104 Capacitor: Mastering the Features, Applications, and Advantages

Explore the comprehensive world of DXM's 104 Capacitor. Discover its unmatched features, diverse applications, and significant advantages. Designed for efficiency, our capacitors meet the highest industry standards, ensuring optimal performance and reliability. Ideal for various electronic projects, the 104 capacitor is your go-to choice for superior quality. Enhance your circuits with DXM's trusted capacitors 104 today.

- What is a 104 Capacitor?

- Key Features of the 104 Capacitor

- Applications of 104 Capacitor in Modern Electronics

- 1. Power Supply Filtering

- 2. Signal Coupling and Decoupling

- 3. Frequency Filtering

- 4. Timing Circuits

- Roles of 104 Capacitors in the Circuit

- Why Choose 104 Capacitor for Your Electronic Projects?

- Advantages of Using 104 Capacitor in Electronic Circuits

- 1. Enhanced Stability

- 2. Improved Efficiency

- 3. Space-Saving Design

- 4. Broad Operating Range

- 5. Longevity and Durability

- 6. High-Frequency Performance

- 7. Cost-Effectiveness

- 8. Easy Integration

- Selecting the Right 104 Capacitor for Your Application

- Manufacturing and Quality Standards for 104 Capacitor

- Environmental Impact and Sustainability of 104 Capacitor

- Common Challenges and Solutions in Using 104 Capacitor

- 1. Temperature Sensitivity

- 2. Voltage Spikes

- 3. Physical Stress

- 4. Aging and Degradation

- 5. Parasitic Inductance and Resistance

- Advancements in 104 Capacitor Technology

- Summary

- Case Studies: 104 Capacitor in Action

- Case Study 1: Power Supply Design

- Case Study 2: Audio Equipment Enhancement

- Case Study 3: Microcontroller Timing Circuits

- Future Trends in 104 Capacitor Usage

- How to Test 104 Capacitor

- 1. Visual Inspection

- 2. Capacitance Measurement

- 3. Equivalent Series Resistance (ESR) Testing

- 4. Leakage Current Testing

- 5. Impedance Analysis

- 6. Temperature Cycling

- 7. Frequency Response Testing

- Best Practices for Soldering 104 Capacitor

- Summary

- Common Misconceptions About 104 Capacitor

- Misconception 1: 104 Capacitor Ia Only Used in High-Voltage Applications

- Misconception 2: All 104 Capacitors Are Ceramic

- Misconception 3: 104 Capacitors Are Polarized

- Misconception 4: Higher Voltage Ratings Are Always Better

- Misconception 5: 104 Capacitor Is Not Suitable for High-Frequency Applications

- Comparing 104 Capacitor with Other Capacitor Types

- 104 Capacitor vs. Electrolytic Capacitor

- 104 Capacitors vs. Film Capacitors

- 104 Capacitor vs. Tantalum Capacitor

- 104 Capacitors vs. Advanced Ceramic Capacitors

- Where to Buy 104 Capacitor

- Maintaining 104 Capacitor for Optimal Performance

- Expert Tips for Working with 104 Capacitor

- Conclusion

- FAQs on 104 Capacitor

- Q1: Can I replace a 104 capacitor with another value?

- Q2: Is 104 capacitor polarized?

- Q3: What is the typical operating temperature range of a 104 capacitor?

- Q4: How long does 104 capacitor typically last?

- Q5: Can 104 capacitors be used in both AC and DC applications?

In the intricate world of modern electronics, the 104 capacitor plays a pivotal role in ensuring stable and efficient circuit operations. Revered for its reliability and versatility, capacitors 104 are indispensable for both seasoned engineers and enthusiastic hobbyists. This comprehensive guide delves into the essential aspects of the 104 capacitor, highlighting its key features, diverse applications, and the numerous advantages it offers in various electronic systems.

What is a 104 Capacitor?

The 104 capacitor is a widely recognized component in electronics, identified by its industry-standard code. The '104' marking signifies a capacitance of 100,000 picofarads (pF), which is equivalent to 0.1 microfarads (µF). This non-polarized component is meticulously designed to store and release electrical energy efficiently, making it a critical element in numerous electronic circuits.

Key Features of the 104 Capacitor

- Capacitance: 0.1 µF or 100nF

- Voltage Ratings: Commonly ranges between 50V and 1000V

- Design: Typically ceramic or disc-shaped for compactness

- Tolerance: ±5% to ±20%

- Temperature Range: Operates between -25°C and 85°C

- Non-Polarized: Can be installed in any direction

- Low Equivalent Series Resistance (ESR): Enhances performance in high-frequency applications

- Compact Size: Facilitates integration into space-constrained circuits

These robust features make the 104 capacitor a preferred choice in a multitude of electronic applications. Its precise capacitance, wide voltage ratings, and reliable performance ensure that capacitors 104 seamlessly integrate into various circuit designs, enhancing functionality and longevity.

Applications of 104 Capacitor in Modern Electronics

The versatility of the 104 capacitor allows it to be employed across a broad spectrum of electronic systems. Below are some of the most prevalent applications:

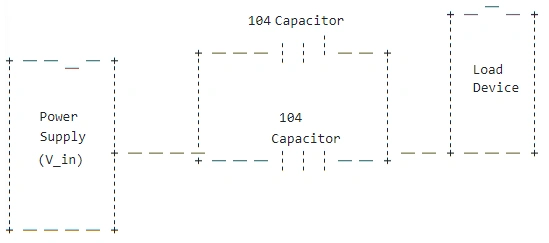

1. Power Supply Filtering

In power supply circuits, 104 capacitors play a pivotal role in smoothing out voltage fluctuations. By filtering out noise and stabilizing the voltage, these capacitors ensure a steady power supply to sensitive electronic components, thereby enhancing the overall performance and longevity of the device.

2. Signal Coupling and Decoupling

When it comes to signal processing, capacitors 104 are essential for separating alternating current (AC) and direct current (DC) signals. This capability allows for effective signal coupling and decoupling, preventing interference and ensuring clear signal transmission within the circuit.

3. Frequency Filtering

In audio equipment and other frequency-sensitive applications, 104 capacitors are utilized to filter specific frequency ranges. By reducing unwanted noise and enhancing desired signals, these capacitors contribute to superior audio quality and overall system performance.

4. Timing Circuits

Timing circuits, such as oscillators and microcontrollers, heavily rely on the precise timing capabilities of 104 capacitors. These capacitors assist in generating accurate timing intervals, which are critical for the synchronized operation of various electronic functions.

Roles of 104 Capacitors in the Circuit

- Decoupling: Stabilizes the power supply by smoothing out voltage fluctuations and filtering high-frequency noise.

- Filtering: Removes unwanted AC signals, ensuring clean DC voltage reaches the load device.

- Transient Response: Provides immediate charge during sudden load changes to prevent voltage dips.

- Noise Suppression: Reduces electromagnetic interference (EMI) and radio frequency interference (RFI).

The use of 104 capacitors in power supply circuits is essential for ensuring stable operation, reducing noise, and improving overall circuit reliability.

Why Choose 104 Capacitor for Your Electronic Projects?

Opting for 104 capacitors offers a multitude of benefits that make them a top choice for electronic designs:

- Reliability: Known for their consistent performance and durability.

- Affordability: Cost-effective, making them accessible for a wide range of projects.

- Wide Availability: Easily obtainable from various suppliers, ensuring quick sourcing.

- Versatility: Suitable for multiple applications, reducing the need for different capacitor types.

- Compact Size: Facilitates integration into space-constrained designs.

- Low ESR: Enhances performance in high-frequency and high-speed applications.

- Non-Polarized: Simplifies installation by allowing bidirectional use.

- Stable Performance: Maintains capacitance over a wide temperature and voltage range.

The reliability and affordability of 104 capacitors make them a staple in both professional and hobbyist electronics toolkits. Their wide availability ensures that engineers can quickly integrate these capacitors into their designs without delays, fostering efficiency and productivity.

Advantages of Using 104 Capacitor in Electronic Circuits

The 104 capacitor offers several advantages that significantly enhance electronic circuit performance:

1. Enhanced Stability

By providing stable voltage levels, capacitors 104 contribute to the overall stability of electronic circuits. They minimize the risk of voltage spikes and fluctuations that could potentially damage sensitive components, ensuring reliable operation under varying electrical conditions.

2. Improved Efficiency

The efficient energy storage and release capabilities of 104 capacitor ensures that circuits operate smoothly. This reduces energy wastage and improves overall system efficiency, making it ideal for power-sensitive applications.

3. Space-Saving Design

With their compact ceramic or disc-shaped designs, 104 capacitor occupies minimal space on circuit boards. This allows for more streamlined and compact electronic devices, which is particularly beneficial in applications where space is at a premium.

4. Broad Operating Range

The ability of 104 capacitor to operate across a wide voltage range makes them suitable for diverse applications, from low-voltage consumer electronics to high-voltage industrial systems. This versatility ensures that a single type of capacitor can meet the needs of various circuit designs.

5. Longevity and Durability

104 capacitor is engineered to withstand prolonged use and harsh environmental conditions. Its robust construction ensures longevity, reducing the need for frequent replacements and maintenance.

6. High-Frequency Performance

Thanks to their low Equivalent Series Resistance (ESR) and low inductance, 104 capacitor performs exceptionally well in high-frequency applications. It is ideal for use in RF circuits, switching power supplies, and high-speed digital circuits.

7. Cost-Effectiveness

Compared to other capacitor types, 104 capacitors offer a balance of performance and affordability. Their cost-effectiveness makes them accessible for large-scale production and various budget constraints without compromising on quality.

8. Easy Integration

The non-polarized nature and standardized packaging of 104 capacitors simplify their integration into electronic designs. This ease of use accelerates the design and prototyping phases, facilitating faster development cycles.

Selecting the Right 104 Capacitor for Your Application

Choosing the appropriate 104 capacitor is crucial for ensuring optimal performance and reliability in your electronic circuits. Several factors must be considered during the selection process:

- Capacitance Value: Ensure the 0.1 µF capacitance aligns with the circuit's requirements. Deviations can lead to altered circuit behavior.

- Voltage Rating: Select a capacitor with a voltage rating that exceeds the maximum voltage present in the circuit to prevent breakdown.

- Tolerance: Choose a tolerance level that matches the precision needed for your application. Lower tolerance capacitors offer more precise capacitance values.

- Temperature Range: Verify that the capacitor can operate within the expected environmental conditions of your application.

- Physical Size: Consider the available space on the circuit board and select a capacitor that fits without compromising other components.

- ESR and ESL: For high-frequency applications, select capacitors with low ESR and Equivalent Series Inductance (ESL) to ensure optimal performance.

- Material Type: Decide between ceramic, tantalum, or other material types based on the specific needs of your application.

- Manufacturer and Quality: Choose capacitors from reputable manufacturers to ensure reliability and adherence to quality standards.

Proper selection of 104 capacitors is essential for the reliable and efficient operation of electronic circuits. Always refer to the specific requirements of your application and consult manufacturer datasheets to make informed decisions.

Manufacturing and Quality Standards for 104 Capacitor

High-quality 104 capacitors are manufactured under stringent quality control standards to ensure their performance and reliability. Key aspects of manufacturing include:

- Material Quality: Utilization of premium ceramic materials ensures consistent capacitance and low loss, contributing to the overall performance of the capacitor.

- Precision Manufacturing: Advanced manufacturing techniques maintain tight tolerance levels, ensuring each capacitor meets its specified capacitance and voltage ratings.

- Testing: Rigorous testing procedures, including capacitance measurement, ESR testing, and temperature cycling, verify performance under various conditions.

- Compliance: Adherence to international standards such as IEC, RoHS, and UL certifications ensures that capacitors 104 meet global quality and safety benchmarks.

- Quality Assurance: Continuous monitoring and quality assurance processes during manufacturing prevent defects and ensure the longevity of the capacitors.

- Environmental Controls: Manufacturing environments are controlled to prevent contamination and ensure the integrity of the ceramic materials used.

Selecting capacitors 104 from reputable manufacturers ensures compliance with these standards, providing peace of mind regarding their performance and longevity in your electronic designs.

Environmental Impact and Sustainability of 104 Capacitor

As the electronics industry increasingly prioritizes sustainability, the environmental impact of components like the 104 capacitor gains significant importance. Manufacturers are adopting eco-friendly practices to minimize the environmental footprint of their products, including:

- RoHS Compliance: Restricting the use of hazardous substances such as lead, mercury, and cadmium in electronic components to reduce environmental and health risks.

- Recyclable Materials: Utilizing materials that can be easily recycled to promote sustainability and reduce waste.

- Energy-Efficient Manufacturing: Implementing manufacturing processes that minimize energy consumption and reduce greenhouse gas emissions.

- Eco-Friendly Packaging: Using recyclable or biodegradable packaging materials to lessen environmental impact.

- Lifecycle Assessments: Conducting assessments to understand and mitigate the environmental impact of capacitors throughout their lifecycle, from production to disposal.

- Waste Reduction: Implementing strategies to reduce waste generated during manufacturing and promote the reuse of materials.

By selecting 104 capacitors that adhere to these sustainability practices, engineers and designers can contribute to environmentally responsible electronic design, aligning with global efforts to promote sustainability and reduce environmental impact.

Common Challenges and Solutions in Using 104 Capacitor

While 104 capacitors are highly reliable, certain challenges may arise during their application. Understanding these challenges and implementing appropriate solutions is key to successful circuit design:

1. Temperature Sensitivity

High temperatures can adversely affect the performance of 104 capacitors. To mitigate this, select capacitors with higher temperature ratings suitable for your application. Additionally, ensure adequate cooling within the circuit design to prevent overheating and maintain optimal performance.

2. Voltage Spikes

Unexpected voltage spikes can damage 104 capacitors. Incorporating protective elements such as varistors or transient voltage suppression (TVS) diodes can safeguard against such occurrences. These protective components help absorb excess voltage, preventing it from reaching the capacitors and other sensitive components.

3. Physical Stress

Mechanical stress during soldering or assembly can crack ceramic 104 capacitors. Handle components with care and use appropriate soldering techniques to prevent physical damage. Employing stress-relief mechanisms in the circuit design can also reduce the risk of mechanical stress on capacitors.

4. Aging and Degradation

Over time, 104 capacitors can experience aging and degradation, leading to reduced capacitance and increased ESR. Regular testing and monitoring of capacitor health can identify potential issues early. Selecting capacitors with longer lifespans and higher reliability ratings can also mitigate this challenge.

5. Parasitic Inductance and Resistance

Parasitic inductance (ESL) and resistance (ESR) can impact the performance of 104 capacitors in high-frequency applications. Choosing capacitors with low ESL and ESR specifications is crucial for maintaining performance. Additionally, optimizing the layout of the circuit board to minimize parasitic elements can enhance capacitor performance.

Advancements in 104 Capacitor Technology

The field of capacitor technology is continuously evolving, with innovations enhancing the performance and capabilities of 104 capacitors. Recent advancements include:

| Advancement | Description |

| Improved Dielectric Materials | New ceramic materials enhance the 104 capacitor. They deliver better temperature stability and lower losses, ensuring reliable performance in all applications. |

| Miniaturization | 104 capacitors are now smaller, with no compromise on performance. Compact designs make them ideal for devices with limited space, like IoT and wearable technology. |

| Enhanced Reliability | Advanced manufacturing processes improve the durability of capacitors 104. This increases lifespan, ensuring stable performance in long-term applications. |

| Integrated Capacitors | Combining 104 capacitors with inductors or resistors reduces circuit complexity. These modules improve efficiency and reduce overall component count. |

| High-Frequency Performance | 104 capacitors now offer lower ESR and ESL. They perform efficiently in high-frequency applications, including RF circuits and switching power supply systems. |

| Eco-Friendly Manufacturing | Sustainable practices in 104 capacitor production reduce environmental impact. New processes comply with global green standards while maintaining top quality. |

Summary

Staying updated on advancements in 104 capacitor technology helps engineers maintain competitive designs. These innovations ensure that capacitors 104 are reliable and efficient in cutting-edge applications.

Case Studies: 104 Capacitor in Action

To illustrate the practical applications and benefits of 104 capacitors, let's explore a few real-world case studies:

Case Study 1: Power Supply Design

In designing a high-efficiency power supply for a consumer electronic device, engineers utilized 104 capacitors for input and output filtering. These capacitors effectively smoothed out voltage fluctuations, resulting in a stable power output and reduced electromagnetic interference (EMI). The low ESR of the 104 capacitors contributed to the overall efficiency of the power supply, minimizing energy losses and enhancing performance.

Case Study 2: Audio Equipment Enhancement

Audio equipment manufacturers incorporated 104 capacitors into their signal processing circuits to filter out unwanted noise and enhance sound clarity. The precise capacitance values ensured that only the desired frequencies were amplified, providing superior audio quality. Additionally, the compact size of the 104 capacitors allowed for more streamlined circuit layouts, contributing to sleeker and more efficient audio device designs.

Case Study 3: Microcontroller Timing Circuits

In microcontroller-based systems, 104 capacitors were employed in timing circuits to generate accurate oscillation frequencies. This precision was crucial for the synchronized operation of various system functions, ensuring reliable performance. The non-polarized nature of the 104 capacitor simplified the design process, allowing for flexible integration into complex timing circuits without the risk of polarity-related issues.

Future Trends in 104 Capacitor Usage

The future of 104 capacitors looks promising, with several trends shaping their usage in upcoming electronic technologies:

- Internet of Things (IoT): As IoT devices proliferate, the demand for reliable and compact 104 capacitors will increase to support the diverse functionalities of these smart devices. Their small size and efficient performance make them ideal for the compact and interconnected nature of IoT applications.

- Wearable Technology: The miniaturization of 104 capacitor will play a crucial role in the development of lightweight and flexible wearable electronics. Its ability to deliver stable performance in compact forms aligns with the requirements of wearable devices.

- Green Electronics: Emphasis on energy-efficient and eco-friendly designs will drive the adoption of sustainable 104 capacitors. Manufacturers will focus on producing capacitors that not only perform well but also minimize environmental impact through sustainable materials and manufacturing processes.

- Advanced Manufacturing: Innovations in manufacturing processes will lead to higher performance and more durable 104 capacitors. Techniques such as 3D printing and automated assembly will enhance precision and reduce production costs, making 104 capacitor more accessible for a wide range of applications.

- High-Frequency and High-Speed Applications: The demand for 104 capacitor that can perform efficiently in high-frequency and high-speed applications will grow. Advances in materials and design will enable capacitors to handle the stringent requirements of modern communication and computing technologies.

- Integration with Other Components: The trend towards integrating capacitors with other electronic components will continue, leading to more compact and efficient circuit designs. Integrated 104 capacitors can simplify circuit layouts and enhance overall system performance.

Staying ahead of these trends will enable engineers to harness the full potential of 104 capacitors in future electronic innovations, ensuring their designs remain relevant and competitive in an ever-evolving technological landscape.

How to Test 104 Capacitor

Ensuring the functionality of 104 capacitors is essential for maintaining reliable circuit performance. Here are common methods for testing these capacitors:

1. Visual Inspection

Begin by performing a visual inspection of the 104 capacitor. Look for any physical damage, such as cracks, burns, discoloration, or bulging. Physical defects can indicate capacitor failure or impending failure.

2. Capacitance Measurement

Using a digital multimeter equipped with a capacitance measurement feature, verify that the 104 capacitor is within its specified capacitance range. Remove the capacitor from the circuit to ensure an accurate measurement, as circuit components can affect the reading.

3. Equivalent Series Resistance (ESR) Testing

Measure the ESR to assess the internal resistance of the 104 capacitor. High ESR values can indicate deterioration or failure, affecting the capacitor's performance in filtering and decoupling applications. Specialized ESR meters provide accurate measurements without requiring capacitor removal.

4. Leakage Current Testing

Apply a voltage within the capacitor's rating and measure the leakage current. Excessive leakage current can signal a faulty capacitor. Ensure that the test voltage does not exceed the capacitor's rated voltage to prevent damage during testing.

5. Impedance Analysis

Conduct an impedance analysis to evaluate the overall performance of the 104 capacitor across a range of frequencies. This test helps identify issues related to ESR, ESL, and dielectric losses, providing a comprehensive assessment of the capacitor's health.

6. Temperature Cycling

Expose the 104 capacitor to varying temperature conditions to assess its performance stability. Temperature cycling can reveal issues related to material degradation and thermal stress, ensuring the capacitor can withstand operational temperature ranges.

7. Frequency Response Testing

Analyze the frequency response of the 104 capacitor to determine its suitability for high-frequency applications. This test ensures that the capacitor maintains its capacitance and low ESR across the desired frequency range.

Regular testing of 104 capacitors ensures their reliability and helps prevent potential circuit issues. Incorporating routine testing protocols in your maintenance schedule can enhance the longevity and performance of your electronic systems.

Best Practices for Soldering 104 Capacitor

Proper soldering techniques are crucial to maintaining the integrity and performance of 104 capacitors. Adhering to best practices during soldering ensures reliable connections and prevents damage to the capacitors. Follow these guidelines:

| Best Practice | Description |

| Temperature Control | Use a soldering iron with adjustable heat settings. Excessive heat can damage the 104 capacitor and its ceramic material, reducing performance. |

| Proper Technique | Simultaneously apply solder to the pad and lead. Avoid excessive solder, which may cause short circuits or bridging in capacitors 104. |

| Minimize Heat Exposure | Limit the time the 104 capacitor is exposed to heat. Prolonged heat can lead to cracks or physical damage to the component. |

| Use Quality Solder | Use high-quality solder with appropriate flux. This ensures stronger connections and reduces resistance for better functionality of 104 capacitors. |

| Inspection | Inspect solder joints for cold soldering, bridging, or incomplete connections. Rework any defects to maintain the reliability of capacitors 104. |

| Proper Handling | Handle 104 capacitors carefully to avoid physical damage. Use tweezers or ESD-safe tools during the soldering process. |

| Pre-Tinning | Pre-tin the leads of the 104 capacitor before soldering. This ensures smoother solder flow and creates secure, consistent connections. |

| Use Soldering Aids | Utilize flux, stencils, or other soldering aids. These tools enhance precision and efficiency when working with capacitors 104. |

Summary

Adhering to these soldering best practices ensures the 104 capacitor maintains optimal functionality and durability. Proper handling and quality soldering techniques protect capacitors 104 from damage, ensuring stable and reliable electronic assemblies.

Common Misconceptions About 104 Capacitor

There are several misconceptions surrounding 104 capacitors. Clarifying these can lead to better usage and understanding:

Misconception 1: 104 Capacitor Ia Only Used in High-Voltage Applications

While 104 capacitor can handle high voltages, it is also widely used in low-voltage applications due to its versatility and reliability. Its ability to function effectively across a broad voltage range makes it suitable for various circuit designs, from simple consumer electronics to complex industrial systems.

Misconception 2: All 104 Capacitors Are Ceramic

Although ceramic is a common material, 104 capacitor can also be made from other materials like tantalum or electrolytic, depending on the application requirements. The choice of material affects the capacitor's performance characteristics, such as ESR, temperature stability, and frequency response.

Misconception 3: 104 Capacitors Are Polarized

Most 104 capacitors are non-polarized, allowing them to be installed in either direction within a circuit without affecting functionality. However, some types, like electrolytic 104 capacitors, may be polarized. It's essential to verify the capacitor's specifications to ensure correct installation.

Misconception 4: Higher Voltage Ratings Are Always Better

While selecting a higher voltage rating provides a safety margin, excessively high ratings can lead to larger physical sizes and higher costs. It's crucial to choose a 104 capacitor with a voltage rating that meets or slightly exceeds the circuit's requirements without unnecessary over-specification.

Misconception 5: 104 Capacitor Is Not Suitable for High-Frequency Applications

With advancements in capacitor technology, many 104 capacitors now offer low ESR and ESL, making them suitable for high-frequency applications. Selecting the right type and manufacturer can ensure optimal performance in demanding scenarios.

Comparing 104 Capacitor with Other Capacitor Types

Understanding how 104 capacitors compare to other capacitor types can help in selecting the right component for your project:

104 Capacitor vs. Electrolytic Capacitor

104 capacitor typically offers better stability and lower equivalent series resistance (ESR) compared to electrolytic capacitors. It is also non-polarized, making it easier to use in AC applications. Electrolytic capacitor, while offering higher capacitance values, is polarized and generally less stable over time.

104 Capacitors vs. Film Capacitors

Film capacitors generally have higher voltage ratings and better frequency characteristics. However, 104 capacitors are more compact and cost-effective for applications requiring lower capacitance values. Film capacitors are preferred in high-precision and high-frequency applications where their superior performance justifies the higher cost.

104 Capacitor vs. Tantalum Capacitor

Tantalum capacitor offers higher capacitance in smaller packages but is more expensive and sensitive to voltage spikes. 104 capacitor provides a balance of performance and affordability for many standard applications. Tantalum capacitor is chosen for its stability and reliability in demanding applications, while 104 capacitor is favored for its versatility and cost-effectiveness.

104 Capacitors vs. Advanced Ceramic Capacitors

All 104 capacitors are essentially ceramic capacitors, but they can vary in terms of dielectric materials and construction. Advanced ceramic capacitors may offer better temperature stability and lower losses, making them suitable for high-performance applications. Standard ceramic 104 capacitor is ideal for general-purpose use where high precision is not critical.

Where to Buy 104 Capacitor

Reliable sourcing of 104 capacitors is essential for maintaining the quality of your electronic projects. Consider the following when purchasing:

- Authorized Distributors: Purchase from reputable distributors to ensure authenticity and quality. Authorized distributors often provide detailed specifications and support.

- Manufacturer Direct: Buying directly from manufacturers can provide access to the latest products and bulk pricing. It also ensures that you receive genuine components with full warranties.

- Online Retailers: Platforms like DXM offers a wide selection of capacitors 104 with detailed specifications, making it easy to find the exact component you need.

- Local Electronics Stores: For quick access, local stores may carry common 104 capacitor. This is ideal for urgent projects or when immediate procurement is necessary.

- Specialized Suppliers: Some suppliers specialize in specific types of capacitors and may offer higher quality or specialized 104 capacitors tailored to particular applications.

- Bulk Suppliers: For large-scale projects, bulk suppliers can provide 104 capacitor at discounted rates, ensuring cost-effectiveness and timely delivery.

Ensure that the 104 capacitors you purchase meet your project’s specifications and quality standards. Verify the manufacturer's reputation and check for compliance with relevant industry standards to guarantee the performance and reliability of your electronic designs.

Maintaining 104 Capacitor for Optimal Performance

Proper maintenance can extend the lifespan of 104 capacitor and ensure consistent performance. Implementing the following maintenance practices can help preserve the integrity and functionality of your capacitors:

- Proper Storage: Store capacitors in a cool, dry place to prevent moisture absorption and degradation. Use anti-static packaging to protect against electrostatic discharge (ESD).

- Handling: Avoid physical stress and static discharge by handling capacitors with care. Use appropriate tools, such as tweezers or ESD-safe gloves, to minimize the risk of damage.

- Regular Testing: Periodically test capacitors in active circuits to monitor their health and performance. Regular testing helps identify potential issues early, allowing for timely replacements.

- Environmental Control: Protect capacitors from extreme temperatures, humidity, and corrosive environments. Use conformal coatings or protective enclosures in harsh environments to shield capacitors from adverse conditions.

- Cleanliness: Keep capacitors and circuit boards clean from dust, debris, and contaminants that can affect performance. Use appropriate cleaning methods to maintain the integrity of the components.

- Documentation: Maintain detailed records of capacitor usage, testing results, and maintenance activities. Proper documentation aids in tracking performance trends and planning preventive maintenance.

- Replacement Scheduling: Implement a schedule for replacing capacitors that are prone to aging or degradation. Proactive replacement ensures uninterrupted performance and prevents circuit failures.

Implementing these maintenance practices ensures that your 104 capacitor remains reliable component in your electronic designs. Proper maintenance not only extends the lifespan of the capacitor but also enhances the overall reliability and performance of your electronic systems.

Expert Tips for Working with 104 Capacitor

Leverage these expert tips to maximize the performance and reliability of your 104 capacitor:

- Understand Circuit Requirements: Clearly define the role of the capacitor within your circuit to select the appropriate 104 capacitor. Understanding the specific needs of your application ensures optimal performance and compatibility.

- Check Polarization: Although most 104 capacitors are non-polarized, verify before installation to prevent circuit issues. Incorrect polarity can lead to capacitor failure or circuit malfunction.

- Use Proper Soldering Techniques: Ensure clean and secure solder joints to maintain electrical integrity. Proper soldering prevents poor connections and enhances the reliability of the capacitor in the circuit.

- Consider ESR and ESL: For high-frequency applications, low ESR and ESL 104 capacitor is preferable. These characteristics ensure that the capacitor performs efficiently in demanding scenarios, maintaining signal integrity and reducing losses.

- Plan for Future Upgrades: Select capacitors with slightly higher ratings to accommodate potential future circuit modifications. Over-specifying capacitors can provide additional margin for unexpected changes or upgrades in the circuit design.

- Optimize Circuit Layout: Position 104 capacitors close to the components they are intended to support, such as ICs or power regulators. Proximity reduces inductive effects and enhances the capacitor's effectiveness in filtering and decoupling.

- Use Thermal Management: Implement adequate cooling and thermal management strategies to prevent overheating of 104 capacitor. Proper thermal management maintains the capacitor's performance and extends its lifespan.

- Verify Component Specifications: Always cross-check the capacitor's specifications with the circuit requirements. Ensuring that the 104 capacitor meets or exceeds the necessary parameters prevents compatibility issues and ensures reliable performance.

Implementing these expert tips can significantly enhance the effectiveness of 104 capacitor in your projects. Attention to detail and adherence to best practices ensure that capacitors perform optimally, contributing to the overall success and reliability of your electronic designs.

Conclusion

Integrating the 104 capacitor into your electronic designs is a strategic decision that can greatly enhance circuit stability and performance. With their robust features, versatile applications, and numerous advantages, capacitors 104 are essential components in the toolkit of any electronics professional or enthusiast. By understanding their characteristics, applications, and best practices, you can leverage 104 capacitors to power your next innovative project with confidence and reliability.

Explore a variety of capacitors 104 from trusted suppliers to ensure your designs are equipped with the highest quality components. For more detailed information and a comprehensive selection, check out our extensive 104 capacitor collection. Embracing the capabilities of 104 capacitor not only enhances your current projects but also paves the way for future technological advancements and innovations.

FAQs on 104 Capacitor

Q1: Can I replace a 104 capacitor with another value?

A: Replacing a 104 capacitor with a different value can significantly affect circuit behavior. It's crucial to consult the circuit requirements and, if necessary, seek professional advice before making any substitutions. Using an incorrect capacitance value can lead to improper filtering, timing inaccuracies, and overall circuit malfunction.

Q2: Is 104 capacitor polarized?

A: No, most 104 capacitors are non-polarized, allowing them to be installed in either direction within a circuit without affecting functionality. However, some types, like electrolytic 104 capacitors, may be polarized. It's essential to verify the capacitor's specifications to ensure correct installation.

Q3: What is the typical operating temperature range of a 104 capacitor?

A: Most 104 capacitors operate effectively between -25°C and 85°C. However, it's essential to verify the specific temperature range by consulting the capacitor's datasheet to ensure suitability for your application. Selecting a capacitor with an appropriate temperature rating ensures reliable performance under varying environmental conditions.

Q4: How long does 104 capacitor typically last?

A: The lifespan of 104 capacitor depends on various factors, including operating conditions, temperature, voltage stress, and quality of the capacitor. High-quality capacitors from reputable manufacturers can last several years, even decades, under normal operating conditions. Regular testing and proper maintenance can help extend their lifespan and ensure consistent performance.

Q5: Can 104 capacitors be used in both AC and DC applications?

A: Yes, most 104 capacitors are non-polarized and can be used in both AC and DC applications. Their ability to handle bidirectional current makes them versatile for various circuit designs, including filtering, coupling, and decoupling applications in both AC and DC environments.

Recommended for you

Water Temperature Sensor: The Key to Engine Health and Efficiency

Lightning Surge Protection Varistor: Essential for Protecting Your Electrical Systems

Water Temp Sensor: How to Test it for Reliable Performance?

Capacitor Impedance: Calculation Guide & FAQs

Temperature Probe Sensor: A Comprehensive Guide

Termistor NTC: What Does a Thermistor Do?

Logistics

How to track my order?

You can track your order through our official website or the order number provided and learn about the logistics status and delivery progress of your order at any time.

Does it support express delivery?

Yes, we support express delivery services. You can choose different delivery methods according to your needs, including ordinary express delivery and expedited express delivery.

Price and Payment

Payment Terms

There are a number of different payment methods that can be used when you deal with us. Two are mostly used: T/T payment in advance for small values and irrevocable L/C at sight for large values.

Customized Services

Free sample availability

You can contact our representative via email, fax or phone to specify the sample you need and provide your courier's account number (such as UPS, FedEx, DHL, TNT, etc.).. And we’ll send you samples free of charge through your courier by freight collection.

Can I customize (OEM) the product?

Yes. You can customize the product with DXM. Our R&D and production technology have already reached an advanced world level, and we can provide qualified OEM service for global customers.Please specify your requirements to our representative or send samples to our factory office, and we will confirm your details.

You may also like

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd