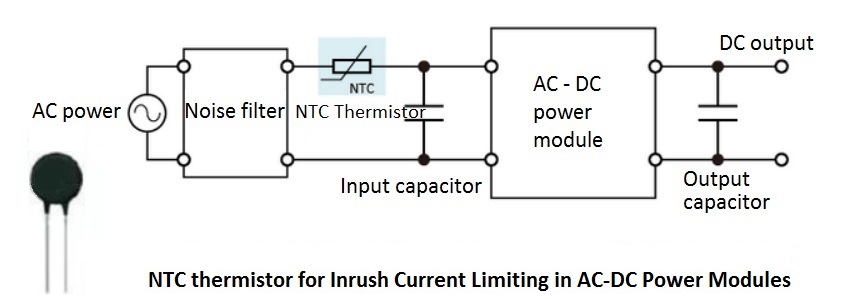

Power modules, integrating various power circuits and peripheral components, are termed built-in power supplies. AC-DC power modules consist of AC-DC rectifier circuits, DC-DC converters, and minimal external components, forming a space-saving optimized power system. An NTC thermistor effectively limits the inrush current applied to the input and output capacitors when powering on.

Figure : NTC thermistor for Inrush Current Limiting in AC-DC Power Modules

3. Inrush Current Limiting in DC-DC Converters

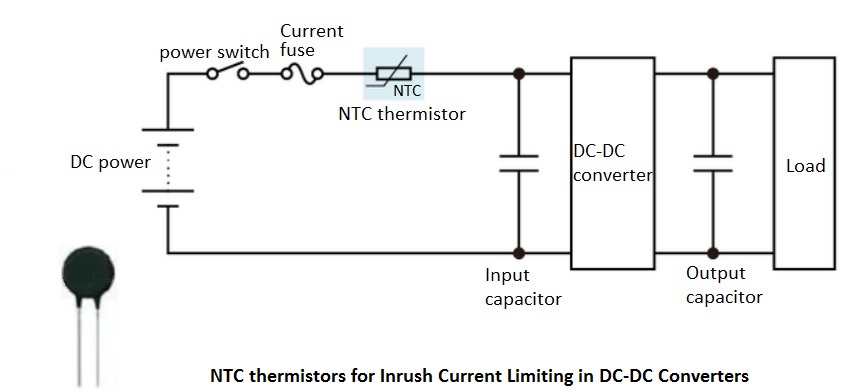

In DC power circuits like DC-DC converters, NTC thermistors serve as power thermistors to limit inrush current during the initial power-on phase when input and output capacitors are charging. The resistance of the NTC thermistor drops significantly after power-on, reducing power loss compared to using a fixed resistor.

Figure : Negative Temperature Coefficient NTC Thermistor for Inrush Current Limiting in DC-DC Converters

4. Inrush Current Limiting in Industrial Inverters

Induction motors, commonly used in factories, large facilities, and office buildings, drive fans, pumps, air conditioners, and other equipment. These motors, while simple and stable, have speeds dependent on frequency and require inverters for speed control. Motors with inverters, known as variable speed drives (VSDs), significantly reduce power consumption.

An inverter system comprises a converter section, an inverter section, and a DC link capacitor (filter capacitor) after the converter. At startup, the device charges, and an inrush current several times larger than the steady-state current fills the DC link capacitor. This inrush current can adversely affect the lifespan of the DC capacitor or damage semiconductor devices. To prevent this, an NTC thermistor (power thermistor) is connected.

Conclusion

NTC thermistors are essential in managing inrush current across various applications, including SMPS, AC-DC power modules, DC-DC converters, and industrial inverters. Their ability to effectively limit inrush current ensures the longevity and reliability of electronic components, making them indispensable in modern electronic systems. By integrating NTC thermistors, engineers can enhance the performance and safety of power systems.

Recommended for you

Water Temperature Sensor: The Key to Engine Health and Efficiency

Lightning Surge Protection Varistor: Essential for Protecting Your Electrical Systems

Water Temp Sensor: How to Test it for Reliable Performance?

Capacitor Impedance: Calculation Guide & FAQs

Temperature Probe Sensor: A Comprehensive Guide

Termistor NTC: What Does a Thermistor Do?

Logistics

How to track my order?

You can track your order through our official website or the order number provided and learn about the logistics status and delivery progress of your order at any time.

Can I change my shipping address?

Yes, you can contact our customer service team to modify the delivery address before order confirmation to ensure that the order can be accurately delivered to the address you specify.

Shipment

1)Small order quantity and small packing:cargo may be arranged by courier;

2)Bulk order and big volume:shipment may be arranged by sea or by air as per customer’s requirements on FOB, C&F,CIF or LCL terms and do prompt shipment which is very important for our customers, so we do this matter seriously and we may arrange our shipment in time due to our rich experiences in this line. We may also accept the shipment on the term of freight prepaid or freight collect.

Price and Payment

Payment Terms

There are a number of different payment methods that can be used when you deal with us. Two are mostly used: T/T payment in advance for small values and irrevocable L/C at sight for large values.

Do you offer bulk purchase discounts?

Yes, we offer bulk purchase discounts; the specific discount rate depends on the order quantity and cooperation method.

You may also like

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd