Ceramic Resistor: High-Performance for Automotive Surge Protection

Discover the unmatched reliability of DXM's ceramic resistor, designed specifically for high-performance automotive surge protection. Our ceramic resistors and cement resistors offer exceptional durability and efficiency, ensuring your vehicle’s electrical system is safeguarded against voltage spikes. Trust DXM for advanced solutions in protecting your automotive electronics.

- Key Features of Ceramic Resistor for Automotive Applications

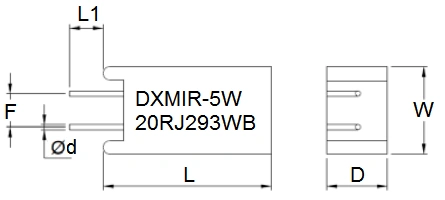

- Ceramic Resistor dimension

- Voltage Rating for Ceramic Resistor

- Technical Specifications of Ceramic Resistor

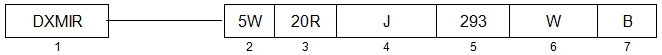

- Ceramic Resistor Marking of Part Number

- Why Ceramic Resistor Is Essential for Automotive Systems?

- Performance and Durability of Ceramic Resistor

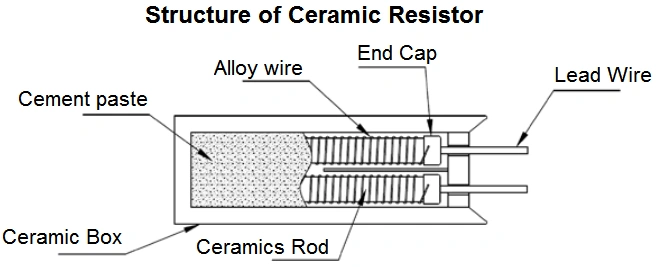

- Ceramic Resistor Structure

- Applications of Ceramic Resistor in Automotive Industry

- Global Standards Compliance of Ceramic Resistor

- The Role of Ceramic Resistor in Automotive Performance

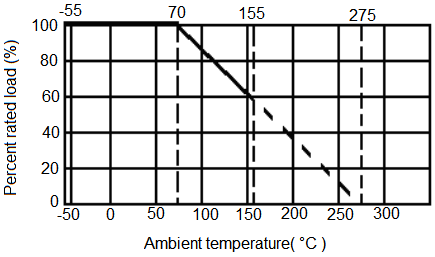

- Ceramic Resistor Derating Curve

- Test Requirement on Ceramic Resistors

- Reliability Testing of Ceramic Resistor

- Performance Test Overview

- Solderability and Heat Resistance

- Load Life Performance

- Mechanical Ratings of Ceramic Resistor

- Vibration Test

- Shock Test

- Environmental Ratings of Ceramic Resistor

- Climatic Sequence

- High Temperature Storage

- Damp Heat Loading

- Temperature Cycle

- Suggested Storage Conditions for Ceramic Resistors

- FAQs of Ceramic Resistors

- 1.Why are ceramic resistors essential for automotive electronics?

- 2.What makes the DXMIR ceramic resistor suitable for automotive applications?

- 3.How does a ceramic resistor protect circuits from inrush currents?

- 4.What is the difference between ceramic resistor and cement resistor?

- 5.How are ceramic resistors tested for reliability?

- Conclusion: Enhancing Automotive Electronics with Ceramic Resistors

Ceramic resistor DXMIR-5W20RJ293WB is a type of cement resistor inrush current limiter,plays a critical role in automotive electronics for inrush current limiting. It ensures precise surge protection, shielding systems from inrush currents and voltage spikes. As industries demand higher performance and reliability, ceramic resistors have become indispensable for robust designs. These components are engineered for extreme conditions, offering superior surge and voltage regulation in automotive applications.

Key Features of Ceramic Resistor for Automotive Applications

- Surge Resistance: Handles high surge currents reliably.

- Material Composition: Built from durable ceramic resistors.

- Compact and Sturdy Design: Fits seamlessly into high-stress automotive environments.

- Fixed Resistance Value: Ensures predictable, constant performance.

- Flame and Moisture Resistance: Offers reliable protection against challenging conditions.

- Thermal Stability: Resists significant value changes with temperature shifts.

- Self-Extinguishing Design: Minimizes fire risk in high-temperature situations.

- Compliance with Standards: Meets RoHS, AEC-Q, and cement resistor regulations for global safety.

-

Ceramic Resistor dimension

-

-

Type W±1 D±1 L±1 L1±1 F±1 Φd±0.05 DXMIR 5W 13.5 9 25 5 5 0.75 DXMIR 7W 15 9 38 10 7.5 0.75 DXMIR 10W 16 12 38 10 7.5 0.75 -

Voltage Rating for Ceramic Resistor

-

The ceramic resistor has a rated DC continuous working voltage or RMS AC voltage. It corresponds to the power rating, calculated using the formula:

RCWV = √(P × R)

- RCWV: Rated DC or RMS AC continuous voltage.

- P: Power rating in watts.

- R: Nominal resistance in ohms.

This calculation ensures that ceramic resistor is compatible with its power rating. It complies with industry standards and can also integrate with cement resistor for improved performance.

-

Technical Specifications of Ceramic Resistor

The High Surge Radial Type ceramic resistor is part of the PRMS series, offering a wide range of specifications tailored for diverse automotive applications:

Item Product Type Power Rating Tolerance Resistance Range Max Overload Voltage Max Working Voltage 1 DXMIR 5W ±5% 、±10% 1.5Ω~2KΩ 700V 350V 2 DXMIR 7W ±5% 、±10% 1.8Ω~2KΩ 1000V 500V 3 DXMIR 10W ±5% 、±10% 2.7Ω~4KΩ 1400V 700V

Ceramic Resistor Marking of Part Number

2.Wattage: 5W=5W, 7W=7W, 10W=10W, 20W=20W,

3.R25 resistance: 5R0-5Ω 6R5-6.5Ω 20R-20Ω 121-120Ω

4.Resistance Tolerance:J = ±5%, K = ±10%

5.Rated Voltage (is powered) (Vac): 293 - 293V

6.Product Type: W=Wire Round type

7.Packing Type: B=Bulk Packing

Why Ceramic Resistor Is Essential for Automotive Systems?

In the advancing automotive industry, ceramic resistors offer precision and safety. Their key features include:

- Resistor surge protection: Reliable defense against voltage spikes and fluctuations.

- Compliance with RoHS and halogen-free standards for environmental safety.

- Self-extinguishing design for safety in demanding conditions.

- Compact, durable structures designed for high-stress systems.

- Compatibility with cement resistors for enhanced performance.

These features make ceramic resistors a vital component in modern automotive systems.

Performance and Durability of Ceramic Resistor

Ceramic resistors are designed to excel in demanding environments. They feature:

- Exceptional temperature coefficient, maintaining precision across varying thermal conditions.

- Resistance to short-term overloads and operational stress.

- Endurance against humidity, ensuring reliable performance under harsh conditions.

- Compatibility with cement resistor for enhanced application robustness.

These attributes make ceramic resistors ideal for automotive and industrial uses.

Ceramic Resistor Structure

Applications of Ceramic Resistor in Automotive Industry

| Applications | Description | |||||||||||

| Inrush Current Limiting | Limits initial surge current when devices are powered on to protect circuits. | |||||||||||

| Voltage Spike Protection | Absorbs voltage spikes to safeguard sensitive electronic components. | |||||||||||

| Power Supply Circuits | Ensures smooth operation by effectively managing current flow in switching power supplies. | |||||||||||

Global Standards Compliance of Ceramic Resistor

Ceramic resistors meet strict global standards, including RoHS,halogen-free directives and AEC-Q Qualification. This ensures operational efficiency and environmental sustainability. Their compliance with automotive safety regulations makes them a reliable choice. The compatibility with cement resistor standards further enhances their trust among engineers and designers worldwide.

The Role of Ceramic Resistor in Automotive Performance

Ceramic resistors manage inrush currents during startup, protecting electronic components. Key benefits include:

- Exceptional surge protection for high-demand circuits.

- Robust designs ensuring automotive durability.

- Compliance with global safety and performance standards.

- Compatibility with cement resistor requirements.

With their reliability, ceramic resistors ensure stable automotive system performance, even in extreme conditions.

Ceramic Resistor Derating Curve

Ceramic Resistor Derating Curve: Graph showing percentage rated load vs. ambient temperature (°C) for ceramic resistors. The curve illustrates power derating as temperature increases.

Test Requirement on Ceramic Resistors

Reliability Testing of Ceramic Resistor

The ceramic resistor undergoes rigorous reliability testing to ensure performance consistency and durability. Below are the tests and results:

Performance Test Overview

- Dielectric Withstanding Voltage: Applied 1000VAC for 60 seconds. Result: No flashover or mechanical damage.

- Temperature Coefficient: Resistance change is kept within ±400PPM/°C (<20Ω) or ±350PPM/°C (≥20Ω).

- Short-Time Overload: Applied 2.5 times RCWV for 5 seconds. Resistance change rate within ±(5% + 0.05Ω).

- Terminal Strength: Direct load test with 2.5 kg for 10 seconds. Result: No mechanical damage.

Solderability and Heat Resistance

- Solderability: Solder at 245°C for 2-3 seconds. Result: 95% coverage minimum.

- Resistance to Soldering Heat: Immersed in 260°C solder for 10 seconds. Resistance change within ±(1% + 0.05Ω), no damage.

Load Life Performance

- Load Life: Operated for 1,000 hours with duty cycle. Resistance change within ΔR/R ≤ ±(5% + 0.05Ω).

- Load Life in Humidity: Operated at RCWV for 1,000 hours in high humidity. Resistance change within ΔR/R ≤ ±(5% + 0.05Ω).

These tests validate the ceramic resistors' reliability and compliance with industry standards, ensuring their compatibility even with cement resistors in automotive applications.

Mechanical Ratings of Ceramic Resistor

The ceramic resistor is tested under rigorous mechanical conditions to ensure durability and stability. Below are the key test parameters:

Vibration Test

- Condition: The resistor is soldered to a baseboard and subjected to oscillation. Frequency ranges from 10 Hz to 55 Hz, with an amplitude of 0.75 mm for 24 cycles in each of three perpendicular planes, over 6 hours.

- Requirement: No visible damage, with resistance variation ∣ΔR/R25∣ ≤ 20%.

Shock Test

- Condition: The ceramic resistors are tested under half-sine shock waves. Velocity is 1.0 m/s with acceleration of 50 m/s² and a pulse time of 30 ms.

- Requirement: No visible damage, with resistance variation ∣ΔR/R25∣ ≤ 20%.

These tests confirm that ceramic resistors are resilient and can withstand harsh mechanical conditions. They are suitable for integration with cement resistors in various applications, ensuring reliable performance.

Environmental Ratings of Ceramic Resistor

The ceramic resistor undergoes rigorous environmental testing to ensure reliability under various conditions. Below are the key tests:

Climatic Sequence

- Steps 1 to 4: Temperature range from +40°C to 100°C, humidity 20% R.H, up to 24 hours. Result: No visible damage, resistance change ∣ΔR/R25∣ ≤ 20%.

- Steps 5 to 7: Temperature from 0°C to +40°C, humidity 90% R.H, up to 24 hours. Result: No visible damage, resistance change ∣ΔR/R25∣ ≤ 20%.

High Temperature Storage

- Condition: Stored in a drying oven at 125°C for 1000 hours with 16Vrms and 1000mA. Result: ΔVB/VB% ≤ ±5%.

Damp Heat Loading

- Condition: Applied maximum allowable voltage at 40°C, 90-95% R.H, for 1000 hours. Result: No visible damage, resistance change ∣ΔR/R25∣ ≤ 20%.

Temperature Cycle

- Condition: Cycled from -40°C to 85°C through four temperature steps for 5 cycles. Result: No visible damage, resistance change ∣ΔR/R25∣ ≤ 20%.

These environmental tests validate ceramic resistors for robust performance. They are suitable for use with cement resistor applications, ensuring high reliability.

Suggested Storage Conditions for Ceramic Resistors

To maintain the quality of ceramic resistors, proper storage conditions are crucial. The guidelines are as follows:

- Temperature: Store between 15°C and 35°C.

- Humidity: Maintain relative humidity of 25% to 75%.

- Carton Placement: Follow indicated direction to avoid deformation.

- Avoid:

- High electrostatic environments.

- Direct sunlight, rain, or condensation.

- Exposure to corrosive gases like Cl₂, H₂S, NH₃, SO₂, NO₂, or Br.

- Storage Period: Up to 1 year.

Proper storage helps ensure ceramic resistors maintain performance. They can also be effectively used with cement resistor applications.

FAQs of Ceramic Resistors

1.Why are ceramic resistors essential for automotive electronics?

Ceramic resistors are critical for managing surge currents and voltage spikes. They provide reliable protection, ensuring stable performance in automotive systems, even under extreme conditions.

2.What makes the DXMIR ceramic resistor suitable for automotive applications?

The DXMIR ceramic resistor offers high surge resistance, thermal stability, and flame resistance. It is designed for demanding automotive environments and complies with RoHS and AEC-Q standards.

3.How does a ceramic resistor protect circuits from inrush currents?

A ceramic resistor limits inrush current during device power-up, protecting sensitive components from damage. This ensures longevity and reliability in power-sensitive automotive applications.

4.What is the difference between ceramic resistor and cement resistor?

Both ceramic resistor and cement resistor provide surge protection, but ceramic resistor offers higher thermal stability and resistance to environmental stress, making it ideal for automotive systems.

5.How are ceramic resistors tested for reliability?

Ceramic resistors undergo multiple tests, including dielectric withstanding voltage, temperature coefficient, and load life in humidity. These ensure consistent performance and durability, even in harsh conditions.

Conclusion: Enhancing Automotive Electronics with Ceramic Resistors

Ceramic resistor is essential for boosting the reliability and longevity of automotive electronic systems. It effectively handle high surge currents, ensuring stable performance under demanding conditions. Its robust design makes them superior to cement resistor, offering better protection against voltage spikes and fluctuations.

With its ability to endure extreme environmental factors, ceramic resistor maintains consistent performance, which is critical in modern vehicle electronics. It is engineered to withstand high surges, making it indispensable in automotive designs.

Incorporating ceramic resistors in automotive systems ensures better durability and performance over time, making them a trusted choice for engineers and designers. Their reliability under various conditions reinforces their importance in enhancing the longevity of automotive electronic systems.

© 2024 DXM Blog. All rights reserved.

Author: Ivan Huang

Recommended for you

Water Temperature Sensor: The Key to Engine Health and Efficiency

Lightning Surge Protection Varistor: Essential for Protecting Your Electrical Systems

Water Temp Sensor: How to Test it for Reliable Performance?

Capacitor Impedance: Calculation Guide & FAQs

Temperature Probe Sensor: A Comprehensive Guide

Termistor NTC: What Does a Thermistor Do?

Logistics

Can I change my shipping address?

Yes, you can contact our customer service team to modify the delivery address before order confirmation to ensure that the order can be accurately delivered to the address you specify.

Is your logistics and distribution service reliable?

Yes, we cooperate with a number of well-known logistics companies to ensure the timeliness and reliability of logistics and distribution services and provide you with a satisfactory distribution experience.

How to track my order?

You can track your order through our official website or the order number provided and learn about the logistics status and delivery progress of your order at any time.

Customized Services

Free sample availability

You can contact our representative via email, fax or phone to specify the sample you need and provide your courier's account number (such as UPS, FedEx, DHL, TNT, etc.).. And we’ll send you samples free of charge through your courier by freight collection.

Price and Payment

How are the prices of your products determined?

Our product prices are based on a variety of factors, including order quantity, customization requirements, and market competition.

You may also like

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd