Temp Sensor for welding machine( CWF-103F3950FA )

Introducing the DXM Temp Sensor for Welding Machine (CWF-103F3950FA), a top-tier solution for precise temperature monitoring in welding operations. Our temp sensor ensures optimal heat management, enhancing both efficiency and safety.

Key Features of Temp Sensor CWF-103F3950FA for Welding Machines:

● High Sensitivity: The Temp Sensor detects small temperature shifts quickly for precise control(±1% tolerance).

● Fast Response Time: The heater sensor Provides rapid readings, essential for dynamic welding.

● Wide Operating Range: The temperature probe sensor effective from -30°C to +200°C, suitable for various industries.

● Customization: Tailored to specific needs, including encapsulation and lead lengths.

● Durability and Quality: Built to withstand harsh conditions, ensuring long-term reliability.

● Competitive Price: Offers high performance and reliability at an attractive price.

Designed with advanced technology, the CWF-103F3950FA heater sensor is essential for professionals seeking reliability and precision. Elevate your welding projects with the trusted performance of DXM.

For detailed specifications and seamless integration, explore our Temp Sensor today. Ideal for all your temperature control needs in welding.

The temp sensor CWF-103F3950FA is a vital NTC thermistor for welding machines. This Heater Sensor provides precise temperature control and heat protection, thanks to its high sensitivity and accuracy. It ensures stable performance with an annual resistance drift rate of ≤5‰. The temperature probe sensor operates in a range of -30°C to +200°C, making it ideal for various welding environments. This temp sensor offers reliable temperature regulation and protection, ensuring efficiency in welding operations.

Application of Temp Sensor CWF-103F3950FA

The heater sensor is essential component in temperature sensing, particularly applied in temperature control and heat protection of welding applications. This temperature probe sensor offers high sensitivity and accuracy, with resistance decreasing as temperature increases, enabling precise measurements. This makes it ideal for monitoring and controlling heat in demanding environments.

Below is an overview of their key applications and advantages.

- Temperature Control:

- Temp Sensor is embedded in welding machines to monitor and regulate the welding process's temperature. This temperature probe sensor provides real-time feedback, enabling precise adjustments to maintain optimal welding conditions.

- Heat Protection:

- This heater sensor prevents overheating of critical components by continuously monitoring temperatures. It can activate protective measures, such as automatic shutdown or power reduction, to prevent damage.

- Quality Assurance:

- Maintaining the correct temperature is essential for producing high-quality welds. Temperature probe sensor ensures the weld pool remains at the desired temperature, critical for proper fusion and joint strength.

- Long-Term Stability:

- NTC thermistors, such as those in the CWF series, offer long-term stability with minimal resistance drift, ensuring consistent and reliable performance over time.

Key Features of Temp Sensor in Welding Machines

-

-

Parameters of Heater Sensor CWF-103F3950FA

Model No.: CWF-103F3950FA

R25 = 10KΩ ± 1 %,

Thermistor B Value = 3950K ± 1 %.

Lead wire: UL2651 2C insulated and pair together 30AWG 105℃ 300V TS Black;

Lead length: 100mm, 160mm, 230mm are normally.Can also be customized according to the length required by the customer.

-

Advantages of Temp Sensor

High Sensitivity: This heater sensor features a high resistance coefficient (2~5%/°C) for rapid and accurate temperature detection, allowing for the quick detection of small temperature shifts, which is crucial in welding applications.

Fast Response Time: The temperature probe sensor offers rapid readings, essential for dynamic environments where conditions change rapidly, ensuring immediate adjustments during the welding process.

Wide Operating Range: The temp sensor, equipped with an NTC thermistor, operates effectively across a broad temperature range from -30°C to +200°C. This versatility makes it suitable for various welding processes.

Customization: This heater sensor can be encapsulated to meet specific installation requirements, including encapsulation and lead lengths, enhancing its adaptability across different welding setups,ensuring easy and flexible use.

Durability: Built to withstand harsh conditions such as mechanical stress and high temperatures, this temperature probe sensor ensures reliable performance in demanding environments.

- Reliability: Excellent insulation, resistance to bending, and protection against mechanical impact make this heater sensor highly reliable.

- Precision: Offers high precision in resistance and Thermistor B Value, with excellent consistency and interchangeability (±1% tolerance).Provides precise temperature control, ideal for critical applications.

In summary, the Temp Sensor CWF-103F3950FA is essential for the efficient operation of welding machines, offering high sensitivity, fast response, and durability to enhance both safety and weld quality.

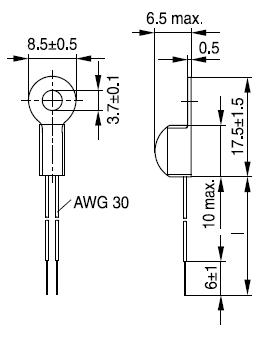

Heater Sensor Dimension(Unit: mm)

1.Product name: NTC Temp Sensor.

2.R25 resistance:R25=10KΩ±1%,

3.Thermistor B Value: B25/50=3950K±1%

4.Thermal response time:T1=25+(85-25)*63.2%=62.9℃ 8S Max.In a water bath

5.Dissipation coefficient:Ta=25±0.5℃ around 2.5mW/℃.In the still air

6.Hi-pot Test:AC 1500V 2mA 6 6S,no flashover ,no breakdown in steel ball

7.Insulation Test:DC 500V 100MΩ,≥100MΩin a steel ball

8.Heater sensor ERP:CWF-103F3950FA

9.Operating temperature:-30℃~200℃.

Temperature Probe Sensor Reliability Test

1. Heater Sensor High temperature experiment: 1000 hrs in air 100 ± 5 °C

2. Low temperature experiment: -30 ± 5 °C 1000 hrs in air

3. Temperature cycle experiment: -30 °C / 30 minutes. Room temperature 10 minutes. 100 °C / 30 minutes 10 cycles

4. Electricity experiment: DCO 0.2 mA 1000 hrs in constant temperature and humidity

5. Temp Sensor Lead strength: The force applied to 20N lasts 1 minute

6. Fall experiment: free fall of mud floor from 1M height

After the above performance test, there is no change in voltage resistance, insulation performance, and appearance without damage.

Temp Sensor Storage Method

1. No more than 4 boxes of products per stack height during storage and transportation of the temperature probe sensor ;

2. Dry agent should be placed in the bag. Avoid direct or indirect showers and mechanical damage from rain and snow;

3. Heater sensor should be stored at room temperature and often wet, and the surrounding environment should not be acidic,alkaline substances and corrosive gases or radiation sources.

Summary of Temp Sensor CWF-103F3950FA

The CWF-103F3950FA Temp Sensor is a reliable NTC thermistor designed for precision. This temperature probe sensor ensures accurate temperature control and heat protection in welding machines. With a fast response and broad operating range (-30°C to +200°C), this heater sensor adapts to various installations. Its robust design suits demanding environments. CWF-103F3950FA temp sensor delivers high sensitivity, durability, and customizable features to meet specific needs. Ideal for applications requiring reliable temperature monitoring.

Author: Ivan Huang

© 2024 DXM Product. All rights reserved.

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd