PT100 RTD & PT100 Temperature Sensor Guide

Learn about PT100 RTD & PT100 temperature sensor: their construction, measurement principles, accuracy, applications, and advantages. Discover why they're ideal for precise temperature control in various industries.

- Understanding PT100 RTD and PT100 Temperature Sensor

- What is a PT100 RTD?

- Construction and Materials of PT100 RTD

- Measurement Principle and Calibration

- Accuracy and Precision of PT100 RTD

- Applications of PT100 RTD and PT100 Temperature Sensor

- Advantages of Using PT100 RTD and PT100 Temperature Sensor

- Frequently Asked Questions (FAQs)

- Conclusion

Understanding PT100 RTD and PT100 Temperature Sensor

Choosing the right temperature sensor for your application is critical. In this guide, we'll explore the characteristics and applications of PT100 RTD and PT100 temperature sensor, focusing on how these devices can benefit your projects. We’ll cover their construction, calibration, accuracy, and common uses. Understanding these aspects will help you make informed decisions when specifying PT100 RTD for industrial or commercial applications.

What is a PT100 RTD?

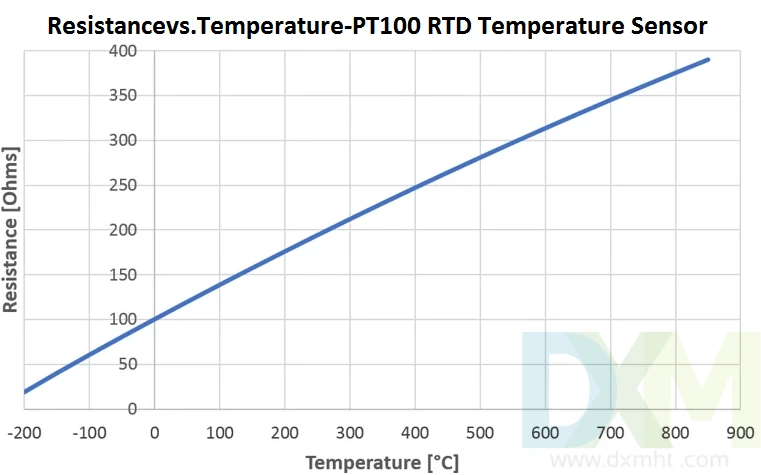

A PT100 RTD (Resistance Temperature Detector) is a highly accurate temperature sensor based on the principle that a metal's electrical resistance changes predictably with temperature. The PT100 designation signifies that the sensor's resistance is 100 ohms at 0°C. These PT100 temperature sensors utilize platinum, chosen for its high stability, linearity, and wide temperature range. This makes the PT100 RTD a highly reliable and precise choice for various applications requiring accurate temperature measurements.

Construction and Materials of PT100 RTD

PT100 RTD sensors are typically constructed with a fine platinum wire wound around a ceramic substrate. This assembly is then encapsulated within a protective sheath, which can be made of various materials like stainless steel, ceramic, or glass, depending on the application requirements. The choice of sheath material significantly impacts the PT100 temperature sensor's durability, resistance to harsh environments, and response time.

Measurement Principle and Calibration

The core of PT100 RTD operation lies in measuring the change in electrical resistance of the platinum element as the temperature varies. Precise measurement circuits are needed to accurately determine resistance, thus providing an accurate temperature reading. Calibration of the PT100 temperature sensor is crucial for ensuring accuracy and is often performed using a traceable standard to guarantee the quality of the measurement. Regular recalibration is recommended for demanding applications to maintain the integrity of the data. High-quality PT100 RTDs from reputable manufacturers often come with detailed calibration certificates.

Accuracy and Precision of PT100 RTD

Compared to other temperature sensing technologies like thermocouples or thermistors, PT100 RTD offers superior accuracy and repeatability. It's high linearity makes it ideal for applications requiring precise temperature control and monitoring. The accuracy of a PT100 temperature sensor depends on factors including the quality of the platinum used, the construction techniques, and the calibration process. High-grade PT100 RTDs can achieve accuracies of ±0.1°C or better over a specified temperature range.

Applications of PT100 RTD and PT100 Temperature Sensor

The versatility and reliability of PT100 RTDs make them suitable for a wide range of applications across diverse industries. Their accuracy and stability are particularly valuable in applications that demand precise temperature control. Some typical uses include:

* Industrial Process Control: In manufacturing, PT100 temperature sensors monitor and control temperature in processes like chemical reactions, heating systems, and food processing.

* HVAC Systems: Building management systems often rely on PT100 RTDs for accurate temperature monitoring and control of heating, ventilation, and air conditioning systems.

* Laboratory Equipment: PT100 RTDs are commonly integrated into scientific instruments and laboratory equipment for precise temperature measurements and control in experiments and testing.

* Automotive Applications: The automotive industry uses PT100 temperature sensors in various applications, from engine temperature monitoring to climate control systems.

* Medical Devices: Some medical devices incorporate PT100 temperature sensors for accurate temperature monitoring in therapeutic and diagnostic applications.

Advantages of Using PT100 RTD and PT100 Temperature Sensor

The benefits of utilizing PT100 RTD and PT100 temperature sensors include:

* High Accuracy: These sensors are known for their superior accuracy and precision, making them suitable for demanding applications.

* Wide Temperature Range: PT100 RTDs operate over a wide temperature range, typically -200°C to +850°C, allowing for diverse application possibilities.

* Excellent Repeatability: PT100 temperature sensors offer excellent repeatability, meaning they consistently provide accurate readings over time.

* Good Linearity: The linear relationship between resistance and temperature simplifies data processing and calibration.

* Stability and Long Lifespan: These sensors are known for their stability and long lifespan, minimizing the need for frequent replacement.

Frequently Asked Questions (FAQs)

Q: What is the difference between a PT100 and a PT1000 RTD?

A: The main difference lies in their resistance at 0°C: PT100 has a resistance of 100 ohms, while PT1000 has a resistance of 1000 ohms. PT1000s offer better sensitivity at lower temperatures.

Q: How do I select the right PT100 RTD for my application?

A: Consider factors such as required accuracy, operating temperature range, response time, and the environmental conditions where the PT100 temperature sensor will be used. Choose a sensor with an appropriate sheath material and construction for optimal performance and longevity.

Q: What is the cost of PT100 RTDs?

A: The cost varies depending on the sensor's accuracy, construction, and features. However, generally, PT100 RTDs are a cost-effective choice for many applications, providing good value for their precision and longevity.

Q: How can I ensure the accuracy of my PT100 RTD measurements?

A: Regular calibration against a traceable standard is essential for maintaining accuracy. Additionally, ensure proper installation and wiring to minimize errors in the measurement circuit. Using high-quality measurement equipment is also critical.

Conclusion

PT100 RTD and PT100 temperature sensor offer a compelling combination of accuracy, reliability, and versatility. Their wide range of applications in diverse industries underscores their importance in temperature measurement and control. Choosing the appropriate PT100 RTD requires careful consideration of the specific application requirements. Understanding the sensor's construction, calibration, and measurement principles will empower you to select the most suitable PT100 temperature sensor for optimal performance. Contact DXM today to explore our range of high-quality PT100 RTD and PT100 temperature sensor and experience the benefits of precise temperature control in your applications.

© 2025 DXM Blog. All rights reserved.

Author: Ivan Huang

Recommended for you

Water Temperature Sensor: The Key to Engine Health and Efficiency

Lightning Surge Protection Varistor: Essential for Protecting Your Electrical Systems

Water Temp Sensor: How to Test it for Reliable Performance?

Capacitor Impedance: Calculation Guide & FAQs

Temperature Probe Sensor: A Comprehensive Guide

Termistor NTC: What Does a Thermistor Do?

Customized Services

Can I customize (OEM) the product?

Yes. You can customize the product with DXM. Our R&D and production technology have already reached an advanced world level, and we can provide qualified OEM service for global customers.Please specify your requirements to our representative or send samples to our factory office, and we will confirm your details.

Custom-made sample/order

SHENZHEN DXM TECHNOLOGY CO., LTD. are structured by high-tech talents from famous university

in China and accompanied with a batch of ceramic-sensitive components experts and technology

specialist, have powerful R&D and technology capabilities.DXM is one of a few manufacturers

master core production technology of ceramic-sensitive components in the world.

Samples and orders can be custom-made per customer’s requirements, as below:

1. Application environment of product

2. Required specifications or technical parameters

3. Reference sample

4. Reference drawing

Price and Payment

Are invoices provided?

Yes, we provide legal invoices that can be used for reimbursement and accounting records.

Payment Terms

There are a number of different payment methods that can be used when you deal with us. Two are mostly used: T/T payment in advance for small values and irrevocable L/C at sight for large values.

What’s the Minimum Order Quantity (MOQ) and Minimum Order Amount (MOA)

MOQ: 10000PCS

You may also like

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd