Capacitor in Parallel: Mastering Formulas, Benefits, and Practical Applications

Explore how DXM's expertise in capacitor in parallel can optimize your electrical systems. Master essential formulas and explore key benefits and practical applications in our detailed guide. Enhance performance and reliability with insights into the capacitors in parallel formula. Dive into the world of efficient energy solutions with DXM's knowledge-driven approach.

- Understanding the Capacitors in Parallel Formula

- Key Characteristics of Capacitor in Parallel

- Practical Example of Capacitors in Parallel Formula

- Advantages of Using Capacitor in Parallel

- Applications of Capacitor in Parallel

- Optimizing Circuit Performance with Capacitor in Parallel

- Advanced Optimization Techniques

- Choosing the Right Capacitor for Parallel Configurations

- Types of Capacitors Suitable for Parallel Configurations

- Design Considerations for Parallel Capacitor Configurations

- Common Challenges and Solutions in Capacitor in Parallel Configurations

- Advanced Topics of Capacitor in Parallel Configurations

- Case Studies: Successful Implementations of Capacitor in Parallel Configurations

- Why Choose Our Capacitor in Parallel Configurations?

- Customer Success Stories

- FAQs

- Q1: How do I calculate the total capacitance for capacitor in parallel?

- Q2: What are the main advantages of using capacitors in parallel?

- Q3: Can I mix different types of capacitors in parallel?

- Q4: What applications benefit most from parallel capacitor configurations?

- Q5: How does temperature affect capacitor in parallel?

- Q6: What is the impact of Equivalent Series Resistance (ESR) in parallel capacitor configurations?

- Q7: How do I ensure proper balancing of capacitor in parallel?

- Q8: What are the best practices for mounting capacitor in parallel on a PCB?

- Q9: Can parallel capacitor configurations be used in high-frequency applications?

- Q10: How do parallel capacitors affect the overall size of an electronic device?

When designing electronic circuits, understanding a capacitor in parallel configuration is crucial. This comprehensive guide covers the capacitors in parallel formula, essential concepts, and practical applications to help you optimize your projects effectively.

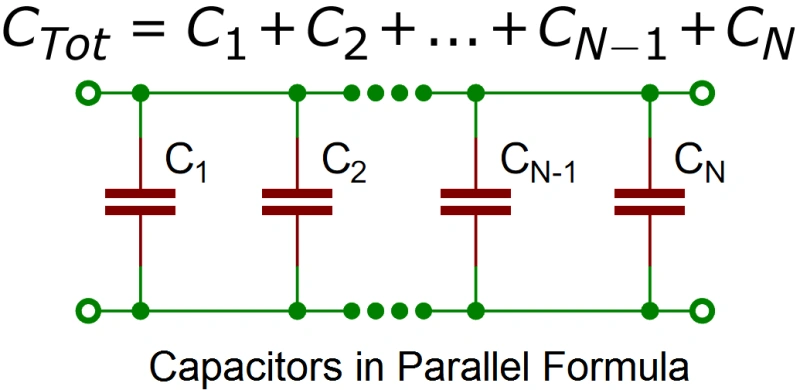

Understanding the Capacitors in Parallel Formula

Equivalent Capacitance (Ceq) = C1 + C2 + C3 + ...

The capacitors in parallel formula is straightforward. To calculate the total or equivalent capacitance (Ceq) of capacitors connected in parallel, simply add their individual capacitances. This formula is fundamental for designing circuits that require specific capacitance values.

Key Characteristics of Capacitor in Parallel

- Same Voltage: In a parallel configuration, each capacitor experiences the same voltage across its terminals. This uniformity ensures that all capacitors operate under identical voltage conditions.

- Charge Distribution: The total charge stored in the system is the sum of the charges on each capacitor. This distribution enhances the overall energy storage capacity of the circuit.

- Increased Capacitance: By adding capacitors in parallel, the total capacitance increases, allowing for greater energy storage without increasing voltage.

- Redundancy: Parallel configurations provide redundancy. If one capacitor fails, others continue to function, maintaining circuit performance.

Practical Example of Capacitors in Parallel Formula

Consider two capacitors with capacitances of 6 μF and 3 μF connected in parallel. Using the capacitors in parallel formula:

Ceq = 6 μF + 3 μF = 9 μF

This simple addition demonstrates how combining capacitors in parallel effectively increases the total capacitance, which is beneficial in applications requiring higher energy storage.

Advantages of Using Capacitor in Parallel

Implementing a capacitor in parallel offers several significant benefits:

- Enhanced Capacitance: Increasing the total capacitance allows circuits to store more energy, which is essential for power supply smoothing and energy storage applications.

- Improved Stability: Distributing the charge among multiple capacitors reduces the stress on individual capacitors, leading to increased reliability and longevity.

- Design Flexibility: Parallel configurations allow for scalable designs. Adding or removing capacitors can easily adjust the total capacitance to meet specific circuit requirements.

- Redundancy: In case one capacitor fails, others continue to function, maintaining the overall performance of the circuit.

- Lower Equivalent Series Resistance (ESR): Combining capacitors in parallel reduces the overall ESR, improving the efficiency of power delivery and reducing heat generation.

- Balanced Load Distribution: Ensures that no single capacitor is overloaded, which can prevent premature failure and extend the lifespan of the capacitors.

Applications of Capacitor in Parallel

Capacitor in parallel is widely utilized across various electronic applications:

- Power Supply Filtering: Parallel capacitors smooth out voltage fluctuations by storing and releasing energy as needed, ensuring a stable power supply.

- Energy Storage Systems: They provide backup power in electronic devices, ensuring functionality during power interruptions.

- Signal Processing: Enhances signal stability and reduces noise in communication systems, leading to clearer and more reliable signals.

- Motor Start Circuits: Provide the necessary surge of energy to start motors, improving their performance and efficiency.

- Decoupling Applications: Isolate different parts of a circuit to prevent interference, ensuring that each component operates correctly.

- Audio Systems: Improve the performance of audio circuits by providing necessary filtering and stabilization.

- Renewable Energy Systems: Store energy generated from renewable sources like solar and wind, ensuring a consistent power supply.

- Automotive Electronics: Stabilize power in automotive circuits, enhancing the reliability of various electronic components.

- Industrial Machinery: Enhance the performance and longevity of industrial equipment by stabilizing power supply and reducing noise.

- Telecommunication Equipment: Ensure stable and reliable power delivery, which is critical for maintaining communication integrity.

Optimizing Circuit Performance with Capacitor in Parallel

To fully leverage the benefits of a capacitor in parallel configuration, consider the following optimization strategies:

- Selecting the Right Capacitance Values: Ensure that the total capacitance meets the circuit’s energy storage requirements. Use the capacitors in parallel formula to calculate the necessary values.

- Balancing Capacitance: Distribute capacitance evenly among capacitors to prevent overloading any single component, enhancing the system’s reliability.

- Choosing High-Quality Components: Use capacitors with low Equivalent Series Resistance (ESR) and high tolerance levels to improve performance and longevity.

- Thermal Management: Properly manage heat dissipation to prevent overheating, which can degrade capacitor performance and lifespan.

- Space Optimization: Arrange capacitors efficiently within the circuit to save space and maintain a compact design.

- Proper Ventilation: Ensure adequate airflow around capacitors to aid in cooling and prevent thermal buildup.

- Voltage Rating: Select capacitors with appropriate voltage ratings to handle the maximum voltage in the circuit without failure.

- Environmental Considerations: Choose capacitors that can withstand the environmental conditions in which they will operate, such as humidity, temperature, and vibration.

- Minimizing Parasitic Inductance: Use short leads and proper layout techniques to minimize parasitic inductance, which can affect high-frequency performance.

- Regular Maintenance: Periodically inspect and test capacitors to ensure they are functioning correctly and replace any that show signs of wear or failure.

Advanced Optimization Techniques

For more complex electronic systems, integrating capacitor in parallel with other components can achieve advanced functionalities:

- Parallel-Series Combinations: Combining parallel and series configurations allows for specific capacitance and voltage ratings tailored to unique circuit needs.

- Temperature Compensation: Use capacitors with temperature-stable characteristics to maintain consistent performance across varying temperatures.

- High-Frequency Applications: Select capacitors with low ESR and inductance for better performance in high-frequency circuits, ensuring minimal energy loss and signal distortion.

- Redundant Systems: Implement redundant capacitor in parallel to enhance system reliability, especially in critical applications like aerospace and medical devices.

- Power Factor Correction: Use parallel capacitors to improve the power factor in electrical systems, reducing energy losses and improving efficiency.

- Dynamic Voltage Regulation: Combine parallel capacitors with voltage regulators to maintain stable voltage levels under dynamic load conditions.

- Resonant Circuits: Integrate parallel capacitors in resonant circuits to fine-tune frequency responses and improve signal clarity.

- Noise Filtering: Use parallel capacitors to filter out unwanted noise and interference, enhancing the overall signal quality.

- Energy Harvesting Systems: Employ parallel capacitors to efficiently store energy harvested from various sources, such as kinetic or thermal energy.

- Smart Grid Applications: Utilize parallel capacitors in smart grids to manage energy distribution and enhance grid stability.

Choosing the Right Capacitor for Parallel Configurations

Selecting the appropriate capacitors for parallel configurations is essential to ensure optimal performance and longevity of your electronic circuits. Here are key factors to consider:

- Capacitance Value: Determine the required total capacitance using the capacitor in parallel formula. Ensure individual capacitors contribute appropriately to the overall capacitance.

- Voltage Rating: Each capacitor should have a voltage rating that meets or exceeds the maximum voltage in the circuit. This prevents breakdown and ensures safety.

- Equivalent Series Resistance (ESR): Lower ESR values are preferable for high-frequency applications and to reduce heat generation, enhancing overall efficiency.

- Physical Size: Ensure that the capacitors fit within the available space in the circuit design. Consider the form factor and mounting type.

- Temperature Range: Select capacitors that can operate effectively within the expected temperature range of the application environment.

- Tolerance: Choose capacitors with appropriate tolerance levels to ensure that the actual capacitance remains within the desired range, maintaining circuit performance.

- Type of Capacitor: Different types of capacitors (e.g., electrolytic, ceramic, film) offer varying performance characteristics. Select the type that best suits your application needs.

- Lifetime and Reliability: Consider the expected lifetime and reliability of the capacitors, especially for critical applications where failure is not an option.

- Cost: Balance the cost of capacitors with their performance and reliability to ensure that you are getting the best value for your investment.

- Manufacturer Reputation: Choose capacitors from reputable manufacturers known for quality and consistency to ensure dependable performance.

Types of Capacitors Suitable for Parallel Configurations

Various types of capacitors can be used in parallel configurations, each offering unique advantages:

-

Capacitor Type Advantages Applications Electrolytic Capacitors High capacitance values enhance energy storage and power filtering. Ideal for circuits requiring capacitor in parallel setups. Power supply filtering, energy storage systems, smoothing circuits. Ceramic Capacitors Perfect for high-frequency circuits and noise filtering. Complement capacitor in parallel with electrolytic capacitors for superior performance. Noise suppression, high-frequency circuits, decoupling in capacitor in parallel setups. Film Capacitors Known for stability and low ESR. Provide precision in capacitors in parallel formula calculations and advanced signal processing applications. Signal processing, audio systems, high-precision filtering in parallel capacitor configurations. Tantalum Capacitors Offer high capacitance in small sizes. Ideal for portable devices needing compact capacitor in parallel configurations. Portable electronics, small circuits, medical devices. Supercapacitors Deliver extremely high capacitance values for energy harvesting. Essential in high-capacity capacitor in parallel designs. Energy harvesting, backup power systems, renewable energy setups. Aluminum Capacitors Reliable and durable. Commonly used in capacitor in parallel configurations for power electronics requiring long-lasting performance. Power electronics, industrial circuits, motor drive systems. Polymer Capacitors Low ESR and high ripple current capability. Ideal for high-performance capacitors in parallel formula applications. High-speed circuits, computing systems, automotive electronics. Mica Capacitors Provide exceptional precision and stability. Suitable for high-frequency and RF capacitor in parallel configurations. RF applications, resonant circuits, communication devices. Glass Capacitors Highly reliable and stable. Designed for critical systems requiring accurate capacitors in parallel formula performance. Aerospace circuits, medical devices, critical safety equipment. Paper Capacitors Rarely used but valuable for vintage and specialized capacitor in parallel applications in legacy circuits. Vintage electronics, specialty circuits, restoration projects.

Design Considerations for Parallel Capacitor Configurations

When designing circuits with capacitor in parallel configurations, several important considerations ensure optimal performance:

- Layout and Placement: Proper placement of capacitors minimizes inductance and resistance, enhancing high-frequency performance and reducing noise.

- Connection Quality: Use secure and low-resistance connections to maintain the integrity of the parallel configuration and prevent performance degradation.

- Thermal Management: Implement adequate cooling solutions to dissipate heat generated by capacitors, especially in high-power applications.

- Component Matching: Use capacitors with similar specifications to ensure balanced charge distribution and prevent mismatches that can affect circuit performance.

- Protection Mechanisms: Incorporate protection elements such as fuses or diodes to safeguard against overvoltage and reverse polarity, which can damage capacitors.

- Grounding and Shielding: Proper grounding and shielding reduce electromagnetic interference (EMI) and enhance the overall stability of the parallel capacitor configuration.

- Redundancy Planning: Design parallel configurations with redundancy in mind to ensure continued operation even if one capacitor fails.

- Testing and Validation: Rigorously test parallel capacitor configurations under various operating conditions to validate performance and reliability.

- Compliance with Standards: Ensure that the design meets relevant industry standards and regulations for safety and performance.

- Future Scalability: Design parallel capacitor configurations with future expansion in mind, allowing for easy addition of capacitors as needed.

Common Challenges and Solutions in Capacitor in Parallel Configurations

While parallel capacitor configurations offer numerous benefits, they also present certain challenges. Here are common issues and their solutions:

- Imbalanced Capacitor Aging: Over time, capacitors may age at different rates, leading to imbalances. Solution: Use capacitors from the same batch and manufacturer to ensure consistent aging rates.

- Voltage Imbalance: Slight differences in voltage across capacitors can occur. Solution: Implement balancing resistors to equalize voltage distribution among parallel capacitors.

- Heat Dissipation: High-power applications can cause capacitors to overheat. Solution: Use capacitors with higher thermal ratings and ensure proper ventilation and cooling.

- Physical Space Constraints: Parallel configurations require more space. Solution: Optimize PCB layout and use surface-mount capacitors to save space.

- Cost Implications: Using multiple capacitors can increase costs. Solution: Balance the number of capacitors with performance needs and explore cost-effective capacitor types.

- Increased Complexity: Managing multiple capacitors adds complexity to the design. Solution: Use design software and thorough planning to manage and simplify the configuration.

- Parasitic Effects: Inductance and resistance can introduce parasitic effects. Solution: Use short, thick leads and proper layout techniques to minimize parasitic inductance and resistance.

- Reliability Concerns: More components mean more potential points of failure. Solution: Choose high-quality capacitors and design for redundancy to enhance overall system reliability.

- Compatibility Issues: Different capacitor types may not work well together. Solution: Use the same type and rating of capacitor in parallel configurations to ensure compatibility.

- Environmental Factors: Exposure to harsh environments can affect capacitors. Solution: Select capacitors with appropriate environmental ratings and protective coatings.

Advanced Topics of Capacitor in Parallel Configurations

For those seeking deeper knowledge, exploring advanced topics related to capacitor in parallel configurations can enhance your understanding and application capabilities:

- Dynamic Capacitance Adjustment: Techniques to dynamically adjust capacitance in parallel configurations based on real-time circuit requirements.

- Energy Efficiency Optimization: Strategies to maximize energy efficiency by optimizing parallel capacitor configurations in power circuits.

- Integration with Renewable Energy Sources: Combining parallel capacitors with renewable energy systems for effective energy storage and management.

- High-Density Capacitor Arrays: Designing compact, high-density parallel capacitor arrays for space-constrained applications.

- Capacitor Health Monitoring: Implementing systems to monitor the health and performance of capacitor in parallel configurations, ensuring timely maintenance and replacement.

- Hybrid Capacitor Systems: Integrating different types of capacitor in parallel to leverage their unique advantages for specific applications.

- High-Temperature Parallel Capacitor Designs: Designing parallel capacitor systems that can operate reliably in high-temperature environments.

- Noise Reduction Techniques: Advanced methods to minimize noise in parallel capacitor configurations, enhancing signal integrity.

- Capacitor Switching Networks: Utilizing switching networks to manage and control parallel capacitor configurations for varying circuit demands.

- Resonant Frequency Tuning: Adjusting parallel capacitor configurations to achieve desired resonant frequencies in oscillatory circuits.

Case Studies: Successful Implementations of Capacitor in Parallel Configurations

Examining real-world case studies can provide valuable insights into the effective use of capacitor in parallel configurations:

-

Industry Implementation Benefits Consumer Electronics A smartphone manufacturer used capacitor in parallel to stabilize power supplies and reduce voltage fluctuations. Enhanced device performance and extended battery life. Renewable Energy Solar systems employed parallel capacitors to increase energy storage capacity and ensure stable power during peak demand. Reliable energy delivery and optimized renewable energy storage. Telecommunications Parallel capacitor arrays filtered noise in communication devices, using the capacitors in parallel formula effectively. Clearer signal transmission and reduced interference. Industrial Machinery Capacitors in parallel improved motor start circuits for industrial equipment, reducing energy usage. Better motor performance and lower power consumption. Automotive Electronics Vehicle power systems incorporated parallel capacitors to stabilize voltage for critical electronic components. Improved stability and efficiency of onboard systems. Medical Devices Medical equipment used capacitor in parallel designs to ensure longevity and stable operation in critical conditions. Enhanced reliability and patient safety in life-critical applications. Aerospace Power systems in aerospace projects integrated capacitors in parallel to maintain stability under extreme environments. Stable and reliable power delivery for high-demand aerospace systems. Signal Processing Research labs optimized high-frequency circuits by applying capacitors in parallel configurations. Superior signal clarity and minimized distortion. Smart Grids Utility companies added parallel capacitors to smart grids for efficient energy distribution and improved grid stability. Higher energy efficiency and reduced system interruptions. Home Appliances Household appliances implemented capacitor in parallel to boost efficiency and reduce power consumption. Significant energy savings and improved appliance performance.

Why Choose Our Capacitor in Parallel Configurations?

Our capacitors are meticulously engineered to excel in capacitor in parallel setups. Here's why our products are the top choice for your electronic projects:

- Superior Reliability: Manufactured using high-quality materials, our capacitors ensure consistent performance and long-term reliability.

- Precision Engineering: Each capacitor is designed with precise capacitance values, ensuring optimal performance in parallel configurations.

- Wide Range of Options: We offer a diverse range of capacitance values and voltage ratings, allowing you to find the perfect fit for any application.

- Enhanced Durability: Our capacitors are built to withstand harsh environmental conditions, making them ideal for industrial and demanding applications.

- Competitive Pricing: High-quality does not mean expensive. We provide top-tier capacitors at competitive prices, ensuring value for your investment.

- Comprehensive Support: Our expert support team is available to assist you with selecting the right capacitors and optimizing your parallel configurations.

- Innovative Technology: We continuously invest in research and development to bring you the latest advancements in capacitor technology.

- Certifications and Standards: Our capacitors comply with international standards and certifications, ensuring safety and performance.

- Custom Solutions: We offer custom capacitor solutions tailored to your specific needs, ensuring the best fit for your unique applications.

- Fast and Reliable Shipping: Enjoy prompt delivery of your orders with our efficient shipping services, ensuring your projects stay on schedule.

Customer Success Stories

"Integrating your capacitor in parallel significantly improved the stability and efficiency of our power supply systems. Exceptional quality!" - Jane D., Electrical Engineer

"The precision and reliability of these capacitors are unmatched. They are perfect for our high-frequency communication devices." - Mark S., IT Specialist

"Using your capacitor in parallel configurations has enhanced our energy storage solutions, providing the performance we need for our projects." - Linda K., Renewable Energy Technician

"Your capacitors have been a game-changer in our automotive electronics, ensuring reliable performance under demanding conditions." - Tom R., Automotive Engineer

"The durability and performance of your capacitor in parallel setups have greatly extended the lifespan of our industrial machinery." - Susan M., Industrial Engineer

"Our medical devices rely on your capacitors for stable power delivery, ensuring patient safety and device reliability." - Dr. Emily T., Medical Device Specialist

"In our aerospace applications, your parallel capacitor configurations have provided the reliability and performance we need for critical missions." - Alex P., Aerospace Engineer

"Your capacitor in parallel have significantly reduced noise in our signal processing circuits, enhancing the clarity and reliability of our communications." - Brian L., Signal Processing Expert

"We appreciate the high-quality and competitive pricing of your capacitors, which have become an essential part of our consumer electronics products." - Rachel H., Consumer Electronics Designer

"Your excellent customer support helped us design the perfect parallel capacitor configuration for our smart grid project, ensuring optimal performance." - Kevin W., Smart Grid Specialist

FAQs

Q1: How do I calculate the total capacitance for capacitor in parallel?

A: To calculate the total capacitance of capacitor in parallel, simply add its individual capacitance values using the capacitors in parallel formula: Ceq = C1 + C2 + C3 + ...

Q2: What are the main advantages of using capacitors in parallel?

A: Using capacitors in parallel increases the total capacitance, improves charge distribution, enhances circuit stability, and provides design flexibility.

Q3: Can I mix different types of capacitors in parallel?

A: While it's possible to mix different types of capacitors in parallel, it's recommended to use capacitors with similar ratings and characteristics to ensure optimal performance and prevent imbalances.

Q4: What applications benefit most from parallel capacitor configurations?

A: Applications such as power supply filtering, energy storage systems, signal processing, motor start circuits, and decoupling applications benefit significantly from parallel capacitor configurations.

Q5: How does temperature affect capacitor in parallel?

A: Temperature can impact the performance and lifespan of capacitors. Using capacitors with temperature-stable characteristics and proper thermal management can mitigate these effects in parallel configurations.

Q6: What is the impact of Equivalent Series Resistance (ESR) in parallel capacitor configurations?

A: Lower ESR in parallel capacitor configurations reduces energy loss and heat generation, improving the overall efficiency and performance of the circuit.

Q7: How do I ensure proper balancing of capacitor in parallel?

A: To ensure proper balancing, use capacitors with similar capacitance and voltage ratings. Additionally, incorporating balancing resistors can help equalize voltage distribution among capacitors.

Q8: What are the best practices for mounting capacitor in parallel on a PCB?

A: Use short and wide traces to minimize inductance and resistance. Place capacitors close to the power supply and ground planes to ensure effective charge distribution and reduce noise.

Q9: Can parallel capacitor configurations be used in high-frequency applications?

A: Yes, parallel capacitor configurations can be optimized for high-frequency applications by selecting capacitors with low ESR and inductance, ensuring minimal energy loss and signal distortion.

Q10: How do parallel capacitors affect the overall size of an electronic device?

A: While adding capacitor in parallel increases the total capacitance, careful selection of compact capacitor types and efficient PCB layout can minimize the impact on the device's overall size.

For more detailed information on optimizing your circuits with capacitor in parallel configurations, visit our resources page.

© 2024 DXM Blog. All rights reserved.

Author: Ivan Huang

Recommended for you

What Is Positive Temperature Coefficient? Expert Guide on PTC Thermistors

Mastering Motor Start: Unleashing Efficiency with PTC Motor Starter for 2025 and Beyond

Unlocking the 103 Capacitor: An Essential Guide for Professionals

Where Can I Buy Resistors? Your Expert Sourcing Guide

How to Find Impedance of a Capacitor: Guide for Professionals

how to calibrate rtd pt100?

Logistics

How to track my order?

You can track your order through our official website or the order number provided and learn about the logistics status and delivery progress of your order at any time.

Does it support express delivery?

Yes, we support express delivery services. You can choose different delivery methods according to your needs, including ordinary express delivery and expedited express delivery.

Customized Services

Custom-made sample/order

SHENZHEN DXM TECHNOLOGY CO., LTD. are structured by high-tech talents from famous university

in China and accompanied with a batch of ceramic-sensitive components experts and technology

specialist, have powerful R&D and technology capabilities.DXM is one of a few manufacturers

master core production technology of ceramic-sensitive components in the world.

Samples and orders can be custom-made per customer’s requirements, as below:

1. Application environment of product

2. Required specifications or technical parameters

3. Reference sample

4. Reference drawing

Price and Payment

How are the prices of your products determined?

Our product prices are based on a variety of factors, including order quantity, customization requirements, and market competition.

What’s the Minimum Order Quantity (MOQ) and Minimum Order Amount (MOA)

MOQ: 10000PCS

You may also like

PT1000 Temperature Sensor: DXM Precision Platinum RTD Solutions

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2025 DXM | All Rights Reserved.

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd