PTC Thermistor Applications

Comprehensive Guide to PTC Thermistor Applications PTC thermistor Introduction PTC thermistors (Positive Temperature Coefficient) are critical components in modern electronic systems, serving as protectors against overcurrent and overtemperature conditions.

- PTC thermistor Introduction

- What is a PTC Thermistor?

- How Does a PTC Thermistor Work?

- Key Properties of PTC Thermistors

- Applications of PTC Thermistors

- Electronic Ballasts

- Energy-Saving Lamps

- Degaussing in CRT Displays

- Overcurrent and Overload Protection in Telecommunication Equipment

- General Circuit Protection

- Motor Startup Protection

- Welding Machine Protection

- Battery Protection

- Heating Elements

- Automotive Electronics

- Computer and Peripheral Protection

- Power Supplies

- HVAC Systems

- Medical Devices

- Industrial Equipment

- Consumer Electronics

- Smart Grid and Renewable Energy Systems

- PTC Thermistor Circuit Diagram

- How to Test a PTC Thermistor

- Step-by-Step Testing Procedure:

- Benefits of Using PTC Thermistors

- Conclusion

Comprehensive Guide to PTC Thermistor Applications

PTC thermistor Introduction

PTC thermistors (Positive Temperature Coefficient) are critical components in modern electronic systems, serving as protectors against overcurrent and overtemperature conditions. This comprehensive guide explores the applications of PTC thermistors in:

- electronic ballasts,

- energy-saving lamps,

- CRT display TV degaussing,

- telecommunication equipment protection,

- general circuit protection,

- motor startup protection,

- welding machine protection.

- Battery Protection,

- Heating Elements,

- Automotive Electronics,

- Computer and Peripheral Protection,

- Power Supplies,

- HVAC Systems,

- Medical Devices

- Industrial Equipment,

- Consumer Electronics,

- Smart Grid and Renewable Energy Systems

What is a PTC Thermistor?

A PTC thermistor is a thermally sensitive resistor whose resistance increases significantly with an increase in temperature. This property makes them ideal for applications requiring a fail-safe response to overheating. PTC thermistors differ from NTC (Negative Temperature Coefficient) thermistors, which decrease in resistance as temperature rises.

How Does a PTC Thermistor Work?

PTC thermistor works based on their positive temperature coefficient property. As the temperature increases, the resistance of the PTC thermistor also increases. This behavior is typically due to the materials used in the thermistor, which undergo a phase change at a certain temperature, causing a rapid increase in resistance. This rapid increase limits the current flow, protecting the circuit from overheating or overcurrent conditions.

Key Properties of PTC Thermistors

- Self-Regulating : Automatically adjusts resistance to prevent overheating.

- Resettable : Functions as a resettable fuse, returning to low resistance after cooling.

- Reliable Protection : Provides consistent protection against overcurrent and overload.

- Wide Temperature Range : Effective over a broad range of temperatures.

Applications of PTC Thermistors

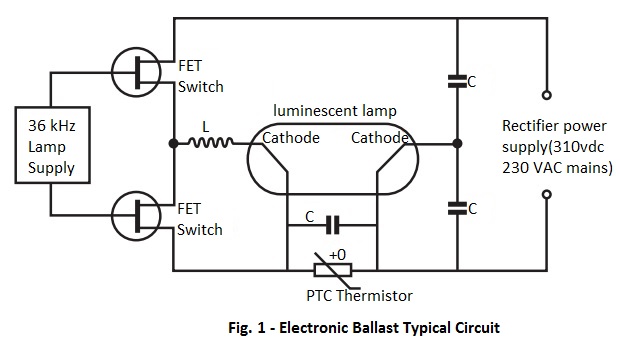

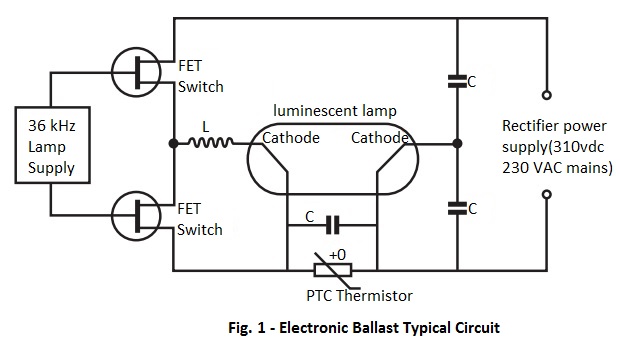

Electronic Ballasts

Electronic ballasts, used to control the starting and operating conditions of fluorescent lamps, rely on PTC thermistor for filament preheating. The Resettable fuse heats up when the lamp starts, increasing its resistance to limit the current flow, thereby protecting the lamp and extending its lifespan.

Energy-Saving Lamps

In energy-saving lamps such as compact fluorescent lamps (CFLs), PTC thermistor manages the startup process. They preheat the filaments before ignition, reducing filament wear and enhancing the lamp’s efficiency and durability.

Degaussing in CRT Displays

PTC thermistors are crucial in the degaussing process of CRT (Cathode Ray Tube) displays. Degaussing eliminates residual magnetism that can distort the display. A PTC thermistor in the degaussing circuit ensures a gradual decrease in current, effectively removing unwanted magnetic fields without causing damage.

Overcurrent and Overload Protection in Telecommunication Equipment

Telecommunication equipment uses PTC thermistors to protect against overcurrent and overload conditions. These thermistors act as resettable fuses, limiting the current flow when excessive current is detected and resetting after cooling.

General Circuit Protection

In various consumer electronics and industrial applications such as transformer, PTC thermistors provide reliable general overcurrent and overload circuit protection. Acting as resettable fuses, they protect circuits from overcurrent conditions, offering a cost-effective and durable solution.

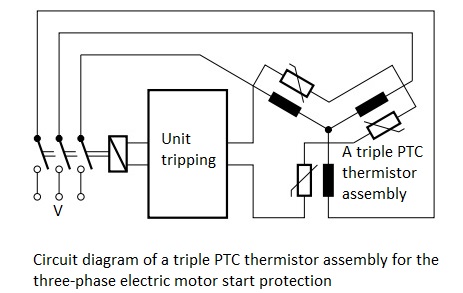

Motor Startup Protection

Motors require a surge of current to start, which can exceed safe operating limits. PTC thermistors in motor startup circuits provide controlled current surges. As the motor reaches its operating speed, the thermistor’s resistance increases, limiting the current and protecting the motor.

Welding Machine Protection

Welding machines, which operate under high current conditions, benefit from PTC thermistors for overcurrent and overload protection. By increasing their resistance in response to excessive current, these thermistors protect the welding equipment and enhance operator safety.

Battery Protection

PTC thermistors are commonly used in rechargeable battery packs to protect against overcurrent conditions. They help prevent overheating and potential damage by limiting the current flow when the temperature rises beyond a safe threshold.

Heating Elements

In applications like seat heaters in automobiles, floor heating systems, and other heating elements, PTC thermistors act as self-regulating heating elements. They provide a consistent heating effect by increasing resistance as the temperature rises, thus preventing overheating.

Automotive Electronics

PTC thermistors are used in various automotive electronic systems, including overcurrent protection for wiring harnesses, sensors, and control modules. They ensure the safety and reliability of vehicle electrical systems by protecting against short circuits and overcurrent conditions.

Computer and Peripheral Protection

In computers and peripheral devices such as printers, scanners, and external storage units, PTC thermistors provide overcurrent and overtemperature protection. They help safeguard critical components from damage due to power surges and overheating.

Power Supplies

PTC thermistors are employed in power supplies and chargers to protect against overcurrent conditions. They help maintain the safety and longevity of power supply units by limiting current flow during fault conditions.

HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, PTC thermistors are used for temperature sensing and control. They help regulate heating and cooling elements, ensuring optimal performance and energy efficiency.

Medical Devices

PTC thermistors are used in medical devices for temperature control and overcurrent protection. Applications include patient monitoring systems, diagnostic equipment, and medical imaging devices where precise temperature regulation is crucial.

Industrial Equipment

In industrial machinery and equipment, PTC thermistors provide overcurrent and thermal protection. They are used in applications such as motor drives, industrial controllers, and automated systems to enhance safety and reliability.

Consumer Electronics

PTC thermistors are widely used in consumer electronics, including smartphones, tablets, and wearable devices. They provide overcurrent protection for battery packs and internal circuits, ensuring safe operation and extending device lifespan.

Smart Grid and Renewable Energy Systems

In smart grid applications and renewable energy systems such as solar and wind power installations, PTC thermistors are used for overcurrent protection and temperature monitoring. They help manage the safety and efficiency of energy storage and distribution systems.

By leveraging the unique properties of PTC thermistors, these applications benefit from enhanced safety, reliability, and efficiency. The versatility of PTC thermistors makes them invaluable across a broad spectrum of industries and technologies.

PTC Thermistor Circuit Diagram

Understanding the circuit diagram of a PTC thermistor is crucial for designing and troubleshooting applications. Below is a typical circuit diagram of a PTC thermistor in an overcurrent protection circuit.

How to Test a PTC Thermistor

Testing a PTC thermistor involves checking its resistance at different temperatures. A multimeter can be used to measure the resistance. At room temperature, the resistance should be relatively low. Upon heating the thermistor, the resistance should increase significantly. If the thermistor does not show a considerable change in resistance, it may be faulty.

Step-by-Step Testing Procedure:

- Identify the PTC Thermistor : Locate the thermistor on the circuit board.

- Measure Initial Resistance : Use a multimeter to measure the resistance at room temperature.

- Heat the Thermistor : Gently heat the thermistor using a heat source like a soldering iron at a safe distance.

- Measure Resistance Again : Measure the resistance as the thermistor heats up. The resistance should increase.

- Cool Down and Reset : Allow the thermistor to cool down and check if the resistance returns to its initial value.

Benefits of Using PTC Thermistors

- Safety : Enhances device safety by preventing overheating and overcurrent conditions.

- Cost-Effective : As resettable fuses, they reduce maintenance costs by eliminating the need for frequent replacements.

- Durability : Their robust design ensures long-term reliability in various operating environments.

- Versatility : Suitable for a wide range of applications from consumer electronics to industrial machinery.

Conclusion

PTC thermistors are essential components in modern electronic and electrical systems. Their self-regulating and resettable properties make them ideal for various applications.

You may also like

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd