Positive Temperature Coefficient Sensor : A Comprehensive Guide

Discover the versatility and reliability of Positive Temperature Coefficient (PTC) sensor. This guide explains its functionality, applications (from automotive to industrial), selection criteria, and answers common FAQs. Learn how PTC sensors enhance safety and precision in various systems.

- What is PTC Sensor? Understanding Positive Temperature Coefficient Sensor

- Understanding the Fundamentals of Positive Temperature Coefficient Sensor

- How Positive Temperature Coefficient Sensor Works

- Applications of Positive Temperature Coefficient (PTC) Sensor

- Advantages of Using Positive Temperature Coefficient Sensor

- Selection Criteria for Positive Temperature Coefficient Sensor

- Frequently Asked Questions (FAQs)

- * Q: What is the difference between a PTC and an NTC thermistor?

- * Q: How can I test a PTC sensor?

- * Q: Are PTC sensors suitable for high-temperature applications?

- * Q: How do I choose the right PTC sensor for my application?

- Conclusion

What is PTC Sensor? Understanding Positive Temperature Coefficient Sensor

Positive Temperature Coefficient (PTC) sensor, also known as PTC thermistor, is essential component in numerous applications. We'll explore everything you need to know about this device, from its fundamental operating principles to its diverse applications. This guide focuses on the core functionality and benefits of the Positive Temperature Coefficient sensor.

Understanding the Fundamentals of Positive Temperature Coefficient Sensor

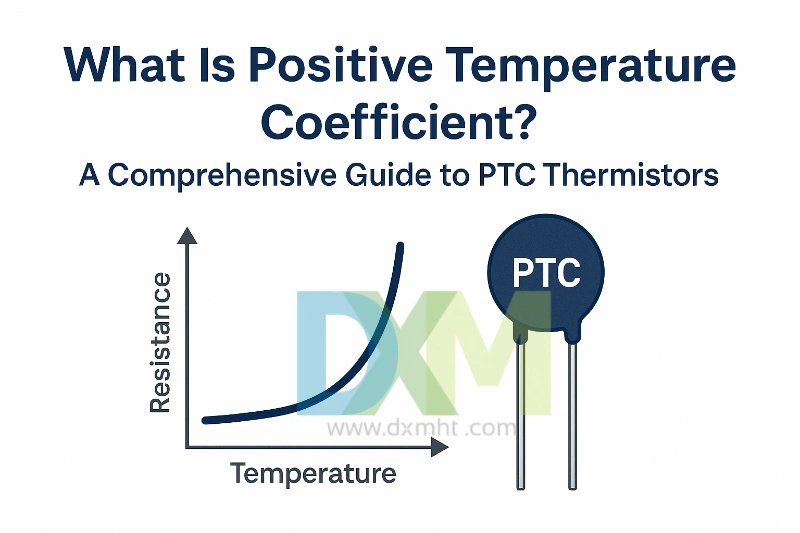

A PTC sensor is a type of thermistor whose resistance increases significantly with temperature. This characteristic is its defining feature, stemming from its Positive Temperature Coefficient. Unlike Negative Temperature Coefficient (NTC) thermistors, whose resistance decreases with rising temperature, PTC sensors exhibit a sharp rise in resistance beyond a specific critical temperature. This distinct behavior makes them particularly suitable for specific applications requiring precise temperature-dependent control. The material composition of a Positive Temperature Coefficient sensor, typically a ceramic-based material, is key to its functionality. The precise mix of materials dictates the specific resistance-temperature curve for each PTC sensor.

How Positive Temperature Coefficient Sensor Works

The operation of a PTC sensor hinges on its material's unique response to temperature changes. As the temperature increases, the material undergoes a phase transition, resulting in a dramatic increase in its electrical resistance. This transition occurs within a relatively narrow temperature range. The exact temperature at which this sharp increase occurs is determined during manufacturing and is crucial for choosing the appropriate PTC sensor for a given application. This abrupt change in resistance makes PTC sensors ideal for applications requiring a distinct ON/OFF switching behavior based on temperature.

Applications of Positive Temperature Coefficient (PTC) Sensor

The versatility of PTC sensors makes them valuable across a wide spectrum of industries and applications. Here are some notable examples:

* Overheating Protection: PTC sensors are widely used in various electronic devices as thermal fuses or safety cut-offs. If a device overheats, the PTC sensor's resistance increases sharply, interrupting the current flow and preventing further damage. This is a critical safety feature in many consumer electronics, industrial equipment, and automotive systems. This application showcases the value of a Positive Temperature Coefficient sensor, PTC sensor as a safety device.

Temperature Control: In heating systems, PTC sensors precisely regulate the temperature. They act as an integral part of the feedback loop, providing accurate temperature readings to maintain the system's set point. This precise control enhances efficiency and prevents overheating. The rapid change in resistance of the PTC sensor makes it ideal for precise control.

* Automotive Applications: The automotive industry relies on Positive Temperature Coefficient sensor for various temperature-sensitive functions. They're found in engine management systems, climate control units, and safety systems. The reliability and robustness of PTC sensors make them suitable for the demanding conditions in vehicles. Their integration with other automotive sensors further enhances control and efficiency.

* Industrial Applications: From industrial heating elements to process monitoring equipment, PTC sensors play a crucial role in maintaining optimal operating conditions. The ability of Positive Temperature Coefficient sensor to withstand harsh environments and offer precise temperature sensing makes it valuable across a wide range of industrial processes. Its accurate and reliable readings are crucial for safety and efficiency.

* Medical Devices: In some medical devices, PTC sensors provide precise temperature monitoring and control, ensuring the safety and efficacy of treatments. This demonstrates the precision and reliability of Positive Temperature Coefficient sensor in critical applications.

Advantages of Using Positive Temperature Coefficient Sensor

Several advantages contribute to the widespread adoption of PTC sensors:

* Simplicity and Cost-Effectiveness: PTC sensors are relatively simple to manufacture and integrate into systems, making them a cost-effective solution for various applications. Their simple design translates into low manufacturing costs.

* Reliability and Durability: Known for its robustness, Positive Temperature Coefficient Sensor exhibits high reliability and durability, even under demanding operating conditions. Its ability to withstand harsh environments is a key advantage.

* High Accuracy: PTC sensors provide highly accurate temperature measurements, ensuring reliable performance in various applications. This precision is critical for applications requiring fine temperature control.

* Self-Regulating: The self-regulating nature of PTC Sensor further contributes to its robustness and reliability, minimizing the need for external temperature compensation.

* Wide Temperature Range: PTC sensors are available with a wide range of operating temperatures, catering to the diverse needs of different applications.

Selection Criteria for Positive Temperature Coefficient Sensor

Choosing the right PTC sensor for a specific application involves considering various factors:

* Operating Temperature Range: The chosen PTC sensor must accurately measure the specific temperature range of the application. This necessitates careful matching of the sensor to the task.

* Resistance-Temperature Characteristic: A PTC sensor's resistance-temperature curve needs to be suitable for its intended purpose.

* Power Dissipation: The PTC sensor's power dissipation capabilities must be sufficient for its application to avoid overheating.

* Size and Packaging: The physical size and packaging of the PTC sensor must be compatible with the system's design constraints.

* Tolerance: The PTC sensor's tolerance specifies its accuracy; choosing a sensor with an appropriate tolerance is important for the precision of the application.

Frequently Asked Questions (FAQs)

* Q: What is the difference between a PTC and an NTC thermistor?

* A: A PTC thermistor's resistance increases with increasing temperature, while an NTC thermistor's resistance decreases with increasing temperature.

* Q: How can I test a PTC sensor?

* A: You can test a PTC sensor using a multimeter to measure its resistance at different temperatures.

* Q: Are PTC sensors suitable for high-temperature applications?

* A: While PTC sensors are robust, the maximum operating temperature depends on the specific sensor. Refer to the manufacturer's specifications for details.

* Q: How do I choose the right PTC sensor for my application?

* A: Consider the operating temperature range, required accuracy, power dissipation needs, size, and packaging requirements when selecting a PTC sensor.

Conclusion

Positive Temperature Coefficient sensor, is versatile component with a wide range of applications. It's reliable performance, cost-effectiveness, and simplicity make it a valuable choice across industries. By carefully considering the selection criteria and understanding its operating principles, engineers can effectively integrate PTC sensor into various systems for precise temperature monitoring and control. We encourage you to explore the possibilities of incorporating PTC sensor into your next project and harness its numerous benefits. The reliability and precision of PTC sensor technology can contribute significantly to the success of your project.

© 2025 DXM Blog. All rights reserved.

Author: Ivan Huang

Recommended for you

What Is Positive Temperature Coefficient? Expert Guide on PTC Thermistors

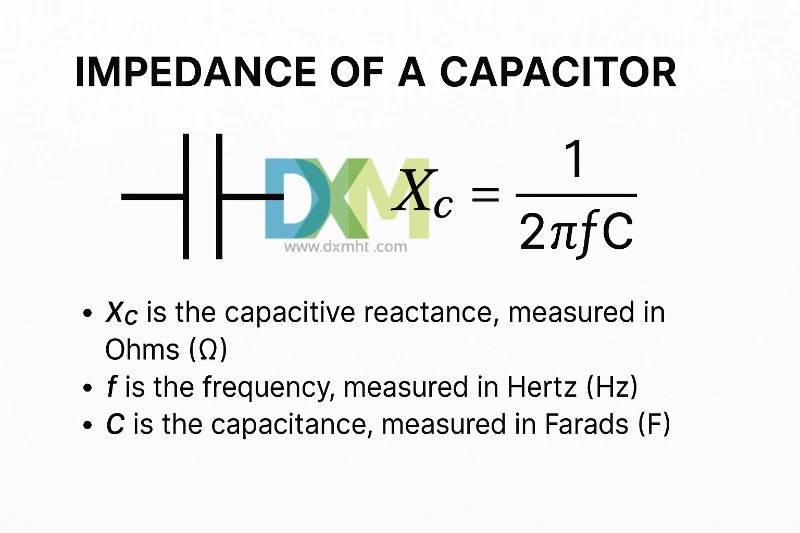

How to Find Impedance of a Capacitor: Guide for Professionals

how to calibrate rtd pt100?

Capacitor 104 Value: Essential Guide for Electronics Professionals

Positive Temperature Coefficient Heater: An Essential Guide of PTC Heater

What is an Electronic Ballast PTC Thermistor? Insights from DXM.

Price and Payment

Payment Terms

There are a number of different payment methods that can be used when you deal with us. Two are mostly used: T/T payment in advance for small values and irrevocable L/C at sight for large values.

Do you offer bulk purchase discounts?

Yes, we offer bulk purchase discounts; the specific discount rate depends on the order quantity and cooperation method.

Customized Services

Custom-made sample/order

SHENZHEN DXM TECHNOLOGY CO., LTD. are structured by high-tech talents from famous university

in China and accompanied with a batch of ceramic-sensitive components experts and technology

specialist, have powerful R&D and technology capabilities.DXM is one of a few manufacturers

master core production technology of ceramic-sensitive components in the world.

Samples and orders can be custom-made per customer’s requirements, as below:

1. Application environment of product

2. Required specifications or technical parameters

3. Reference sample

4. Reference drawing

Logistics

Does your product support global logistics and distribution?

Yes, our products support global logistics and distribution services, and you can receive our products anytime and anywhere.

Shipment

1)Small order quantity and small packing:cargo may be arranged by courier;

2)Bulk order and big volume:shipment may be arranged by sea or by air as per customer’s requirements on FOB, C&F,CIF or LCL terms and do prompt shipment which is very important for our customers, so we do this matter seriously and we may arrange our shipment in time due to our rich experiences in this line. We may also accept the shipment on the term of freight prepaid or freight collect.

You may also like

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2025 DXM | All Rights Reserved.

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd