Temp Sensors: Enhance Your Operations with Advanced Temperature Sensor

Enhance your operations with DXM's advanced temp sensors. Our state-of-the-art temperature sensors deliver precise readings crucial for optimizing efficiency and ensuring safety. Trusted across industries, DXM temp sensors offer reliability and accuracy. Discover how our cutting-edge temperature sensor technology can transform your business performance today.

- Introduction to Temp Sensors

- Fundamental Types of Temp Sensors

- Thermocouples

- RTDs (Resistance Temperature Detectors)

- Thermistors

- Infrared Sensors

- Semiconductor Sensors

- How Temp Sensors Work

- Thermocouples

- RTDs (Resistance Temperature Detectors)

- Thermistors

- Infrared Sensors

- Semiconductor Sensors

- Applications of Temp Sensors

- Benefits of Using Temp Sensors

- Common Challenges and Solutions in Using Temp Sensors

- Advanced Technologies in Temp Sensors

- Wireless Temperature Sensor

- Smart Temperature Sensor

- High-Precision Temp Sensors

- Flexible and Wearable Temp Sensors

- Choosing the Right Temp Sensors for Your Application

- Temperature Range

- Accuracy and Precision

- Response Time

- Environmental Conditions

- Installation and Integration

- Power Requirements

- Cost and Budget

- Benefits of Integrating Temp Sensors into Your Systems

- Real-Time Monitoring

- Predictive Maintenance

- Energy Efficiency

- Enhanced Product Quality

- Regulatory Compliance

- Implementing Temp Sensors: Best Practices

- Case Studies: Successful Implementation of Temp Sensors

- Manufacturing Industry

- Healthcare Sector

- Food and Beverage Industry

- Automotive Sector

- Future Trends in Temp Sensors Technology

- Internet of Things (IoT) Integration

- Miniaturization and Portability

- Enhanced Accuracy and Stability

- Energy Harvesting Technologies

- Artificial Intelligence and Machine Learning

- Conclusion of Temp Sensors

- Temp Sensors Optimize Your Operations Today!

- Frequently Asked Questions about Temp Sensors (FAQs)

- Q1: What industries benefit the most from temp sensors?

- Q2: Are temp sensors easy to integrate into existing systems?

- Q3: What maintenance does temperature sensor require?

- Q4: Can temperature sensor function under extreme conditions?

- Q5: How do I choose the right temp sensor for my application?

- Learn More About Temp Sensors

Temp Sensors play a crucial role in industrial processes, ensuring accurate temperature monitoring and control. These devices enhance efficiency, reduce downtime, and improve product durability. Understanding the types and technologies behind Temp Sensors helps businesses achieve precision and reliability. From Resistance Temperature Detectors (RTDs) to Thermocouples and Infrared Sensors, each type serves specific applications. Selecting the right Temperature Sensor ensures optimal performance and operational safety.

This guide explores Temp Sensors' technologies, benefits, and industrial uses while addressing common questions to help you make informed decisions.

Introduction to Temp Sensors

In industries ranging from manufacturing to healthcare, temperature regulation is key. Temp sensors offer an efficient solution for monitoring temperature, ensuring processes run smoothly and safely. With advancements in technology, temperature sensor has become indispensable tools in modern industry, enabling precise control and monitoring that enhance both safety and efficiency.

Modern temp sensors are designed to meet the diverse needs of various sectors. Whether it's maintaining the delicate temperatures in medical equipment or ensuring optimal conditions in manufacturing processes, temp sensors play a critical role in achieving desired outcomes. Their ability to provide real-time data allows for immediate adjustments, preventing potential issues before they escalate.

Fundamental Types of Temp Sensors

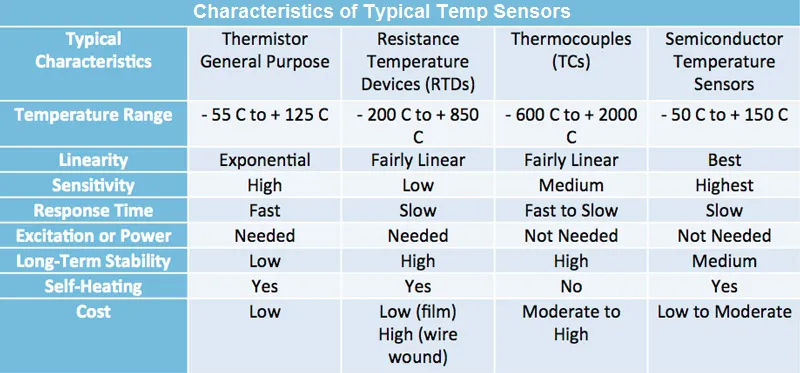

Understanding the different types of temperature sensors is crucial for selecting the right one for your application. Here are the most common types:

Thermocouples

Thermocouples are renowned for their wide temperature range and durability. They are ideal for industrial applications where robustness is required. By generating a voltage difference based on the Seebeck effect, thermocouples provide reliable temperature readings in harsh environments.

These sensors consist of two different metals joined at one end. When there is a temperature difference between the joined end and the other ends, a voltage is produced, which can be measured and interpreted to determine temperature. Their ability to operate at extreme temperatures makes them suitable for applications such as kilns, gas turbine exhausts, and diesel engines.

RTDs (Resistance Temperature Detectors)

RTDs offer precise temperature readings by measuring the resistance changes in metals like platinum. They are used in situations where exact data is essential, such as in research laboratories and high-precision manufacturing processes.

RTDs work on the principle that the electrical resistance of a metal changes with temperature. Platinum RTDs are particularly popular due to their high accuracy and stability. They are commonly found in applications like environmental monitoring, industrial process control, and quality assurance in manufacturing.

Thermistors

Thermistors are best suited for applications requiring high sensitivity rather than a wide range. They are commonly used in consumer electronics and medical devices where small temperature changes need to be detected accurately.

Thermistors are made from ceramic or polymer materials and exhibit significant resistance changes with temperature variations. This makes them ideal for applications like digital thermostats, automotive temperature controls, and wearable health devices, where precise temperature measurement is crucial.

Infrared Sensors

Infrared sensors measure temperature without direct contact with the object. This makes them ideal for applications where contact is impractical, such as in moving machinery or hazardous environments.

These sensors detect infrared radiation emitted by objects and convert it into temperature readings. They are widely used in applications like monitoring electrical equipment, measuring body temperature in medical settings, and detecting overheating in mechanical systems.

Semiconductor Sensors

Semiconductor sensors are compact and efficient, making them widely used in consumer electronics. They provide reliable temperature measurements with minimal power consumption.

These sensors utilize the properties of semiconductor materials to measure temperature. They are commonly found in devices such as smartphones, laptops, and gaming consoles, where space and power efficiency are paramount.

How Temp Sensors Work

The working principle of temperature sensor varies depending on their type. Generally, they measure temperature through electrical signals converted by changes in resistance, voltage, or current. Understanding these principles is essential for selecting the right sensor for your application.

Thermocouples

Thermocouples operate on the Seebeck effect, which generates a voltage difference across two different metals when there is a temperature gradient. This voltage is proportional to the temperature difference and can be measured to determine the actual temperature.

RTDs (Resistance Temperature Detectors)

RTDs utilize the predictable change in electrical resistance of metals, typically platinum, with temperature. As temperature increases, the resistance of the RTD increases in a linear fashion, allowing for precise temperature measurements.

Thermistors

Thermistors exhibit rapid resistance changes with small temperature shifts, offering high sensitivity. They are typically made from ceramic or polymer materials, which provide a large change in resistance for a given temperature change, making them ideal for precise temperature monitoring.

Infrared Sensors

Infrared sensors measure the infrared radiation emitted by objects to determine their temperature. They use lenses to focus the infrared energy onto a detector, which converts it into an electrical signal proportional to the temperature.

Semiconductor Sensors

Semiconductor sensors use the temperature-dependent properties of semiconductor materials to measure temperature. They often incorporate integrated circuits that process the temperature data, providing digital outputs that are easy to interface with modern electronics.

Applications of Temp Sensors

Temp sensors are employed in numerous fields for precise thermal monitoring:

- Industrial Automation: Monitoring processes, machinery, and environments to ensure optimal performance. Temp sensors help in maintaining consistent production quality and preventing equipment failures.

- HVAC Systems: Ensuring optimal climate management for comfort and energy efficiency. Temperature sensor regulate heating and cooling systems, maintaining desired indoor temperatures.

- Medical Devices: Maintaining precise temperature control in sensitive equipment like incubators and imaging devices. Temp Sensors ensure patient safety and equipment reliability.

- Food and Beverage: Quality control during processing and storage to ensure product safety. Temp sensors monitor temperatures to prevent spoilage and ensure compliance with health standards.

- Automotive: Regulating engine and battery temperatures to enhance performance and longevity. Temperature sensor is critical for engine management systems and battery thermal management.

- Aerospace: Monitoring temperatures in aircraft and spacecraft systems to ensure safety and performance. Temp sensors help in managing thermal loads and preventing overheating of critical components.

- Electronics: Protecting components from overheating in devices like computers and smartphones. Temperature sensor triggers cooling mechanisms to maintain optimal operating conditions.

- Renewable Energy: Managing temperatures in solar panels and wind turbines to improve efficiency and lifespan. Temp sensors optimize the performance of renewable energy systems.

Benefits of Using Temp Sensors

Implementing the right temp sensor offers numerous benefits:

- Enhanced Safety: Prevents overheating, reducing fire hazards and ensuring safe operation. Temp sensors are crucial in environments where temperature control is vital for safety.

- Improved Efficiency: Keeps systems running at optimal levels, reducing energy consumption. Accurate temperature monitoring allows for better resource management and operational efficiency.

- Cost Savings: Lowers operational costs by reducing energy use and prolonging equipment lifespan. By preventing overheating and ensuring efficient operation,temp sensors contribute to significant cost reductions.

- Quality Control: Maintains consistent product quality by monitoring and controlling temperature during production processes. Temp sensors help in adhering to stringent quality standards.

- Data Collection and Analysis: Provides valuable data for process optimization and predictive maintenance. Temperature sensor enables data-driven decision-making to enhance overall performance.

- Regulatory Compliance: Helps meet industry regulations and standards by providing accurate temperature measurements. Temp sensors ensure compliance with health, safety, and environmental guidelines.

Common Challenges and Solutions in Using Temp Sensors

Proper installation and regular maintenance can address many challenges associated with temperature sensor. Understanding these challenges and implementing effective solutions ensures reliable performance and longevity of the sensors.

-

Challenge Description Solution Calibration Regular calibration is critical to ensure accurate readings from Temp Sensors, especially in critical applications. Schedule regular calibration to maintain the accuracy of Temperature Sensors and prevent measurement errors. Environmental Factors Moisture, dust, and extreme temperatures can affect Temp Sensors. Select Temperature Sensors designed to withstand specific conditions with proper protection for durability and reliable performance. Signal Interference Electrical noise and interference can disrupt temperature readings. Use shielded cables or wireless Temp Sensors to minimize interference and ensure stable signal transmission. Installation Challenges Poor placement or improper mounting can lead to inaccurate readings and sensor damage. Follow best installation practices, ensuring proper placement and secure mounting to enhance the performance of Temp Sensors. Power Supply Issues Fluctuations in power supply can affect the accuracy of Temperature Sensors. Use stable power sources and voltage regulators to maintain consistent operation of Temp Sensors. Data Integration Seamless integration with existing systems is essential for real-time monitoring and analysis. Choose Temp Sensors with compatible communication protocols and interfaces to ensure smooth integration with software and data systems.

Advanced Technologies in Temp Sensors

The field of temperature sensor is continuously evolving, with advancements enhancing their accuracy, reliability, and functionality. Understanding these technologies can help in selecting the best sensor for specific applications.

Wireless Temperature Sensor

Wireless temp sensors offer flexibility in installation and real-time data transmission without the need for extensive wiring. They are ideal for applications where wired connections are impractical or costly.

These sensors use wireless communication protocols like Bluetooth, Zigbee, or Wi-Fi to transmit data to central monitoring systems. This allows for easy installation and scalability, making them suitable for large-scale industrial environments.

Smart Temperature Sensor

Smart temperature sensor comes with built-in processing capabilities that enable data analysis and decision-making at the sensor level. They can provide insights and alerts based on predefined parameters.

These sensors often integrate with IoT platforms, allowing for remote monitoring and control. Smart temp sensors are used in advanced manufacturing, smart buildings, and automated systems where real-time data and proactive management are essential.

High-Precision Temp Sensors

High-precision temperature sensor offers exceptional accuracy and stability, making it suitable for applications requiring meticulous temperature control. This sensor is essential in scientific research, pharmaceuticals, and high-precision manufacturing.

They utilize advanced materials and manufacturing techniques to minimize errors and drift, ensuring consistent and reliable temperature measurements over extended periods.

Flexible and Wearable Temp Sensors

Flexible and wearable temperature sensor is designed for integration into clothing, medical devices, and portable electronics. It offers comfort and adaptability, enabling continuous temperature monitoring in dynamic environments.

These sensors use flexible substrates and low-power technologies, making them ideal for applications like health monitoring, sports performance tracking, and smart textiles.

Choosing the Right Temp Sensors for Your Application

Selecting the appropriate temp sensor involves considering several factors to ensure optimal performance and reliability. Here are key aspects to evaluate:

Temperature Range

Determine the minimum and maximum temperatures the sensor needs to measure. Different types of temperature sensors are suitable for varying temperature ranges. For instance, thermocouples can handle extreme temperatures, while thermistors are ideal for more moderate ranges.

Accuracy and Precision

Assess the required accuracy and precision for your application. RTDs and high-precision thermistors offer superior accuracy, making them suitable for applications where precise temperature control is critical.

Response Time

Consider the response time needed for your application. Fast-response temp sensors are essential in dynamic environments where temperatures change rapidly, such as in automotive engines or industrial processes.

Environmental Conditions

Evaluate the environmental conditions where the sensor will operate. Factors like moisture, dust, vibration, and chemical exposure can affect sensor performance. Choose sensors with appropriate protection ratings to withstand these conditions.

Installation and Integration

Consider how easily the temperature sensor can be installed and integrated into your existing systems. Wireless and smart sensors offer easier installation and integration with modern data systems and IoT platforms.

Power Requirements

Evaluate the power requirements of the sensor. Low-power sensors are ideal for battery-operated devices and remote installations where power supply is limited.

Cost and Budget

Balance the cost of the sensor with its performance and features. While high-precision sensors offer better accuracy, they may come at a higher cost. Determine your budget and select a sensor that meets your requirements without exceeding financial constraints.

Benefits of Integrating Temp Sensors into Your Systems

Integrating temp sensors into your systems offers numerous advantages that can significantly impact your operations:

Real-Time Monitoring

With temp sensors, you can monitor temperatures in real-time, allowing for immediate adjustments and responses to any anomalies. This ensures that processes remain within desired parameters, enhancing overall efficiency and safety.

Predictive Maintenance

Temperature data from sensors can be used to predict maintenance needs before failures occur. By analyzing temperature trends, you can identify potential issues and address them proactively, reducing downtime and maintenance costs.

Energy Efficiency

Accurate temperature control leads to better energy management. By maintaining optimal temperatures, you can reduce energy consumption, lower utility costs, and minimize your environmental footprint.

Enhanced Product Quality

Consistent temperature control ensures that products are manufactured under optimal conditions, leading to higher quality and uniformity. This is particularly important in industries like food processing, pharmaceuticals, and electronics.

Regulatory Compliance

Many industries have strict regulations regarding temperature control and monitoring. Integrating temp sensors helps you comply with these regulations, avoiding legal issues and ensuring the safety and quality of your products.

Implementing Temp Sensors: Best Practices

To maximize the benefits of temperature sensor, follow these best practices during implementation:

- Proper Placement: Ensure sensors are placed in locations that accurately reflect the temperature of the area or component being monitored. Avoid placing sensors near heat sources or in areas with poor airflow.

- Regular Calibration: Schedule regular calibration to maintain accuracy. Follow manufacturer guidelines and industry standards for calibration intervals.

- Protective Enclosures: Use protective enclosures to shield sensors from harsh environmental conditions. This extends the lifespan of the sensors and ensures reliable performance.

- Data Integration: Integrate sensor data with your existing monitoring and control systems. Use compatible communication protocols and software to facilitate seamless data flow.

- Maintenance and Inspection: Conduct regular maintenance and inspections to identify and address any issues promptly. Clean sensors and check for signs of wear or damage.

- Training and Education: Train your staff on the proper use and maintenance of temperature sensor. Educate them on interpreting sensor data and responding to alerts.

Case Studies: Successful Implementation of Temp Sensors

Examining real-world applications of temp sensors can provide valuable insights into their benefits and best practices:

Manufacturing Industry

A leading automotive manufacturer integrated RTDs into their assembly lines to monitor engine temperatures in real-time. This implementation led to a 15% reduction in production downtime and a significant improvement in product quality by ensuring engines operated within optimal temperature ranges.

Healthcare Sector

A hospital upgraded its medical equipment with high-precision thermistors to maintain the necessary temperatures in incubators and imaging devices. This enhancement improved patient safety and equipment reliability, ensuring consistent and accurate medical procedures.

Food and Beverage Industry

A food processing plant implemented wireless temperature sensor in their storage facilities. This allowed for continuous monitoring of refrigeration temperatures, preventing spoilage and ensuring compliance with health and safety regulations. The plant reported a 20% decrease in energy costs due to optimized temperature control.

Automotive Sector

An electric vehicle manufacturer utilized semiconductor temperature sensor to monitor battery temperatures. This integration helped in preventing overheating, thereby extending battery life and enhancing vehicle performance. The company noted a 10% improvement in battery efficiency and longevity.

Future Trends in Temp Sensors Technology

The evolution of temp sensors continues to drive innovation across various industries. Emerging trends are set to enhance their capabilities and applications further:

Internet of Things (IoT) Integration

The integration of temperature sensor with IoT platforms is enabling smarter and more connected systems. IoT-enabled sensors facilitate remote monitoring, data analytics, and automated responses, enhancing overall system intelligence and efficiency.

Miniaturization and Portability

Advancements in sensor technology are leading to smaller and more portable temp sensors. These compact sensors can be easily integrated into wearable devices, portable electronics, and tight spaces within machinery, expanding their application scope.

Enhanced Accuracy and Stability

Ongoing research is focused on improving the accuracy and stability of temperature sensor. Innovations in materials science and sensor design are resulting in sensors that offer higher precision, lower drift, and better long-term reliability.

Energy Harvesting Technologies

Energy harvesting technologies are being integrated into temp sensors, allowing them to generate their own power from environmental sources like light, heat, or vibrations. This reduces the need for external power supplies, making sensors more versatile and sustainable.

Artificial Intelligence and Machine Learning

Artificial intelligence (AI) and machine learning (ML) are being applied to temperature sensor data to provide predictive analytics and advanced monitoring capabilities. AI-driven algorithms can analyze vast amounts of temperature data to identify patterns, predict failures, and optimize processes.

Conclusion of Temp Sensors

Temp Sensors are indispensable in the modern technological landscape, aiding in precision, safety, and efficiency across various sectors. By selecting the right temp sensor type and maintaining it correctly, professionals can ensure optimal outcomes in their specific applications. Embracing advanced temperature sensor technologies can lead to significant improvements in operational performance, cost savings, and product quality.

Temp Sensors Optimize Your Operations Today!

Our expertise in temperature sensor can help you choose and maintain the ideal solution for your specific needs. Get in touch with us to leverage advanced temp sensor technology and enhance your operational efficiency.

Frequently Asked Questions about Temp Sensors (FAQs)

Q1: What industries benefit the most from temp sensors?

A1: Industries such as manufacturing, healthcare, automotive, food and beverage, HVAC, aerospace, electronics, and renewable energy significantly benefit from using temp sensors. These sensors enhance operational efficiency, safety, and product quality across various applications.

Q2: Are temp sensors easy to integrate into existing systems?

A2: Yes, modern temp sensors are designed for easy integration with various systems. Many sensors support multiple communication protocols and can interface seamlessly with existing data acquisition and monitoring systems, facilitating smooth implementation.

Q3: What maintenance does temperature sensor require?

A3: Regular calibration, cleaning, and inspection are essential to ensure the accuracy and longevity of temperature sensor. Following manufacturer guidelines for maintenance schedules and procedures helps maintain optimal sensor performance.

Q4: Can temperature sensor function under extreme conditions?

A4: Yes, temp sensors are available in various types designed to operate under extreme conditions. Thermocouples, for instance, are well-suited for high-temperature environments, while RTDs and infrared sensors can perform reliably in extremely cold conditions.

Q5: How do I choose the right temp sensor for my application?

A5: Consider factors such as the required temperature range, accuracy, response time, environmental conditions, installation constraints, power requirements, and budget. Evaluating these aspects will help you select the most suitable temperature sensor for your specific needs.

Learn More About Temp Sensors

For more detailed information on temperature sensor and other industrial solutions, visit our products page. Discover how our advanced temp sensors can enhance your operations and ensure optimal performance across various applications.

© 2024 DXM Blog. All rights reserved.

Author: Ivan Huang

Recommended for you

Water Temperature Sensor: The Key to Engine Health and Efficiency

Lightning Surge Protection Varistor: Essential for Protecting Your Electrical Systems

Water Temp Sensor: How to Test it for Reliable Performance?

Capacitor Impedance: Calculation Guide & FAQs

Temperature Probe Sensor: A Comprehensive Guide

Termistor NTC: What Does a Thermistor Do?

Logistics

Does it support express delivery?

Yes, we support express delivery services. You can choose different delivery methods according to your needs, including ordinary express delivery and expedited express delivery.

Is your logistics and distribution service reliable?

Yes, we cooperate with a number of well-known logistics companies to ensure the timeliness and reliability of logistics and distribution services and provide you with a satisfactory distribution experience.

Shipment

1)Small order quantity and small packing:cargo may be arranged by courier;

2)Bulk order and big volume:shipment may be arranged by sea or by air as per customer’s requirements on FOB, C&F,CIF or LCL terms and do prompt shipment which is very important for our customers, so we do this matter seriously and we may arrange our shipment in time due to our rich experiences in this line. We may also accept the shipment on the term of freight prepaid or freight collect.

Customized Services

Free sample availability

You can contact our representative via email, fax or phone to specify the sample you need and provide your courier's account number (such as UPS, FedEx, DHL, TNT, etc.).. And we’ll send you samples free of charge through your courier by freight collection.

Price and Payment

Price

The price will be quoted in US dollars.

1) For small order quantities and small packing, normally our quotation is based on the ex-works price. The cargo will be delivered by courier after being finished normally.

2) For bulk orders and large volumes, normally our quotation is based on the FOB price. Please inform us of your destination seaport and estimated quantity, and our representative will quote you the C&F or CIF price accordingly. If you feel our freight is higher than your expectation, you can recommend your shipping company to us. Our principal is looking for a shipping company with a good reputation that offers competitive freight costs and can deliver your cargo promptly.

You may also like

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd