HVAC Capacitor - How To Test?

Learn how to properly test your HVAC capacitor with our comprehensive guide. We cover safety precautions, tools needed, troubleshooting, and replacement. Regular testing saves you money and ensures your HVAC system's longevity.

- How to Test a Capacitor HVAC: A Comprehensive Guide

- Understanding HVAC Capacitor

- Safety First: Precautions Before Testing

- Tools Required for HVAC Capacitor Testing

- Step-by-Step Guide: How to Test an HVAC Capacitor

- Troubleshooting Common HVAC Capacitor Issues

- Replacing a Faulty HVAC Capacitor

- Why Regular Testing Matters

- Conclusion

- FAQ

- * Q: How often should I test my HVAC capacitors?

- * Q: Can I use a different type of multimeter?

- * Q: What if I don't have a capacitor discharge tool?**

- Call to Action:

How to Test a Capacitor HVAC: A Comprehensive Guide

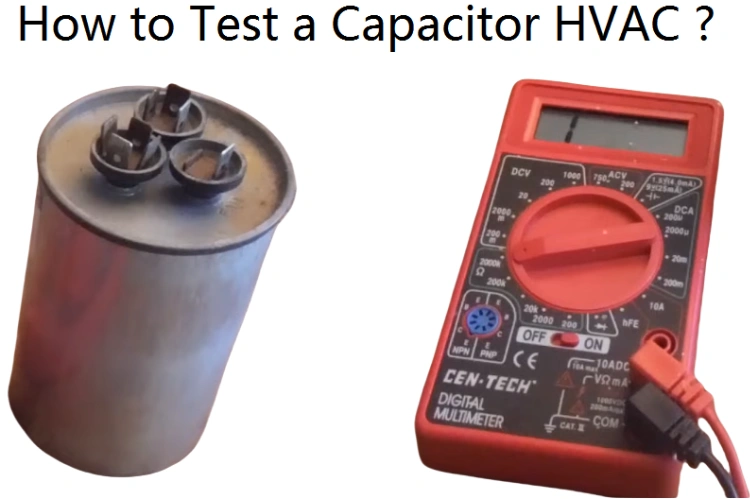

Troubleshooting HVAC systems often leads technicians directly to the HVAC capacitor, understanding how to test a capacitor hvac is crucial for efficient repairs. This guide provides a step-by-step process for testing your HVAC capacitor, ensuring you can quickly identify faulty components and restore your system's functionality. We’ll cover the necessary safety precautions, tools, and techniques to confidently test your HVAC capacitors.

Understanding HVAC Capacitor

HVAC capacitors are essential components in your HVAC system. They store electrical energy, providing the necessary surge of power for the compressor and fan motor to start. A faulty HVAC capacitor can lead to system failure, resulting in no cooling or heating. Therefore, knowing how to test a capacitor hvac is a valuable skill for HVAC professionals. Regular inspection and testing of your HVAC capacitors are key preventative maintenance measures. The lifespan of HVAC capacitors varies, but regular testing helps avoid unexpected failures and costly repairs. Different HVAC systems may utilize different capacitors types and sizes, making them essential to correctly identify your unit's specific requirements before replacing faulty capacitors.

Safety First: Precautions Before Testing

Before you begin testing your HVAC capacitors, always prioritize safety. Disconnect the power supply completely to the HVAC system. Never work on live electrical components. Improper handling of capacitors can lead to serious injury from electrical shock or capacitor discharge. Always wear appropriate safety equipment, including insulated gloves and safety glasses, when working with electrical components. Always discharge the capacitor before handling it using a proper discharge tool. Failure to properly discharge a capacitor can result in a dangerous electrical shock.

Tools Required for HVAC Capacitor Testing

To accurately test your HVAC capacitors, you'll need a few essential tools:

* Multimeter: A digital multimeter (DMM) is essential for measuring capacitance and resistance. A good quality multimeter provides accurate readings. Ensure your multimeter is properly calibrated before commencing testing.

* Screwdrivers: You'll need screwdrivers of appropriate sizes to remove the HVAC capacitors from their housing. Properly sized screwdrivers will avoid damaging the capacitors or their housing.

* Capacitor Discharge Tool: This tool safely discharges the capacitor before handling, preventing electrical shock. Always prioritize safety and use a capacitor discharge tool before commencing testing.

Step-by-Step Guide: How to Test an HVAC Capacitor

1. Visual Inspection: Begin by visually inspecting the HVAC capacitors for any signs of damage, such as bulging, leaking, or burning. A damaged HVAC capacitor may exhibit physical signs of failure. These visual cues can help identify a faulty component before electrical testing.

2. Disconnect the Power: Always disconnect the power supply to the HVAC system before beginning any testing. Failure to disconnect the power is extremely dangerous.

3. Discharge the Capacitor: Use a capacitor discharge tool to safely discharge any remaining charge in the HVAC capacitor. Never assume a capacitor is fully discharged. Always use a discharge tool.

4. Measure Capacitance: Use your multimeter to measure the capacitance of the HVAC capacitors. Compare the measured value to the capacitor's rated value, which is usually printed on the capacitor itself. A significant discrepancy indicates a faulty HVAC capacitor.

5. Measure Resistance: After measuring capacitance, check the resistance. A good HVAC capacitor will show a very high resistance. A low resistance reading generally indicates a short circuit and a faulty component.

6. Interpreting the Results: Based on your capacitance and resistance measurements, you can determine the condition of your HVAC capacitors. Refer to the manufacturer's specifications for the acceptable ranges.

Troubleshooting Common HVAC Capacitor Issues

* Low Capacitance: If the measured capacitance is significantly lower than the rated value, it indicates a failing HVAC capacitor.

* High Resistance: A high resistance value in an HVAC capacitor is indicative of an open circuit, suggesting failure.

* Low Resistance: A low resistance reading signals a short circuit within the HVAC capacitors, indicating a faulty component.

* Physical Damage: Visible physical damage, such as bulging or leaking, is a clear sign that the HVAC capacitors needs to be replaced.

Replacing a Faulty HVAC Capacitor

Once you've confirmed that the HVAC capacitors are faulty, carefully remove and replace them with capacitors of the same rating. Always replace a faulty HVAC capacitor with a component of identical specifications. Improper replacement can lead to further system failures.

Why Regular Testing Matters

Regular testing of your HVAC capacitors is crucial for preventative maintenance. Failing HVAC capacitors can lead to compressor failure, resulting in costly repairs. Early detection and replacement can extend the lifespan of your entire HVAC system. Regular testing is a cost-effective preventative measure.

Conclusion

Testing your HVAC capacitors is a vital skill for HVAC professionals. By following these steps and safety precautions, you can accurately assess the condition of your HVAC capacitors and ensure the efficient and reliable operation of your HVAC system. Remember that a properly functioning HVAC capacitor is essential for optimal system performance. Regular testing prevents costly repairs and ensures system longevity.

FAQ

* Q: How often should I test my HVAC capacitors?

* A: We recommend testing them at least annually as part of routine HVAC maintenance.

* Q: Can I use a different type of multimeter?

* A: We recommend using a digital multimeter for accurate readings.

* Q: What if I don't have a capacitor discharge tool?**

* A: Never attempt to test a capacitor without a proper discharge tool. Safety is paramount.

Call to Action:

Regular HVAC capacitor testing is vital for preventing costly breakdowns and ensuring optimal system performance. Contact us today to learn more about our high-quality HVAC capacitors and preventative maintenance services.

© 2025 DXM Blog. All rights reserved.

Author: Ivan Huang

Recommended for you

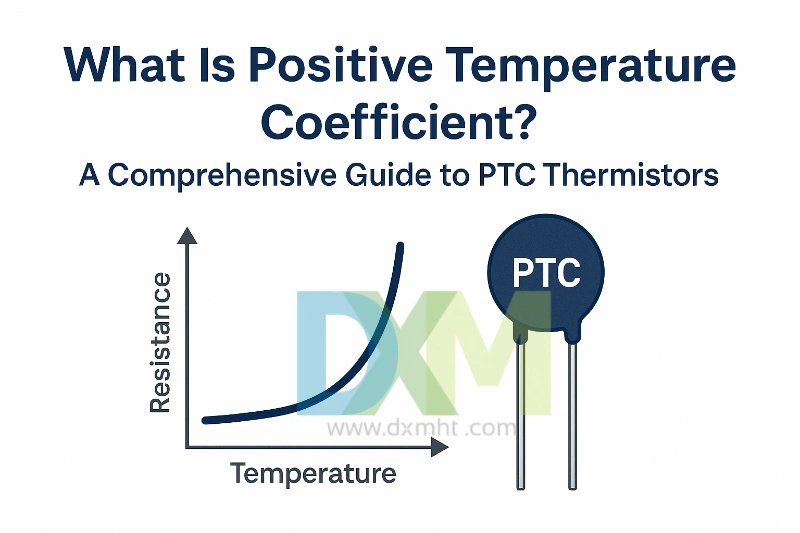

What Is Positive Temperature Coefficient? Expert Guide on PTC Thermistors

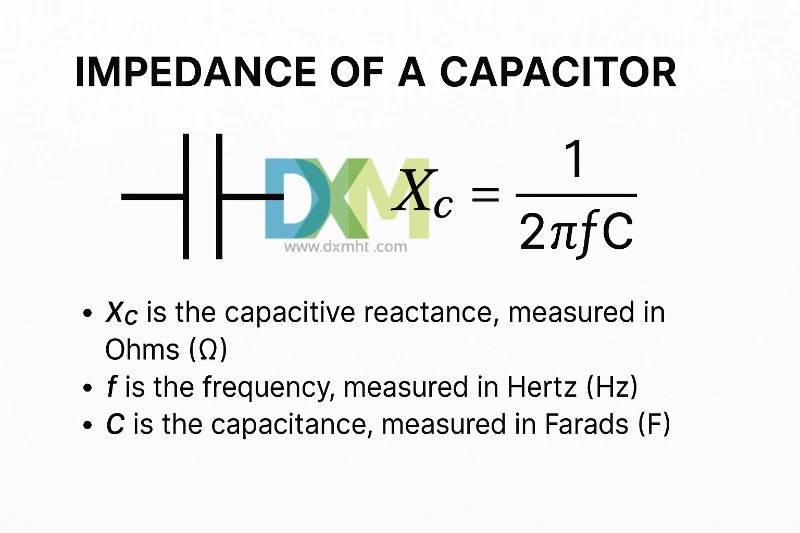

How to Find Impedance of a Capacitor: Guide for Professionals

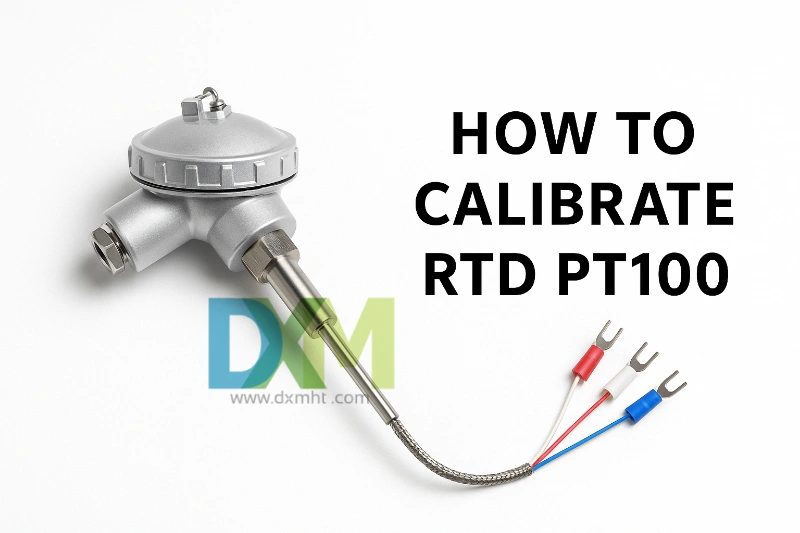

how to calibrate rtd pt100?

Capacitor 104 Value: Essential Guide for Electronics Professionals

Positive Temperature Coefficient Heater: An Essential Guide of PTC Heater

What is an Electronic Ballast PTC Thermistor? Insights from DXM.

Logistics

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

Does your product support global logistics and distribution?

Yes, our products support global logistics and distribution services, and you can receive our products anytime and anywhere.

Customized Services

Can I customize (OEM) the product?

Yes. You can customize the product with DXM. Our R&D and production technology have already reached an advanced world level, and we can provide qualified OEM service for global customers.Please specify your requirements to our representative or send samples to our factory office, and we will confirm your details.

Free sample availability

You can contact our representative via email, fax or phone to specify the sample you need and provide your courier's account number (such as UPS, FedEx, DHL, TNT, etc.).. And we’ll send you samples free of charge through your courier by freight collection.

Price and Payment

Price

The price will be quoted in US dollars.

1) For small order quantities and small packing, normally our quotation is based on the ex-works price. The cargo will be delivered by courier after being finished normally.

2) For bulk orders and large volumes, normally our quotation is based on the FOB price. Please inform us of your destination seaport and estimated quantity, and our representative will quote you the C&F or CIF price accordingly. If you feel our freight is higher than your expectation, you can recommend your shipping company to us. Our principal is looking for a shipping company with a good reputation that offers competitive freight costs and can deliver your cargo promptly.

You may also like

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2025 DXM | All Rights Reserved.

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd