MOV Varistor 14D Series : Essential Metal Oxide Varistor Surge Protection

Discover the DXM MOV Varistor 14D Series, your essential solution for overvoltage protection. Engineered to safeguard electronic devices, these metal oxide varistors offer superior surge protection.

14D Series MOV Varistor Overvoltage Protection Key Features

- Excellent Surge Limiter:MOV Varistor can handle large surges excellently.

- Competitive price: Cost-Effective ideal for electronics, machinery, and surge devices.

- Wide Voltage Range: Metal Oxide Varistor Surge Protection can Protect diverse systems.

- Fast Response:Instant spike protection.

- Reliable, Durable:Long-term use across wide applications.

Trust DXM for reliable MOV overvoltage protection in demanding environments.

-

- Discover the unparalleled protection offered by our 14D Series Metal-Oxide Varistor(MOV Varistor) surge protection . Designed specifically for MOV overvoltage protection, this MOV varistor is indispensable in safeguarding your electrical circuits against harmful voltage spikes and transients.

What Is MOV Varistor?

Metal Oxide Varistor surge protection , commonly known as MOV Varistor, is pivotal component in MOV overvoltage protection systems. This device functions as voltage-dependent resistor, displaying a nonlinear resistance that changes in response to the applied voltage. This unique characteristic allows MOV Varistor to effectively clamp voltage spikes, ensuring metal oxide varistor surge protection and maintaining the integrity of your electronic systems.

Metal Oxide Varistor(MOV Varistor) Surge Protection 14D: Essential for Voltage Spike Protection

N (Standard) Series

- Varistor Element Diameter: 14mm

- Voltage Range: 18~1800V

- Max. Allowable Voltage: 10~1000V (AC), 14~1465V (DC)

- Capacitance @1KHz: 130-11100pf

J (High Surge & High Energy) Series

- Varistor Element Diameter: 14mm

- Voltage Range: 18~1800V

- Max. Allowable Voltage: 10~1000V (AC), 14~1465V (DC)

- Capacitance @1KHz: 130-11100pf

Comprehensive Applications of MOV Varistor

-

- Our MOV Varistor is engineered to provide metal oxide varistor surge protection across a diverse array of applications. Its versatility makes it suitable for both consumer and industrial environments:

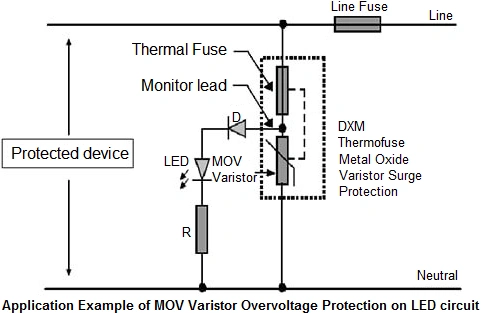

- Surge Protectors: Integrated into power strips and surge protection devices, mov overvoltage protection shields against unexpected voltage spikes, ensuring the safety of connected electronics.

- Consumer Electronics: Essential in devices like televisions, computers, and home appliances, Metal Oxide Varistor Surge Protection protects sensitive circuitry from transient voltage fluctuations.

- Industrial Equipment: Utilized in machinery and control systems, these varistors prevent damage from electrical transients, enhancing the reliability and longevity of industrial operations.

- Telecommunications: Protecting communication infrastructure from voltage surges, MOV Varistor ensures uninterrupted service and data integrity.

- Automotive Systems: Employed in vehicle electronics to guard against voltage spikes caused by alternator noise or other electrical disturbances.

- Renewable Energy Systems: Critical in solar and wind energy systems, MOV Overvoltage Protection protects inverters and other component from voltage transients.

- Medical Equipment: Ensuring the safety and functionality of sensitive medical devices by protecting against voltage surges.

Benefits of MOV Varistor for Overvoltage Protection

The MOV varistor is a highly reliable solution for metal oxide varistor surge protection, ensuring exceptional performance in protecting electronic systems from voltage spikes. Here are the key advantages:

Wide Voltage Range

MOV Overvoltage Protection supports a broad voltage spectrum, offering versatility across consumer and industrial applications.

High Surge Capacity

They handle substantial transient currents, ensuring reliable Metal Oxide Varistor Surge Protection in high-energy environments.

Nonlinear Resistance

MOV varistors clamp voltage spikes effectively due to their significant nonlinear coefficient, protecting sensitive electronics.

Low Leakage Current

Under normal conditions, they exhibit minimal leakage, improving energy efficiency and ensuring stable circuit performance.

Symmetrical Protection

Their symmetrical volt-ampere characteristics ensure consistent surge protection in both polarities for greater reliability.

Effective Residual Voltage Suppression

MOV Overvoltage Protection suppresses residual voltage effectively, shielding delicate components from potential damage.

Rapid Response Time

With an ultra-fast reaction to surges, MOV Overvoltage Protection protects your system instantly, ensuring uninterrupted operation.

No Continuous Flow

They prevent continuous current flow after clamping, reducing overvoltage risks and prolonging protection system lifespan.

Excellent Voltage Stability

MOV Overvoltage Protection maintains stable voltage ratios under changing conditions, ensuring consistent metal oxide varistor surge protection.

Strong Energy Absorption

They absorb and dissipate substantial energy during surges, offering robust protection against high-voltage transients.

Durable and Long-Lasting

Manufactured with high-quality materials, MOV Overvoltage Protection delivers reliable, long-term performance with minimal need for replacement.

Versatile Applications

From consumer electronics to industrial systems, Metal Oxide Varistor Surge Protection provides reliable protection for a wide range of devices.

Choose an MOV varistor for durable, efficient, and trustworthy overvoltage protection that meets the demands of modern electronic systems. Ensure your systems remain safe with the superior performance of metal oxide varistor surge protection.

Composition and Structure of MOV Varistor

The 14D Series Metal-Oxide Varistors are meticulously crafted from high-purity zinc oxide (ZnO) combined with minor amounts of other metal oxides such as bismuth, cobalt, and manganese. This precise composition results in a matrix of conductive grains separated by grain boundaries, forming diode-like junctions. These junctions are critical for the functionality of MOV Varistor:

- Conductive Grains: Zinc oxide grains provide the primary conductive pathways within the varistor.

- Grain Boundaries: The boundaries between grains form barriers that create diode-like junctions, essential for voltage-dependent behavior.

- Nonlinear Characteristics: At low voltages, the varistor maintains high resistance, preventing current flow. When voltage spikes occur, the resistance drops, allowing the varistor to conduct excess current and protect the circuit.

This intricate structure ensures that MOV Varistor can effectively clamp transient voltages, providing reliable metal oxide varistor surge protection and safeguarding sensitive electronic components from damage.

Key Features of MOV Varistor

MOV Varistor Operation

Under normal operating conditions, Metal-Oxide Varistors maintain high resistance, effectively preventing current flow through the device. However, during a voltage spike or transient event, the resistance of the MOV Varistor decreases dramatically. This rapid change allows the varistor to conduct and divert excess current away from sensitive circuit components, thereby providing immediate and effective MOV overvoltage protection. This behavior is crucial for shielding electronic devices from overvoltage conditions caused by lightning strikes, switching surges, and other transient voltage events.

Key Characteristics

- Voltage Rating: Each MOV Overvoltage Protection is rated for specific voltage ranges, determining its operational limits and clamping capabilities. Selecting the appropriate voltage rating is essential for ensuring optimal metal oxide varistor surge protection.

- Energy Rating: Measured in joules, the energy rating indicates the amount of energy the MOV surge protector can absorb during a transient event. This rating is typically specified using standard transient waveforms, such as 8/20 microseconds, to guarantee performance under expected conditions.

- Response Time: MOV Varistors boast a rapid response time, typically ranging from 40 to 60 nanoseconds. This swift reaction is vital for effective transient suppression and reliable MOV surge protection, ensuring that voltage spikes are clamped before causing damage to electronic components.

-

Considerations for Selecting MOV Varistor

- Continuous Operating Voltage: Ensure that the MOV Overvoltage Protection's voltage rating exceeds the normal operating voltage of the circuit. This guarantees that the varistor remains non-conductive during regular operation, only activating during transient events.

- Surge Energy Rating: Select an MOV surge protector with an appropriate energy rating to handle the expected transient energies without failure. This ensures that the varistor can absorb and dissipate the energy from voltage spikes effectively.

- Configuration: Depending on your protection needs, MOV Varistor can be connected in parallel to increase energy handling capacity or in series to achieve higher voltage ratings. This flexibility allows for tailored metal oxide varistor surge protection solutions.

- Response Time: Verify that the varistor's response time meets the requirements of your application. Faster response times provide more effective suppression of transient voltages, enhancing overall protection.

- Environmental Conditions: Consider the operating environment, including temperature, humidity, and potential exposure to contaminants. Selecting varistors with appropriate ratings ensures reliable performance under varying conditions.

- Physical Size and Mounting: Ensure that the MOV Overvoltage Protection fits within the available space and is compatible with the mounting methods used in your application.

- Regulatory Compliance: Verify that the selected varistors meet relevant industry standards and certifications, ensuring safety and performance compliance.

By carefully evaluating these factors, you can select the most suitable MOV Varistor to provide effective metal oxide varistor surge protection for your specific application needs.

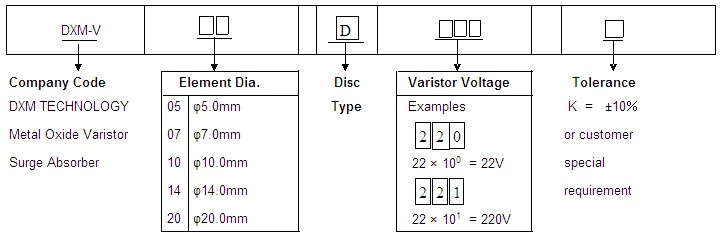

Varistor Naming Rules and Packing Specifications

MOV Varistor Naming Rules

Our MOV Varistor adheres to a standardized naming convention, simplifying identification and ensuring consistency across product lines. The naming typically includes series designation, voltage ratings, and specific characteristics, making it easier to select the appropriate varistor for your application.

MOV Overvoltage Protection Packing Specifications

These packing specifications ensure that MOV Varistor is delivered in optimal quantities and packaging formats, catering to both small-scale and large-scale operational needs.

| Part No. | Bulk | Reel | Ammo | ||||||

| Bag | Box | Carton | Box | Carton | Box | Carton | |||

| 1 | 14D | 120M-471K | 500 | 1000 | 6000 | 500 | 3500 | 500 | 5000 |

| 2 | 511K-182K | 250 | 500 | 3000 | 400 | 2800 | 500 | 5000 | |

Technical Insights and Practical Examples

Understanding the technical aspects of MOV Varistor enhances their effective implementation in MOV overvoltage protection systems. Here are some detailed insights and practical examples:

Nonlinear Resistance Characteristics

MOV Varistor exhibits a voltage-dependent nonlinear resistance. At voltages below the clamping threshold, they present high resistance, minimizing current flow and ensuring that normal operations are unaffected. When a transient voltage exceeds the clamping threshold, the resistance drops sharply, allowing the varistor to conduct and divert excess current. This behavior is fundamental to metal oxide varistor surge protection, ensuring that voltage spikes are effectively managed.

Energy Absorption and Dissipation

The energy rating of an MOV Varistor indicates its capacity to absorb and dissipate energy during transient events. For instance, an mov overvoltage protection with a higher energy rating can handle larger voltage spikes without degrading, making it suitable for industrial applications where high-energy transients are common. This capability is crucial for maintaining the longevity and reliability of both the varistor and the protected circuitry.

Temperature Stability

MOV Varistor is designed to operate efficiently across a wide temperature range. Its performance remains stable even in extreme conditions, ensuring consistent metal oxide varistor surge protection. For example, in outdoor installations where temperature fluctuations are significant, mov overvoltage protection maintains its protective characteristics without performance degradation.

Real-World Application Example: Consumer Electronics

In consumer electronics like televisions and computers, MOV Varistor protects sensitive internal components from power surges caused by lightning strikes or power grid fluctuations. By clamping excess voltage, it prevents damage to critical circuitry, thereby extending the lifespan of electronic devices and reducing maintenance costs.

Real-World Application Example: Industrial Machinery

In industrial settings, machinery and control systems are prone to electrical transients that can disrupt operations and cause costly downtime. Integrating MOV Varistor into these systems provides robust metal oxide varistor surge protection, ensuring uninterrupted operation and safeguarding expensive equipment from voltage-induced damage.

Installation and Maintenance Tips for MOV Varistor

Proper installation and maintenance of MOV Varistor is essential to maximize its effectiveness and lifespan. Here are some key tips:

- Correct Sizing: Ensure that the mov overvoltage protection is appropriately sized for the application by considering the voltage and energy ratings. An undersized varistor may fail to provide adequate protection, while an oversized varistor may be unnecessarily costly.

- Secure Mounting: Install Metal Oxide Varistor Surge Protection securely to prevent physical damage and ensure reliable electrical connections. Proper mounting reduces the risk of mechanical stress that could impair the varistor's performance.

- Environmental Protection: Protect Metal Oxide Varistor Surge Protection from harsh environmental conditions such as moisture, dust, and corrosive substances. Using appropriate enclosures or protective coatings can enhance durability and performance.

- Regular Inspections: Periodically inspect MOV Varistor for signs of wear, damage, or degradation. Early detection of issues can prevent failures and ensure continuous metal oxide varistor surge protection.

- Temperature Management: Ensure adequate ventilation and cooling in installations where MOV Overvoltage Protection is exposed to high temperatures. Overheating can accelerate degradation and reduce the varistor's effectiveness.

- Compliance with Standards: Follow industry standards and manufacturer guidelines during installation to ensure safety and optimal performance of MOV Overvoltage Protection.

Adhering to these installation and maintenance practices ensures that provides reliable metal oxide varistor surge protection throughout its operational lifespan.

Summary of 14D Series Metal Oxide Varistor Surge Protection

The 14D Series Metal-Oxide Varistor (MOV Varistor) surge protection stands out as essential component for MOV surge protection, delivering a wide voltage range, high energy tolerance, and rapid response time. Engineered to protect electronic circuits from voltage spikes and transients, this MOV Overvoltage Protection is versatile, reliable, and ideal for a multitude of applications including consumer electronics, industrial machinery, power strips, and more. Its robust construction and superior performance make it a cornerstone in modern electronic protection systems.

FAQs: MOV Varistor Overvoltage Protection

What is a MOV Varistor?

A MOV varistor is a voltage-dependent resistor designed for MOV overvoltage protection. It effectively clamps voltage spikes to protect electronic circuits from damage.

How does MOV Overvoltage Protection provide surge protection?

The MOV Overvoltage Protection adjusts its resistance based on the applied voltage. During voltage spikes, it conducts excess current, preventing damage to connected devices.

What are the primary applications of metal oxide varistor surge protection?

Metal oxide varistor surge protection is widely used in surge protectors, consumer electronics, industrial equipment, telecommunications, automotive systems, and renewable energy systems.

How do I select the right MOV Varistor for my application?

Choose a MOV varistor based on factors like continuous operating voltage, surge energy rating, response time, environmental conditions, and compliance with relevant standards.

What are the benefits of using the 14D Series MOV Varistor?

The 14D Series MOV varistor offers a wide voltage range, high energy tolerance, fast response time, and minimal leakage current, making it ideal for diverse applications needing MOV Overvoltage Protection.

Can a Metal Oxide Varistor Surge Protection handle high-energy transients?

Yes, MOV Varistor is designed to manage significant transient currents and absorb large amounts of energy, ensuring reliable MOV Overvoltage Protection in high-energy environments.

What materials is a MOV Varistor made from?

MOV varistors are made primarily from zinc oxide (ZnO) mixed with small amounts of other metal oxides, including bismuth, cobalt, and manganese, which form conductive grains and diode-like junctions.

How long does a MOV Overvoltage Protection typically last?

With proper installation and maintenance, MOV Overvoltage Protection can last as long as the protected equipment, providing reliable protection over time.

Is a Metal Oxide Varistor Surge Protection suitable for outdoor applications?

Yes, Metal Oxide Varistor Surge Protection can be used outdoors with proper environmental protection to guard against voltage surges caused by lightning and other external factors.

What is the response time of a MOV Varistor?

The response time of a MOV varistor is typically between 40 to 60 nanoseconds, ensuring quick reaction to voltage transients.

For more detailed information, visit our Contact Us page or explore our product range to find the ideal MOV varistor for your needs. Enhance your surge protection strategy with the datasheet for the 14D Series metal oxide varistor surge protection available below.

© 2025 DXM Product. All rights reserved.

Author: Ivan Huang

Updated on 1st January 2025

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd