10k PTC Thermistors: Enhancing Efficiency & Reliability

Discover the efficiency and reliability of DXM's 10k PTC thermistors. Ideal for temperature sensing and protection circuits, our PTC thermistors provide accurate performance and durability. Enhance your systems with DXM's advanced solutions. Experience superior thermal management with our trusted 10k PTC thermistor technology.

- Understanding the Power of 10k PTC Thermistors

- What is a 10k PTC Thermistor?

- How Does a 10k PTC Thermistor Work?

- Key Features of 10k PTC Thermistors

- Why Choose 10k PTC Thermistors?

- Applications of 10k PTC Thermistors Across Industries

- Automotive Industry

- Consumer Electronics

- Industrial Equipment

- HVAC Systems

- Medical Devices

- Renewable Energy Systems

- Telecommunications

- Advantages of Using 10k PTC Thermistors

- Reliability

- Durability

- Cost-Effectiveness

- Precision

- Fast Response Time

- Energy Efficiency

- Ease of Integration

- Key Parameters of 10K PTC Thermistors to Consider

- Selecting the Right 10k PTC Thermistors

- Installation and Maintenance Tips of PTC Thermistor

- Proper Installation

- Regular Maintenance

- Best Practices for 10k PTC Thermistors Maintenance

- Advanced Technical Insights of 10K PTC Thermistors

- Material Composition

- Thermal Stability

- Electrical Characteristics

- Response Time

- Integration in Circuit Design

- Case Studies and Real-World Applications of PTC Thermistors

- Automotive Battery Management

- Consumer Electronics Battery Protection

- Industrial Machinery Thermal Management

- Medical Device Temperature Monitoring

- Renewable Energy Systems

- Telecommunications Equipment Cooling

- Future Trends in PTC Thermistor Technology

- Miniaturization

- Enhanced Material Properties

- Smart Thermistors

- Energy Efficiency

- Customization

- FAQs: Everything You Need to Know About 10k PTC Thermistors

- What Makes a 10k PTC Thermistor Different from an NTC Thermistor?

- How Does Temperature Variation Impact PTC Thermistors?

- Are There Specific Storage Requirements for 10k PTC Thermistors?

- Can 10k PTC Thermistors Work in High-Frequency Applications?

- What Are the Common Failure Modes of 10k PTC Thermistors?

- How Does a 10k PTC Thermistor Enhance Circuit Protection?

- Which Industries Benefit Most from 10k PTC Thermistors?

- Are There Different Types of 10k PTC Thermistors?

- How Do 10k PTC Thermistors Compare to Other Temperature Sensors?

- What Maintenance Extends the Life of a 10k PTC Thermistor?

- Why Choose 10k PTC Thermistors?

PTC Thermistors are transforming the electronics landscape with their superior temperature sensing and circuit protection capabilities. Our 10k PTC Thermistor offers unparalleled reliability and efficiency, making it essential for a myriad of applications across diverse industries.

Understanding the Power of 10k PTC Thermistors

What is a 10k PTC Thermistor?

A 10k PTC Thermistor is a temperature-sensitive resistor characterized by a Positive Temperature Coefficient. At a reference temperature of 25°C, it exhibits a resistance of 10,000 ohms. As the temperature increases, the resistance of the PTC Thermistor rises sharply, providing effective overcurrent protection and precise temperature sensing.

How Does a 10k PTC Thermistor Work?

The core functionality of a 10k PTC Thermistor lies in its self-regulating temperature mechanism. When integrated into a circuit, it monitors the temperature continuously. Upon detecting an overheating condition, the thermistor's resistance increases significantly, thereby reducing the current flow. This immediate response protects sensitive electronic components from potential damage due to excessive heat or overcurrent scenarios.

Key Features of 10k PTC Thermistors

- Material Composition: Manufactured using high-purity ceramic materials, ensuring consistent and stable performance across various temperatures.

- Durability: Engineered to withstand harsh environmental conditions, making them suitable for long-term applications without degradation.

- Precision: Offers reliable and accurate resistance changes over a wide temperature range, essential for precise temperature monitoring.

- Fast Response Time: Quickly reacts to temperature changes, providing real-time protection and control in dynamic environments.

- Energy Efficiency: Contributes to reduced energy consumption by effectively managing temperature levels and preventing unnecessary power usage.

Why Choose 10k PTC Thermistors?

Opting for our 10k PTC Thermistors means investing in superior temperature control and robust circuit protection. These thermistors are versatile, finding applications in consumer electronics, automotive systems, industrial machinery, HVAC systems, and more. Their ability to seamlessly integrate into various designs without extensive modifications makes them a preferred choice for engineers and designers alike.

Applications of 10k PTC Thermistors Across Industries

Automotive Industry

In the automotive sector, 10k PTC Thermistors play a critical role in battery management systems and engine control units. They monitor battery temperatures, preventing overheating and extending battery life. Additionally, in engine management systems, these thermistors regulate coolant temperatures, ensuring optimal engine performance and preventing overheating-related failures.

Consumer Electronics

From smartphones to laptops, 10k PTC Thermistors manage battery temperatures, ensuring safe and efficient operation. They prevent thermal runaway during charging and discharging cycles, safeguarding devices from potential hazards and enhancing battery longevity.

Industrial Equipment

In industrial machinery, 10k PTC Thermistor provides essential thermal management, preventing overheating of critical components. Its integration in heaters and circuit protection systems ensures machinery operates within safe temperature ranges, reducing downtime and maintenance costs.

HVAC Systems

Heating, Ventilation, and Air Conditioning (HVAC) systems utilize 10k PTC Thermistors for precise temperature regulation. They monitor and control the temperatures of various components, optimizing energy consumption and maintaining comfortable indoor environments.

Medical Devices

In the medical field, 10k PTC Thermistor is indispensable in patient monitoring systems and therapeutic devices. It provides accurate temperature readings, ensuring patient safety and the reliable operation of medical equipment.

Renewable Energy Systems

As renewable energy technologies advance, 10k PTC Thermistors are increasingly used in solar panels and wind turbines. They monitor and regulate temperatures, ensuring the efficiency and longevity of energy storage systems and renewable installations.

Telecommunications

Telecommunication equipment generates significant heat, necessitating effective thermal management. 10k PTC Thermistor monitors temperatures within network equipment, preventing overheating and ensuring uninterrupted service.

Advantages of Using 10k PTC Thermistors

Reliability

10k PTC Thermistors are renowned for their stable and consistent performance. Their reliable resistance changes in response to temperature fluctuations make them a trusted choice for critical applications where consistent operation is paramount.

Durability

Designed to endure harsh conditions, these thermistors maintain their structural and functional integrity even in extreme environments. This durability ensures long-term usage without significant performance degradation.

Cost-Effectiveness

Offering a balance of affordability and high performance, 10k PTC Thermistors are a cost-effective solution for temperature sensing and circuit protection. Their long lifespan and minimal maintenance requirements further enhance their value proposition.

Precision

With tight tolerance levels, 10k PTC Thermistor provides precise temperature measurements. This precision is crucial for applications that demand exact temperature control, ensuring optimal performance and safety.

Fast Response Time

The rapid response of 10k PTC Thermistors to temperature changes ensures immediate protection and control. This fast reaction time is essential in dynamic environments where swift adjustments are necessary to maintain system stability.

Energy Efficiency

By effectively regulating temperature levels, 10k PTC Thermistor contributes to energy savings. It prevents energy wastage by ensuring systems operate within optimal temperature ranges, thereby enhancing overall energy efficiency.

Ease of Integration

With standardized resistance values and compact sizes, integrating 10k PTC Thermistors into existing designs is straightforward. Their versatility allows for seamless incorporation into a variety of circuit configurations without extensive modifications.

Key Parameters of 10K PTC Thermistors to Consider

When selecting a 10k PTC Thermistor, it's essential to evaluate several key parameters to ensure optimal performance in your specific application:

-

Parameter Description Nominal Resistance The resistance value at the reference temperature, typically 10,000 ohms at 25°C. This defines the baseline performance of PTC Thermistors. Response Time The speed at which the thermistor reacts to temperature changes. Fast response is crucial for immediate thermal regulation in sensitive circuits. Temperature Coefficient Indicates how resistance changes with temperature, showcasing the sensitivity and effectiveness of the 10k PTC Thermistor. Operating Temperature Range The temperature range where the PTC Thermistors function effectively without degradation. This ensures stability in various environments. Physical Size Ensures the thermistor fits within your device's design constraints. Compact 10k PTC Thermistors are ideal for space-limited applications. Environmental Durability The ability to withstand humidity, vibration, and chemical exposure. Critical for thermistor use in challenging environments. Electrical Characteristics Includes parameters like maximum current rating and power dissipation. These factors ensure compatibility with your circuit design. Long-Term Stability The thermistor’s ability to maintain consistent performance over its lifespan, ensuring reliable functionality in the long term.

Selecting the Right 10k PTC Thermistors

Choosing the appropriate 10k PTC Thermistor involves a careful assessment of your application's specific requirements. Consider factors such as the desired temperature range, response time, and environmental conditions. Additionally, evaluate the thermistor's electrical characteristics to ensure compatibility with your circuit design.

Consulting with manufacturers or suppliers can provide valuable insights and technical support, helping you select a thermistor that aligns with your performance and budgetary needs. It's also beneficial to consider future scalability and the potential for customization to accommodate evolving project demands.

Installation and Maintenance Tips of PTC Thermistor

Proper Installation

Correct installation is vital for the optimal functioning of 10k PTC Thermistors. Follow these guidelines to ensure reliable performance:

- Correct Placement: Position the thermistor where it can accurately monitor the temperature without interference from other heat sources or cooling elements.

- Secure Mounting: Firmly secure the thermistor to prevent movement or vibration, which could affect its accuracy and responsiveness.

- Proper Wiring: Use appropriate wiring techniques to connect the thermistor to your circuit. Ensure that connections are clean and free from corrosion to maintain consistent electrical performance.

- Ambient Conditions: Install the thermistor in an environment that matches its rated operating conditions. Avoid exposure to excessive moisture, dust, or corrosive substances unless the thermistor is specifically designed to withstand such environments.

- Orientation: Install the thermistor in the correct orientation as specified by the manufacturer to ensure accurate temperature sensing and response.

- Testing After Installation: After installation, test the thermistor to ensure it functions correctly within the circuit. Verify that it responds appropriately to temperature changes.

Regular Maintenance

Routine maintenance of 10k PTC Thermistors can prevent unexpected failures and extend their operational lifespan. Follow these maintenance tips:

- Periodic Inspections: Regularly inspect the thermistor for signs of wear, damage, or corrosion. Early detection of issues can prevent more significant problems down the line.

- Testing and Calibration: Periodically test the thermistor's resistance at the reference temperature to ensure it remains within specified tolerances. Calibration may be necessary to maintain accuracy.

- Cleaning: Keep the thermistor and its surrounding area clean to prevent contamination that could affect its performance. Use appropriate cleaning methods that do not damage the thermistor.

- Replacement: Replace the thermistor if it shows signs of significant wear or if it fails to meet performance specifications during testing.

- Documentation: Maintain records of maintenance activities, including inspection dates, test results, and any corrective actions taken. This documentation helps track the thermistor's performance over time.

- Environmental Monitoring: Continuously monitor the environmental conditions surrounding the thermistor to ensure they remain within acceptable ranges. Adjust protective measures as needed to maintain optimal conditions.

Best Practices for 10k PTC Thermistors Maintenance

To maximize the lifespan of 10k PTC Thermistors, adhere to the following best practices:

-

Best Practice Description Avoid Overheating Operate the PTC Thermistor within its specified temperature range to prevent thermal degradation and maintain performance. Minimize Mechanical Stress Handle the thermistor carefully during installation to avoid physical damage that may impair its functionality. Environmental Control Keep environmental conditions stable to prevent accelerated wear due to humidity, dust, or other external factors. Use Quality Components Pair the 10k PTC Thermistor with high-quality components to ensure overall system reliability and long-term performance. Proper Ventilation Provide adequate ventilation to dissipate heat efficiently and avoid localized overheating in the thermistor. Protective Coatings Apply protective coatings if necessary to shield the thermistor from corrosive environments or physical abrasion. Stress Testing Conduct stress tests during design phases to ensure the thermistor can handle expected operating conditions without failure.

Following these best practices ensures that your 10k PTC Thermistors remain effective and reliable throughout their service life, providing consistent performance in your applications.

Advanced Technical Insights of 10K PTC Thermistors

Material Composition

The performance of 10k PTC Thermistors is heavily influenced by their material composition. Typically, these thermistors are fabricated using barium titanate-based ceramics. The precise formulation of the ceramic material is crucial, as it determines the thermistor's resistance characteristics and thermal response. Additional dopants and additives are incorporated to enhance stability and performance, ensuring consistent resistance changes across a wide temperature range.

Thermal Stability

Thermal stability refers to the ability of a 10k PTC Thermistor to maintain consistent resistance changes in response to temperature fluctuations without significant drift over time. High thermal stability is essential for applications that involve continuous thermal cycling, ensuring reliable performance throughout the thermistor's lifespan. This stability is achieved through optimized design and manufacturing processes, which minimize resistance drift and enhance overall reliability.

Electrical Characteristics

The electrical characteristics of 10k PTC Thermistors include parameters such as resistance at the reference temperature (10k ohms at 25°C), temperature coefficient of resistance (TCR), and activation temperature. The TCR determines the rate at which resistance increases with temperature, influencing the thermistor's sensitivity and response time. The activation temperature is the threshold at which the thermistor begins to significantly increase its resistance, providing effective circuit protection.

Response Time

Response time is the duration it takes for a 10k PTC Thermistor to react to a change in temperature. A fast response time is critical in applications where immediate thermal regulation is necessary to prevent overheating or maintain precise temperature control. Factors influencing response time include thermal mass, thermal conductivity, and the intrinsic properties of the ceramic materials used. Optimizing these factors during manufacturing ensures that the thermistor can deliver the desired response times for various applications.

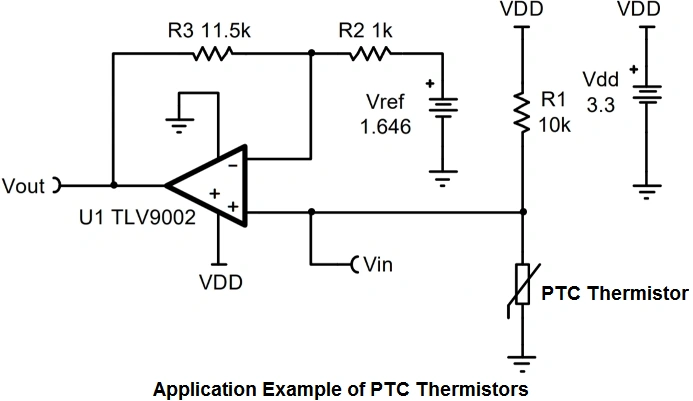

Integration in Circuit Design

Integrating 10k PTC Thermistors into circuit designs requires careful consideration of their electrical and thermal properties. In circuit protection applications, thermistors are typically connected in series with sensitive components. As temperature rises, the increasing resistance limits current flow, protecting the components from potential damage. In temperature sensing applications, thermistors are often part of a voltage divider or bridge circuit, providing accurate temperature readings essential for monitoring and control.

Understanding the interaction between 10k PTC Thermistor and other circuit elements, such as resistors and capacitors, is vital for optimizing circuit performance. Proper design and testing ensure that the thermistor functions as intended, providing reliable temperature control and protection.

Case Studies and Real-World Applications of PTC Thermistors

Automotive Battery Management

A leading automotive manufacturer integrated 10k PTC Thermistor into their battery management systems to enhance safety and performance. The thermistors effectively monitored battery temperatures, preventing overheating and extending battery life. This integration resulted in improved vehicle reliability and customer satisfaction.

By using 10k PTC Thermistors, the manufacturer was able to implement more efficient thermal management strategies, reducing the incidence of battery failures and enhancing the overall lifespan of the batteries. This application highlights the critical role of 10k PTC Thermistor in ensuring the safety and reliability of automotive battery systems.

Consumer Electronics Battery Protection

A major smartphone manufacturer employed 10k PTC Thermistors in their battery packs to manage thermal conditions. The thermistors provided real-time temperature regulation, preventing thermal runaway and ensuring safe charging and discharging cycles. This application significantly reduced the risk of battery-related incidents and enhanced user safety.

The integration of 10k PTC Thermistors in smartphone batteries allowed for more compact and efficient battery designs. By maintaining optimal temperature levels, the thermistors contributed to longer battery life and improved device performance, benefiting both manufacturers and consumers.

Industrial Machinery Thermal Management

An industrial equipment manufacturer used 10k PTC Thermistors in their heating systems to maintain optimal operating temperatures. The thermistors provided precise temperature control, preventing overheating and reducing maintenance costs. This implementation led to increased machinery uptime and operational efficiency.

The use of 10k PTC Thermistors in industrial heating systems ensured that equipment operated within safe temperature ranges, minimizing the risk of thermal damage and extending the lifespan of critical components. This case study demonstrates the effectiveness of 10k PTC Thermistors in enhancing the reliability and efficiency of industrial machinery.

Medical Device Temperature Monitoring

A medical device company integrated 10k PTC Thermistors into their patient monitoring systems. The thermistors offered accurate temperature readings, ensuring reliable patient data and enhancing the overall effectiveness of the monitoring systems. This application underscored the critical role of 10k PTC Thermistors in healthcare technology.

The precise temperature sensing capabilities of 10k PTC Thermistors enabled the medical device to provide real-time monitoring of patient vitals, facilitating timely interventions and improving patient outcomes. This integration highlights the importance of 10k PTC Thermistors in life-saving medical applications.

Renewable Energy Systems

A renewable energy company incorporated 10k PTC Thermistors into their solar panel systems to monitor and regulate temperature levels. The thermistors ensured that the solar panels operated within optimal temperature ranges, enhancing their efficiency and lifespan. This application contributed to more reliable and efficient renewable energy solutions.

By utilizing 10k PTC Thermistors, the company was able to implement advanced thermal management strategies that minimized energy losses and extended the operational life of their solar panels. This case study illustrates the role of 10k PTC Thermistors in supporting sustainable and efficient energy production.

Telecommunications Equipment Cooling

A telecommunications provider integrated 10k PTC Thermistors into their network equipment cooling systems. The thermistors provided real-time temperature monitoring, ensuring that cooling systems operated effectively and preventing overheating of critical components. This integration enhanced the reliability and performance of the telecommunications infrastructure.

The use of 10k PTC Thermistors in cooling systems allowed the provider to maintain optimal temperature levels within their equipment racks, reducing the risk of thermal-related failures and improving overall network stability. This application highlights the importance of 10k PTC Thermistors in maintaining the integrity of telecommunications systems.

Future Trends in PTC Thermistor Technology

Miniaturization

As electronic devices continue to shrink in size, the demand for miniature 10k PTC Thermistors is increasing. Advances in manufacturing techniques are enabling the production of smaller, more efficient thermistors without compromising their performance. These miniaturized thermistors are ideal for integration into ultra-compact devices such as wearable technology, portable medical devices, and micro-electronics.

Enhanced Material Properties

Research into new ceramic materials and composites is leading to PTC Thermistors with enhanced thermal and electrical properties. These advancements aim to increase the temperature range, response time, and overall reliability of thermistors, expanding their applicability across diverse industries. Enhanced material properties also contribute to greater durability and longevity, ensuring that PTC Thermistors remain effective in their roles over extended periods.

Smart Thermistors

The integration of smart technologies with 10k PTC Thermistors is an emerging trend. Smart thermistors can communicate temperature data wirelessly, enabling real-time monitoring and control in advanced applications such as IoT devices and smart home systems. These smart thermistors offer enhanced functionality, allowing for remote monitoring, data logging, and automated responses based on temperature changes.

Energy Efficiency

With a growing emphasis on energy efficiency, 10k PTC Thermistors are being designed to minimize power consumption while maintaining high performance. This focus aligns with global sustainability goals and the increasing demand for energy-efficient electronic solutions. Energy-efficient thermistors contribute to lower operational costs and reduced environmental impact, making them attractive options for applications where energy conservation is a priority.

Customization

Manufacturers are offering more customizable 10k PTC Thermistors to meet specific application requirements. Tailored resistance values, response times, and form factors allow for greater flexibility in design and application, catering to the unique needs of various industries. Customized thermistors enable designers to select components that precisely match their application specifications, enhancing system performance and reliability.

FAQs: Everything You Need to Know About 10k PTC Thermistors

What Makes a 10k PTC Thermistor Different from an NTC Thermistor?

A 10k PTC Thermistor increases resistance as temperature rises, while NTC thermistors do the opposite. This feature makes PTC Thermistors ideal for circuit protection, effectively limiting current during temperature surges.

How Does Temperature Variation Impact PTC Thermistors?

PTC Thermistors self-regulate by increasing resistance when temperatures rise. This ensures stable performance, prevents overheating, and maintains circuit integrity.

Are There Specific Storage Requirements for 10k PTC Thermistors?

Yes. Store 10k PTC Thermistors in a dry, moisture-controlled environment. Excessive humidity can degrade resistance properties and affect performance.

Can 10k PTC Thermistors Work in High-Frequency Applications?

Their use in high-frequency environments depends on their design. Always check the manufacturer's specifications for suitability in such applications.

What Are the Common Failure Modes of 10k PTC Thermistors?

Failure modes include thermal degradation, mechanical damage, and electrical overstress. Proper installation and routine maintenance can reduce these risks.

How Does a 10k PTC Thermistor Enhance Circuit Protection?

By increasing resistance during temperature surges, a 10k PTC Thermistor limits current flow, safeguarding sensitive components from overcurrent and overheating.

Which Industries Benefit Most from 10k PTC Thermistors?

Industries such as automotive, consumer electronics, HVAC, medical devices, and renewable energy rely on PTC Thermistors for their reliability and efficient temperature control.

Are There Different Types of 10k PTC Thermistors?

Yes, 10k PTC Thermistors come in various sizes, shapes, and materials. Choose based on operating conditions, response time, and physical constraints.

How Do 10k PTC Thermistors Compare to Other Temperature Sensors?

PTC Thermistors are self-regulating, cost-effective, and durable. Compared to NTC thermistors and RTDs, they excel in applications needing consistent temperature management.

What Maintenance Extends the Life of a 10k PTC Thermistor?

Regular inspections, proper handling, environmental control, and periodic calibration ensure longevity and reliability of 10k PTC Thermistors.

Why Choose 10k PTC Thermistors?

Reliable, durable, and versatile, 10k PTC Thermistors are critical for protecting and optimizing electronic circuits across diverse industries.

© 2024 DXM Blog. All rights reserved.

Author: Ivan Huang

Recommended for you

Water Temperature Sensor: The Key to Engine Health and Efficiency

Lightning Surge Protection Varistor: Essential for Protecting Your Electrical Systems

Water Temp Sensor: How to Test it for Reliable Performance?

Capacitor Impedance: Calculation Guide & FAQs

Temperature Probe Sensor: A Comprehensive Guide

Termistor NTC: What Does a Thermistor Do?

Customized Services

Custom-made sample/order

SHENZHEN DXM TECHNOLOGY CO., LTD. are structured by high-tech talents from famous university

in China and accompanied with a batch of ceramic-sensitive components experts and technology

specialist, have powerful R&D and technology capabilities.DXM is one of a few manufacturers

master core production technology of ceramic-sensitive components in the world.

Samples and orders can be custom-made per customer’s requirements, as below:

1. Application environment of product

2. Required specifications or technical parameters

3. Reference sample

4. Reference drawing

Free sample availability

You can contact our representative via email, fax or phone to specify the sample you need and provide your courier's account number (such as UPS, FedEx, DHL, TNT, etc.).. And we’ll send you samples free of charge through your courier by freight collection.

Price and Payment

Are invoices provided?

Yes, we provide legal invoices that can be used for reimbursement and accounting records.

How are the prices of your products determined?

Our product prices are based on a variety of factors, including order quantity, customization requirements, and market competition.

Logistics

Is your logistics and distribution service reliable?

Yes, we cooperate with a number of well-known logistics companies to ensure the timeliness and reliability of logistics and distribution services and provide you with a satisfactory distribution experience.

You may also like

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd