Steinhart Hart Equation: Exploring Temperature and Resistance in NTC Thermistors

Discover the fundamentals of the Steinhart Hart Equation with DXM, a leading model in precision technology. This critical NTC thermistor equation is essential for understanding how temperature influences resistance in thermistors, ensuring accurate temperature measurements. Dive into the intricacies of this formula and learn how it optimizes performance in various applications. Trust DXM for reliable insights and solutions, enhancing your technical expertise and optimizing your device performance with our comprehensive knowledge on NTC thermistors.

- What is the Steinhart-Hart Equation?

- Common Steinhart-Hart Equation:

- Calculation Steps for Coefficients A, B, and C:

- Solving for Constants:

- Alternate Equation for Known Temperature (10k Thermistor):

- Coefficient Determination

- How the Steinhart-Hart Equation Works

- The Role of Coefficients

- Applications of the Steinhart-Hart Equation

- Precision in Environmental, Industrial, and Medical Temperature Measurement

- Simplifying Temperature Monitoring with NTC Thermistor Equations in Sensitive Environments

- Resistance Prediction with the Steinhart-Hart Equation

- Calibration

- Effective Calibration for Accurate Steinhart-Hart Equation Results

- Automating Calibration with a Steinhart-Hart Equation Calculator

- Limitations of the Steinhart-Hart Equation

- Practical Considerations

- Advantages and Limitations of the Steinhart-Hart Equation in Industry

- Advantages

- Case Studies

- Limitations

- Conclusion:Why the Steinhart-Hart Equation is Essential for Accurate Temperature Sensing in Modern Technology

- FAQs Section

- What is the Steinhart-Hart equation used for?

- Why is calibration crucial for the Steinhart-Hart?

- Can the Steinhart-Hart equation predict resistance?

The Steinhart-Hart equation is a widely used model that relates the resistance of a thermistor to its temperature. This model offers precise temperature measurements from resistance data, providing an indispensable tool for engineers and researchers in fields where accuracy is crucial.The ntc thermistor equation and 10k thermistor equation both benefit from this approach, enhancing temperature control in complex systems.

In this article, we delve into the derivation, applications, and calibration of the Steinhart-Hart equation, highlighting its value in NTC thermistors and various industries.Below is a concise overview of the equation.

What is the Steinhart-Hart Equation?

The steinhart hart equation is a proven formula for calculating the relationship between resistance and temperature in NTC thermistors.

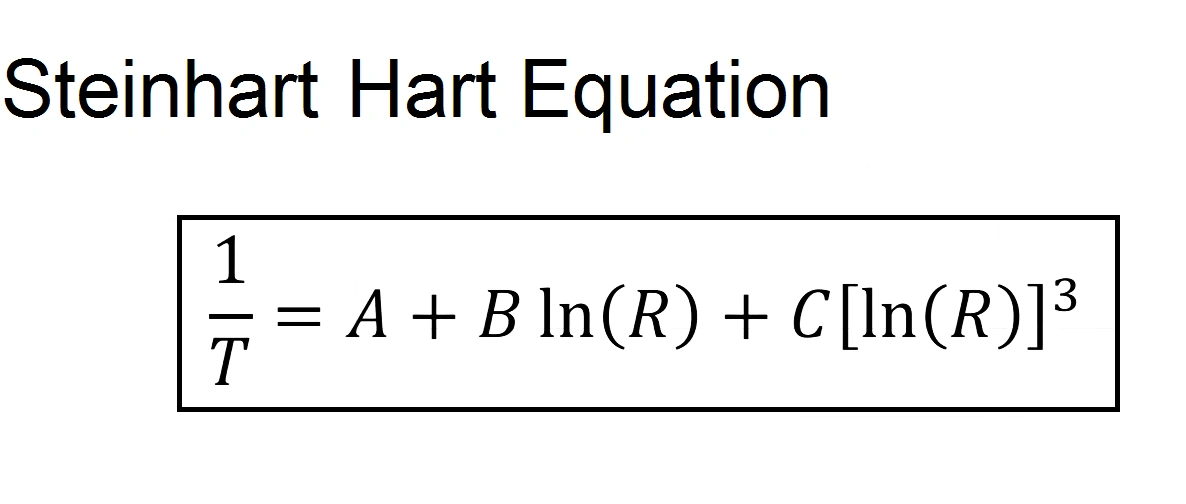

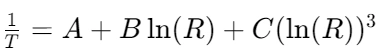

Common Steinhart-Hart Equation:

where

T is the temperature in Kelvin,

R is the thermistor resistance,

with constants A, B, and C derived from measured resistance at different temperatures.

The ntc thermistor equation is essential because these coefficients are derived through calibration and differ between thermistor types. This equation adapts to various industries, from medical devices to industrial automation, allowing thermistors to provide accurate, real-time temperature data.

Calculation Steps for Coefficients A, B, and C:

- Measure resistance at three different temperatures (preferably 10°C apart).

- Use the following equations to solve for each coefficient:

1/T1 = A + B ln(R1) + C [ln(R1)]³

1/T2 = A + B ln(R2) + C [ln(R2)]³

1/T3 = A + B ln(R3) + C [ln(R3)]³

Solving for Constants:

L1 = ln(R1), L2 = ln(R2), L3 = ln(R3)

Y1 = 1/T1, Y2 = 1/T2, Y3 = 1/T3

γ₂ = (Y₂ - Y₁) / (L₂ - L₁), γ₃ = (Y₃ - Y₁) / (L₃ - L₁)

Using the values above, apply the following formulas to find A, B, and C:

C = (Y3 - Y2) / (L3 - L2) * (L1 + L2 + L3)-1

B = Y2 - C(L1² + L1L2 + L2²)

A = Y1 - L1(B + CL1²)

Alternate Equation for Known Temperature (10k Thermistor):

If the temperature is predetermined, use this 10k thermistor equation:

R = exp(³√(y - x/2) - ³√(y + x/2))

Where:

- x = 1 / C (A - 1/T)

- y = √((B/3C)³ + (x/2)²)

Coefficient Determination

To determine the coefficients A, B, and C, resistance measurements at three known temperatures are required. These coefficients can then be used to predict temperature from resistance or vice versa

How the Steinhart-Hart Equation Works

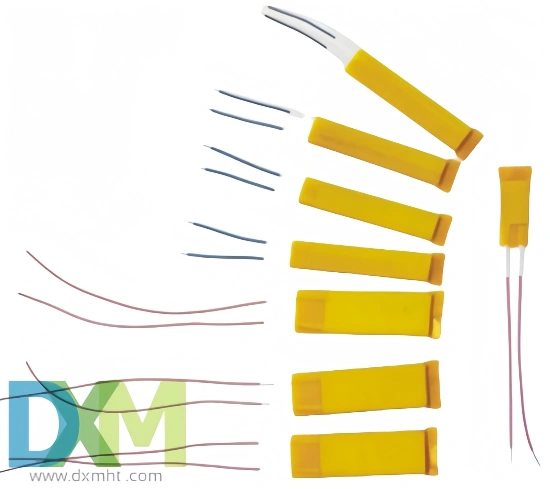

Thermistors, specifically NTC (Negative Temperature Coefficient) thermistors, display a significant change in resistance as temperature shifts. The Steinhart-Hart equation translates this analog resistance data into readable temperature information, a crucial feature in systems requiring precise environmental control. By inputting resistance values into the equation, engineers can obtain corresponding temperature readings with high accuracy. In devices using the 10k thermistor equation, for instance, this method converts fluctuations in resistance into practical temperature data, forming the backbone of many temperature-sensitive applications.

The Role of Coefficients

The coefficients A, B, and C in the Steinhart-Hart equation are calibrated from measurements at multiple temperature points across the thermistor's operational range. This process is essential to achieve accurate results, as these coefficients tailor the equation to the specific thermistor in use. Calibration enables the ntc thermistor equation to precisely reflect real-world data.

Each coefficient directly influences the accuracy of temperature predictions, and any error in calibration can impact the equation’s performance. For applications using a 10k thermistor equation, correctly derived coefficients are essential to ensure measurement consistency.

Applications of the Steinhart-Hart Equation

Precision in Environmental, Industrial, and Medical Temperature Measurement

The Steinhart-Hart is invaluable in temperature measurement across many industries.

It is particularly useful in applications requiring precise temperature measurements, such as:

- Environmental monitoring: Used in climate studies and weather stations.

- Industrial processes: Employed in manufacturing and quality control settings.

- Medical devices: Utilized in patient monitoring systems where accurate temperature readings are critical.

Simplifying Temperature Monitoring with NTC Thermistor Equations in Sensitive Environments

By providing a model that relates thermistor resistance to temperature, the equation is used in various fields, including HVAC, medical equipment, and industrial automation. The ntc thermistor equation simplifies data translation, allowing engineers to automate temperature monitoring and achieve precise control in temperature-sensitive environments. For instance, in medical devices, the 10k thermistor equation converts the thermistor’s resistance to an accurate temperature readout, ensuring patient safety and reliable device performance.

Resistance Prediction with the Steinhart-Hart Equation

The Steinhart-Hart equation can predict resistance for a known temperature, a crucial feature for applications in electronic circuits and environmental sensors where components must stay within specific thermal limits.

In sensor design, engineers use the 10k thermistor equation to estimate resistance changes with temperature, ensuring circuit performance remains within safe thresholds. This predictive capability of the NTC thermistor equation supports operational reliability and stability, especially in high-precision fields like aerospace and laboratory research.

Calibration

Calibration using the Steinhart-Hart equation allows for improved accuracy in thermistor readings. It involves measuring resistance at known temperatures and solving simultaneous equations to derive the coefficients necessary for accurate calculations

Streamline calibration with the Steinhart-Hart equation calculator for precise, automated NTC thermistor calculations. Essential for consistent accuracy across industries like medical and environmental sectors.

Effective Calibration for Accurate Steinhart-Hart Equation Results

Effective calibration of the Steinhart-Hart requires precise resistance readings at various temperature points. This step is crucial to ensure the coefficients A, B, and C accurately represent the thermistor's performance in real-world conditions.

For applications using the 10k thermistor equation, calibration must cover the thermistor’s full temperature range to reduce errors. This process is typically performed in controlled environments, where stable temperatures allow for precise measurements and reliable calculation of the coefficients.

Automating Calibration with a Steinhart-Hart Equation Calculator

Using a Steinhart-Hart equation calculator automates the calibration process, simplifying calculations and minimizing human error. This tool is particularly valuable in industrial environments where consistent calibration is essential for achieving accurate results.

By automating coefficient calculations, the NTC thermistor equation can provide reliable outputs with minimal manual intervention. Automation is especially beneficial for industries that require frequent recalibrations due to changing operating conditions, such as medical and environmental applications.

Limitations of the Steinhart-Hart Equation

While the Steinhart-Hart equation is highly versatile, its accuracy depends heavily on precise calibration. Errors in calibration or incorrect temperature points can result in inaccuracies, particularly under extreme temperature conditions.

For applications using the 10k thermistor equation, it’s crucial to select calibration points that cover the entire expected temperature range. Additionally, NTC thermistors may exhibit nonlinear behavior under certain conditions, which can affect the reliability of the NTC thermistor equation in extreme environments.

Practical Considerations

Engineers should consider the thermistor's expected range and application environment when using the Steinhart-Hart equation. For example, high-temperature fluctuations can necessitate frequent recalibrations. In applications like HVAC or industrial systems, the equation needs to be recalibrated periodically to account for changes in thermistor performance. In such cases, the ntc thermistor equation may require further adjustment to maintain precision.

Advantages and Limitations of the Steinhart-Hart Equation in Industry

Advantages

From medical devices to automotive systems, the Steinhart-Hart offers reliability and adaptability. Its precision in temperature measurement is crucial in industries where environmental control is integral to operations.

- High Accuracy: The equation provides a good fit for the nonlinear resistance-temperature characteristics of NTC thermistors over specific ranges, often yielding errors within 1 mK when properly calibrated.

- Versatility: It can be adapted for various types of thermistors and different temperature ranges.

By using the 10k thermistor equation, engineers can achieve high accuracy and efficient data conversion, enhancing performance in temperature-sensitive settings. The ntc thermistor equation is also favored in laboratory applications, where accuracy and reliability are paramount for experimental consistency.

Case Studies

For instance, in a recent study within the automotive industry, the Steinhart-Hart equation was utilized to monitor engine temperatures, ensuring stability under varied conditions. Similarly, medical devices have benefited from the 10k thermistor equation, enabling accurate body temperature monitoring for patient care. Such applications highlight the importance of the ntc thermistor equation in enhancing precision across critical sectors.

Limitations

- Temperature Range: The accuracy diminishes outside the calibrated range of temperatures.

- Complexity: Requires multiple measurements and calculations to derive coefficients, which may not be feasible in all situations.

Conclusion:Why the Steinhart-Hart Equation is Essential for Accurate Temperature Sensing in Modern Technology

The Steinhart-Hart equation is a crucial tool for converting thermistor resistance into accurate temperature readings across industries. From industrial applications using the NTC thermistor equation to specialized uses like the 10k thermistor equation in sensor design, this formula ensures precise data conversion.

Its adaptability and precision make it indispensable for environments where temperature control is vital, including environmental monitoring, industrial automation, and medical devices. With continuous advancements, the Steinhart-Hart equation is set to remain a cornerstone in temperature-sensing technology, enhancing accuracy and reliability across diverse applications.

FAQs Section

What is the Steinhart-Hart equation used for?

The Steinhart-Hart calculates the relationship between temperature and resistance in NTC thermistors, allowing for precise temperature measurement.

Why is calibration crucial for the Steinhart-Hart?

Proper calibration ensures accurate coefficients, essential for precise readings, especially in the ntc thermistor equation.

Can the Steinhart-Hart equation predict resistance?

Yes, it predicts resistance from a known temperature, crucial for sensor design using the 10k thermistor equation.

For more resources on thermistor applications and to explore our Steinhart-Hart Calculator tool, visit our website.

© 2024 DXM Blog. All rights reserved.

Author: Ivan Huang

Recommended for you

Wire Heater: How to Properly Wire a Heating Element for Safety and Efficiency

PT100 RTD & PT100 Temperature Sensor Guide

HVAC Capacitor - How To Test?

Resistance Heating & Heater: A Guide for Professionals

Understanding Thermistor: A Comprehensive Guide

Coolant Temp Sensor – Expert Maintenance Tips

Customized Services

Custom-made sample/order

SHENZHEN DXM TECHNOLOGY CO., LTD. are structured by high-tech talents from famous university

in China and accompanied with a batch of ceramic-sensitive components experts and technology

specialist, have powerful R&D and technology capabilities.DXM is one of a few manufacturers

master core production technology of ceramic-sensitive components in the world.

Samples and orders can be custom-made per customer’s requirements, as below:

1. Application environment of product

2. Required specifications or technical parameters

3. Reference sample

4. Reference drawing

Free sample availability

You can contact our representative via email, fax or phone to specify the sample you need and provide your courier's account number (such as UPS, FedEx, DHL, TNT, etc.).. And we’ll send you samples free of charge through your courier by freight collection.

Logistics

Does it support express delivery?

Yes, we support express delivery services. You can choose different delivery methods according to your needs, including ordinary express delivery and expedited express delivery.

Price and Payment

Payment Terms

There are a number of different payment methods that can be used when you deal with us. Two are mostly used: T/T payment in advance for small values and irrevocable L/C at sight for large values.

Do you offer bulk purchase discounts?

Yes, we offer bulk purchase discounts; the specific discount rate depends on the order quantity and cooperation method.

You may also like

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd