NTC Thermistor Calculator: Understanding and Utilizing Beta Values

Discover the power of precision with the DXM NTC Thermistor Calculator. This essential tool is designed for industry professionals seeking accurate NTC calculation. Understand and utilize beta values effectively to enhance thermal management in your applications. Our calculator simplifies complex equations, providing reliable data for optimal performance. Trust DXM for innovative solutions and amplify your project's efficiency today. Explore the potential of NTC calculator and make informed decisions with confidence. Visit our site to learn more!

- What is an NTC Thermistor Calculator?

- The Importance of Beta Value in NTC Thermistor Calculator

- How to Calculate Beta Value

- Using an NTC Thermistor Calculator

- NTC Thermistor Resistance Calculator

- Benefits of Using an NTC Thermistor Calculator

- Advanced NTC Thermistor Calculator

- Steinhart-Hart Equation

- Self-Heating Effects

- Practical Applications of NTC calculation

- Choosing the Right NTC Thermistor

- Common Mistakes in NTC Calculation

- Future Trends in NTC Thermistor Technology

- Conclusion

- Frequently Asked Questions

In temperature sensing and control, the NTC thermistor calculator is an invaluable tool. This NTC calculation help engineers and technicians accurately determine resistance values at various temperatures. This guide explores Negative Temperature Coefficient thermistors, beta values, and effective use of an NTC calculator.

What is an NTC Thermistor Calculator?

NTC (Negative Temperature Coefficient) thermistors are temperature-sensitive resistors. Their resistance decreases as temperature increases, making them ideal for precise temperature measurements. An NTC thermistor calculator is essential for working with these components.

The Importance of Beta Value in NTC Thermistor Calculator

The beta value is crucial in NTC calculations. It represents the thermistor's sensitivity to temperature changes. Understanding and accurately calculating the beta value using an NTC thermistor calculator is key for designing efficient temperature-sensing systems.

How to Calculate Beta Value

To calculate the beta value, you need two temperature points and their corresponding resistance values. The NTC thermistor calculator uses this formula:

Where:

- T1 and T2 are temperatures in Kelvin

- R1 and R2 are resistances at T1 and T2 respectively

- Explore the Beta Calculator for quick and precise calculation.

Using an NTC Thermistor Calculator

An NTC thermistor calculator simplifies the process of determining resistance values at different temperatures. Here's how to use one effectively:

- Input the known beta value of your thermistor into the NTC calculation

- Enter the reference temperature and resistance

- Specify the temperature at which you want to know the resistance

- The NTC calculation will provide the resistance value

- Saves time on complex manual calculations

- Reduces the risk of human error

- Allows for quick comparisons of different thermistors

- Facilitates efficient circuit design

- HVAC systems for precise temperature control

- Medical equipment for patient monitoring

- Automotive industry for engine temperature sensing

- Consumer electronics for overheating protection

- Temperature range of operation

- Required accuracy and sensitivity

- Response time

- Size and shape constraints

- Environmental factors (humidity, vibration, etc.)

- Using incorrect temperature units (Celsius instead of Kelvin)

- Neglecting the effects of lead wire resistance

- Overlooking the impact of self-heating

- Failing to account for the non-linear behavior of thermistors

- Development of nano-scale thermistors for increased sensitivity

- Integration of Negative Temperature Coefficient thermistors with IoT devices for remote temperature monitoring

- Advanced materials research for wider temperature ranges and improved stability

- AI-powered NTC thermistors calculations for more accurate predictions and analysis

NTC Thermistor Resistance Calculator

Benefits of Using an NTC Thermistor Calculator

Using an NTC calculation offers several advantages:

Advanced NTC Thermistor Calculator

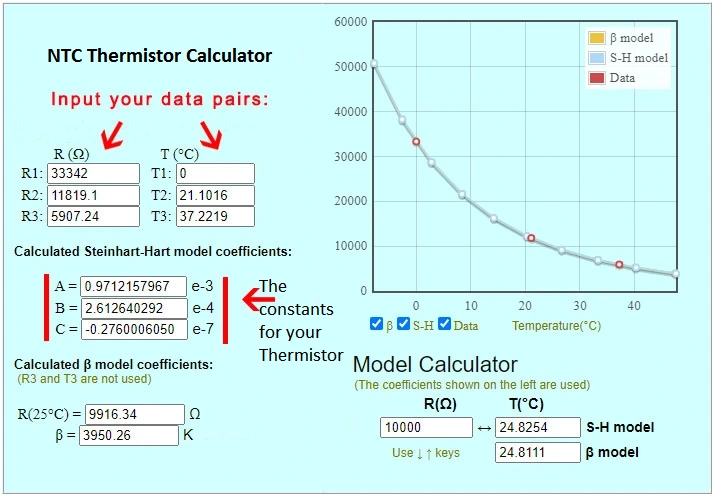

For more precise temperature sensing applications, advanced thermistors calculations may be necessary. A sophisticated NTC thermistor calculator can handle these complex equations:

Steinhart-Hart Equation

This equation provides a more accurate model of the Negative Temperature Coefficient Resistor's behavior across a wider temperature range. An advanced NTC calculation often incorporates this equation:

Where A, B, and C are coefficients specific to the thermistor, and R is the resistance at temperature T (in Kelvin).

Self-Heating Effects

In some applications, the current passing through the thermistor can cause self-heating, affecting the accuracy of measurements. Advanced NTC calculation takes this into account:

Where P is the power dissipated, I is the current, and R is the thermistor's resistance.

Practical Applications of NTC calculation

NTC calculation finds use in various fields:

Choosing the Right NTC Thermistor

Selecting the appropriate Negative Temperature Coefficient resistor for your application involves considering several factors. An NTC calculation can help in this process by allowing you to compare different thermistors:

An NTC thermistor calculator is invaluable in comparing different thermistors and determining which one best suits your needs.

Common Mistakes in NTC Calculation

When using an NTC thermistor calculator, be aware of these common pitfalls:

Future Trends in NTC Thermistor Technology

The field of Negative Temperature Coefficient thermistors continues to evolve. Some emerging trends include:

Conclusion

Understanding and effectively using NTC calculation is crucial for anyone working with temperature-sensitive applications. By mastering thermistor calculations and utilizing an NTC thermistor calculator, you can ensure accurate temperature measurements and optimal performance in your projects. Remember, the key to success lies in choosing the right thermistor, accurately calculating its beta value with an NTC calculation, and properly interpreting the results. With the knowledge gained from this guide, you're well-equipped to tackle temperature sensing challenges in your future endeavors.

Frequently Asked Questions

Q: What is the main function of an NTC thermistors calculation?

A: An Negative Temperature Coefficient thermistors calculation primarily helps determine the resistance of an Negative Temperature Coefficient resistor at various temperatures using the beta value. It simplifies complex calculations and aids in designing temperature-sensitive circuits.

Q: How does temperature affect Negative Temperature Coefficient thermistors?

A: As temperature increases, the resistance of an Negative Temperature Coefficient resistor decreases. This inverse relationship is the key principle behind their operation in temperature sensing applications. An NTC thermistor calculator helps quantify this relationship.

Q: Can I use the same beta value for all Negative Temperature Coefficient thermistors in an NTC calculator?

A: No, beta values are specific to each thermistor. Different Negative Temperature Coefficient thermistors have different beta values, which reflect their unique temperature-resistance characteristics. Always use the correct beta value in your thermistor calculation for accurate results.

Q: Are there online tools available for thermistors calculations?

A: Yes, many online thermistors calculations are available. These tools can quickly compute resistance values, beta values, and other parameters based on input data.

Q: How accurate are thermistor calculations using an NTC thermistor calculator?

A: The accuracy of NTC calculation depends on several factors, including the precision of the input data, the quality of the thermistors, and the calculation method used. Advanced NTC calculation using methods like the Steinhart-Hart equation can provide highly accurate results.

For more information on advanced thermistor technologies and calculations, check out our comprehensive guide on thermistor advancements.

Recommended for you

What Is Positive Temperature Coefficient? Expert Guide on PTC Thermistors

How to Find Impedance of a Capacitor: Guide for Professionals

how to calibrate rtd pt100?

Capacitor 104 Value: Essential Guide for Electronics Professionals

Positive Temperature Coefficient Heater: An Essential Guide of PTC Heater

What is an Electronic Ballast PTC Thermistor? Insights from DXM.

Customized Services

Custom-made sample/order

SHENZHEN DXM TECHNOLOGY CO., LTD. are structured by high-tech talents from famous university

in China and accompanied with a batch of ceramic-sensitive components experts and technology

specialist, have powerful R&D and technology capabilities.DXM is one of a few manufacturers

master core production technology of ceramic-sensitive components in the world.

Samples and orders can be custom-made per customer’s requirements, as below:

1. Application environment of product

2. Required specifications or technical parameters

3. Reference sample

4. Reference drawing

Free sample availability

You can contact our representative via email, fax or phone to specify the sample you need and provide your courier's account number (such as UPS, FedEx, DHL, TNT, etc.).. And we’ll send you samples free of charge through your courier by freight collection.

Price and Payment

Price

The price will be quoted in US dollars.

1) For small order quantities and small packing, normally our quotation is based on the ex-works price. The cargo will be delivered by courier after being finished normally.

2) For bulk orders and large volumes, normally our quotation is based on the FOB price. Please inform us of your destination seaport and estimated quantity, and our representative will quote you the C&F or CIF price accordingly. If you feel our freight is higher than your expectation, you can recommend your shipping company to us. Our principal is looking for a shipping company with a good reputation that offers competitive freight costs and can deliver your cargo promptly.

Do you offer bulk purchase discounts?

Yes, we offer bulk purchase discounts; the specific discount rate depends on the order quantity and cooperation method.

Logistics

Does your product support global logistics and distribution?

Yes, our products support global logistics and distribution services, and you can receive our products anytime and anywhere.

You may also like

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2025 DXM | All Rights Reserved.

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd