Understanding the Role of the PTC Thermistor Formula in Electronics

Learn how the PTC thermistor formula is crucial for electronic safety and efficiency with DXM. Our expertise in thermal resistor ensures optimal performance and reliability. Explore our insights to understand how this essential component protects circuits from overheating, maintaining device longevity. With DXM, enhance your knowledge and application of electronic components.

- What is a PTC Thermistor Formula?

- Exploring the PTC Thermistor Formula

- Understanding the PTC Thermistor Formula in Circuit Design

- Additional PTC Thermistor Formula Calculations

- Resistance Calculation

- Temperature Coefficient

- Curie Temperature

- Characteristics and Behavior of PTC Thermal Resistor

- Functions of a Thermal Resistor

- PTC Thermistor Applications

- Benefits of PTC Thermal Resistor

- FAQs

- Conclusion

- Call to Action

PTC thermistor formula is essential in electronics, particularly for managing thermal resistor in circuits. This component helps regulate temperature by increasing resistance as heat rises, ensuring circuit safety and stability. Engineers use the PTC thermistor formula to calculate precise responses in dynamic electronic environments, making it an indispensable tool. The formula’s application spans across various sectors, providing reliability in circuit design.

Key Takeaways: By applying thermal resistor knowledge, designers can improve circuit functionality and longevity, achieving enhanced performance and protection.This article delves into the intricacies of these crucial components, their operations, and their applications.

What is a PTC Thermistor Formula?

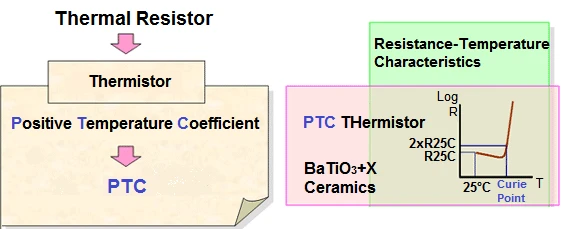

The PTC thermistor formula is essential for calculating the behavior of Positive Temperature Coefficient thermistor. This thermal resistor increases its resistance as temperatures rise, helping manage circuit stability and protection. PTC thermistors are vital in applications that require precise temperature regulation and measurement, such as in automotive and industrial systems. Its resistance change, as defined by the PTC formula, makes it ideal for safeguarding electronic components against overheating.

Exploring the PTC Thermistor Formula

Understanding the PTC Thermistor Formula in Circuit Design

The PTC thermistor formula is a vital tool for designing safe, efficient electronic circuits using thermal resistor. This formula helps engineers predict and control temperature changes that impact electronic components.

Understanding the PTC thermistor formula is essential for designing efficient electronic systems. The basic formula for thermal resistor is:

- Key Formulas for the PTC Thermistor Formula

One core equation for calculating resistance in PTC thermistors is:

R(T) = R0(1 + α(T - T0) + β(T - T0)2 + ... )

Here, R(T) represents resistance at temperature T, while R0 is the resistance at reference temperature T0. The coefficients α and β indicate the rate of resistance change with temperature.

Additional PTC Thermistor Formula Calculations

Resistance Calculation

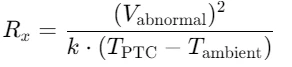

The resistance of a PTC thermistor at a given temperature can be calculated using the formula:

Vabnormal: Applied voltagek: Dissipation constantTPTC: Operating temperature of the PTCTambient: Ambient temperature

Temperature Coefficient

The temperature coefficient α can be defined as the relative change in resistance per degree change in temperature. This coefficient is generally constant in the steep rise region of the resistance-temperature curve.

Curie Temperature

The Curie point (or Curie temperature, TC) is a critical temperature where the resistance of the PTC thermistor becomes significantly higher than at lower temperatures. It is typically defined as the temperature at which the resistance is double that at 25°C.

Characteristics and Behavior of PTC Thermal Resistor

- Self-Heating: thermal resistor exhibits self-heating due to electrical load, calculated by:

P = I2 R - Tripping Mechanism: When current exceeds a certain threshold (trip current), the thermistor switches from a low-resistance state to a high-resistance state, protecting circuits from overloads.

- Operating Range: Below the Curie point, thermal resistor behaves like regular resistors with slight decreases in resistance; above this point, their resistance increases sharply with temperature.

Functions of a Thermal Resistor

A thermal resistor, like the PTC thermistor, helps in managing current flow in circuits based on the temperature. It acts as a self-regulating heating element, which is helpful in many practical applications such as:

- Overcurrent Protection: PTC thermistors can limit the current in a circuit automatically after detecting potential overloading.

- Self-regulating Heaters: Used in applications where maintaining a particular temperature is critical.

- Temperature Sensing: Integral to systems that require precise measurement of temperature changes.

PTC Thermistor Applications

Combining PTC thermistor formula with practical applications, we see them utilized across industries such as:

- Consumer Electronics:** To protect circuits in devices like hair dryers, laptops, and smartphones.

- **Industrial Equipment:** Monitoring temperature in heavy machinery to prevent overheating.

- **Automotive:** Managing battery performance and temperature in electric vehicles.

Benefits of PTC Thermal Resistor

Incorporating thermal resistor and understanding their formula offers several advantages:

1. Versatility:They are suitable for a wide range of devices and environments.

2. Cost-effectiveness: PTC thermistors are generally inexpensive and durable.

3. Efficiency: Automatic response to temperature changes without needing additional external controls.

FAQs

Q: How does a PTC thermistor differ from an NTC thermistor?

A: While the resistance of a PTC thermistor increases with temperature, an NTC thermistor's resistance decreases as the temperature rises.

Q: Can PTC thermal resistor be used in high-temperature environments?

A: Yes, thermal resistor is specifically designed to operate efficiently even in high-temperature conditions.

Q: How do you test a PTC thermistor?

A: Testing involves measuring its resistance with a multimeter at room temperature and then comparing it with the expected value.

Conclusion

In summary, understanding the PTC thermistor formula and effectively integrating a thermal resistor into applications can enhance the overall functionality and safety of electronic devices. These components provide precise temperature control and protection due to their unique properties.

We encourage our readers to consider PTC thermal resistor in projects involving temperature regulation and protection. Their benefits in efficiency and reliability are significant in advancing technology.

Call to Action

For those eager to implement the PTC thermistor formula in your systems, reach out to us for more detailed guides and practical resources. A world of efficient electronic management and design awaits with PTC thermal resistor.

© 2024 DXM Blog. All rights reserved.

Author: Ivan Huang

Recommended for you

Water Temperature Sensor: The Key to Engine Health and Efficiency

Lightning Surge Protection Varistor: Essential for Protecting Your Electrical Systems

Water Temp Sensor: How to Test it for Reliable Performance?

Capacitor Impedance: Calculation Guide & FAQs

Temperature Probe Sensor: A Comprehensive Guide

Termistor NTC: What Does a Thermistor Do?

Logistics

Can I change my shipping address?

Yes, you can contact our customer service team to modify the delivery address before order confirmation to ensure that the order can be accurately delivered to the address you specify.

Does it support express delivery?

Yes, we support express delivery services. You can choose different delivery methods according to your needs, including ordinary express delivery and expedited express delivery.

Price and Payment

Payment Terms

There are a number of different payment methods that can be used when you deal with us. Two are mostly used: T/T payment in advance for small values and irrevocable L/C at sight for large values.

Do you offer bulk purchase discounts?

Yes, we offer bulk purchase discounts; the specific discount rate depends on the order quantity and cooperation method.

Customized Services

Custom-made sample/order

SHENZHEN DXM TECHNOLOGY CO., LTD. are structured by high-tech talents from famous university

in China and accompanied with a batch of ceramic-sensitive components experts and technology

specialist, have powerful R&D and technology capabilities.DXM is one of a few manufacturers

master core production technology of ceramic-sensitive components in the world.

Samples and orders can be custom-made per customer’s requirements, as below:

1. Application environment of product

2. Required specifications or technical parameters

3. Reference sample

4. Reference drawing

You may also like

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd