PT100 Temperature Sensors: Precision and Reliability in Industrial Applications

Explore the exceptional precision and reliability of DXM's PT100 temperature sensors. Perfectly designed for industrial applications, our PT100 sensor ensures accurate temperature measurements and enhanced operational efficiency. Trust in DXM's commitment to quality and innovation for your temperature sensing needs. Discover how our PT100 sensors can elevate your industrial processes today.

- Understanding PT100 Temperature Sensors

- What is a PT100 Temperature Sensor?

- How Does PT100 Sensor Work?

- Advantages of Using PT100 Temperature Sensors

- Selecting the Right PT100 Sensor

- Temperature Range Considerations

- Environmental Protection

- Accuracy and Precision

- Wiring Configurations

- Form Factor and Installation

- PT100 Sensor Calibration and Maintenance

- Calibration Process

- Maintenance Best Practices

- Technical Specifications of PT100 Temperature Sensors

- Installation Guidelines for PT100 Temperature Sensors

- Enhancing Performance with PT100 Temperature Sensors

- Comparing PT100 Temperature Sensors with Other Sensors

- PT100 vs. Thermocouples

- PT100 vs. Thermistors

- PT100 vs. Infrared Sensors

- Applications of PT100 Temperature Sensors

- Case Studies: PT100 Temperature Sensors in Action

- Automotive Industry: Engine Temperature Monitoring

- Food and Beverage: Precision Temperature Control in Processing

- Aerospace: Critical Temperature Monitoring in Testing

- HVAC Systems: Enhancing Energy Efficiency

- Future Trends in PT100 Temperature Sensors

- FAQs About PT100 Temperature Sensors

- What makes PT100 sensors superior to thermocouples?

- Can PT100 sensor be used in hazardous environments?

- How often should PT100 temperature sensors be calibrated?

- What is the typical lifespan of a PT100 temperature sensor?

- Are PT100 temperature sensors compatible with all data acquisition systems?

- How does PT100 sensor handle extreme temperatures?

- Can PT100 temperature sensors be used for both liquid and gas measurements?

- What maintenance practices ensure the longevity of PT100 sensor?

- Are there different types of PT100 temperature sensors available?

- How does PT100 sensor contribute to energy efficiency?

- Conclusion

PT100 temperature sensors are the cornerstone of precise temperature measurement in various industrial settings. This PT100 sensor offers unparalleled accuracy and reliability, making it the preferred choice for professionals seeking dependable temperature monitoring solutions. Whether in automotive, aerospace, or food processing, PT100 temperature sensors deliver consistent performance that meets stringent industry standards.

Understanding PT100 Temperature Sensors

PT100 temperature sensors are renowned for their exceptional reliability and accuracy, making them indispensable in critical temperature measurement applications. PT100 sensor is widely used across different environments due to its consistent performance, ensuring precise readings even in the most demanding conditions.

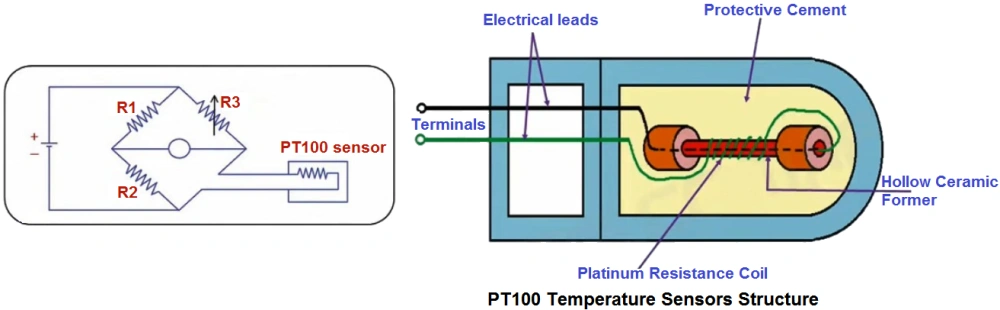

What is a PT100 Temperature Sensor?

A PT100 temperature sensor is a type of Resistance Temperature Detector (RTD). The "PT" stands for platinum, the material used, and "100" indicates the resistance value in ohms at 0°C. Platinum is chosen for its precise temperature readings and stable resistance characteristics, making PT100 temperature sensors a preferred choice in many applications where accuracy is paramount.

How Does PT100 Sensor Work?

PT100 temperature sensors operate based on the principle that the electrical resistance of platinum changes predictably with temperature variations. As the temperature increases, the resistance of the sensor increases proportionately. This linear relationship ensures high accuracy in temperature measurement, making sensor ideal for critical temperature monitoring in industrial processes.

Advantages of Using PT100 Temperature Sensors

PT100 temperature sensors offer numerous advantages that make them the go-to choice for precise temperature measurement in various industrial applications. Here are the key benefits:

- High Accuracy: PT100 sensor is renowned for its precision, capable of detecting minute temperature changes with high reliability.

- Stability and Repeatability: They offer consistent performance, providing dependable readings over time and under varying conditions, which is essential for maintaining process control.

- Wide Temperature Range: PT100 temperature sensor can function effectively from -200°C to +850°C, covering a broad spectrum of industrial needs, from cryogenic processes to high-temperature furnaces.

- Durability: The robust nature of platinum makes sensor highly durable, suitable for use in harsh environments where other sensors might fail.

- Linearity: The linear response of sensor simplifies the calibration and integration process, ensuring straightforward implementation in various systems.

- Interchangeability: PT100 sensor is standardized, allowing for easy replacement and compatibility across different systems and manufacturers.

Selecting the Right PT100 Sensor

Choosing the appropriate PT100 temperature sensor involves considering several factors to ensure optimal performance and compatibility with your specific application. Here are the key considerations:

- Temperature Range: Determine the required temperature range for your application. PT100 temperature sensors are available in configurations that can handle temperatures from cryogenic levels to high-temperature environments.

- Environment: Evaluate the sensor’s exposure to elements such as moisture, chemicals, or pressure. Select a PT100 temperature sensor with suitable protection, such as stainless steel or Inconel sheaths, to withstand harsh conditions.

- Accuracy Requirements: Assess the level of precision needed to meet your operational objectives. Such sensor comes in different accuracy classes, typically Class A and Class B, to cater to varying precision needs.

- Form Factor: Consider the size and configuration of the PT100 temperature sensor for easy integration into existing systems. Options include surface mount, immersion, and probe styles to fit different installation requirements.

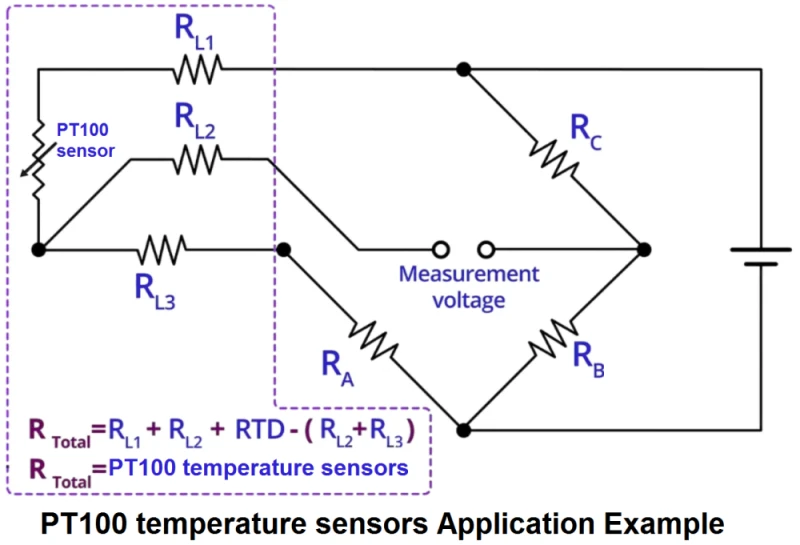

- Wiring Configuration: PT100 temperature sensors are available in two-wire, three-wire, or four-wire configurations. The choice affects measurement accuracy and installation flexibility. Four-wire configurations offer the highest accuracy by compensating for lead wire resistance.

- Response Time: Depending on your application, you may require a PT100 temperature sensor with a fast response time to capture rapid temperature changes accurately.

- Certification and Standards: Ensure that the PT100 temperature sensor complies with relevant industry standards and certifications, such as ISO, ANSI, or IEC, to guarantee quality and interoperability.

Temperature Range Considerations

PT100 temperature sensors are available in various temperature ranges to suit different applications. For instance, sensors designed for cryogenic applications can accurately measure temperatures as low as -200°C, while those intended for high-temperature environments can withstand temperatures up to +850°C. Selecting the appropriate temperature range ensures that the sensor operates within its optimal performance parameters.

Environmental Protection

Industrial environments can be harsh, with exposure to moisture, chemicals, and mechanical stress. PT100 sensor is often encapsulated in protective sheaths made from materials like stainless steel or Inconel to enhance durability and resistance to environmental factors. Choosing the right encapsulation material is crucial for maintaining sensor integrity and longevity.

Accuracy and Precision

The accuracy of PT100 sensor is a critical factor in applications requiring precise temperature control. PT100 temperature sensors are available in different accuracy classes:

- Class A: ±0.15°C accuracy up to 150°C.

- Class B: ±0.3°C accuracy up to 200°C.

Selecting the appropriate accuracy class ensures that the sensor meets the specific precision requirements of your application.

Wiring Configurations

PT100 temperature sensors come in various wiring configurations to accommodate different measurement needs:

- Two-Wire: Simplest configuration, suitable for short-distance measurements but susceptible to lead wire resistance errors.

- Three-Wire: Compensates for lead wire resistance, providing more accurate measurements over longer distances.

- Four-Wire: Offers the highest accuracy by eliminating lead wire resistance errors entirely, ideal for precise applications.

Choosing the right wiring configuration enhances measurement accuracy and system reliability.

Form Factor and Installation

PT100 temperature sensors are available in various form factors to suit different installation environments. Options include:

- Probe Style: Ideal for immersion in liquids or gases, ensuring accurate temperature readings in process fluids.

- Surface Mount: Designed for mounting on the surface of equipment, suitable for non-contact temperature measurement.

- Inline: Used for inline temperature measurement in pipelines and process flows, providing real-time data.

Selecting the appropriate form factor ensures seamless integration into your existing systems and processes.

PT100 Sensor Calibration and Maintenance

Maintaining the accuracy and reliability of PT100 temperature sensors requires regular calibration and maintenance. Calibration involves comparing the sensor's readings to a known standard and making necessary adjustments to ensure precision. Here are the key steps for calibration and maintenance:

- Regular Calibration: Schedule periodic calibration checks to maintain sensor accuracy. Use calibrated reference standards to verify and adjust the sensor's performance.

- Environmental Cleaning: Ensure that the PT100 temperature sensor is free from contaminants, such as dust, moisture, and chemicals, which can affect performance. Regular cleaning of the sensor and its protective sheath is essential.

- Inspecting for Damage: Regularly inspect the sensor for signs of physical damage, such as cracks or corrosion. Replace or repair damaged sensors promptly to prevent measurement errors.

- Connection Checks: Verify that all electrical connections are secure and free from corrosion. Loose or corroded connections can lead to inaccurate readings and unreliable performance.

- Documentation: Keep detailed records of calibration and maintenance activities. Documentation helps track sensor performance over time and ensures compliance with industry standards.

Calibration Process

The calibration process for PT100 temperature sensors typically involves the following steps:

- Preparation: Gather calibration equipment, including a calibrated reference thermometer, calibration bath, and necessary tools.

- Baseline Measurement: Record the PT100 sensor's resistance at a known reference temperature using the calibration bath.

- Comparison: Compare the sensor's readings to the reference thermometer to identify any discrepancies.

- Adjustment: Adjust the sensor's calibration coefficients if necessary to align with the reference standard.

- Verification: Repeat the measurements to ensure that the sensor's readings are now accurate and consistent.

- Documentation: Record the calibration results and any adjustments made for future reference.

Maintenance Best Practices

Implementing best practices for maintenance ensures the longevity and reliability of PT100 temperature sensors:

- Routine Inspections: Conduct regular visual and functional inspections to detect early signs of wear or damage.

- Proper Handling: Handle sensors with care to avoid physical damage during installation, maintenance, and calibration.

- Environmental Control: Maintain optimal environmental conditions around the sensor to prevent exposure to extreme conditions that could degrade performance.

- Training: Ensure that personnel involved in handling and maintaining PT100 sensor is adequately trained and follow standardized procedures.

Technical Specifications of PT100 Temperature Sensors

Understanding the technical specifications of PT100 temperature sensors is crucial for selecting the right sensor for your application. Below are the detailed specifications and what they mean:

| Feature | Specification |

|---|---|

| Resistance at 0°C | 100Ω |

| Temperature Range | -200°C to +850°C |

| Accuracy Class A | ±0.15°C |

| Accuracy Class B | ±0.3°C |

| Wiring Configuration | Two-Wire, Three-Wire, Four-Wire |

| Encapsulation Material | Stainless Steel, Inconel |

| Response Time | Varies by form factor; typically < 1 second |

| Connector Type | Various options available, including M8, M12, and custom connectors |

| Compliance | ISO 9001, IEC 60751, ANSI/ISA standards |

| Common Applications | Industrial furnaces, HVAC systems, automotive engines, aerospace systems |

Installation Guidelines for PT100 Temperature Sensors

Proper installation of PT100 temperature sensors is vital to ensure accurate and reliable temperature measurements. Here are some guidelines to follow during installation:

- Placement: Install the sensor at the optimal location within the process to ensure accurate temperature readings. Avoid areas with excessive vibration or flow disturbances that could affect sensor performance.

- Secure Mounting: Ensure that the sensor is securely mounted to prevent movement or mechanical stress, which can lead to measurement inaccuracies or sensor damage.

- Proper Wiring: Use appropriate wiring techniques to minimize electrical noise and interference. For high-precision applications, consider using shielded cables and proper grounding practices.

- Environmental Protection: Protect the sensor from exposure to harsh environmental conditions by using suitable protective sheaths or housings. This is especially important in environments with high moisture, corrosive chemicals, or extreme temperatures.

- Calibration Verification: After installation, verify the sensor's calibration to ensure it is functioning correctly within the desired temperature range.

Enhancing Performance with PT100 Temperature Sensors

Maximizing the performance of PT100 temperature sensors involves optimizing their integration into your systems and adhering to best practices in usage and maintenance. Here are some strategies to enhance sensor performance:

- System Integration: Ensure seamless integration of PT100 sensor with your control systems. Utilize compatible interfaces and communication protocols to facilitate accurate data transmission.

- Signal Conditioning: Implement proper signal conditioning techniques, such as using precision amplifiers and filters, to improve the quality of the temperature signal and reduce noise.

- Redundancy: In critical applications, consider using redundant PT100 sensor to provide backup measurements and enhance system reliability.

- Data Logging: Utilize data logging systems to track temperature measurements over time. This helps in identifying trends, detecting anomalies, and maintaining quality control.

- Regular Maintenance: Adhere to a regular maintenance schedule to ensure that PT100 sensor remains accurate and reliable. Address any issues promptly to prevent measurement errors.

Comparing PT100 Temperature Sensors with Other Sensors

Understanding the differences between PT100 temperature sensors and other types of temperature sensors can help you make an informed decision based on your specific requirements. Here's a comparison with common temperature sensors:

PT100 vs. Thermocouples

While both PT100 temperature sensors and thermocouples are widely used for temperature measurement, they have distinct differences:

- Accuracy: PT100 sensor offers higher accuracy and stability compared to thermocouples, making them suitable for applications where precision is critical.

- Temperature Range: Thermocouples can measure a wider temperature range, from -200°C to +1750°C, whereas PT100 sensor typically operates up to +850°C.

- Linearity: PT100 sensor provides a more linear output, simplifying calibration and data interpretation.

- Durability: Thermocouples are generally more rugged and can withstand harsher environments, but PT100 temperature sensors are sufficiently durable for most industrial applications.

- Cost: PT100 sensor is typically more expensive than thermocouples, but its superior accuracy can justify the investment in precision-critical applications.

PT100 vs. Thermistors

Thermistors are another type of temperature sensor, and here's how they compare to PT100 temperature sensors:

- Material: Thermistors are typically made from ceramic or polymer materials, whereas PT100 sensor uses platinum, offering better stability.

- Temperature Range: Thermistors have a narrower temperature range, generally from -50°C to +150°C, making this sensor more versatile for a wider range of applications.

- Accuracy: PT100 sensor provides higher accuracy and repeatability, which is essential for industrial and scientific applications.

- Response Time: Thermistors can offer faster response times, which may be advantageous in applications requiring rapid temperature changes detection.

- Durability: PT100 temperature sensors are more durable and can withstand harsh industrial environments better than thermistors.

PT100 vs. Infrared Sensors

Infrared temperature sensors measure temperature remotely by detecting infrared radiation. Here's how they compare to PT100 temperature sensors:

- Contact vs. Non-Contact: PT100 sensor requires direct contact with the target object, while infrared sensor can measure temperature without contact, which is useful for moving objects or hazardous environments.

- Accuracy: Generally offers higher accuracy and reliability compared to infrared sensors, which can be affected by emissivity and environmental factors.

- Application Suitability: Infrared sensors are ideal for applications where contact measurement is impractical, whereas this sensor is preferred for precise, contact-based measurements.

- Response Time: Infrared sensors provide instant readings, whereas PT100 temperature sensors have a finite response time based on their construction.

-

Applications of PT100 Temperature Sensors

PT100 temperature sensors are versatile and find applications across various sectors due to their reliability and accuracy:

Sector Application Automotive Monitor engine and exhaust temperatures. They ensure optimal performance and prevent overheating. Food and Beverage Ensures precise temperature control in processing and storage. It maintains product quality and safety. Aerospace Critical temperature monitoring with PT100 temperature sensors ensures safety and efficiency during testing and operation. HVAC Systems Regulate heating, ventilation, and air conditioning processes to maintain energy efficiency. Pharmaceuticals Ensure strict temperature control during manufacturing and storage to meet standards. Energy Production Monitor temperatures in power plants and renewable systems. They optimize performance and safety. Industrial Manufacturing Control temperatures in processes like metal forging and chemical production for consistency. Laboratory Research Accurate temperature measurement using sensor supports experimental setups and scientific studies.

Case Studies: PT100 Temperature Sensors in Action

Real-world applications demonstrate the effectiveness and reliability of PT100 sensor in various industries. Here are a few case studies:

Automotive Industry: Engine Temperature Monitoring

In the automotive industry, maintaining optimal engine temperature is crucial for performance and longevity. A leading automotive manufacturer integrated PT100 temperature sensors into their engine control systems. The sensors provided real-time temperature data, enabling precise control of engine cooling systems. This integration resulted in improved engine efficiency, reduced wear and tear, and enhanced overall vehicle performance.

Food and Beverage: Precision Temperature Control in Processing

A major food processing company implemented PT100 temperature sensors in their production lines to ensure consistent temperature control during processing and storage. The high accuracy of this sensor allowed for precise regulation of cooking and cooling processes, ensuring product quality and safety. This led to reduced waste, increased efficiency, and compliance with stringent food safety standards.

Aerospace: Critical Temperature Monitoring in Testing

In the aerospace sector, accurate temperature monitoring is vital during testing and operation of aircraft systems. An aerospace engineering firm utilized PT100 temperature sensors in their wind tunnel testing setups. The sensors provided reliable temperature data under extreme conditions, enabling engineers to assess the thermal performance of aircraft components. This contributed to the development of more efficient and safer aerospace technologies.

HVAC Systems: Enhancing Energy Efficiency

A commercial building management company upgraded their HVAC systems with PT100 temperature sensors to optimize heating, ventilation, and air conditioning processes. The sensors provided precise temperature measurements, allowing for better control and energy management. As a result, the building experienced significant energy savings, improved occupant comfort, and reduced operational costs.

Future Trends in PT100 Temperature Sensors

The evolution of industrial processes and technological advancements continues to drive innovation in PT100 temperature sensors. Here are some emerging trends shaping the future of this sensor:

- Smart Sensors: Integration with smart technologies, such as IoT and wireless communication, enables real-time data monitoring and remote management.

- Enhanced Materials: Development of advanced materials for sensor construction improves durability, resistance to harsh environments, and overall performance.

- Miniaturization: Smaller and more compact sensor allows for installation in tight spaces and applications requiring minimal sensor footprint.

- Advanced Signal Processing: Improved signal processing techniques enhance the accuracy and reliability of temperature measurements, even in noisy environments.

- Sustainability: Focus on sustainable manufacturing practices and recyclable materials contributes to the environmental friendliness of sensor.

- Customization: Increased demand for customized sensor tailored to specific industry requirements drives innovation in sensor design and functionality.

FAQs About PT100 Temperature Sensors

What makes PT100 sensors superior to thermocouples?

PT100 temperature sensors provide higher accuracy and stability compared to thermocouples, especially in temperature-critical sectors. Their linear response and repeatability make them ideal for precise temperature monitoring.

Can PT100 sensor be used in hazardous environments?

Yes, PPT100 sensor can be designed with protective housings to function safely in hazardous conditions. It robusts construction ensures reliable performance even in challenging environments.

How often should PT100 temperature sensors be calibrated?

PT100 temperature sensors should be calibrated regularly, typically once a year, or more frequently depending on the application's criticality and environmental conditions. Regular calibration ensures continued accuracy and reliability.

What is the typical lifespan of a PT100 temperature sensor?

With proper maintenance and calibration, PT100 temperature sensors can last several years, often exceeding a decade. The lifespan depends on factors such as operating conditions, environmental exposure, and usage frequency.

Are PT100 temperature sensors compatible with all data acquisition systems?

PT100 temperature sensors are highly compatible with a wide range of data acquisition systems. However, it's essential to ensure that the system supports the sensor's wiring configuration and signal type for optimal performance.

How does PT100 sensor handle extreme temperatures?

PT100 sensor is designed to operate effectively across a broad temperature range, from -200°C to +850°C. Its platinum construction ensures stable resistance characteristics even under extreme temperatures, providing reliable measurements.

Can PT100 temperature sensors be used for both liquid and gas measurements?

Yes, PT100 temperature sensors are versatile and can be used for measuring temperatures in both liquids and gases. Their robust design and wide temperature range make them suitable for various mediums.

What maintenance practices ensure the longevity of PT100 sensor?

Regular calibration, environmental cleaning, inspecting for physical damage, secure wiring connections, and adhering to proper handling procedures are essential maintenance practices that ensure the longevity and reliability of PT100 sensor.

Are there different types of PT100 temperature sensors available?

Yes, PT100 temperature sensors come in various types, including probe-style, surface mount, and inline sensors. They also vary in wiring configurations and encapsulation materials to suit different application requirements.

How does PT100 sensor contribute to energy efficiency?

By providing accurate and reliable temperature measurements, PT100 sensor enables precise control of heating, cooling, and other processes. This leads to optimized energy usage, reduced waste, and improved overall energy efficiency in industrial operations.

Conclusion

Investing in PT100 sensor is a strategic decision for achieving precision and reliability in industrial temperature measurement. PT100 temperature sensors offer high accuracy, stability, and durability, making them indispensable across various sectors such as automotive, aerospace, food processing, and HVAC systems. By selecting the right PT100 temperature sensor and adhering to best practices in installation, calibration, and maintenance, you can enhance your operational efficiency and ensure consistent performance in your temperature monitoring systems.

Elevate your temperature monitoring capabilities by incorporating PT100 sensor into your systems today. Explore our comprehensive range of PT100 temperature sensors to find the perfect fit for your specific needs. Discover our PT100 sensors and take your industrial temperature measurement to the next level.

© 2024 DXM Blog. All rights reserved.

Author: Ivan Huang

Recommended for you

Water Temperature Sensor: The Key to Engine Health and Efficiency

Lightning Surge Protection Varistor: Essential for Protecting Your Electrical Systems

Water Temp Sensor: How to Test it for Reliable Performance?

Capacitor Impedance: Calculation Guide & FAQs

Temperature Probe Sensor: A Comprehensive Guide

Termistor NTC: What Does a Thermistor Do?

Customized Services

Free sample availability

You can contact our representative via email, fax or phone to specify the sample you need and provide your courier's account number (such as UPS, FedEx, DHL, TNT, etc.).. And we’ll send you samples free of charge through your courier by freight collection.

Logistics

How to track my order?

You can track your order through our official website or the order number provided and learn about the logistics status and delivery progress of your order at any time.

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

Does it support express delivery?

Yes, we support express delivery services. You can choose different delivery methods according to your needs, including ordinary express delivery and expedited express delivery.

Can I change my shipping address?

Yes, you can contact our customer service team to modify the delivery address before order confirmation to ensure that the order can be accurately delivered to the address you specify.

You may also like

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd