High Voltage Capacitor-Reliable Ceramic Disc Capacitor in Advanced Electronics

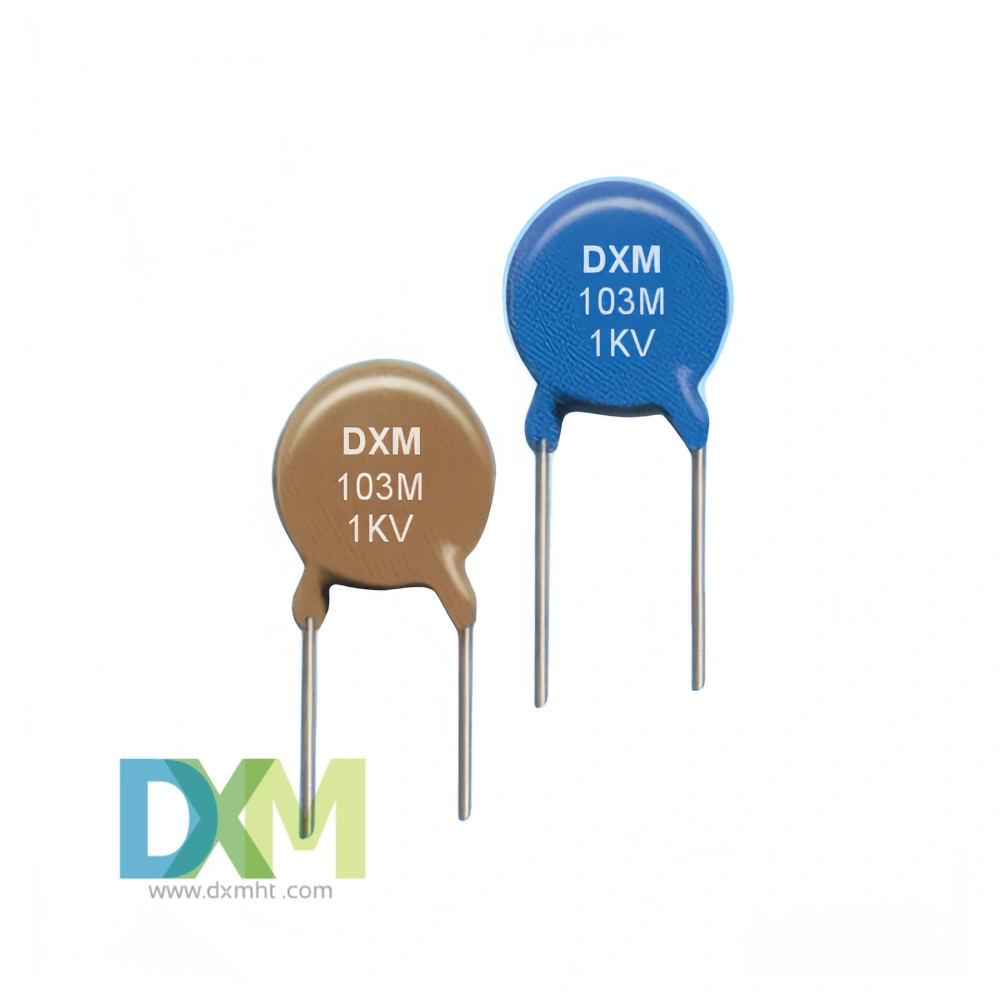

Introducing the DXM High Voltage Capacitor, a reliable ceramic disc capacitor designed for advanced electronics applications. Engineered for durability and efficiency, this high-performance component ensures optimal functionality in high voltage environments. Perfect for electronic circuits requiring stable and dependable performance, the DXM High Voltage Capacitor stands as a testament to quality and innovation. Trust DXM to elevate your projects with our high voltage capacitors, expertly crafted to meet the demands of cutting-edge technology.

Overview of High Voltage Capacitor

High Voltage Capacitor is a type of Ceramic Disc Capacitor.It provides exceptional capacitance stability with minimal energy loss. These Ceramic Disc Capacitors offer a wide range of voltage options, making them essential for various electronic applications. High Voltage Capacitor is crucial in radio communications, electronic devices, and advanced equipment, ensuring optimal performance. By managing circuit structures and voltages, this ceramic disc capacitor guarantees reliability in both direct and coupling circuits.

Why Choose High Voltage Capacitor?

High Voltage Capacitor, including Ceramic Disc Capacitor, deliver unmatched reliability and efficiency. Their stability and low energy loss make them a preferred choice in demanding applications.

Key Advantages of High Voltage Capacitor

Voltage Versatility and Stability

Ceramic Disc Capacitors offer a wide range of voltage specifications, making them ideal for various electronic needs. From consumer electronics to industrial applications, these Ceramic Disc Capacitors deliver unmatched versatility.

Exceptional Stability and Efficiency

Ceramic disc capacitor features high stability and low energy loss. They maintain consistent performance, ensuring reliability and longevity in electronic circuits. They are designed to support sophisticated equipment with demanding voltage requirements.

Broad Applicability

High Voltage Ceramic Disc Capacitors, are essential in radio communications and various electronic devices. Their versatility makes them a preferred choice for engineers and technicians in multiple fields.

Reliable Circuit Control

Enhance circuit performance by providing stable capacitance across voltage ranges. Whether used in direct or coupling circuits, they ensure efficient and reliable operation.

Applications of Ceramic Disc Capacitor

Radio Communications

Ceramic disc capacitor is essential for maintaining signal clarity and stability in communication devices. Ceramic Disc Capacitors ensure reliable performance in high-frequency circuits, making them crucial for radio communications.

Electronic Devices

From household electronics to industrial machinery, High Voltage Capacitor enhance the performance and durability of various products. Ceramic Disc Capacitors are vital in managing circuit structure and voltage, ensuring efficient operation.

Circuit Control

Ceramic disc capacitor plays a crucial role in the functionality and efficiency of electronic systems. They provide stable performance in both direct and coupling circuits, making them indispensable for advanced electronics.

Advanced Electronics

Supporting sophisticated equipment, ceramic disc capacitors meet high voltage needs in complex systems. They are integral in high-voltage circuits, especially in compact designs where space is a premium.

Industrial Equipment

In industrial machinery, High Voltage Capacitor ensures reliability and longevity. Ceramic disc capacitor is vital for managing complex, high-voltage circuits, ensuring consistent performance in demanding environments.

Key Features of High Voltage Capacitor

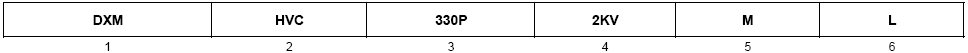

Ceramic Disc Capacitors Symbol

1.DXM:Company Brand;

2.Type-HVC:high voltage capacitors;

3.Capacitance:330P=330 pF; 4N7=4700 pF;

4. Rated voltage:2KV=2000VDC

5.Capacitance Tolerance:K=10%;M=20%

6. Lead type:L-Straight,K-Kink

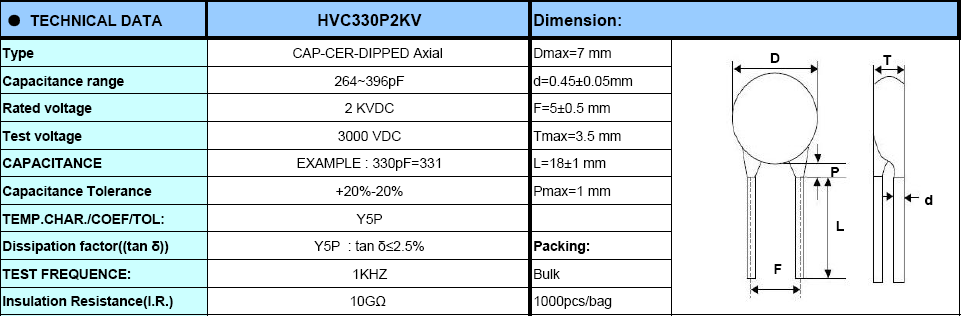

TECHNICAL DATA of HVC330P2KV Ceramic Disc Capacitor

How to Test High Voltage Capacitor: Key Parameters and Procedures

Testing a High Voltage Capacitor is crucial for ensuring its reliability and performance in demanding environments. Below are the key parameters and methods used to test these Ceramic Disc Capacitors.

1. Capacitance Measurement of Ceramic Disc Capacitor

- CC1, CC81 Type: Test at 1MHz, 1.0V.

- CT1, CT81, CT7 Type: Test at 1kHz, 1.0V.

- CS1 Type: Test at 1kHz, 0.1V.

- Conditions: T=25±5℃, Humidity 60±15%.

2. Insulation Resistance (I.R.)

- CT1, CC1, CS1 Types: Apply rated voltage for 60±5 seconds.

- CT81, CC81, CT7 Types: Apply 500V for 60±5 seconds.

3. Voltage Proof Testing

- CT1, CC1 Type: Apply 2.5 times the rated voltage for 60±5 seconds.

- CT81, CC81 Type: Apply 1.5 times the rated voltage plus 500V for 60±5 seconds.

- CS1 Type: Apply 1.5 times the rated voltage for 60±5 seconds.

- CT7 Type: Apply 10 times the rated voltage for 60±5 seconds.

- Performance Requirement: No breakdown or flashover.

4. Temperature Range of High Voltage Capacitor

- Testing Range: -25℃ to +85℃.

5. Ceramic Disc Capacitors Terminal Bending Strength

- Test: Apply 10N / 10S axial torque force on the lead wire.

- Performance Requirement: No visible damage.

6. Resistance to Soldering Heat

- Test: Distance from welding spot to capacitor body: 2-5mm, T=260℃ for 5 seconds.

- Performance Requirement: No visible damage.

7. Ceramic Disc Capacitor Soldering-Solderability

- Test: 260±10℃ for 3 seconds.

- Performance Requirement: Terminations uniformly tinned >95%.

8. Ceramic Disc Capacitor Durability Testing

- CT1, CC1 Type: Apply 1.5 times the rated voltage at T=85℃ for 1000 hours.

- CS1 Type: Apply 1.0 times the rated voltage at T=85℃ for 1000 hours.

- CT81, CC81 Type: Apply 1.5 times the rated voltage at T=85℃ for 1000 hours.

- CT7 Type: Apply 6.0 times the rated voltage at T=85℃ for 1000 hours.

- Performance Requirement: No visible damage, ΔC/C ≤20%.

9. Ceramic Disc Capacitor Marking Solvent Resistance

- Test: Wipe gently with a cotton swab dipped in alcohol three times.

- Performance Requirement: Marking must remain clear and complete.

10. Flammability of Ceramic Disc Capacitors

- Test: Needle flame test; residual flame time should not exceed 15 seconds.

- Performance Requirement: Residual flame time ≤3 seconds.

-

Frequently Asked Questions (Q&A)

1.What is a high-voltage capacitor?

A high-voltage capacitor is an electronic component designed to handle high levels of voltage and provide stability in critical electronic applications. High-voltage capacitors are ideal for industrial environments and telecommunications systems due to their high reliability.

2.How is a high-voltage capacitor tested?

High-voltage capacitors are tested by applying nominal voltage and measuring their capacitance under controlled conditions. These tests ensure that the capacitor can withstand voltage spikes without failure.

3.Where are ceramic capacitors used?

They are used in a wide variety of electronic devices, including radio communications, industrial equipment, and advanced circuit control systems. High-voltage ceramic capacitors are indispensable in these systems due to their ability to handle elevated voltages.

For more information about our products and specifications, please visit our DXM Technology page.

Conclusion

These tests ensure that High Voltage Capacitor, meets the necessary standards for performance and safety. Regular testing helps optimize electrical systems, ensuring reliability in high-stress environments.

DXM is one of the leading capacitor manufacturers in China.Visit us to explore the vital roles, types, and common issues of Ceramic Disc Capacitors to enhance your systems' performance and reliability.

© 2024 DXM Product. All rights reserved.

Author: Ivan Huang

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd