Ceramic Disc Y Capacitor: High-Quality for Reliable AC Circuit Performance

Introducing the DXM Ceramic Disc Y Capacitor, engineered for superior reliability in AC circuits. This high-quality ceramic disc capacitor ensures optimal performance and durability.

Ceramic Disc Y Capacitor Key Features:

● Safety Compliance: Meets global safety certifications for AC voltage circuits.

● Wide Capacitance Range: Suitable for diverse electronic applications.

● EMI Suppression: Essential for reducing electromagnetic interference.

● Fire-Resistant: UL 94V-0 epoxy coating for enhanced safety.

● Cost-Effective, Good Quality: High performance at a competitive price.

Trust DXM for your electronic needs with our top-tier ceramic disc capacitors, designed for excellence in challenging environments.

Ceramic disc capacitor, also called Y capacitor, is vital for electronic systems. It ensures safety and stability by filtering noise and suppressing EMI.At DXM, we manufacture premium ceramic disk capacitor products that meet strict global standards. Our capacitors are built for noise filtering, EMI suppression, and circuit stabilization, offering unmatched performance and reliability.DXM’s ceramic disc capacitors solutions are trusted by engineers for industrial and consumer applications. Designed to meet international safety standards, they provide durability, efficiency, and innovation for a wide range of needs.

What is a Ceramic Disc Capacitor?

A ceramic disc capacitor is a passive electronic component that utilizes a ceramic dielectric material to store and release electrical energy. These ceramic disc capacitors are typically disc-shaped and are often encapsulated in epoxy resin to protect against environmental factors. Renowned for their ability to withstand high voltages and maintain performance over extended periods, ceramic disc capacitor are integral in a variety of electronic systems. They are extensively used for noise suppression, signal stabilization, and interference reduction, making them indispensable in both consumer electronics and industrial applications. Additionally, Y capacitor is a specific type of ceramic disc capacitor designed to provide enhanced safety and EMI suppression in critical circuit applications.

Key Features of Ceramic Disc Capacitor

The ceramic disc capacitor offered by DXM Capacitors are distinguished by a multitude of features that cater to the diverse needs of modern electronics. These features ensure that our capacitor provide optimal performance, reliability, and safety across various applications. Below, we delve into the key features that make our ceramic disc capacitor a preferred choice among professionals.

Wide Capacitance Range

Our ceramic disc capacitor are available in a broad range of capacitance values, typically spanning from 100pF to 10,000pF. This extensive range allows for flexibility in design and application, enabling engineers to select capacitor that precisely match the requirements of their specific circuits. Whether it's for high-frequency filtering or energy storage in power supply circuits, the wide capacitance range ensures that our capacitor can meet diverse electrical needs. The availability of different ceramic disk capacitor values makes it easier to integrate these components into various electronic designs.

High Voltage Ratings

Designed to operate safely in environments with high voltage, our ceramic disc capacitor come with voltage ratings ranging from 250V~ to 400V~ AC. This high voltage tolerance makes them suitable for use in power line applications, ensuring stable performance even under demanding electrical conditions. The ability to handle high voltages without compromising on performance or safety is a testament to the robust construction and quality materials used in our capacitor. Additionally, Y capacitor provides enhanced protection against voltage spikes, making it ideal for critical circuit applications.

Temperature Tolerance

The operational reliability of electronic components is often influenced by temperature variations. Our ceramic disc capacitor are engineered to function effectively across a wide temperature range, from as low as -25°C to as high as +125°C. This temperature tolerance ensures consistent performance in both extreme cold and heat, making them ideal for applications in environments with fluctuating temperatures. The thermal stability of our ceramic disk capacitor ensures that performance remains unaffected in diverse operational conditions.

Compact and Lightweight Design

Space constraints are a common challenge in electronic device design. Our ceramic disc capacitor address this issue with their compact and lightweight build, allowing for easy integration into densely packed circuit boards. The small form factor does not compromise the capacitor's performance, making them an excellent choice for portable and compact electronic devices where space optimization is crucial. The efficient design of our ceramic disk capacitor ensures that they fit seamlessly into modern, miniaturized electronics.

Fire-Resistant Coating

Safety is paramount in electronic component design. Our ceramic disc capacitor are coated with UL 94V-0 rated epoxy resin, ensuring high fire resistance and preventing the spread of flames in case of overheating or electrical faults. This fire-resistant property enhances the overall safety of the electronic systems in which these capacitor are employed, providing peace of mind to designers and end-users alike. Y capacitor further incorporates these safety features to ensure compliance with stringent safety standards.

Global Safety Compliance

Compliance with international safety standards is essential for electronic components used worldwide. Our ceramic disc capacitor are certified by renowned safety organizations such as UL and CE, ensuring that they meet stringent quality and safety criteria. This global compliance guarantees that our capacitor can be reliably used in various markets, adhering to local regulations and standards. The adherence to global safety norms makes our ceramic disk capacitor a trustworthy choice for manufacturers across different regions.

Low Equivalent Series Resistance (ESR)

Low Equivalent Series Resistance (ESR) is a critical parameter that affects the efficiency and performance of capacitor in high-frequency applications. Our ceramic disc capacitor are designed with low ESR, minimizing energy losses and ensuring efficient operation in switching power supplies, RF circuits, and other high-frequency environments. This feature enhances the overall performance and reliability of the electronic systems utilizing our capacitor. Additionally, the low ESR of our Y capacitor ensures minimal energy dissipation and optimal signal integrity in sensitive applications.

High Dielectric Strength

The dielectric material used in our ceramic disc capacitor possesses high dielectric strength, allowing for greater energy storage capacity and improved insulation properties. This high dielectric strength ensures that the capacitor can handle higher electric fields without breakdown, contributing to their longevity and reliability in demanding applications. The robust dielectric properties of our ceramic disk capacitor make them suitable for high-performance electronic designs.

Stable Capacitance Over Time

Stability in capacitance is vital for maintaining consistent performance in electronic circuits. Our ceramic disc capacitor exhibit minimal capacitance drift over time, ensuring that the electrical characteristics of the circuit remain stable. This stability is particularly important in precision applications such as signal processing and measurement systems. The long-term reliability of our ceramic disk capacitor ensures sustained performance and accuracy in critical electronic functions.

Environmental Durability

Exposure to harsh environmental conditions can degrade the performance of electronic components. Our ceramic disc capacitor are designed to withstand moisture, vibration, and other environmental stressors, ensuring long-term reliability and performance. This environmental durability makes them suitable for use in automotive, aerospace, and industrial applications where exposure to challenging conditions is common. The rugged construction of our Y capacitor ensures it remain functional and dependable even in the most demanding environments.

Applications of Ceramic Disc Capacitors

The versatility of ceramic disc capacitor allows them to be employed across a wide range of industries and applications. Their inherent properties such as high voltage tolerance, temperature stability, and compact design make them suitable for diverse uses, from consumer electronics to industrial machinery. Below, we explore the various applications where ceramic disc capacitor play a critical role.

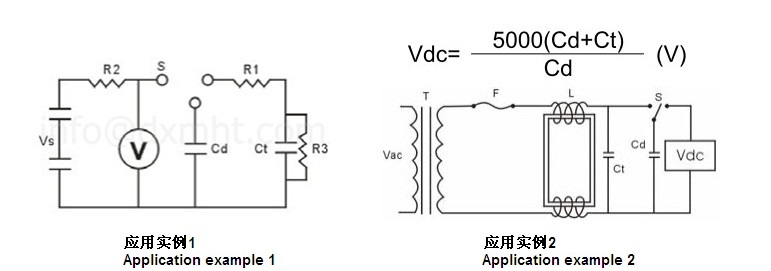

Across the Line Applications

Ceramic disc capacitor plays a key role in "Across the Line" (ATL) applications. It filters noise directly from AC power lines, ensuring circuit stability and safety. This reduces voltage spikes and electrical noise, protecting sensitive electronic components from disruption.

Ceramic disc capacitors are essential for smooth and consistent power delivery, enhancing the performance and lifespan of electronic devices. ATL applications demand reliability, and our Y capacitor is engineered for superior noise suppression and circuit stabilization.DXM also offers ceramic disk capacitor solutions, designed to meet industry standards, ensuring efficient and durable performance in ATL systems.

Line Bypass Applications

Line bypassing is a technique used to ensure clean signal transmission by eliminating unwanted noise and interference from power lines. Ceramic disc capacitor are integral to this process, acting as filters that allow only the desired frequency signals to pass through while blocking high-frequency noise. This application is particularly important in audio equipment, telecommunications, and data processing systems, where signal integrity is paramount. Our ceramic disk capacitor offer exceptional performance in line bypass applications, ensuring that only the necessary signals are transmitted without any distortion or interference.

Antenna Coupling

In telecommunication systems, ceramic disc capacitor are used for antenna coupling, which involves the transfer of signals between the antenna and the transceiver. These capacitor help in maintaining a stable signal transmission by filtering out unwanted frequencies and ensuring that only the necessary signals are amplified and processed. This application is vital for achieving clear and reliable communication in mobile phones, radios, and other wireless devices. The high dielectric strength and low ESR of our ceramic disk capacitor make them ideal for antenna coupling applications, ensuring optimal performance and signal quality.

EMI Suppression

Electromagnetic Interference (EMI) can disrupt the functionality of electronic circuits, leading to erratic behavior and reduced performance. Y capacitor, a type of ceramic disc capacitor, is specifically designed for EMI suppression. It is strategically placed in circuits to filter out electromagnetic noise, thereby protecting sensitive components from interference. This application is crucial in maintaining the reliability and efficiency of electronic systems in environments with high electromagnetic activity. Our Y capacitor provides robust EMI suppression, ensuring that electronic devices operate smoothly without interference from external electromagnetic sources.

High-Frequency Ballasts

High-frequency ballasts are used in lighting systems to regulate the current and voltage supplied to lamps. Ceramic disc capacitor enhance the performance of these ballasts by supporting high-frequency operations and ensuring stable power delivery. This application is essential in modern lighting solutions, including LED and fluorescent lighting, where efficient and reliable power regulation is required for optimal performance and energy efficiency. The high dielectric strength and thermal stability of our ceramic disk capacitor make them well-suited for high-frequency ballast applications.

Automotive Electronics

The automotive industry relies heavily on ceramic disc capacitor for various applications, including engine control units (ECUs), infotainment systems, and advanced driver-assistance systems (ADAS). These capacitor help in filtering noise, stabilizing signals, and ensuring reliable power delivery in the harsh and variable conditions found in automotive environments. Their durability and performance under high temperatures and vibrations make them ideal for use in vehicles. Our Y capacitor provides enhanced EMI suppression and circuit stability, contributing to the overall reliability of automotive electronic systems.

Consumer Electronics

In consumer electronics such as smartphones, tablets, laptops, and televisions, ceramic disc capacitor are essential for maintaining signal integrity, filtering noise, and ensuring stable power supply. Their compact size and high reliability make them suitable for the intricate circuitry found in these devices, contributing to improved performance and longevity. The versatile design of our ceramic disk capacitor allows them to seamlessly integrate into various consumer electronic products, enhancing their functionality and user experience.

Industrial Machinery

Industrial machinery often operates in environments with high electrical noise and varying power conditions. Ceramic disc capacitor are used in these settings to filter out noise, stabilize power supplies, and protect sensitive control systems from electrical disturbances. Their robust construction and ability to withstand harsh conditions make them ideal for use in industrial automation, manufacturing equipment, and heavy machinery. Our Y capacitor provides reliable EMI suppression, ensuring the smooth operation of industrial electronic systems.

Medical Devices

In the medical field, reliability and precision are paramount. Ceramic disc capacitor are utilized in various medical devices such as imaging systems, diagnostic equipment, and monitoring devices to ensure stable and accurate operation. Their high reliability and compliance with stringent safety standards make them suitable for use in life-critical applications where performance cannot be compromised. The exceptional dielectric properties of our ceramic disk capacitor ensure consistent performance in sensitive medical applications.

Telecommunications

The telecommunications industry depends on ceramic disc capacitor for signal processing, noise reduction, and power stabilization in communication equipment. These capacitor help in maintaining clear and uninterrupted communication by filtering out unwanted noise and ensuring that signals are transmitted and received accurately. Their role is crucial in the infrastructure that supports mobile networks, internet services, and broadcasting systems. Our ceramic disk capacitor deliver exceptional performance in telecommunications applications, ensuring reliable and high-quality signal transmission.

Renewable Energy Systems

Renewable energy systems, such as solar inverters and wind turbine controllers, utilize ceramic disc capacitor for power conditioning, noise suppression, and signal stabilization. These capacitor help in managing the variable power inputs and ensuring that the energy conversion processes operate smoothly and efficiently. Their durability and high performance make them well-suited for the demanding conditions of renewable energy applications. The reliable performance of our ceramic disk capacitor ensures efficient energy management in renewable energy systems.

Ceramic Disc Capacitor Technical Specifications

Detailed Specifications of Ceramic Disc Capacitors:

- Capacitance: Ranges from 100pF to 10,000pF.

- Voltage Ratings: From 250V~ to 400V~ AC.

- Temperature Range: -25°C to +125°C.

- Insulation Resistance: Greater than 10,000 MΩ at DC 500V.

- Dissipation Factor: Maximum of 2.5% at 1kHz.

- Compliance: Meets X1/Y1 and X1/Y2 safety standards.

- Equivalent Series Resistance (ESR): Typically below 0.1Ω.

- Dielectric Material: High-permittivity ceramic, often Class Y.

- Size Dimensions: Various sizes available, typically ranging from 0402 to 1210 in metric units.

- Mounting Type: Surface mount technology (SMT) compatible.

- Packaging: Available in tape and reel or bulk packaging for ease of integration into manufacturing processes.

- Longevity: Designed for long operational lifespan, often exceeding 100,000 hours under standard operating conditions.

-

Datasheet

For comprehensive details, you can explore the Ceramic Disk Capacitor Datasheet, which provides in-depth specifications and models for various Ceramic Disc Capacitors. This datasheet is an essential resource for understanding the key features, safety certifications, and application suitability of each capacitor model.

-

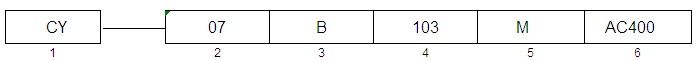

Ceramic Disc Capacitors Model Description

1. Category :CY: Y capacitor, Ceramic Disk Capacitor,

2. Chip diameter,

3. Medium material :B:Y5P, E:Y5U, F:Y5V,

4. Power capacity: 100pF=101,2200pF=222,10000pF=103,

5.Tolerance range :K:±10%, M:±20%,

6.Rated AC voltage: AC400= AC voltage 400V.

Capacitance and Voltage Ratings

The capacitance value of a ceramic disc capacitor determines its ability to store electrical energy, while the voltage rating indicates the maximum voltage the capacitor can safely handle. Our capacitors offer a wide range of capacitance values from 100pF to 10,000pF, catering to diverse circuit requirements. The voltage ratings, spanning from 250V~ to 400V~ AC, ensure that the capacitors can be used in high-voltage applications without the risk of failure or degradation. This extensive range of ceramic disk capacitor provides engineers with the flexibility needed to design robust and efficient electronic systems.

Temperature Range and Stability

Operating temperature is a critical factor in capacitor performance. Our ceramic disc capacitor are engineered to operate reliably within a temperature range of -25°C to +125°C. This wide range ensures that the capacitors maintain their performance in both low-temperature environments and high-temperature conditions, making them suitable for applications in various climates and industrial settings. The thermal stability of our ceramic disk capacitor ensures that capacitance remains consistent, contributing to the overall reliability of electronic circuits.

Insulation Resistance and Dissipation Factor

Ceramic disc capacitor ensures minimal leakage with insulation resistance exceeding 10,000 MΩ at DC 500V. This feature guarantees high reliability and stable performance in demanding applications.The dissipation factor, limited to 2.5% at 1kHz, ensures efficient performance with low energy losses. This makes our ceramic disc capacitors ideal for high-frequency circuits requiring consistent efficiency.

The exceptional insulation properties of our ceramic disk capacitor contribute to long-term durability. Whether in consumer electronics or industrial systems, these capacitors deliver dependable and energy-efficient performance.Additionally, Y capacitors provide enhanced safety and stability in AC circuits, making them essential for noise-sensitive environments.

Compliance with Safety Standards

Adherence to safety standards is paramount in the design and manufacturing of electronic components. Our ceramic disc capacitor comply with X1/Y1 and X1/Y2 safety standards, ensuring they meet rigorous safety and performance criteria. These certifications guarantee that the capacitor are suitable for use in safety-critical applications, providing peace of mind to designers and end-users regarding their reliability and safety. The compliance of our ceramic disk capacitor with international safety standards underscores our commitment to quality and safety in all our products.

Equivalent Series Resistance (ESR)

Equivalent Series Resistance (ESR) affects the efficiency and thermal performance of capacitor in AC circuits. When selecting a ceramic disc capacitor, consider the following:

- Application Needs: High-frequency and switching applications benefit from capacitor with low ESR to minimize energy losses and heat generation.

- Performance Requirements: Lower ESR values contribute to better performance in terms of signal integrity and power efficiency.

- Thermal Management: Capacitor with low ESR generate less heat, reducing the need for additional thermal management measures.

Our ceramic disc capacitor are designed with low ESR, typically below 0.1Ω, which minimizes energy losses and reduces heat generation during operation. Low ESR enhances the performance of switching power supplies, RF circuits, and other high-frequency applications by ensuring efficient energy transfer and reducing the risk of thermal issues. This makes our ceramic disk capacitor an excellent choice for applications where thermal performance is critical.

Dielectric Material and Class Y Capacitor

The dielectric material and classification of the capacitor influence its performance characteristics. Key points to consider include:

- Dielectric Type: High-permittivity ceramic dielectrics offer better energy storage capabilities and stability.

- Class Y Dielectric: Class Y dielectrics are preferred for applications requiring high reliability and safety, such as EMI suppression.

- Dielectric Stability: Choose capacitor with stable dielectric properties to ensure consistent performance over time and varying conditions.

The dielectric material used in our ceramic disc capacitor is a high-permittivity ceramic, often classified as Class Y. Class Y dielectric materials are known for their stability and reliability, making them ideal for applications that require precise capacitance and long-term performance. The use of high-quality dielectric materials ensures that our capacitor can handle high electric fields without degradation, contributing to their longevity and consistent performance. This makes our Y capacitor particularly suitables for critical applications demanding high reliability.

Size Dimensions and Mounting Type

Our ceramic disc capacitor come in various size dimensions to accommodate different design requirements. The availability of different sizes and mounting types makes our capacitor versatile for a wide range of applications. Whether you require a compact ceramic disk capacitor for a tight space or a larger size for enhanced performance, our product range has you covered.

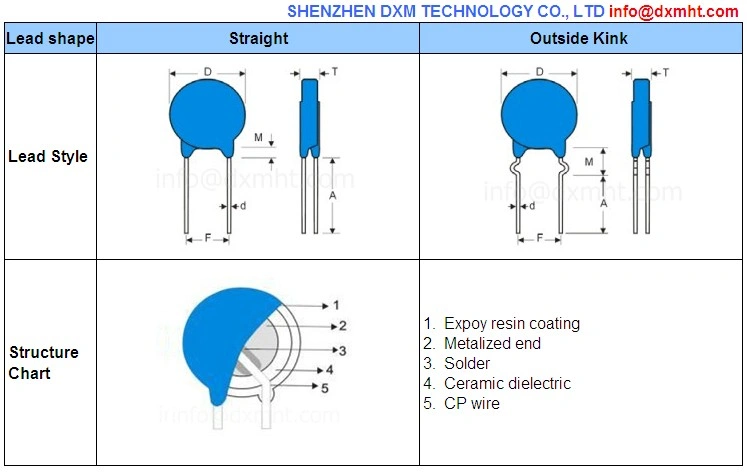

Lead Style and Structure Chart of Ceramic Disc Capacitors

Packaging and Longevityn

To facilitate seamless integration into manufacturing workflows, our ceramic disc capacitor are available in both tape and reel and bulk packaging options. This flexibility allows manufacturers to select the packaging method that best suits their production processes. Additionally, our capacitor are designed for longevity, often exceeding 100,000 hours under standard operating conditions. This extended lifespan ensures that the capacitor remain functional and reliable throughout the lifecycle of the electronic devices they are incorporated into. The durability of our Y capacitor ensures sustained performance even in demanding applications.

How to Choose the Right Ceramic Disc Capacitor

Selecting the appropriate ceramic disc capacitor for your application involves careful consideration of several key factors. Making the right choice ensures optimal performance, reliability, and longevity of your electronic circuits. Below, we outline the primary factors to consider when choosing a ceramic disc capacitor.

Capacitance Value

The capacitance value is a fundamental parameter that determines the amount of electrical energy a capacitor can store. It is essential to select a capacitor with a capacitance value that matches the specific needs of your circuit. Consider the following when determining the appropriate capacitance:

- Application Requirements: Different applications require different capacitance values. For instance, high-frequency filtering may require lower capacitance, while energy storage applications may need higher capacitance.

- Signal Processing: In signal processing circuits, precise capacitance values are crucial for maintaining signal integrity and stability.

- Power Supply Filtering: Power supply circuits often require capacitors with specific capacitance values to filter out noise and stabilize voltage levels.

Voltage Rating

The voltage rating of a capacitor indicates the maximum voltage it can safely handle. Selecting a capacitor with an appropriate voltage rating is critical to prevent breakdown and ensure reliable operation. Factors to consider include:

- Operating Voltage: Ensure that the capacitor's voltage rating exceeds the maximum operating voltage of the circuit to provide a safety margin.

- Transient Voltages: Consider any potential voltage spikes or transients that may occur in the circuit and select a capacitor with a voltage rating that can accommodate these surges.

- Safety Standards: Compliance with safety standards may require capacitors with specific voltage ratings, especially in applications involving high voltages.

Temperature Range

The operational environment of your electronic device can significantly impact capacitor performance. It's important to choose a ceramic disc capacitor that can withstand the temperature conditions of your application. Key considerations include:

- Ambient Temperature: Ensure the capacitor can operate effectively within the expected ambient temperature range.

- Thermal Cycling: In applications with fluctuating temperatures, select capacitors that can endure thermal cycling without degradation.

- Heat Dissipation: High-temperature applications may require capacitors with enhanced thermal properties to manage heat dissipation.

Physical Size and Mounting 0f Ceramic Disc Capacitors

The physical dimensions and mounting type of the capacitor are important for integration into your circuit board design. Factors to consider include:

- Space Constraints: Ensure the capacitor fits within the available space on the circuit board without causing layout issues.

- Mounting Type: Choose between surface mount or through-hole capacitors based on your manufacturing process and design requirements.

- Orientation: Consider the orientation of the capacitor in the circuit to facilitate efficient layout and heat dissipation.

Equivalent Series Resistance (ESR)

ESR affects the efficiency and thermal performance of capacitor in AC circuits. When selecting a ceramic disc capacitor, consider the following:

- Application Needs: High-frequency and switching applications benefit from capacitor with low ESR to minimize energy losses and heat generation.

- Performance Requirements: Lower ESR values contribute to better performance in terms of signal integrity and power efficiency.

- Thermal Management: Capacitor with low ESR generate less heat, reducing the need for additional thermal management measures.

Our ceramic disc capacitor are designed with low ESR, typically below 0.1Ω, which minimizes energy losses and reduces heat generation during operation. Low ESR enhances the performance of switching power supplies, RF circuits, and other high-frequency applications by ensuring efficient energy transfer and reducing the risk of thermal issues. This makes our ceramic disk capacitor an excellent choice for applications where thermal performance is critical.

Dielectric Material and Class

The dielectric material and classification of the capacitor influence its performance characteristics. Key points to consider include:

- Dielectric Type: High-permittivity ceramic dielectrics offer better energy storage capabilities and stability.

- Class Y Dielectric: Class Y dielectrics are preferred for applications requiring high reliability and safety, such as EMI suppression.

- Dielectric Stability: Choose capacitor with stable dielectric properties to ensure consistent performance over time and varying conditions.

The dielectric material used in our ceramic disc capacitor is a high-permittivity ceramic, often classified as Class Y. Class Y dielectric materials are known for their stability and reliability, making them ideal for applications that require precise capacitance and long-term performance. The use of high-quality dielectric materials ensures that our capacitor can handle high electric fields without degradation, contributing to their longevity and consistent performance. This makes our Y capacitor particularly suitables for critical applications demanding high reliability.

Compliance and Certifications

Ensuring that the capacitor meets relevant safety and quality standards is essential, especially for applications in regulated industries. Consider the following:

- Safety Standards: Look for certifications such as UL, CE, and RoHS to ensure compliance with international safety and environmental regulations.

- Quality Assurance: Select capacitor from reputable manufacturers that adhere to strict quality control processes.

- Application-Specific Standards: Some industries may have specific standards that the capacitor must meet, such as medical or automotive certifications.

Cost and Availability

While performance and reliability are paramount, cost and availability are also important factors in capacitor selection. Consider the following:

- Budget Constraints: Balance the cost of the capacitor with its performance benefits to ensure it fits within your project budget.

- Supply Chain: Choose capacitor that are readily available to avoid delays in your manufacturing process.

- Bulk Purchasing: For large-scale projects, consider suppliers that offer bulk purchasing options to reduce costs.

Why Choose DXM for Ceramic Disc Capacitor?

Selecting the right supplier for ceramic disc capacitor is crucial for ensuring the quality and reliability of your electronic products. DXM ceramic disc capacitors stands out as a premier choice for numerous reasons, each contributing to the superior performance and trustworthiness of our products.

Unmatched Durability and Longevity

Our ceramic disc capacitor are built to last, offering exceptional durability and a long operational lifespan. Designed to withstand harsh conditions and continuous use, our capacitor ensure that your electronic systems remain reliable over time. This longevity translates to lower maintenance costs and fewer replacements, providing significant value to your projects. The robust construction of our ceramic disk capacitor ensures they perform consistently throughout their lifecycle.

Superior Performance in High-Frequency Applications

High-frequency applications demand capacitors that can operate efficiently without significant energy losses. Our ceramic disc capacitor are engineered with low Equivalent Series Resistance (ESR) and high dielectric strength, making them ideal for use in switching power supplies, RF circuits, and other high-frequency environments. This superior performance ensures that your circuits operate smoothly and efficiently, even under demanding conditions. Our Y capacitor is optimized for high-frequency EMI suppression, providing unparalleled performance in noise-sensitive applications.

Global Safety Standards Compliance

Safety and reliability are non-negotiable in electronic component manufacturing. Our capacitor comply with global safety standards such as UL and CE, ensuring that they meet rigorous quality and safety criteria. This compliance guarantees that our products are safe to use in a wide range of applications, from consumer electronics to industrial machinery, providing peace of mind to designers and end-users alike. The adherence of our ceramic disk capacitor to international safety standards underscores our commitment to excellence and safety.

Cost-Effective Solutions for Large-Scale Projects

At DXM Capacitors, we understand the importance of cost-efficiency, especially for large-scale projects. Our ceramic disc capacitor offer high performance at competitive prices, allowing you to achieve your project goals without exceeding your budget. Additionally, our flexible packaging options and bulk purchasing discounts provide further cost savings, making our capacitor an economical choice for manufacturers and designers. The affordability of our ceramic disk capacitor ensures that high-quality components are accessible for all types of projects.

Expertise and Customer Support

With years of experience in the industry, DXM Capacitors boasts a team of experts dedicated to supporting your capacitor needs. Whether you require technical assistance in selecting the right capacitor or need support with integration and testing, our knowledgeable staff is here to help. Our commitment to customer satisfaction ensures that you receive not only high-quality products but also the guidance and support necessary for successful implementation. The expert support for our Y capacitor ensures seamless integration into your electronic designs.

Innovative Technology and Continuous Improvement

Staying ahead in the rapidly evolving electronics industry requires continuous innovation. At DXM Capacitors, we invest in research and development to enhance our product offerings and incorporate the latest technological advancements. This commitment to innovation ensures that our ceramic disc capacitor remain at the forefront of performance and reliability, meeting the changing needs of the market and providing cutting-edge solutions to our customers. Our ceramic disk capacitor leverage the latest technologies to deliver superior performance in all applications.

Ceramic Disc Capacitor Comprehensive Datasheet

For detailed specifications and certifications, explore our ceramic disc capacitor datasheet. It is an essential resource for engineers and designers, offering all the information needed for seamless integration into projects.

The datasheet includes technical parameters, performance characteristics, and compliance details. It helps in selecting the right ceramic disc capacitors for your application, ensuring optimal performance and reliability.

Whether you require a Y capacitor for EMI suppression or a ceramic disk capacitor for signal stabilization, this document provides clear guidance for informed decisions. Trust our datasheet to support your design and engineering needs effectively.

FAQs: Frequently Asked Questions

1. What are ceramic disc capacitors used for?

Ceramic disc capacitors are primarily used for noise filtering, EMI suppression, and signal stabilization in AC circuits. Their ability to handle high voltages and operate reliably under varying temperature conditions makes them ideal for a wide range of applications, including power supply systems, telecommunications, and consumer electronics.

2. Are ceramic disc capacitors fire-resistant?

Yes, they feature UL 94V-0 rated epoxy resin, ensuring exceptional fire resistance. This fire-resistant property enhances the safety of electronic systems by preventing the spread of flames in case of overheating or electrical faults, making them suitable for use in safety-critical applications.

3. What is the difference between ceramic disc capacitors and ceramic disc capacitors?

Both terms refer to the same component, known for its ceramic dielectric and disc-shaped design. The difference is purely in terminology, with "disc" and "disk" being used interchangeably in the industry to describe these capacitors.

4. Why is Y capacitor important?

Y capacitor is designed to suppress EMI and ensure circuit safety, making it essential for modern electronic systems. It is specifically used in applications where safety and noise reduction are critical, such as in power supply filtering and signal stabilization, helping to maintain the integrity and reliability of electronic circuits.

5. How do ceramic disc capacitors compare to other types of capacitors?

Ceramic disc capacitors offer several advantages over other capacitor types, including high voltage tolerance, wide temperature range, compact size, and excellent stability. Compared to electrolytic or film capacitors, ceramic disc capacitors typically have lower ESR and better performance in high-frequency applications, making them a preferred choice for noise filtering and signal stabilization tasks.

6. What factors affect the lifespan of ceramic disc capacitors?

The lifespan of ceramic disc capacitors is influenced by factors such as operating temperature, voltage stress, mechanical stress, and environmental conditions. Ensuring that the capacitors are operated within their specified temperature and voltage ranges, as well as protecting them from physical damage and exposure to harsh environments, can significantly extend their operational lifespan.

7. Can ceramic disc capacitors be used in high-frequency circuits?

Absolutely. In fact, ceramic disc capacitors are highly suited for high-frequency circuits due to their low ESR and high-frequency performance characteristics. They are commonly used in RF applications, switching power supplies, and other circuits where high-frequency filtering and stability are required.

Learn more about our products and solutions by visiting the DXM official website. Trust DXM for top-quality ceramic disc capacitor and Y capacitor that enhance performance and safety in your electronic designs. Our commitment to quality, innovation, and customer satisfaction makes us the ideal partner for all your capacitor needs. Whether you need a reliable ceramic disk capacitor for a consumer device or a specialized Y capacitor for industrial machinery, DXM Capacitors has the solution to meet your requirements.

Summary of Ceramic disc capacitor

Ceramic disc capacitor (also known as Y capacitor) is a critical component in AC circuits. It effectively reduces noise, suppresses EMI, and supports high-frequency applications. These ceramic disc capacitors meet international safety standards and feature a robust fire-resistant coating for enhanced reliability.

With a wide capacitance range, ceramic disc capacitors ensure consistent performance across various electronic systems. DXM offers premium-quality ceramic disk capacitor solutions that improve efficiency and safety for industrial and consumer devices.

DXM: Your Trusted Partner for Ceramic Disc Capacitor Solutions. As a leading manufacturer, we provide high-performance, cost-effective capacitors designed for long-term reliability. Choose DXM for unmatched quality and value in every ceramic disc capacitor we deliver.

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd