Advanced Thermal Sensors: Precision and Reliability for Every Industry

Experience unmatched precision and reliability with DXM's Advanced Thermal Sensors, designed for diverse industry applications. Our cutting-edge thermal sensors ensure accurate temperature monitoring, enhancing operational efficiency and safety. Trust DXM for state-of-the-art thermal sensor solutions tailored to meet your specific industry needs. Explore how our innovative technology can transform your business operations today.

- Comprehensive Overview of Thermal Sensors

- Common Types of Thermal Sensors

- 1. Thermistors

- 2. Resistance Temperature Detectors (RTDs)

- 3. Thermocouples

- 4. Semiconductor-Based Thermal Sensors

- 5. Infrared (IR) Sensors

- Extensive Applications of Thermal Sensors

- Thermal Sensor In Industrial Processes

- Automotive Systems

- Medical Devices

- Consumer Electronics

- Aerospace and Defense

- Environmental Monitoring

- Energy Management

- The Importance of Selecting the Right Thermal Sensors

- Accuracy and Precision

- Operating Temperature Range

- Response Time

- Environmental Conditions

- Integration and Compatibility

- Latest Innovations in Thermal Sensors Technology

- Nanomaterial-Based Thermal Sensors

- Wireless and IoT-Enabled Thermal Sensors

- Flexible and Wearable Thermal Sensors

- Enhanced Energy Efficiency

- Case Studies: Thermal Sensors in Action

- Case Study 1: Automotive Engine Monitoring

- Case Study 2: Medical Diagnostic Equipment

- Case Study 3: Industrial Process Control

- Case Study 4: Consumer Electronics Cooling Systems

- Case Study 5: Aerospace Thermal Management

- Choosing the Right Thermal Sensors for Your Needs

- Define Your Requirements

- Evaluate Sensor Types

- Consider Environmental Factors

- Assess Integration and Compatibility

- Evaluate Cost and Availability

- Seek Expert Advice

- Maintenance and Calibration of Thermal Sensors

- Regular Cleaning

- Periodic Calibration

- Protect from Physical Damage

- Monitor Environmental Conditions

- Update Firmware and Software

- Future Trends in Thermal Sensors Technology

- Smart Thermal Sensors

- Enhanced Sensitivity and Accuracy

- Energy Harvesting Thermal Sensors

- Miniaturization and Flexibility

- Advanced Data Analytics and AI Integration

- FAQs: Frequently Asked Questions About Thermal Sensors

Thermal sensors accurately measure temperature and heat flux changes. These thermal sensors ensure systems operate safely and efficiently. Thermal Sensor technology is vital in automotive, aerospace, medical, and consumer electronics industries. They provide the reliability and precision essential for modern advancements. By maintaining optimal temperature limits, thermal sensor enhances performance and safety across various applications. Trust our expert-engineered thermal sensors to deliver consistent and accurate results for your technological needs.

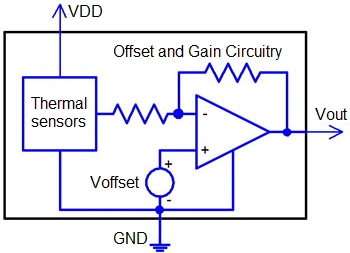

Comprehensive Overview of Thermal Sensors

Thermal sensors are engineered to detect temperature variations with high precision. These sensors are utilized in environments where temperature control is paramount, safeguarding equipment and enhancing performance. From monitoring industrial processes to ensuring the safety of medical devices, thermal sensor plays a pivotal role in maintaining the integrity of systems.

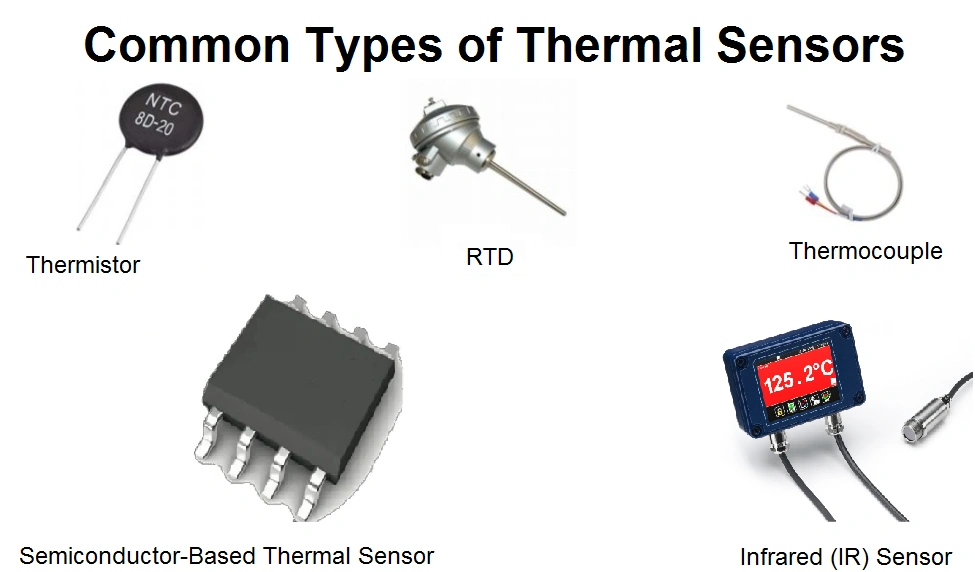

Common Types of Thermal Sensors

Understanding the different types of thermal sensors is essential for selecting the right sensor for specific applications. Each thermal sensor type offers unique benefits and operates effectively under varying conditions.

1. Thermistors

Thermistors are temperature-sensitive resistors that exhibit significant changes in resistance with temperature fluctuations. There are two primary types of thermistors: Negative Temperature Coefficient (NTC) and Positive Temperature Coefficient (PTC). NTC thermistors decrease in resistance as temperature rises, making them suitable for applications like temperature monitoring and control in consumer electronics. PTC thermistors, on the other hand, increase in resistance with rising temperature, which can be used for overcurrent protection and temperature regulation. Typically, NTC thermistors operate between -50°C and 250°C, providing versatility in various applications.

2. Resistance Temperature Detectors (RTDs)

RTDs are highly accurate thermal sensors that measure temperature by correlating the resistance changes in a material, usually platinum, with temperature variations. This thermal sensor offers excellent stability and repeatability, operating effectively from -200°C to 600°C. RTDs are ideal for applications where precise temperature control is critical, such as in laboratory equipment, industrial processes, and high-precision manufacturing. Its high accuracy and durability make RTDs a preferred choice for many demanding environments.

3. Thermocouples

Thermocouples are among the most widely used thermal sensors due to their simplicity and wide temperature range. These sensors consist of two dissimilar metals joined at one end, creating a junction that generates a voltage proportional to the temperature difference between the junctions. Thermocouples can measure temperatures from -200°C to 1750°C, making them suitable for high-temperature applications such as furnaces, gas turbines, and engines. Despite their broad range, thermocouples offer lower accuracy, typically between 0.5°C to 5°C, which can be a limitation in applications requiring precise measurements.

4. Semiconductor-Based Thermal Sensors

Semiconductor-based thermal sensors utilize semiconductor materials to detect temperature changes through variations in voltage or current. This thermal sensor offers a linear response and is relatively inexpensive, making it suitable for consumer electronics, HVAC systems, and automotive applications. While it provides reliable performance within a moderate temperature range of -70°C to 150°C, its accuracy is generally lower compared to RTDs and thermocouples. Nonetheless, semiconductor-based thermal sensor is favored for its compact size and ease of integration into electronic circuits.

5. Infrared (IR) Sensors

Infrared thermal sensor measures temperature without direct contact by detecting the infrared radiation emitted by objects. This non-contact sensor is invaluable in applications where direct measurement is impractical or impossible, such as in moving objects, hazardous environments, or sensitive materials. IR sensors are widely used in medical thermometers, thermal imaging cameras, and environmental monitoring systems, providing accurate temperature readings while maintaining safety and efficiency.

Extensive Applications of Thermal Sensors

Thermal sensors are integral components in a wide array of applications, each leveraging the unique capabilities of different thermal sensor to achieve optimal performance and safety.

Thermal Sensor In Industrial Processes

In industrial settings, thermal sensors monitor temperatures within manufacturing and processing environments to prevent overheating and ensure consistent product quality. Thermal sensor is used in machinery, kilns, and chemical processing plants to maintain precise temperature control, enhancing operational efficiency and reducing the risk of equipment failure.

Automotive Systems

Thermal sensors play a crucial role in automotive systems by monitoring engine temperatures, exhaust gases, and battery performance. This thermal sensor ensures that engine components operate within its designated thermal limits, improving fuel efficiency, reducing emissions, and extending the lifespan of automotive parts. Additionally, thermal sensor contributes to advanced safety features such as automatic climate control and tire temperature monitoring.

Medical Devices

In the medical field, thermal sensors are essential for patient monitoring and diagnostic equipment. Non-contact thermal sensor is used in medical thermometers to provide accurate and hygienic temperature readings. Thermal sensor is also integrated into imaging devices, surgical instruments, and patient monitoring systems, enhancing the precision and reliability of medical procedures and patient care.

Consumer Electronics

Thermal sensors are ubiquitous in consumer electronics, ensuring devices operate efficiently and safely. They are found in smartphones, laptops, refrigerators, and microwaves, where they regulate temperatures to prevent overheating and optimize energy consumption. By maintaining optimal operating temperatures, thermal sensor enhances device performance, extend battery life, and improve user safety.

Aerospace and Defense

In the aerospace and defense industries, thermal sensors are critical for monitoring the thermal conditions of aircraft, spacecraft, and military equipment. This thermal sensor ensures that sensitive component operates within safe temperature ranges, preventing malfunctions and enhancing the reliability of missions. Applications include engine monitoring, environmental control systems, and thermal imaging for navigation and targeting.

Environmental Monitoring

Thermal sensors are vital for environmental monitoring, tracking temperature changes in weather systems, oceans, and ecosystems. These sensors provide data for climate research, disaster prevention, and natural resource management, contributing to informed decision-making and sustainable practices.

Energy Management

In the energy sector, thermal sensors monitor the performance and safety of power generation and distribution systems. They are used in renewable energy installations, such as solar panels and wind turbines, to optimize energy production and detect potential issues. Thermal sensor also plays a role in smart grids, enhancing energy efficiency and reliability.

The Importance of Selecting the Right Thermal Sensors

Selecting the appropriate thermal sensor is paramount for ensuring system reliability, performance, and safety. The choice of thermal sensors depends on several factors, including the required accuracy, operating temperature range, response time, and environmental conditions. Proper thermal sensor selection ensures optimal functionality, minimizes downtime, and enhances the overall efficiency of the system.

Accuracy and Precision

The accuracy of thermal sensors is a critical consideration, especially in applications requiring precise temperature control. RTDs offer the highest accuracy among thermal sensor, making them ideal for laboratory and industrial applications. Thermocouples provide a broader temperature range but with lower accuracy, suitable for high-temperature environments where precision is less critical.

Operating Temperature Range

The operating temperature range of thermal sensor determines their suitability for specific applications. Thermocouples can withstand extreme temperatures, while thermistors are better suited for moderate temperature ranges. Semiconductor-based sensors are ideal for consumer electronics, where compact size and moderate temperature ranges are essential.

Response Time

Response time refers to how quickly a thermal sensor can detect temperature changes. Infrared sensors offer rapid response times, making them suitable for applications requiring real-time monitoring. RTDs and thermocouples may have slower response times but provide greater accuracy and stability.

Environmental Conditions

Environmental factors such as humidity, pressure, and exposure to chemicals can impact the performance of thermal sensors. Choosing thermal sensor that is resilient to specific environmental conditions ensures longevity and reliable operation. For instance, thermocouples are often used in harsh industrial environments due to their durability.

Integration and Compatibility

Compatibility with existing systems and ease of integration are important factors in thermal sensor selection. Semiconductor-based sensors are preferred for their ease of integration into electronic circuits, while RTDs may require specialized interfaces for accurate readings. Ensuring that the chosen sensors are compatible with the system architecture enhances overall performance.

Latest Innovations in Thermal Sensors Technology

The field of thermal sensors is continually evolving, with advancements aimed at improving accuracy, reducing size, and enhancing functionality. Innovations in materials science, nanotechnology, and wireless communication are driving the development of next-generation thermal sensor.

Nanomaterial-Based Thermal Sensors

Nanomaterials are being utilized to create ultra-sensitive thermal sensors with enhanced performance. This thermal sensor can detect minute temperature changes, making it ideal for applications in biomedical research, environmental monitoring, and advanced manufacturing.

Wireless and IoT-Enabled Thermal Sensors

The integration of thermal sensors with wireless technology and the Internet of Things (IoT) is revolutionizing temperature monitoring. Wireless thermal sensor enables remote monitoring and data collection, facilitating real-time analysis and decision-making. IoT-enabled thermal sensor is used in smart homes, industrial automation, and healthcare, providing seamless connectivity and enhanced functionality.

Flexible and Wearable Thermal Sensors

Advancements in flexible electronics have led to the development of wearable thermal sensors. This thermal sensor can conform to the body's contours, making it suitable for wearable health monitors, smart textiles, and flexible consumer electronics. Flexible thermal sensor offers comfort and convenience without compromising on accuracy or reliability.

Enhanced Energy Efficiency

Modern thermal sensors are designed to consume less power, extending the battery life of portable devices and reducing energy costs in large-scale applications. Energy-efficient thermal sensor is crucial for sustainable practices and the development of green technologies.

Case Studies: Thermal Sensors in Action

Real-world applications demonstrate the critical role of sensors in enhancing system performance and safety. Below are some case studies highlighting the effective use of thermal sensor across different industries.

Case Study 1: Automotive Engine Monitoring

In the automotive industry, thermal sensors are used to monitor engine temperatures in real-time. By integrating RTDs into the engine cooling system, manufacturers can ensure that engine components operate within safe temperature ranges. This thermal sensor setup prevents overheating, reduces wear and tear, and enhances fuel efficiency, ultimately extending the engine's lifespan.

Case Study 2: Medical Diagnostic Equipment

Medical devices such as non-contact thermometers rely on infrared sensors to provide accurate and hygienic temperature measurements. In hospitals, this thermal sensor enables quick and reliable patient temperature monitoring, facilitating timely diagnosis and treatment. The non-contact nature of IR thermal sensor also reduces the risk of cross-contamination, enhancing patient safety.

Case Study 3: Industrial Process Control

In chemical manufacturing, maintaining precise temperature control is essential for product quality and safety. Thermal sensors integrated into the production line monitor temperature fluctuations, allowing for immediate adjustments to the process. This thermal sensor-driven control system minimizes the risk of accidents, ensures consistent product quality, and optimizes resource utilization.

Case Study 4: Consumer Electronics Cooling Systems

Consumer electronics, such as laptops and smartphones, generate significant heat during operation. Thermal sensors are embedded in these devices to monitor and regulate temperatures, preventing overheating and ensuring optimal performance. By managing heat effectively, thermal sensor enhances device longevity and user experience.

Case Study 5: Aerospace Thermal Management

In aerospace applications, thermal sensors monitor the temperatures of critical components in aircraft and spacecraft. This thermal sensor ensures that systems operate within safe thermal limits, preventing failures during flight. Advanced thermal sensor contributes to the reliability and safety of aerospace missions, supporting successful operations in extreme environments.

Choosing the Right Thermal Sensors for Your Needs

Selecting the appropriate thermal sensor involves evaluating various factors to match the sensor's capabilities with the application's requirements. Consider the following guidelines to make an informed decision:

Define Your Requirements

Start by clearly defining the temperature range, accuracy, response time, and environmental conditions of your application. Understanding these requirements will help you narrow down the thermal sensor options that best meet your needs.

Evaluate Sensor Types

Review the different types of thermal sensors, such as thermocouples, RTDs, thermistors, IR sensors, and semiconductor-based sensors. Consider the advantages and limitations of each type in relation to your specific application.

Consider Environmental Factors

Assess the environmental conditions where the thermal sensor will be used. Factors like humidity, pressure, exposure to chemicals, and physical vibrations can affect sensor performance. Choose a thermal sensor that is resilient to these conditions.

Assess Integration and Compatibility

Ensure that the thermal sensor can be easily integrated into your existing systems. Check for compatibility with data acquisition systems, communication protocols, and power requirements to facilitate seamless integration.

Evaluate Cost and Availability

Consider the cost of the thermal sensor and its availability. Balance the budget constraints with the performance requirements to select a thermal sensor that offers the best value for your investment.

Seek Expert Advice

If you are unsure about which thermal sensor to choose, consult with experts or contact thermal sensor manufacturers. They can provide valuable insights and recommendations based on your specific application needs.

Maintenance and Calibration of Thermal Sensors

Proper maintenance and regular calibration are essential for ensuring the accuracy and longevity of thermal sensors. Follow these best practices to maintain your sensor effectively:

Regular Cleaning

Keep thermal sensors clean and free from dust, debris, and contaminants. Regular cleaning prevents interference with temperature measurements and ensures reliable performance.

Periodic Calibration

Calibrate thermal sensor periodically to maintain its accuracy. Calibration involves comparing the sensor's readings with a known standard and making necessary adjustments. Regular calibration helps identify and correct any deviations in sensor performance.

Protect from Physical Damage

Ensure that thermal sensors are protected from physical shocks, vibrations, and mechanical stresses. Proper mounting and handling prevent damage that could affect sensor functionality.

Monitor Environmental Conditions

Monitor the environmental conditions surrounding the thermal sensor to prevent exposure to extreme temperatures, humidity, or corrosive substances. Implement protective measures such as enclosures or shielding to safeguard the sensors.

Update Firmware and Software

If your thermal sensors are part of a digital system, keep the firmware and software up to date. Updates can enhance sensor performance, fix bugs, and improve integration with other systems.

Future Trends in Thermal Sensors Technology

The landscape of thermal sensor technology is rapidly evolving, driven by advancements in materials science, electronics, and data analytics. Here are some future trends that are shaping the next generation of thermal sensor:

Smart Thermal Sensors

Smart sensors are equipped with advanced processing capabilities and connectivity features. These sensors can analyze data in real-time, communicate wirelessly, and integrate with IoT platforms, enabling intelligent temperature monitoring and control systems.

Enhanced Sensitivity and Accuracy

Research is focused on developing thermal sensor with higher sensitivity and accuracy. Innovations in nanotechnology and materials engineering are leading to sensors that can detect minute temperature changes, expanding their applications in fields like biomedical research and environmental science.

Energy Harvesting Thermal Sensors

Energy harvesting technology is being integrated into thermal sensors to eliminate the need for external power sources. These sensors can generate their own power from temperature gradients or ambient energy, making them ideal for remote and inaccessible applications.

Miniaturization and Flexibility

Thermal sensors are becoming smaller and more flexible, allowing for integration into compact and wearable devices. Miniaturized sensors offer greater versatility and are essential for applications in wearable technology, smart textiles, and portable electronics.

Advanced Data Analytics and AI Integration

The integration of artificial intelligence (AI) and machine learning with thermal sensor is enhancing data analysis and predictive maintenance. AI algorithms can process large volumes of temperature data, identify patterns, and predict potential issues, improving system reliability and efficiency.

FAQs: Frequently Asked Questions About Thermal Sensors

- What are thermal sensors used for?

- Thermal sensors are used to measure temperature or heat flux changes in various applications, ensuring systems operate within safe temperature limits.

- What types of thermal sensors are available?

- Common types include thermocouples, RTDs, thermistors, infrared sensors, and semiconductor-based sensors, each with unique characteristics and applications.

- How do thermocouples work?

- Thermocouples generate a voltage proportional to the temperature difference between two joined metal junctions, allowing temperature measurement over a wide range.

- Why choose RTDs over thermocouples?

- RTDs offer higher accuracy and stability, making them suitable for precise temperature measurements in demanding environments.

- Can thermal sensor be used in medical devices?

- Yes, thermal sensor is widely used in medical devices like non-contact thermometers for accurate patient temperature monitoring.

- What is the operating temperature range of thermistors?

- NTC thermistors typically operate between -50°C and 250°C, while PTC thermistors have similar ranges depending on their specific design.

- How do infrared thermal sensors measure temperature?

- Infrared thermal sensors detect temperature by measuring the infrared radiation emitted by objects, allowing for non-contact temperature measurement.

- What factors should be considered when selecting a thermal sensor?

- Key factors include accuracy, operating temperature range, response time, environmental conditions, integration compatibility, and cost.

- Are thermal sensors maintenance-intensive?

- Proper maintenance, including regular cleaning and calibration, is essential to ensure the accuracy and longevity of sensors.

- What are the latest trends in thermal sensor technology?

- Recent trends include smart thermal sensors with IoT integration, enhanced sensitivity and accuracy, energy harvesting capabilities, miniaturization, and AI-driven data analytics.

Interested in learning more about our cutting-edge thermal sensors? Visit our product page to find the perfect thermal sensor solutions tailored to your specific needs.

© 2025 DXM Blog. All rights reserved.

Author: Ivan Huang

Recommended for you

Water Temperature Sensor: The Key to Engine Health and Efficiency

Lightning Surge Protection Varistor: Essential for Protecting Your Electrical Systems

Water Temp Sensor: How to Test it for Reliable Performance?

Capacitor Impedance: Calculation Guide & FAQs

Temperature Probe Sensor: A Comprehensive Guide

Termistor NTC: What Does a Thermistor Do?

Price and Payment

How are the prices of your products determined?

Our product prices are based on a variety of factors, including order quantity, customization requirements, and market competition.

Are invoices provided?

Yes, we provide legal invoices that can be used for reimbursement and accounting records.

Payment Terms

There are a number of different payment methods that can be used when you deal with us. Two are mostly used: T/T payment in advance for small values and irrevocable L/C at sight for large values.

Logistics

Does your product support global logistics and distribution?

Yes, our products support global logistics and distribution services, and you can receive our products anytime and anywhere.

Customized Services

Can I customize (OEM) the product?

Yes. You can customize the product with DXM. Our R&D and production technology have already reached an advanced world level, and we can provide qualified OEM service for global customers.Please specify your requirements to our representative or send samples to our factory office, and we will confirm your details.

You may also like

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd