The Complete Guide to Ceramic Heater and Heating Element

Discover the unmatched efficiency of DXM's Ceramic Heater and Heating Element. Our comprehensive guide dives into the advanced technology behind our Ceramic Heater Element, showcasing its durability and superior heating performance. Trust DXM for your heating needs, and experience cutting-edge solutions that enhance comfort and energy efficiency. Learn why our Ceramic Heating Element sets the industry standard.

- Understanding Ceramic Heater Element

- Types of Ceramic Heater Element

- Ceramic Infrared Heating Element

- PTC Ceramic Heater Element

- Ceramic Band Heaters

- Benefits of Using Ceramic Heating Element

- Energy Efficiency

- Longevity and Robustness

- Versatility in Applications

- Optimal Usage and Maintenance

- Installation Guidelines

- Regular Maintenance

- Troubleshooting Common Issues

- Why Choose Our Ceramic Heater Element

- FAQs About Ceramic Heater Element

- Are Ceramic Heater Elements Safe to Use?

- How Do I Choose the Right Ceramic Heater Element?

- Can Ceramic Heater Elements Operate Continuously?

- What Makes Ceramic Heater Element More Efficient Than Traditional Heaters?

- How Long Do Ceramic Heater Elements Last?

- Which Industries Benefit Most from Ceramic Heating Elements?

- Can Ceramic Heater Element Be Customized?

- What Maintenance Practices Are Recommended?

Ceramic Heater Element delivers efficient heating solutions. Its robust structure ensures durability and uniform heat distribution. The Ceramic Heating Element effectively converts electricity into heat, guaranteeing reliable performance. Benefits include energy efficiency, rapid heating, and enhanced safety features. Our guide offers professional insights to optimize your Ceramic Heater Element for improved performance and longevity. Trust our expertise to enhance your applications with superior Ceramic Heating Elements technology, ensuring consistent and dependable heating in all your projects.

Understanding Ceramic Heater Element

The Ceramic Heater Element is a pivotal component in modern heating systems. By efficiently converting electrical energy into heat, it ensures consistent and reliable warmth across various applications. The durability of the Ceramic Heating Element makes it a preferred choice in both industrial and residential settings.

Constructed from high-grade ceramic materials, the Ceramic Heater Element offers excellent electrical insulation and thermal stability. This composition not only enhances its lifespan but also ensures safe operation under extreme temperatures. The structural integrity of the Ceramic Heating Element allows it to withstand harsh environments, making it ideal for continuous use in demanding applications.

Moreover, the design of the Ceramic Heater Element facilitates even heat distribution, preventing hotspots and ensuring uniform heating. This is crucial in applications where precise temperature control is necessary, such as in industrial ovens and space heaters.

Types of Ceramic Heater Element

Ceramic Infrared Heating Element

The Ceramic Infrared Heating Element is designed for applications requiring radiant heating. It efficiently transmits heat over distances without significantly warming the surrounding air, making it ideal for targeted heating solutions. This type of Ceramic Heating Element is commonly used in outdoor heating systems and industrial processes where direct heat application is necessary.

Infrared heating with Ceramic Heater Element offers several advantages, including energy efficiency and reduced heat loss. By focusing heat directly on the desired area, it minimizes waste and enhances overall heating performance.

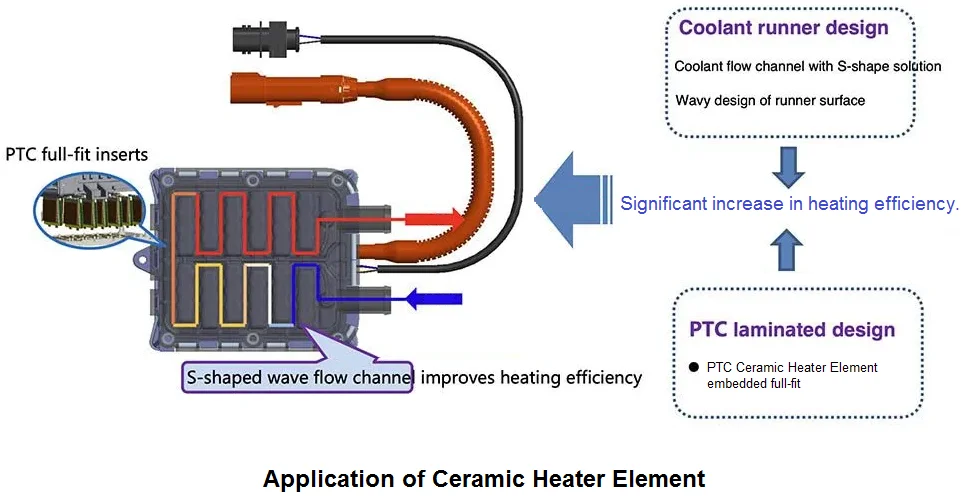

PTC Ceramic Heater Element

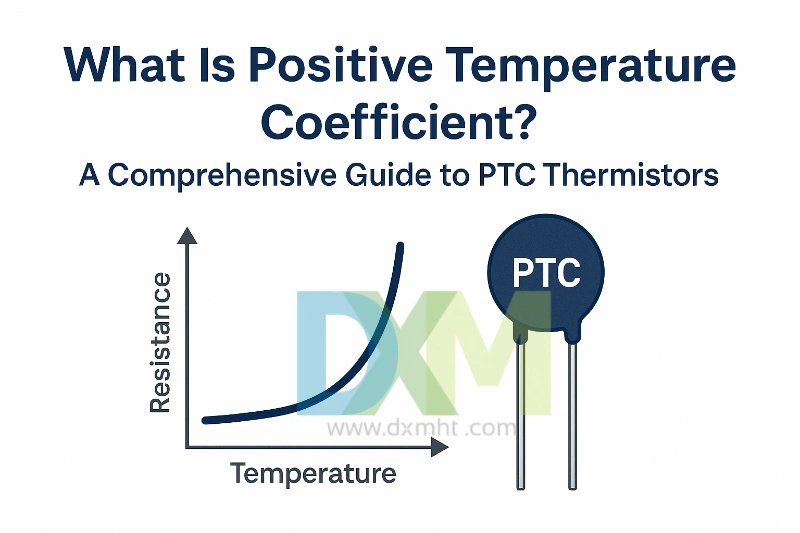

PTC Ceramic Heater Element features a Positive Temperature Coefficient, making it self-regulating. This means it naturally limits the current as the temperature rises, preventing overheating and ensuring safer operation. The self-regulating nature of PTC elements eliminates the need for external temperature controls, simplifying the heating system design.

Additionally, PTC Ceramic Heating Element responds quickly to temperature changes, providing rapid heating and cooling cycles. This responsiveness makes it suitable for applications where temperature control and safety are paramount, such as in automotive heating systems and electronic devices.

Ceramic Band Heaters

Ceramic Heating Element in band heaters is specifically designed to heat cylindrical objects uniformly. These are crucial in manufacturing processes where consistent thermal distribution is essential for product quality and efficiency. The band heaters wrap around pipes, tanks, and other cylindrical equipment, providing steady and reliable heat.

The uniform heating capability of Ceramic Heater Element in band heaters ensures that the entire surface of the object is heated evenly, preventing thermal stress and deformation. This is vital in industries such as food processing, chemical manufacturing, and metalworking.

Benefits of Using Ceramic Heating Element

Energy Efficiency

Ceramic Heater Element stands out for its energy-efficient characteristics. It provides more heat per watt compared to traditional heating solutions, effectively lowering energy costs and reducing the environmental footprint. The high energy efficiency of Ceramic Heating Element ensures that less power is wasted, making it a cost-effective choice for long-term use.

Moreover, the ability of Ceramic Heater Element to deliver consistent heat ensures that heating systems operate optimally without unnecessary energy consumption. This efficiency is particularly beneficial in large-scale industrial applications where energy costs can significantly impact overall operational expenses.

Longevity and Robustness

The durable nature of Ceramic Heating Element ensures it remains functional over extended periods, even under strenuous conditions. This minimizes the need for frequent replacements, offering cost savings and reliability. The robust construction of Ceramic Heater Element allows it to withstand high temperatures and mechanical stress, making it suitable for continuous operation in demanding environments.

Additionally, the resistance to corrosion and wear of Ceramic Heating Elements extend their lifespan, reducing maintenance requirements and downtime. This durability is essential in industrial settings where consistent performance is critical to maintaining production schedules and product quality.

Versatility in Applications

Ceramic Heating Element is highly adaptable, serving both commercial and residential heating needs. From small household appliances like toasters and hairdryers to large industrial machinery, its versatility makes it an indispensable component in various sectors. The wide range of applications for Ceramic Heater Elements include space heaters, ovens, dryers, and HVAC systems.

The adaptability of Ceramic Heating Element extends to its ability to operate efficiently in different environments, whether it be in high-humidity areas or extreme temperatures. This makes it a reliable choice for diverse applications, ensuring that heating systems remain effective and efficient regardless of the operating conditions.

Optimal Usage and Maintenance

Installation Guidelines

Proper installation of the Ceramic Heater Element is crucial for maintaining operational efficiency and extending its lifespan. Adhering to manufacturer instructions ensures optimal performance and safety. It is important to follow the specified installation procedures, including securing the element correctly and ensuring adequate ventilation to prevent overheating.

Additionally, selecting the appropriate mounting hardware and ensuring that the Ceramic Heating Element is positioned correctly within the heating system can enhance its efficiency and durability. Proper installation also involves verifying electrical connections and ensuring that all safety features, such as thermal cutoffs, are functional.

Regular Maintenance

Routine checks for wear and tear, as well as regular cleaning, are essential for the Ceramic Heating Element. This is especially important in environments prone to dust or residue, ensuring sustained performance and safety. Regular maintenance involves inspecting the element for signs of damage, such as cracks or discoloration, and addressing any issues promptly to prevent further deterioration.

Cleaning the Ceramic Heater Elements regularly help maintain their efficiency by removing any buildup that could impede heat transfer. Using appropriate cleaning agents and techniques ensures that the element remains free from contaminants without causing damage to its structure.

Troubleshooting Common Issues

Addressing common issues such as inconsistent heating or abnormal noise promptly can minimize downtime and prevent further damage to your Ceramic Heating Elements. Regular maintenance plays a key role in this process. For instance, uneven heating may indicate a problem with the electrical connections or the presence of contaminants on the element's surface.

Abnormal noises, such as buzzing or humming, could signal issues with the electrical current or mechanical stress on the element. Identifying and rectifying these problems early ensures that the Ceramic Heater Element continues to operate efficiently and safely, prolonging its lifespan and maintaining the integrity of the heating system.

-

Why Choose Our Ceramic Heater Element

- Our Ceramic Heater Element products are engineered with precision to meet the highest standards of efficiency and durability. Whether for industrial applications or residential use, our elements deliver unmatched performance and longevity. We utilize advanced manufacturing techniques to ensure each Ceramic Heating Element meets stringent quality controls, providing reliable and consistent heating solutions.

Investing in our Ceramic Heating Element means choosing a reliable partner for your heating needs, backed by expert support and innovative technology. Our commitment to excellence ensures that you receive products that not only meet but exceed your expectations, providing optimal heating performance and long-term value.

Additionally, our Ceramic Heater Element is backed by comprehensive warranties and customer support, ensuring that any issues are promptly addressed and resolved. This dedication to customer satisfaction sets us apart as a trusted leader in the heating solutions industry.

Implementing the Ceramic Heater Element ensures efficient, versatile, and robust heating solutions. Trust our expertise to enhance your applications with superior Ceramic Heating Elements technology, providing consistent and dependable heating across all your projects. By choosing our Ceramic Heater Elements, you are investing in a solution that offers unparalleled performance, durability, and energy efficiency, meeting the highest standards of quality and reliability.

FAQs About Ceramic Heater Element

Are Ceramic Heater Elements Safe to Use?

Yes, Ceramic Heater Elements are designed with built-in safety features. They include thermal cutoffs to prevent overheating, ensuring safe operation across various applications.

How Do I Choose the Right Ceramic Heater Element?

When selecting a Ceramic Heater Element, consider your specific application, required heat range, and environmental factors. This will help you choose the best Ceramic Heating Element for your needs.

Can Ceramic Heater Elements Operate Continuously?

Yes, Ceramic Heater Elements can operate continuously if they are rated for such use. Proper maintenance is necessary to avoid wear and ensure reliable performance.

What Makes Ceramic Heater Element More Efficient Than Traditional Heaters?

Ceramic Heating Elements generate more heat per watt, significantly reducing energy consumption and operational costs compared to traditional heaters.

How Long Do Ceramic Heater Elements Last?

With proper maintenance, Ceramic Heater Elements can last several years. Regular maintenance minimizes the need for frequent replacements and ensures long-term reliability.

Which Industries Benefit Most from Ceramic Heating Elements?

Industries like manufacturing, residential heating, and appliance production benefit from the durability and efficiency of Ceramic Heater Element. Its versatility makes it ideal for various applications.

Can Ceramic Heater Element Be Customized?

Yes, Ceramic Heater Elements can be tailored to meet specific application needs, ensuring maximum performance and compatibility.

What Maintenance Practices Are Recommended?

Regular inspections, cleaning to remove dust and residue, and following manufacturer guidelines are essential to maintain the performance and safety of Ceramic Heating Elements.

For more information and to explore our range of Ceramic Heater Element, visit our product page. Ready to upgrade your heating solutions? Experience the efficiency and durability of Ceramic Heater Element today!

© 2024 DXM Blog. All rights reserved.

Author: Ivan Huang

Recommended for you

What Is Positive Temperature Coefficient? Expert Guide on PTC Thermistors

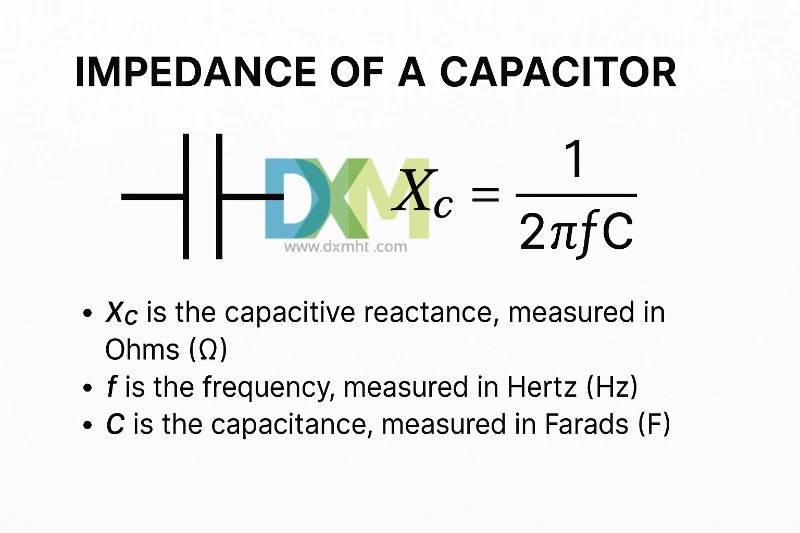

How to Find Impedance of a Capacitor: Guide for Professionals

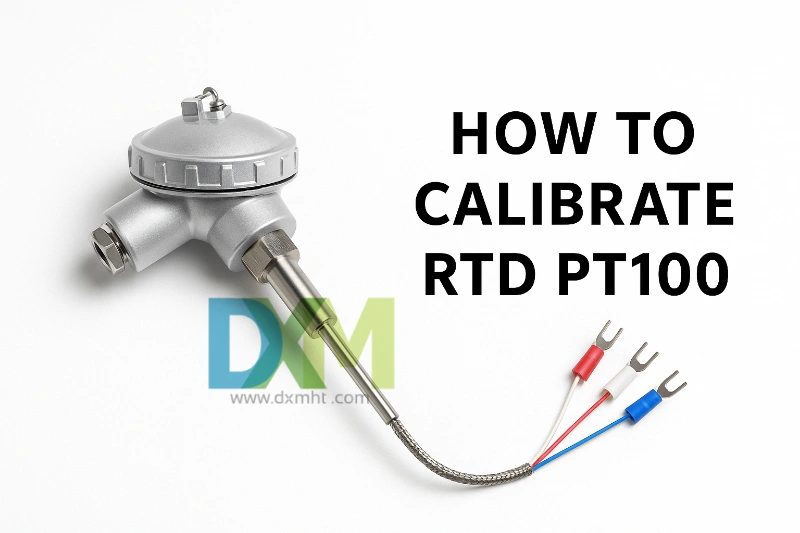

how to calibrate rtd pt100?

Capacitor 104 Value: Essential Guide for Electronics Professionals

Positive Temperature Coefficient Heater: An Essential Guide of PTC Heater

What is an Electronic Ballast PTC Thermistor? Insights from DXM.

Price and Payment

How are the prices of your products determined?

Our product prices are based on a variety of factors, including order quantity, customization requirements, and market competition.

Payment Terms

There are a number of different payment methods that can be used when you deal with us. Two are mostly used: T/T payment in advance for small values and irrevocable L/C at sight for large values.

Customized Services

Free sample availability

You can contact our representative via email, fax or phone to specify the sample you need and provide your courier's account number (such as UPS, FedEx, DHL, TNT, etc.).. And we’ll send you samples free of charge through your courier by freight collection.

Can I customize (OEM) the product?

Yes. You can customize the product with DXM. Our R&D and production technology have already reached an advanced world level, and we can provide qualified OEM service for global customers.Please specify your requirements to our representative or send samples to our factory office, and we will confirm your details.

Logistics

How to track my order?

You can track your order through our official website or the order number provided and learn about the logistics status and delivery progress of your order at any time.

You may also like

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2025 DXM | All Rights Reserved.

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd