The different classification of thermal resistor

Explore diverse classifications of thermal resistor with DXM, a leader in innovation. Our comprehensive guide covers key types, including PTC and NTC thermistor, highlighting their unique properties and applications. Thermal resistors play a crucial role in temperature sensing and control, applicable across various industries. Understanding these classifications can enhance your project’s precision and efficiency. Learn how DXM’s expertise in thermal resistors technology can support your specific needs. Discover more about thermal resistor on our corporate website today.

- Understanding Thermal Resistor

- What is a PTC Thermistor?

- What is an NTC Thermistor?

- Applications of NTC Thermistor

- Comparison of PTC and NTC Thermistor

- How to Select the Right Thermal Resistor?

- Advancements in Thermal Resistor Technology

- Implementing Thermal Resistor in Circuit Design

- Future Trends in Thermal Resistor Applications

- Conclusion

- FAQs About Thermal Resistor

- Q: What is the difference between PTC and NTC thermistor?

- Q: Where are PTC thermistors commonly used?

- Q: What are NTC thermistors made of?

- Q: What makes NTC thermistor ideal thermal resistor for temperature measurement?

- Q: How do I choose the correct thermal resistor for my application?

- Q: How does thermal resistor contribute to energy efficiency in electronic devices?

- Q: What are some emerging applications for thermal resistor in modern technology?

Thermal resistor, also known as thermistor, is a type of resistor whose resistance varies significantly with temperature commonly used in various applications. Thermal resistor can be classified into two main categories: PTC thermistor and NTC thermistor, based on their different temperature coefficients. In this blog, we'll delve into these two types of thermal resistors, their properties, and their uses in practical applications. Thermal resistor plays a vital role in controlling and sensing temperature in electronic circuits.

Understanding Thermal Resistor

Thermal resistor can be divided into PTC Thermistor and NTC Thermistor in accordance with the different temperature coefficient.Each with distinct characteristics and applications.

- Negative Temperature Coefficient (NTC) Thermistor:

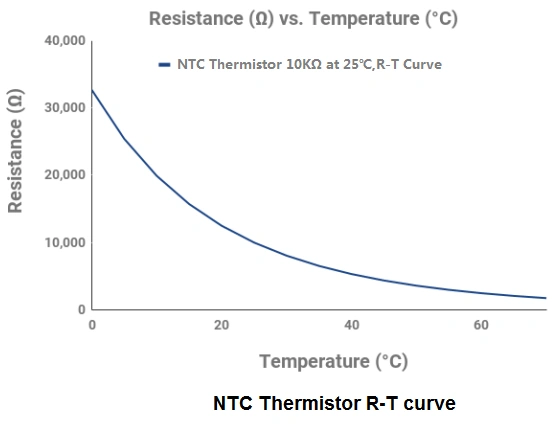

- Resistance Behavior: Resistance decreases as temperature increases.

- Common Materials: Typically made from metal oxides such as cobalt, nickel, and manganese.

- Temperature Range: Operate effectively between -55 °C and 200 °C.

- Applications: Used in temperature sensing, inrush-current limiting, and flow measurement etc. due to their high sensitivity and rapid response times.

- Positive Temperature Coefficient (PTC) Thermistor:

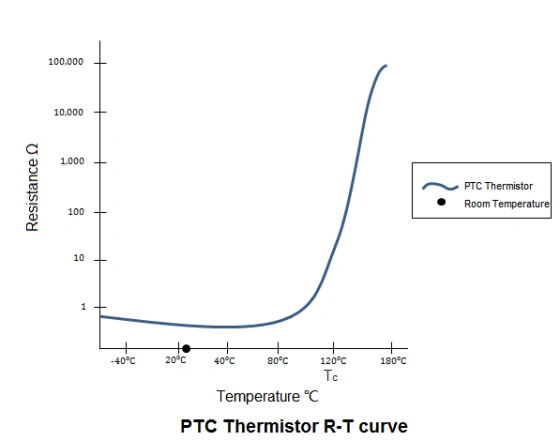

- Resistance Behavior: Resistance increases with rising temperature.

- Common Materials: Often made from barium, strontium, or lead titanates.

- Temperature Range: Commonly switch at temperatures between 60 °C and 120 °C.

- Applications: Utilized for over-current protection, self-regulating heating elements, and time-delay circuits etc.

What is a PTC Thermistor?

PTC thermistor (Positive Temperature Coefficient) is a semiconductor thermal resistor whose resistance increases as temperature rises. This temperature sensitivity makes it highly suitable for specific applications where temperature regulation or current limiting is needed.

PTC thermistors can be divided into below two types in accordance with the different material:

- Ceramic PTC thermistor

- Organic polymer PTC thermistor

PTC thermistors can also be divided into below types in accordance with the different APPLICATIONS:

A.Delay start thermal resistor for lighting and ballast.

B.Intelligent preheat start thermal resistor.

C.Degaussing thermal resistor for color TV and CRT monitors in CRTs .

D.Telecom circuit protection PTC thermistor.

E.Overcurrent and overload protection thermal resistor.

F.Motor protection PTC thermistor.

G.Welding machine overload protection thermal resistor.

H.PTC thermistor for Constant temperature heating;

I.PTC thermistor for temperature sensing.

Generally, Organic polymer PTC thermistor (PPTC) is preferred for overcurrent protection, whereas Ceramic PTC thermistor is more suitable for applications listed as above. The versatility of thermal resistor, especially PTC thermistor, makes it indispensable in safety and temperature control systems.

What is an NTC Thermistor?

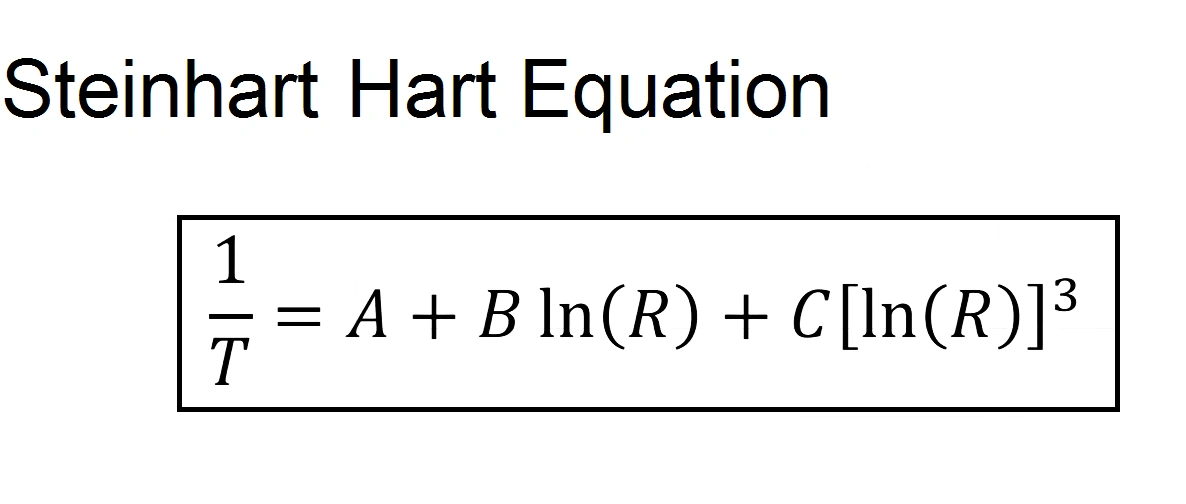

The NTC thermistor (Negative Temperature Coefficient) is another type of typical semiconductor thermal resistor with temperature sensitivity, but with a key difference: its resistance decreases as temperature rises. The primary materials used in NTC thermistor are metal oxides such as manganese, cobalt, nickel, and copper,which make them highly temperature-sensitive and versatile for various uses. Thermal resistors like NTC thermistors are crucial in temperature measurement and compensation circuits.

NTC thermistor is manufactured through ceramic processing, making it highly reliable. These metal oxide materials behave like semiconductors, much like germanium and silicon. At low temperatures, the number of metal oxide material carriers (electrons and carriers) in these materials is lower, resulting in a higher resistance. With the temperature arising, carriers number increases, so the resistance value reduced accordingly.NTC thermistors are widely used in automotive, industrial, and consumer electronics for accurate temperature control.

Applications of NTC Thermistor

NTC thermistor can be divided into below types in accordance with the different APPLICATIONS:

- Power type surge suppression NTC thermistor

- NTC thermistor for temperature compensation

- NTC thermistor for temperature measurement and control

Thermal resistors like NTC thermistors are ideal for applications requiring precise temperature monitoring and response. Their ability to adjust resistance according to temperature changes makes them perfect for a variety of industries.

Comparison of PTC and NTC Thermistor

Both PTC thermistor and NTC thermistor serve crucial roles in thermal management, but their behaviors differ significantly:

- PTC Thermistor: Resistance increases with temperature. Ideal for applications such as overcurrent protection, degaussing, and heating elements. These thermal resistors are particularly useful in safety applications where rising temperatures need to trigger protective actions.

- NTC Thermistor: Resistance decreases with temperature. Commonly used for temperature measurement, surge suppression, and compensation. NTC termistor is essential in maintaining stability in temperature-sensitive circuits.

-

Type Temperature

Coefficient

Common Materials Normal Working Temperature Range Main Applications NTC Thermistor Negative Cobalt, Nickel -45 °C to 300 °C Temperature sensing, inrush-current limiting etc. PTC Thermistor Positive Barium, Strontium -40 °C °C to 150 °C Over-current overload protection, self-regulating heaters etc.

How to Select the Right Thermal Resistor?

Choosing between a PTC thermistor and an NTC thermistor largely depends on the intended application. For example, if you need a component for temperature measurement or compensation, an NTC thermistor is a better choice. If you need current limiting or motor protection, a PTC thermistor would be more appropriate. Understanding the properties of thermal resistors helps in making the correct selection for your circuit's needs.

Advancements in Thermal Resistor Technology

Recent advancements in material science and manufacturing techniques have led to improved thermal resistor with better stability, accuracy, and response times. These innovations are expanding the applications of thermistors in emerging fields such as IoT devices, wearable technology, and advanced automotive systems. Both PTC and NTC thermistor are benefiting from these advancements, enhancing their performance as thermal resistors.

Implementing Thermal Resistor in Circuit Design

When incorporating thermal resistors into circuit designs, engineers must consider factors such as the temperature range, response time, and accuracy requirements of the application. Proper calibration and compensation techniques are essential for achieving optimal performance from these temperature-sensitive components. Whether using PTC or NTC thermistor, understanding the characteristics of thermal resistors is crucial for successful implementation.

Future Trends in Thermal Resistor Applications

The future of thermal resistors looks promising, with ongoing research focusing on developing new materials and miniaturization techniques. These advancements are expected to open up new applications for both PTC and NTC thermistor in fields such as biomedical devices, energy harvesting systems, and smart home technologies. The evolution of thermal resistors technology continues to drive innovation across various industries.

Conclusion

Thermal resistors, encompassing both PTC and NTC thermistor, are fundamental components in modern electronics. Their unique temperature-dependent properties make thermal resistor invaluable in a wide range of applications, from simple temperature sensing to complex thermal management systems. As technology continues to advance, the role of thermal resistor in ensuring the efficiency, safety, and reliability of electronic devices will only grow in importance.

FAQs About Thermal Resistor

Q: What is the difference between PTC and NTC thermistor?

A: The main difference lies in their response to temperature changes. PTC (Positive Temperature Coefficient) thermistor increases in resistance as temperature rises, while NTC (Negative Temperature Coefficient) thermistor decreases in resistance as temperature increases. Both types of thermal resistors have unique applications based on these properties.

Q: Where are PTC thermistors commonly used?

A: PTC thermistors are commonly used in applications such as overcurrent protection, motor starting, self-regulating heating elements, and telecom circuit protection. These thermal resistors are particularly useful in situations where automatic temperature control or current limiting is required.They are highly effective in safety applications.

Q: What are NTC thermistors made of?

A: NTC thermistors are typically made of metal oxides such as manganese, cobalt, nickel, and copper. These materials give the thermal resistor its characteristic temperature sensitivity.

Q: What makes NTC thermistor ideal thermal resistor for temperature measurement?

A: NTC thermistor is ideal for temperature measurement due to its high sensitivity to temperature changes, especially in the range of -50°C to 150°C. As thermal resistor, NTC thermistor provides precise resistance changes over a wide temperature range, making it excellent for accurate temperature sensing and control applications.

Q: How do I choose the correct thermal resistor for my application?

A: Consider the temperature coefficient and application requirements. For current limiting or overcurrent protection, PTC thermistors are ideal. For temperature measurement, NTC thermistors are preferred. Selecting the right thermal resistor ensures optimal performance and reliability in your application.

Q: How does thermal resistor contribute to energy efficiency in electronic devices?

A: Thermal resistor contributes to energy efficiency by enabling precise temperature control and management in electronic devices. PTC thermistor can act as self-regulating heating elements, reducing energy waste, while NTC thermistor allows for accurate temperature compensation in circuits, optimizing performance and reducing power consumption.

Q: What are some emerging applications for thermal resistor in modern technology?

A: Emerging applications for thermal resistor include their use in IoT devices for environmental sensing, wearable technology for health monitoring, advanced automotive systems for battery management and engine control, and in smart home technologies for efficient HVAC and appliance operation. Both PTC and NTC thermistor are finding new roles as thermal resistor in these cutting-edge fields.

Author: Ivan Huang

© 2024 DXM Blog. All rights reserved

Recommended for you

Steinhart Hart Equation: Exploring Temperature and Resistance in NTC Thermistors

Steinhart Hart Equation Calculator

Temperature Coefficient Calculation for NTC Thermistors

Temperature Coefficient (Alpha) Calculator

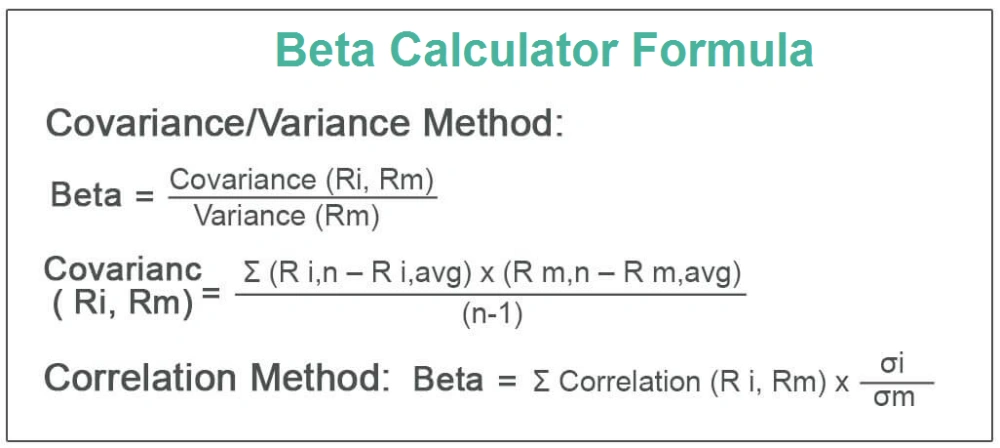

NTC Beta Calculator

Parallel Capacitor Calculator

Logistics

Can I change my shipping address?

Yes, you can contact our customer service team to modify the delivery address before order confirmation to ensure that the order can be accurately delivered to the address you specify.

Does it support express delivery?

Yes, we support express delivery services. You can choose different delivery methods according to your needs, including ordinary express delivery and expedited express delivery.

Price and Payment

What’s the Minimum Order Quantity (MOQ) and Minimum Order Amount (MOA)

MOQ: 10000PCS

Payment Terms

There are a number of different payment methods that can be used when you deal with us. Two are mostly used: T/T payment in advance for small values and irrevocable L/C at sight for large values.

Customized Services

Custom-made sample/order

SHENZHEN DXM TECHNOLOGY CO., LTD. are structured by high-tech talents from famous university

in China and accompanied with a batch of ceramic-sensitive components experts and technology

specialist, have powerful R&D and technology capabilities.DXM is one of a few manufacturers

master core production technology of ceramic-sensitive components in the world.

Samples and orders can be custom-made per customer’s requirements, as below:

1. Application environment of product

2. Required specifications or technical parameters

3. Reference sample

4. Reference drawing

You may also like

PTC SMD Thermistor: Cutting-Edge Temperature Sensing Technology

KTY81-210 KTY Sensor: Reliable and Precise Temperature Monitoring for Various Applications

Heat Sensors for sensing temperature-NTC-MF52D series

NTC 5D-15 Thermistor for limitting inrush current

Temp. Sensor for coffee machine

NTC 10D 9 Thermistor MF72: Reliable Inrush Current Limiting and Overcurrent Protection

High-Quality Ceramic Disc Capacitor (Y Capacitor) for Reliable AC Circuit Performance

PTC sensor thermistor for overheat protection-MZ5 series

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd