Thermistors: Essential Components for Accurate Temperature Sensing

Explore the vital role of thermistors in accurate temperature sensing with DXM. What is a thermistor? It’s a sensitive resistor that efficiently measures temperature changes, ensuring precision in various applications. Learn how DXM's cutting-edge thermistors enhance stability and performance in your systems. Explore our range to elevate your temperature control solutions.

- Introduction to Thermistors: Key to Temperature Control

- Types of Thermistors

- Negative Temperature Coefficient (NTC) Thermistor

- Positive Temperature Coefficient (PTC) Thermistor

- How Thermistors Work: Understanding Temperature Sensing

- Applications of Thermistors

- Advantages of Thermistors

- Challenges in Using Thermistors

- Choosing the Right Thermistors

- Resistance Value for Thermistors

- Operating Temperature Range of Thermistors

- NTC or PTC Thermistors: Which to Choose?

- Thermistor Accuracy and Precision

- Response Time of Thermistors

- Thermistor Size and Packaging

- Environmental Conditions for Thermistors

- Long-Term Stability of Thermistor

- Balancing Cost and Performance of Thermistors

- Choosing Reliable Thermistor Suppliers

- Advanced Applications of Thermistors

- Innovations in Thermistor Technology

- Thermistors vs. Other Temperature Sensors

- Design Considerations for Thermistor Integration

- Thermistors in IoT and Smart Devices

- Environmental Impact and Sustainability

- Future Trends in Thermistor Technology

- FAQs: Everything You Need to Know About Thermistors

- What Are Thermistors Made Of?

- Why Are Thermistors Better Than Thermocouples?

- How Do You Calibrate a Thermistor?

- What Is the Typical Lifespan of Thermistor?

- Can Thermistors Withstand High-Vibration Environments?

- What Are the Limitations of Thermistors?

- How Can You Protect Thermistors from Environmental Damage?

- What Affects Thermistor Accuracy?

- Can Thermistors Work in Both AC and DC Circuits?

- What Is the Difference Between Bead and Disk Thermistor?

- What Is a Thermistor?

- Conclusion

Thermistors are critical components in temperature sensing and control systems. But what is a thermistor? A thermistor is a temperature-sensitive resistor that changes resistance with temperature variations.Widely used in industries like electronics, automotive, and medical devices, thermistors provide precise temperature monitoring and control.

Their accuracy, reliability, and versatility make them essential in ensuring system performance and safety.From preventing overheating in consumer electronics to managing HVAC systems, thermistors play a pivotal role in modern technology.

Introduction to Thermistors: Key to Temperature Control

Thermistors are resistors with resistance that changes significantly with temperature. But what is a thermistor exactly? It is a critical component in temperature measurement and control systems, ensuring precise performance across applications.

The name "thermistor" combines "thermal" and "resistor," reflecting its temperature sensitivity. These components are typically made from ceramic semiconductor materials like cobalt, nickel, and manganese oxides. Through sintering, these materials are engineered to deliver the precise resistance characteristics needed for accurate temperature detection and regulation.

By leveraging the unique properties of thermistors, industries achieve efficient, reliable, and accurate temperature management, enhancing system performance and safety.

Types of Thermistors

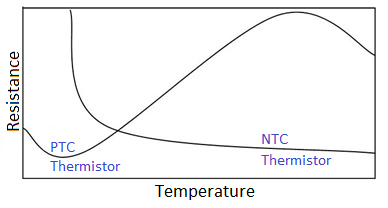

Negative Temperature Coefficient (NTC) Thermistor

NTC thermistor decreases in resistance as temperature increases. This characteristic makes them ideal for precise temperature measurement and control applications. They are widely used in digital thermometers, automotive sensors, and consumer electronics. The high sensitivity of NTC thermistor allows for accurate detection of minor temperature fluctuations, which is essential in applications requiring tight temperature regulation.

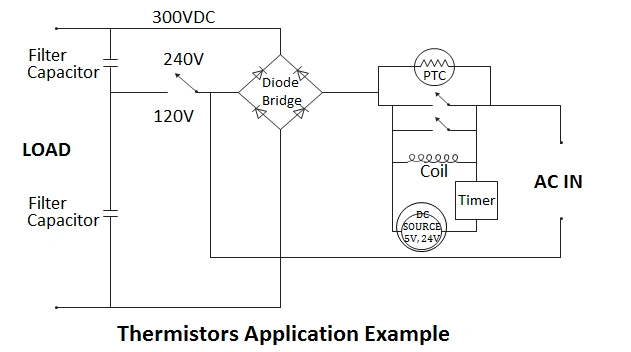

Positive Temperature Coefficient (PTC) Thermistor

PTC thermistor exhibits an increase in resistance with rising temperature. This behavior is useful for overcurrent protection, self-regulating heating elements, and as resettable fuses in various electronic circuits. PTC thermistor helps prevent overheating by limiting the current flow when the temperature exceeds a specific threshold, thereby enhancing the safety and reliability of electronic devices.

How Thermistors Work: Understanding Temperature Sensing

Thermistors operate by changing resistance in response to temperature fluctuations. What is a thermistor, and how does it work? These components rely on semiconductor materials that react predictably to temperature changes, ensuring precise temperature measurement.

When integrated into a circuit, a thermistor’s resistance shifts as the temperature changes. These resistance variations are measured and converted into accurate temperature readings. The non-linear relationship between temperature and resistance in thermistors allows for exceptional sensitivity and accuracy, making them ideal for diverse applications across industries.

Applications of Thermistors

Thermistors are versatile components used across multiple industries due to their reliability and accuracy. Understanding the various applications of thermistors can help in selecting the right type for your specific needs:

| Application | Description |

| Consumer Electronics | Thermistor prevents overheating in devices like smartphones and laptops, ensuring longevity. |

| Automotive Industry | Monitor engine temperatures, manage batteries, and control HVAC systems for vehicle efficiency. |

| Medical Devices | Maintain precise temperatures in diagnostic tools, such as MRI machines and incubators. |

| HVAC Systems | Regulate temperatures in heating and cooling systems for comfort and energy efficiency. |

| Industrial Manufacturing | Control heat in processes like plastic molding and metal forging to ensure product quality. |

| Environmental Monitoring | Measure and control conditions in weather stations and greenhouses for optimal performance. |

| Energy Management | Manage battery heat in renewable systems and EVs to extend battery life and improve performance. |

| Telecommunications | Protect equipment by monitoring and controlling temperature in sensitive environments. |

Advantages of Thermistors

Thermistors offer numerous benefits that make them essential in modern engineering and technology:

- High Sensitivity: Thermistor can detect minute temperature changes with high precision, making them ideal for applications requiring accurate temperature monitoring and control.

- Cost-Effectiveness: They provide an affordable solution for temperature sensing compared to other temperature sensors like thermocouples and RTDs, making them accessible for a wide range of applications.

- Fast Response Time: Thermistors can quickly respond to temperature changes, allowing for rapid adjustments in dynamic systems, which enhances control and efficiency.

- Compact Size: Their small form factor enables easy integration into various devices and systems without requiring significant space, which is crucial for miniaturized electronics.

- Wide Temperature Range: Available in both NTC and PTC types, thermistor can operate effectively over a broad temperature range, accommodating diverse application needs.

- Durability: Thermistors are built to withstand harsh environmental conditions, ensuring long-term reliability and performance in demanding applications.

- Energy Efficiency: By enabling precise temperature control, thermistor contributes to the overall energy efficiency of systems, reducing operational costs and environmental impact.

Challenges in Using Thermistors

While thermistors offer many advantages, they also present certain challenges that need to be addressed to ensure optimal performance:

- Non-linear Response: The resistance change in thermistor is non-linear with temperature, which can complicate calibration and require complex algorithms for accurate temperature readings.

- Limited Measurement Range: Thermistors are most effective within specific temperature ranges. Selecting the appropriate type based on the application’s temperature requirements is crucial for accurate measurements.

- Self-Heating: In high-precision applications, the current passing through a thermistor can cause self-heating, leading to measurement errors. Proper circuit design is necessary to minimize this effect.

- Long-Term Stability: Over time, thermistor can experience drift in their resistance values, affecting measurement accuracy. Regular calibration and quality selection can mitigate this issue.

- Environmental Factors: Exposure to moisture, chemicals, and mechanical stress can impact the performance of thermistors. Protective coatings and proper installation are essential to ensure durability.

Choosing the Right Thermistors

Selecting the right thermistor is crucial for ensuring accurate temperature control and reliable performance. Here are the key factors to consider when choosing thermistors for your application:

Resistance Value for Thermistors

Determine the thermistor’s resistance at a specific temperature. This ensures accurate measurements and compatibility with your system.

Operating Temperature Range of Thermistors

Evaluate the operating temperature range of your application. Choose a thermistor that performs reliably without degradation within this range.

NTC or PTC Thermistors: Which to Choose?

Select between NTC thermistors (ideal for precise temperature sensing) or PTC thermistors (better for circuit protection and self-regulating heating).

Thermistor Accuracy and Precision

Consider the required accuracy. High-precision thermistors are essential for applications needing exact temperature control.

Response Time of Thermistors

For dynamic systems, choose thermistors with fast response times to detect rapid temperature changes effectively.

Thermistor Size and Packaging

Ensure the thermistor’s size and packaging fit your system design. Compact devices may require smaller thermistors.

Environmental Conditions for Thermistors

Assess environmental factors like moisture, chemicals, and vibration. Choose thermistors with protective coatings or robust materials for durability.

Long-Term Stability of Thermistor

Select thermistor with minimal drift over time. Stable thermistor ensures consistent performance throughout the product’s lifecycle.

Balancing Cost and Performance of Thermistors

Balance accuracy, durability, and cost. Opt for thermistors that meet your performance needs without exceeding your budget.

Choosing Reliable Thermistor Suppliers

Work with reputable suppliers offering high-quality thermistors and technical support. This guarantees consistent performance and reliable components.

By considering these factors, you can choose the best thermistor for your needs. A well-selected thermistor ensures accurate temperature sensing and enhances the reliability of your system.

Advanced Applications of Thermistors

Thermistors play a pivotal role in advanced and specialized fields, showcasing their versatility and importance in technology. What is a thermistor in these contexts? Below are key applications where thermistors excel:

- Laser Stabilization: Thermistors are used in laser systems to maintain stable operating temperatures, ensuring consistent laser output and performance.

- Optical Systems: In optical fibers and systems, thermistor helps control temperatures to prevent signal loss and maintain clarity.

- Space Exploration: Thermistor is critical in spacecraft and satellite systems to monitor and control temperatures in extreme space environments, ensuring the functionality of sensitive equipment.

- Renewable Energy Systems: In solar panels and wind turbines, thermistor monitors component temperatures to optimize performance and prevent overheating, enhancing energy efficiency.

- Biotechnology: In bioreactors and other biotech equipment, thermistors ensure precise temperature control, which is vital for biological processes and experiments.

- Food Processing: Thermistor monitors and regulate temperatures in food processing equipment, ensuring product quality and safety by maintaining optimal cooking and storage conditions.

- Aerospace Engineering: Thermistors are used in various aerospace applications to monitor and control temperatures in aircraft systems, contributing to safety and performance.

-

Innovations in Thermistor Technology

Thermistors are advancing rapidly, driven by innovations in materials and manufacturing techniques. What is a thermistor, and how is it evolving? Below are key breakthroughs shaping the future of thermistor technology:

- Nano-Thermistor: Utilizing nanotechnology to create thermistor with enhanced sensitivity and faster response times, suitable for cutting-edge applications in electronics and medical devices.

- Flexible Thermistor: Development of flexible and stretchable thermistor allows for integration into wearable technology and flexible electronics, expanding their application scope.

- Wireless Thermistor Sensors: Incorporating wireless communication capabilities into thermistors enables remote temperature monitoring and control, improving convenience and functionality in various applications.

- High-Temperature Thermistor: Advances in materials have led to the creation of thermistor that can operate reliably at extremely high temperatures, broadening their use in industrial and aerospace applications.

- Smart Thermistor: Integration of smart features such as self-calibration and diagnostic capabilities enhances the performance and reliability of thermistor in complex systems.

These innovations are pushing the boundaries of what thermistor can achieve, making them even more indispensable in modern technology and industrial applications.

Thermistors vs. Other Temperature Sensors

When selecting a temperature sensor, it's essential to compare thermistors with other types such as thermocouples and Resistance Temperature Detectors (RTDs) to determine the best fit for your application:

- Thermistors vs. Thermocouples:

- Sensitivity: Thermistor offer higher sensitivity and accuracy within a limited temperature range, whereas thermocouples can measure a broader range of temperatures but with lower sensitivity.

- Response Time: Thermistor typically has faster response times compared to thermocouples, making it suitable for applications requiring rapid temperature changes.

- Cost: Thermistor is generally more cost-effective for applications within its operating range, while thermocouple can be more expensive due to its broader temperature capabilities.

- Durability: Thermocouples are more robust and can withstand harsher environments compared to thermistors, which may be more sensitive to environmental factors.

- Thermistors vs. RTDs:

- Accuracy: RTDs offer higher accuracy and stability over a wider temperature range compared to thermistor, making them suitable for precision industrial applications.

- Cost: Thermistor is typically less expensive than RTDs, making it a cost-effective choice for applications where extreme precision is not required.

- Response Time: Thermistor generally has faster response times than RTDs, which is beneficial in applications requiring quick temperature detection and control.

- Application Range: RTDs are preferred in applications requiring long-term stability and accuracy, while thermistor is ideal for short-term, high-sensitivity measurements.

Choosing between thermistors, thermocouples, and RTDs depends on the specific requirements of your application, including temperature range, sensitivity, accuracy, response time, and budget.

Design Considerations for Thermistor Integration

Integrating thermistors into your system requires careful design considerations to ensure accurate temperature measurement and control. Here are some key factors to consider:

| Design Aspect | Description |

| Placement of Thermistor | Place thermistors where they can sense target temperatures accurately without external interference. |

| Wiring and Connections | Use shielded cables and proper grounding to minimize noise and enhance measurement accuracy. |

| Signal Conditioning | Add amplifiers and filters to convert resistance changes into precise, usable temperature data. |

| Thermistor Calibration | Regularly calibrate using known temperature standards to ensure long-term accuracy. |

| Environmental Protection | Apply coatings or encapsulation to protect thermistor from moisture, chemicals, or harsh conditions. |

| Power Supply Stability | Use a stable power source to prevent fluctuations that can affect thermistor readings. |

| Thermistor Mounting | Secure thermistor with adhesives or fixtures to prevent movement and maintain consistent sensing. |

| Thermal Mass | Minimize thermal mass to allow thermistor to respond quickly to temperature changes. |

By addressing these design considerations, you can effectively integrate thermistors into your systems, ensuring reliable and accurate temperature sensing and control.

Thermistors in IoT and Smart Devices

The rise of the Internet of Things (IoT) has revolutionized temperature management, with thermistors playing a crucial role in connected systems. But what is a thermistor in IoT? Below are key applications:

- Smart Home Devices: Thermistors are used in smart thermostats, smart refrigerators, and other home automation systems to provide precise temperature control and energy management.

- Wearable Technology: In fitness trackers and smartwatches, thermistor monitors body temperature, enhancing health and wellness features.

- Industrial IoT: Thermistor enables real-time temperature monitoring in industrial equipment, facilitating predictive maintenance and reducing downtime.

- Environmental Sensors: Connected environmental monitoring systems use thermistor to collect temperature data, aiding in climate control and sustainability efforts.

- Healthcare IoT: In connected medical devices, thermistors ensure accurate temperature measurements, supporting patient monitoring and telemedicine applications.

Integrating thermistor into IoT and smart devices enhances its functionality and enables more sophisticated temperature management, contributing to the advancement of connected technologies.

Environmental Impact and Sustainability

Thermistors contribute to environmental sustainability by enabling precise temperature control, which can lead to significant energy savings and reduced waste:

- Energy Efficiency: By accurately regulating temperatures in HVAC systems, consumer electronics, and industrial processes, thermistors help reduce energy consumption and lower carbon footprints.

- Resource Optimization: Precise temperature control ensures optimal performance of systems, reducing the need for excess resources and minimizing waste in manufacturing and processing.

- Longevity of Devices: Preventing overheating and temperature-related failures extends the lifespan of electronic devices and industrial equipment, reducing the frequency of replacements and the associated environmental impact.

- Renewable Energy Systems: In renewable energy applications, thermistor helps manage battery temperatures, enhancing the efficiency and reliability of energy storage solutions.

- Green Building Technologies: Thermistor is integral in smart building systems that optimize heating, cooling, and ventilation, contributing to sustainable building practices and reduced energy usage.

By enabling more efficient and sustainable temperature management, thermistors play a vital role in advancing environmental sustainability across various sectors.

Future Trends in Thermistor Technology

The future of thermistor technology is promising, with ongoing research and development aimed at enhancing their capabilities and expanding their applications:

- Integration with AI and Machine Learning: Combining thermistors with AI and machine learning algorithms can lead to smarter temperature control systems that adapt and optimize based on real-time data and predictive analytics.

- Advanced Materials: Development of new semiconductor materials can improve the performance, durability, and temperature range of thermistor, making them suitable for even more demanding applications.

- Miniaturization: Continued miniaturization of thermistor will enable their integration into increasingly compact and portable devices, enhancing their applicability in emerging technologies.

- Wireless and Remote Sensing: Advances in wireless communication will allow thermistor to be used in remote sensing applications, providing real-time temperature data without the need for wired connections.

- Enhanced Durability: Improving the robustness of thermistors will expand their use in extreme environments, such as deep-sea exploration and space missions, where reliable temperature sensing is critical.

- Energy Harvesting: Incorporating energy harvesting technologies with thermistor can create self-powered temperature sensing devices, reducing the need for external power sources and enhancing sustainability.

These future trends are set to further solidify the importance of thermistors in technological advancements, ensuring their continued relevance and application in diverse fields.

FAQs: Everything You Need to Know About Thermistors

What Are Thermistors Made Of?

Thermistors are made from ceramic compounds of metallic oxides, such as cobalt, nickel, and manganese. These materials are sintered to achieve precise resistance and temperature sensitivity.

Why Are Thermistors Better Than Thermocouples?

Thermistors provide higher accuracy and sensitivity within specific temperature ranges. While thermocouples cover wider ranges, thermistors are ideal for precise, narrow-range measurements.

How Do You Calibrate a Thermistor?

Calibration involves comparing thermistor readings to known temperature standards. This ensures accuracy and requires precise tools in controlled environments.

What Is the Typical Lifespan of Thermistor?

With proper care, thermistor can last many years. However, exposure to harsh temperatures or corrosive environments may shorten their lifespan.

Can Thermistors Withstand High-Vibration Environments?

Yes, thermistors work in high-vibration settings if securely mounted. Robust packaging and proper installation prevent mechanical stress.

What Are the Limitations of Thermistors?

Thermistors have a limited measurement range and non-linear temperature response. Self-heating can also affect readings, requiring careful calibration.

How Can You Protect Thermistors from Environmental Damage?

Use protective coatings or encapsulation materials to shield thermistors from moisture and chemicals. Proper housing and installation enhance durability.

What Affects Thermistor Accuracy?

Material quality, precise manufacturing, and proper calibration are critical. Stable environments and careful handling also maintain accuracy.

Can Thermistors Work in Both AC and DC Circuits?

Thermistors primarily work in DC circuits for direct resistance-to-temperature readings. They can operate in AC circuits with appropriate conditioning.

What Is the Difference Between Bead and Disk Thermistor?

Bead thermistor is small and highly sensitive, perfect for compact applications. Disk thermistor is larger, offering better heat dissipation and stability.

What Is a Thermistor?

A thermistor is a temperature-sensitive resistor. It changes resistance based on temperature, making it ideal for accurate temperature control and measurement.

Conclusion

Thermistors are indispensable in temperature sensing and control systems. But what is a thermistor? It is a temperature-sensitive resistor that ensures precise temperature monitoring and regulation across industries.Their high sensitivity, reliability, and adaptability make thermistor ideal for applications ranging from consumer electronics to industrial automation. By understanding their types and uses, engineers can develop systems with enhanced temperature management.

Whether you're designing advanced electronics or optimizing industrial processes, thermistors ensure performance, safety, and energy efficiency. Ready to integrate thermistor into your projects? Contact us to find the perfect solution for reliable and accurate temperature control.

For more detailed information on thermistors and their applications, visit our Thermistor Resources.Ready to integrate high-quality thermistors into your projects? Contact us today to find the perfect thermistors for your needs and ensure your systems operate with precision and reliability.

Recommended for you

Water Temperature Sensor: The Key to Engine Health and Efficiency

Lightning Surge Protection Varistor: Essential for Protecting Your Electrical Systems

Water Temp Sensor: How to Test it for Reliable Performance?

Capacitor Impedance: Calculation Guide & FAQs

Temperature Probe Sensor: A Comprehensive Guide

Termistor NTC: What Does a Thermistor Do?

Logistics

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

Can I change my shipping address?

Yes, you can contact our customer service team to modify the delivery address before order confirmation to ensure that the order can be accurately delivered to the address you specify.

Is your logistics and distribution service reliable?

Yes, we cooperate with a number of well-known logistics companies to ensure the timeliness and reliability of logistics and distribution services and provide you with a satisfactory distribution experience.

Customized Services

Free sample availability

You can contact our representative via email, fax or phone to specify the sample you need and provide your courier's account number (such as UPS, FedEx, DHL, TNT, etc.).. And we’ll send you samples free of charge through your courier by freight collection.

Price and Payment

Payment Terms

There are a number of different payment methods that can be used when you deal with us. Two are mostly used: T/T payment in advance for small values and irrevocable L/C at sight for large values.

You may also like

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd