Disk Varistor 05D series: Advanced Solutions for Effective Surge Protection

Introducing the DXM Disk Varistor 05D series, your ultimate solution for effective surge protection. Engineered for reliability, this MOV for surge protection ensures superior performance in safeguarding your devices.

Key Features of Disk Varistor 05D Series

● Superior Surge Protection: Disk Varistor effectively shields circuits from voltage spikes, ensuring the safety and longevity of your devices.

● Wide Voltage Range: MOV for Surge Protection Versatile and suitable for a broad range of applications, from telecommunications to industrial systems.

● Quick Response: Instantly reacts to overvoltage, providing reliable and immediate protection.

● Durable and Reliable: Engineered for long-term performance, delivering consistent results even in demanding conditions.

● Competitive Price, Compact Design: Offers exceptional value with space-saving design, making it an ideal choice for various applications.

Choose DXM MOV for Surge Protection for unparalleled security and peace of mind in electronic systems.

Introduction to Disk Varistor

In the realm of electronic protection, the disk varistor stands out as a pivotal component. Engineered to provide reliable surge protection, our disk varistor ensures the longevity and stability of your electronic devices. Whether you're dealing with sensitive communication systems or robust electrical infrastructures, our MOV for surge protection delivers unparalleled performance.Your trusted partner in safeguarding electronic devices with top-notch MOV for surge protection.

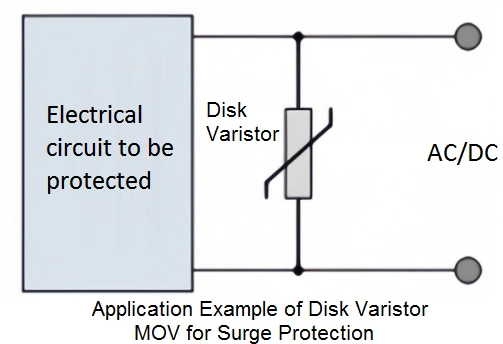

The primary function of a disk varistor is to protect electronic circuits from voltage spikes by clamping excessive voltage and thereby preventing damage to the components. This is achieved through the unique properties of metal oxide varistors (MOVs), which exhibit nonlinear voltage-dependent resistance. When the voltage exceeds a certain threshold, the MOV rapidly changes its resistance, diverting the surge away from sensitive parts of the circuit.

Disk Varistor 05D Product Specifications

| Specification | Details |

|---|---|

| Varistor Chip Diameter | 5mm |

| Pressure Sensitive Voltage | 18~750V |

| Maximum Allowable Voltage | 11~460V (AC), 14~615V (DC) |

| Flow Capacity @1KHz | 30-1400pf |

| Operating Temperature Range | -40°C to +125°C |

| Nonlinear Coefficient | 20-40 |

| Energy Absorption | Up to 10kJ |

| Response Time | Less than 1 nanosecond |

| Leakage Current | Minimal |

These specifications make our disk varistor highly adaptable to various applications, providing robust protection against electrical surges and ensuring the safety of your electronic infrastructure.

Disk Varistor MOV for Surge Protection Working Principle

The functionality of a disk varistor is grounded in the principles of metal oxide varistor technology. At rest, the varistor exhibits high impedance, typically in the megaohm range, ensuring it does not interfere with the normal operation of the circuit. This high resistance state prevents any unnecessary current flow, maintaining the integrity of the system.

However, during a transient surge event—such as a lightning strike or a power line spike—the voltage across the varistor exceeds its breakdown threshold. At this point, the varistor's impedance drops dramatically to just a few ohms. This swift transition creates a low-resistance path, effectively diverting the excess voltage away from sensitive electronic components. By doing so, the disk varistor protects the circuit from potential damage caused by overvoltage conditions.

The rapid response time of less than a nanosecond ensures that the varistor can react almost instantaneously to surges, providing immediate protection. Moreover, the high energy absorption capacity allows the varistor to handle significant surge events without degradation, ensuring long-term reliability and effectiveness.

Applications of Disk Varistor

1. Disk Varistor in Communication Systems

In communication infrastructures, disk varistor protects sensitive equipment such as telephone lines, routers, and switches from voltage surges caused by lightning strikes or power fluctuations. By safeguarding these critical components, disk varistor ensures uninterrupted communication services.

2. MOV for Surge Protection Used in Electrical Infrastructure

Electrical distribution systems are susceptible to transient overvoltages due to switching operations or external surges. Disk varistor is employed in distribution cabinets, socket boxes, and power meters to mitigate these surges, enhancing the reliability and safety of electrical grids.

3. Disk Varistor in Home Appliances

Modern households rely heavily on electronic appliances that are vulnerable to voltage spikes. Incorporating disk varistor in devices like televisions, refrigerators, and air conditioners provides an additional layer of protection, prolonging the lifespan of these appliances and preventing costly repairs.

4. MOV for Surge Protection Used in Industrial Electronics

In industrial settings, machinery and control systems depend on stable power supplies. Disk varistor protects industrial electronics from surges, ensuring smooth operation and minimizing downtime caused by electrical disturbances.

5. Disk Varistor Applied in Automotive Electronics

Automotive systems, including infotainment and navigation units, are increasingly dependent on electronic components. Disk varistor protects these systems from voltage fluctuations caused by the vehicle's electrical system, enhancing the reliability of automotive electronics.

6. Renewable Energy Systems

Renewable energy installations, such as solar panels and wind turbines, generate power that is susceptible to voltage spikes. Disk varistor safeguards these systems by clamping excess voltage, ensuring the efficient and safe operation of renewable energy sources.

7. Medical Devices

Medical equipment requires precise and stable power supplies. Disk varistor protects sensitive medical devices from electrical surges, ensuring patient safety and the accuracy of medical diagnostics and treatments.

8. Consumer Electronics

Devices like smartphones, tablets, and laptops benefit from the protection provided by disk varistor. By preventing voltage spikes, disk varistor helps maintain the performance and longevity of consumer electronics.

These diverse applications highlight the critical role that disk varistor plays in modern electronic protection, making it essential component in ensuring the safety and reliability of various electronic systems.

Key Advantages of Using Disk Varistor for Surge Protection

Choosing a disk varistor for your electronic systems provides reliable and efficient surge protection. Below are the key benefits:

Exceptional Performance and Protection

- Wide Voltage Range: Supports diverse applications from low to high voltage systems.

- High Flow Capacity: Handles large surge currents and dissipates high energy effectively.

- Minimal Leakage Current: Ensures efficient circuit operation without interference.

- Rapid Response Time: Protects your system instantly, responding in less than a nanosecond.

Advanced Features for Enhanced Efficiency

- Large Nonlinear Coefficient: Offers precise clamping against voltage spikes.

- Symmetrical Volt-Ampere Characteristics: Provides reliable protection for both voltage cycles.

- Residual Depression: Returns to a high-impedance state after surges for normal operation.

- No Continuous Flow: Prevents unnecessary current flow, conserving energy.

Built for Durability and Reliability

- Strong Surge Absorption: Absorbs and dissipates significant voltage spikes efficiently.

- Stable Voltage Suppression: Maintains consistent circuit protection over time.

- Premium Material Quality: Made from high-quality zinc oxide for superior durability.

- Long Operational Lifespan: Reduces the need for frequent replacements.

Versatile Applications and Use

- High-Efficiency Surge Handling: Operates efficiently under extreme conditions without overheating.

- Excellent Voltage Ratio: Handles significant voltage differences without degradation.

- Mov for Surge Protection: Provides universal solutions for various industries and applications.

Disk varistor is essential for modern electronic systems, offering proven reliability and versatility. Its ability to protect circuits from severe voltage surges makes it the preferred choice for professionals.

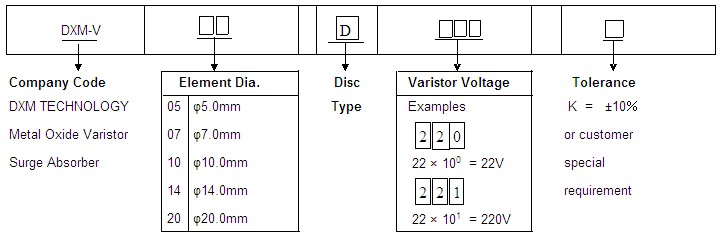

Disk Varistor Naming Rules

Our disk varistor products follow a systematic naming convention to simplify identification and selection based on application requirements. Below is an overview of our 05D series part numbers:

Disk Varistor N (Standard) Series

The N series is designed for standard applications requiring reliable surge protection. These varistors offer a balance between performance and cost, making them ideal for general-purpose use.

- Diameter: 5mm

- Part Numbers: 05D-100, 05D-200, 05D-300, etc.

- Applications: Home appliances, communication devices, general electronics.

MOV for Surge Protection J (High Surge & High Energy) Series

The J series is tailored for high-energy environments where enhanced surge protection is necessary. These varistors can handle larger surges, making them suitable for industrial and specialized applications.

- Diameter: 5mm

- Part Numbers: 05D-J100, 05D-J200, 05D-J300, etc.

- Applications: Industrial machinery, power distribution systems, renewable energy setups.

For a comprehensive list of part numbers and their specific applications, please refer to our detailed product catalog or contact our technical support team.

Disk Varistor 05D series part of the product model summary table

Please see details of the 05D Varistor Part Numbers here.

Disk Varistor Packing Specifications

Our disk varistor is available in various packing options to accommodate different order sizes and distribution needs. Below are the packing specifications for our 05D series:

| Item | Part No. | Bulk | Reel | Ammo | |||||

| Bag | Box | Carton | Box | Carton | Box | Carton | |||

| 1 | 05D | 8R0M-391K | 1000 | 2000 | 12000 | 2000 | 16000 | 2000 | 10000 |

| 2 | 431K-751K | 1500 | 7500/ | ||||||

We offer flexible packaging solutions to meet the diverse needs of our customers, ensuring that you receive your disk varistor in the most convenient and efficient manner possible.

Disk Varistor Technical Details and Design Considerations

When selecting a disk varistor, it's essential to consider various technical factors to ensure optimal performance and compatibility with your application. Here are some key technical details and design considerations:

1. Voltage Rating of Disk Varistor

The voltage rating of a varistor determines the maximum voltage it can handle before it starts conducting. It's crucial to select a varistor with a voltage rating that matches or slightly exceeds the normal operating voltage of your circuit to ensure effective protection without unnecessary conduction during normal operation.

2. Energy Absorption Capacity of MOV for Surge Protection

The energy absorption capacity indicates how much energy the varistor can absorb during a surge event without sustaining damage. Higher energy absorption capacity is necessary for applications prone to frequent or severe voltage spikes.

3. Disk Varistor Response Time

Response time is the duration the varistor takes to transition from high to low impedance upon detecting a surge. Faster response times provide better protection by minimizing the exposure of sensitive components to overvoltages.

4. MOV for Surge Protection Nonlinear Coefficient

The nonlinear coefficient reflects the varistor's ability to change its resistance in response to voltage changes. A higher nonlinear coefficient means a more significant change in resistance, leading to more effective surge suppression.

5. Physical Size and Mounting

Disk varistor comes in various sizes, and their physical dimensions can impact its suitability for specific applications. Ensure that the varistor fits within the designated space on your circuit board or within your device housing.

6. Temperature Stability

Operating temperature ranges should align with the environmental conditions of your application. Varistors with wide temperature stability ensure reliable performance across varying temperatures.

7. Long-Term Reliability

Consider the long-term reliability and lifespan of the varistor. High-quality materials and robust construction contribute to extended operational life, reducing the need for frequent replacements.

8. Compliance with Standards

Ensure that the varistors comply with relevant industry standards and certifications. Compliance guarantees that the components meet safety and performance benchmarks essential for your application.

By carefully evaluating these technical factors, you can select the most appropriate disk varistor that aligns with your application's requirements, ensuring effective surge protection and enhancing the overall reliability of your electronic systems.

Implementing Disk Varistor in Your Systems

Proper implementation of disk varistor is crucial for maximizing their protective capabilities. Here are some guidelines and best practices for integrating varistors into your electronic systems:

1. Placement in the Circuit

Varistors should be placed as close as possible to the power entry point of the device or system you intend to protect. This placement ensures that the varistor can intercept surges before they propagate to sensitive components.

2. Parallel Connection

Disk varistor is typically connected in parallel with the power supply lines. This configuration allows the varistor to clamp excess voltage effectively while allowing normal current flow during regular operation.

3. PCB Layout Considerations

When integrating varistors onto a printed circuit board (PCB), minimize the distance between the varistor and the protected components. Short, direct traces reduce the inductance and resistance, enhancing the varistor's response to surges.

4. Thermal Management

Ensure adequate thermal management around the varistor. Proper heat dissipation prevents overheating during frequent or severe surge events, maintaining the varistor's integrity and performance.

5. Redundancy for Critical Systems

In critical applications, consider using multiple varistors in parallel to provide redundancy. This approach ensures continued protection even if one varistor fails, enhancing the overall reliability of the system.

6. Regular Inspection and Maintenance

Periodically inspect varistors for signs of wear, degradation, or damage. Regular maintenance ensures that the varistors remain effective in protecting against surges and extends the lifespan of your electronic systems.

7. Selecting the Right Series

Choose between the N (Standard) and J (High Surge & High Energy) series based on your application's specific needs. The N series is suitable for general-purpose protection, while the J series is designed for high-energy environments requiring enhanced surge handling capabilities.

By adhering to these implementation guidelines, you can ensure that your disk varistor provides optimal surge protection, safeguarding your electronic devices and systems against potential electrical disturbances.

Quality Assurance and Testing of Disk Varistor

Ensuring the highest quality of our disk varistor products is paramount. Our stringent quality assurance processes encompass various stages of testing and validation to guarantee that each varistor meets the highest industry standards.

1. Material Selection

We use premium-grade zinc oxide and other high-quality materials in the manufacturing of our varistors. This careful selection ensures superior electrical properties and long-term reliability.

2. Precision Manufacturing

Our state-of-the-art manufacturing facilities employ precision techniques to produce varistors with consistent and accurate specifications. This precision ensures that each varistor performs reliably under specified conditions.

3. Electrical Testing

Each varistor undergoes rigorous electrical testing, including voltage rating verification, response time measurement, and energy absorption capacity assessment. These tests ensure that the varistor can handle the intended surge levels effectively.

4. Thermal Testing

Thermal testing evaluates the varistor's performance under various temperature conditions. This testing ensures that the varistor maintains its protective capabilities across the specified operating temperature range.

5. Mechanical Stress Testing

Mechanical stress tests assess the varistor's durability and resilience against physical stresses such as vibration, shock, and pressure. This ensures that the varistor can withstand the rigors of real-world applications.

6. Longevity and Endurance Testing

Endurance testing evaluates the varistor's ability to perform consistently over extended periods and multiple surge events. This testing ensures that the varistor remains effective throughout its intended lifespan.

7. Compliance and Certification

Our varistors comply with international standards such as IEC, UL, and RoHS, ensuring safety, environmental friendliness, and global compatibility. Certifications provide assurance of quality and performance to our customers.

Through comprehensive quality assurance and testing, we ensure that our disk varistor delivers reliable surge protection, meeting the diverse needs of various industries and applications.

Installation Guide for Disk Varistor

Proper installation of disk varistor is essential to maximize their protective capabilities and ensure the longevity of your electronic systems. Below is a step-by-step installation guide:

1. Identify the Surge Entry Point

Determine the primary entry points for voltage surges in your system. Common entry points include power supply lines, communication lines, and external connectors.

2. Select the Appropriate Varistor

Choose a disk varistor with specifications that match your system's voltage and energy requirements. Refer to the product specifications table to select the right varistor.

3. Prepare the Circuit

Ensure that the circuit is powered off before installation. Identify the points where the varistor will be connected, typically across the power supply lines.

4. Mount the Varistor

Securely mount the varistor in the designated location. Ensure that it is firmly connected to prevent movement or dislodging during operation.

5. Connect in Parallel

Connect the varistor in parallel with the power supply lines. This configuration allows the varistor to clamp excess voltage effectively while maintaining normal operation during regular voltage conditions.

6. Soldering and Secure Connections

If mounting on a PCB, solder the varistor terminals to the designated pads. Ensure secure connections to prevent intermittent contacts, which can compromise protection effectiveness.

7. Test the Installation

After installation, perform a continuity test to ensure that the varistor is properly connected. Verify that the varistor does not conduct under normal operating voltages.

8. Power On and Monitor

Power on the system and monitor the varistor's performance. Observe for any signs of abnormal behavior, such as excessive heating or frequent clamping, which may indicate overvoltage issues.

9. Regular Maintenance

Incorporate regular inspections into your maintenance schedule to ensure that the varistors remain in optimal condition. Replace any varistor that shows signs of wear or damage to maintain effective surge protection.

By following this installation guide, you can ensure that your disk varistor is correctly integrated into your electronic systems, providing reliable surge protection and enhancing the overall safety and longevity of your devices.

Maintenance and Troubleshooting of Disk Varistor

To ensure the continued effectiveness of your disk varistor in providing surge protection, regular maintenance and timely troubleshooting are essential. Here are some guidelines to maintain and troubleshoot your varistors:

1. Regular Inspection

Periodically inspect the varistors for any physical signs of damage, such as cracks, discoloration, or deformation. Physical damage can compromise the varistor's ability to protect against surges.

2. Monitoring Electrical Parameters

Use appropriate testing equipment to monitor the electrical parameters of the varistor, including leakage current and voltage levels. Any deviation from standard specifications may indicate a malfunction.

3. Checking for Overheating

Overheating is a sign of excessive current flow, which may result from repeated surge events or an internal fault. Ensure that the varistor operates within its specified temperature range to prevent thermal damage.

4. Verifying Proper Functionality

After a surge event, verify that the varistor has clamped the voltage effectively. Persistent high voltage after a surge may indicate that the varistor has degraded or failed.

5. Replacing Faulty Varistors

If a varistor shows signs of failure or degradation, replace it immediately to restore the protection mechanism. Use a varistor with identical or higher specifications to maintain system integrity.

6. Cleaning and Environmental Protection

Ensure that the varistor is kept in a clean environment free from dust, moisture, and corrosive substances. Cleaning the area around the varistor can prevent contamination that may affect its performance.

7. Documentation and Record-Keeping

Maintain detailed records of varistor installations, inspections, and replacements. Documentation helps in tracking the performance and lifespan of varistors, facilitating proactive maintenance strategies.

8. Training and Awareness

Ensure that personnel responsible for maintaining electronic systems are trained in identifying and handling varistor-related issues. Proper training enhances the ability to respond effectively to protection system failures.

By adhering to these maintenance and troubleshooting practices, you can ensure that your disk varistor continues to provide reliable surge protection, safeguarding your electronic systems from potential electrical disturbances.

Disk Varistor Compliance with Industry Standards

Our disk varistor products comply with a range of international industry standards, ensuring that they meet the necessary safety, performance, and environmental requirements. Compliance with these standards underscores our commitment to quality and reliability.

1. IEC Standards

Our varistors adhere to the International Electrotechnical Commission (IEC) standards, which govern the safety and performance of electrical and electronic components. Compliance with IEC standards ensures global compatibility and acceptance.

2. UL Certification of MOV for Surge Protection

Underwriters Laboratories (UL) certification verifies that our varistors meet rigorous safety and performance criteria. This certification is essential for products used in environments where safety is paramount.

3. MOV for Surge Protection RoHS Compliance

The Restriction of Hazardous Substances (RoHS) directive ensures that our varistors are free from harmful materials such as lead, mercury, and cadmium. RoHS compliance promotes environmental sustainability and reduces the ecological footprint of our products.

4. Disk Varistor REACH Regulation

The Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation ensures that our varistors are manufactured with safe materials and processes. Compliance with REACH promotes safe handling and reduces environmental impact.

5. Disk Varistor CE Marking

CE marking indicates that our varistors conform to European Union safety, health, and environmental protection standards. This marking facilitates the free movement of products within the European market.

6. ANSI Standards

The American National Standards Institute (ANSI) sets standards for a wide range of products and services. Our varistors meet ANSI standards, ensuring their suitability for use in North American applications.

7. MOV for Surge Protection Custom Certification

We offer customized certification processes to meet specific regional or industry requirements. This flexibility ensures that our varistors are suitable for diverse markets and specialized applications.

By adhering to these industry standards, we ensure that our disk varistor provides safe, reliable, and high-performance surge protection solutions tailored to meet the diverse needs of our global clientele.

Case Studies: Successful Implementation of Disk Varistor

Our disk varistor products have been successfully implemented across various industries, demonstrating their effectiveness in providing reliable surge protection. Below are some notable case studies:

1. MOV for Surge Protection in Telecommunications Infrastructure

A major telecommunications company integrated our disk varistor into their network infrastructure to protect critical communication lines from lightning-induced surges. Post-implementation, the company reported a significant reduction in equipment downtime and maintenance costs, highlighting the varistor's effectiveness in safeguarding sensitive communication equipment.

2. Renewable Energy Systems with Disk Varistor

A solar energy provider employed our disk varistor in their photovoltaic systems to mitigate voltage spikes caused by cloud cover fluctuations and grid disturbances. The varistor ensured the stability of the energy output and prevented damage to inverters and other critical components, enhancing the overall reliability of the renewable energy installations.

3. Industrial Automation

An industrial automation company used our high-energy J series disk varistor to protect their control systems from electrical surges generated by heavy machinery operations. The implementation resulted in improved system uptime and extended the lifespan of automation components, demonstrating the varistors' capability to handle high-energy surge events.

4. Consumer Electronics Manufacturing

A leading consumer electronics manufacturer incorporated our disk varistor into their product designs to protect devices like smartphones and tablets from power surges during charging. This integration reduced product returns related to surge damage and enhanced customer satisfaction by ensuring the durability of their electronic devices.

5. Medical Equipment Protection

A healthcare facility installed our disk varistor in their medical imaging equipment to protect against power surges that could disrupt sensitive diagnostic tools. The varistors maintained the operational integrity of the medical devices, ensuring accurate diagnostics and uninterrupted patient care.

6. Automotive Electronics

An automotive manufacturer integrated our disk varistor into their vehicle infotainment systems to safeguard against voltage fluctuations caused by the vehicle's electrical system. This integration enhanced the reliability of the infotainment systems and improved the overall driving experience by preventing electronic malfunctions.

7. Home Appliance Surge Protection

A home appliance company utilized our disk varistor in their high-end refrigerators and air conditioners to protect against power surges during thunderstorms and grid instability. The varistor ensured the longevity of the appliances and reduced the incidence of surge-related failures, providing customers with durable and reliable products.

These case studies illustrate the diverse applications and effectiveness of our disk varistor in providing robust surge protection across various industries. By choosing our varistor, businesses and organizations can enhance the reliability and longevity of its electronic systems and devices.

Disk Varistor Environmental Impact and Sustainability

At the forefront of our manufacturing philosophy is a commitment to environmental sustainability. Our disk varistor products are designed and produced with eco-friendly practices to minimize their environmental footprint.

1. MOV for Surge Protection RoHS Compliance

Our varistors comply with the Restriction of Hazardous Substances (RoHS) directive, ensuring that they are free from harmful materials like lead, mercury, and cadmium. This compliance not only makes our products safer for the environment but also aligns with global sustainability standards.

2. Energy-Efficient Manufacturing

We employ energy-efficient manufacturing processes that reduce energy consumption and minimize greenhouse gas emissions. By optimizing our production methods, we contribute to the reduction of our overall carbon footprint.

3. Sustainable Material Sourcing

Our commitment to sustainability extends to the sourcing of raw materials. We prioritize the use of materials that are responsibly sourced and recyclable, ensuring that our products are environmentally friendly from production to end-of-life.

4. Waste Minimization

We implement waste minimization strategies in our manufacturing facilities, recycling and reusing materials wherever possible. This approach reduces the amount of waste sent to landfills and promotes a circular economy.

5. MOV for Surge Protection Lifecycle Management

Our MOV for Surge Protection is designed for longevity, reducing the need for frequent replacements and minimizing electronic waste. Additionally, we offer recycling programs to ensure that end-of-life products are disposed of responsibly.

6. Eco-Friendly Packaging of MOV for Surge Protection

We use recyclable and biodegradable materials for our product packaging, further reducing the environmental impact of our products. Eco-friendly packaging not only protects the varistors during transit but also aligns with our sustainability goals.

7. MOV for Surge Protection Compliance with Environmental Regulations

Our operations comply with local and international environmental regulations, ensuring that our manufacturing practices meet stringent environmental standards. This compliance underscores our dedication to environmental stewardship.

By integrating sustainable practices into every aspect of our operations, we ensure that our MOV for Surge Protection not only provides exceptional surge protection but also contributes positively to environmental conservation efforts.

Disk Varistor Innovation and Future Developments

Innovation is at the core of our mission to provide cutting-edge disk varistor solutions. We continuously invest in research and development to enhance the performance, reliability, and efficiency of our varistors, anticipating the evolving needs of the electronics industry.

1. MOV for Surge Protection Enhanced Material Composition

Our R&D team is focused on developing new material compositions that improve the varistor's energy absorption capacity and response time. By experimenting with different metal oxide blends, we aim to create varistors that offer superior performance under extreme conditions.

2. MOV for Surge Protection Miniaturization for Compact Electronics

With the trend towards smaller and more compact electronic devices, we are innovating ways to miniaturize our MOV for Surge Protection without compromising their protective capabilities. These advancements enable the integration of varistor into increasingly compact and portable devices.

3. Smart Disk Varistor Technologies

We are exploring the integration of smart technologies into our varistors, allowing for real-time monitoring and diagnostics. Smart varistors can provide valuable data on surge events and varistor health, facilitating proactive maintenance and enhancing overall system reliability.

4. MOV for Surge Protection Improved Thermal Management

Innovations in thermal management materials and designs are being developed to enhance the varistor's ability to dissipate heat during surge events. Improved thermal management ensures the varistor maintains optimal performance and extends its operational lifespan.

5. Sustainable Manufacturing Processes

We are committed to advancing sustainable manufacturing techniques that further reduce energy consumption and environmental impact. Innovations in production processes contribute to our goal of achieving greater environmental sustainability.

6. Customizable Disk Varistor Solutions

Recognizing the diverse needs of our clients, we are developing customizable varistor solutions tailored to specific applications. This flexibility allows us to address unique surge protection challenges across various industries effectively.

7. MOV for Surge Protection Enhanced Durability and Longevity

Continuous improvements in varistor design and materials aim to enhance durability and longevity. These advancements ensure that our disk varistor provides reliable protection over extended periods, reducing the need for frequent replacements.

8. Integration with Renewable Energy Systems

As the adoption of renewable energy sources grows, we are developing varistors specifically designed to protect solar and wind energy systems. These specialized varistors cater to the unique surge protection needs of renewable energy infrastructures.

Through relentless innovation, we strive to stay ahead of industry trends and technological advancements, ensuring that our disk varistor continues to set the standard for surge protection solutions in the ever-evolving electronics landscape.

MOV for Surge Protection Quality Certifications and Awards

Our commitment to excellence is recognized through various quality certifications and industry awards. These accolades attest to the superior performance and reliability of our disk varistor products.

1. ISO 9001 Certification of MOV for Surge Protection

We are proud to hold the ISO 9001 certification, which signifies our adherence to international quality management standards. This certification reflects our dedication to continuous improvement and customer satisfaction.

2. UL Listing of MOV for Surge Protection

Our varistors are UL listed, ensuring that they meet stringent safety and performance criteria set by Underwriters Laboratories. This listing is a testament to the varistors' reliability and suitability for use in critical applications.

3. MOV for Surge Protection with CE Marking

CE marking on our products indicates compliance with European Union safety, health, and environmental protection standards. This certification facilitates the global distribution and acceptance of our varistors.

4. RoHS Compliance

Our MOV for Surge Protection complies with the RoHS directive, ensuring it is free from hazardous substances. This compliance underscores our commitment to environmental sustainability and product safety.

5. Industry Innovation Awards

We have been honored with several industry innovation awards for our advancements in varistor technology. These awards recognize our efforts to push the boundaries of surge protection and deliver cutting-edge solutions to our clients.

6. Customer Satisfaction Awards

Our dedication to customer satisfaction has earned us accolades from various clients across different industries. These awards highlight our ability to meet and exceed customer expectations through high-quality products and exceptional service.

7. Sustainable Product Awards

Our environmentally friendly manufacturing practices and sustainable product designs have been recognized with sustainability awards. These honors reflect our commitment to reducing our environmental impact and promoting sustainable development.

These quality certifications and awards not only validate the excellence of our disk varistor but also reinforce our position as a trusted leader in surge protection solutions. We remain dedicated to maintaining these high standards and continuously striving for improvement.

Disk Varistor Customer Testimonials

Our customers' satisfaction speaks volumes about the quality and reliability of our disk varistor products. Here are some testimonials from clients who have benefited from our surge protection solutions:

John D., Electrical Engineer at TechSolutions

"We've been using this MOV for Surge Protection in our power distribution systems for over a year now. The surge protection is impeccable, and we've noticed a significant decrease in equipment failures due to voltage spikes. Highly recommended!"

Maria S., Project Manager at GreenEnergy

"Integrating disk varistor into our solar panel systems has been a game-changer. The protection it offers against voltage fluctuations ensures our systems operate smoothly, even in unstable grid conditions."

Alex T., CTO at SmartHome Inc.

"Our smart home devices are now more reliable thanks to these varistors. They effectively prevent surge-induced damages, which has enhanced our product's reputation for durability and quality."

Linda K., Senior Technician at MediCare Hospital

"The medical imaging equipment in our facility is sensitive to power surges. Since we started using this MOV for Surge Protection, we've had no issues with equipment downtime due to electrical disturbances. It's been invaluable."

Robert L., Automotive Engineer at AutoDrive Motors

"Incorporating these varistors into our vehicle electronics has significantly improved the reliability of our infotainment systems. They provide excellent protection against voltage fluctuations, ensuring a seamless user experience."

These testimonials reflect our commitment to delivering high-quality surge protection solutions that meet the diverse needs of our clients across various industries.

FAQs: Frequently Asked Questions of Disk Varistor

1. What is a Disk Varistor and How Does It Work?

A disk varistor is a metal oxide semiconductor that protects electronic circuits by clamping excess voltage. It operates with high impedance under normal conditions and switches to low impedance during voltage surges, effectively diverting excess energy.

2. What Specifications Should I Consider When Choosing a Disk Varistor?

Key specifications include:

- Varistor chip diameter

- Pressure sensitive voltage

- Maximum allowable AC/DC voltage

- Energy absorption capacity

- Surge capacity at 1kHz

- Operating temperature range

- Nonlinear coefficient

- Response time and leakage current

These ensure compatibility with your surge protection needs.

3. How Does a Disk Varistor Compare to Other Surge Protection Devices?

Compared to other devices like MOV for surge protection, disk varistor provides:

- Wide voltage handling

- High energy absorption

- Minimal leakage current

- Rapid response time

This makes it highly effective for protecting sensitive electronics.

4. Where Is Disk Varistor Commonly Used?

Disk varistor is widely applied in:

- Communication systems

- Home appliances

- Automotive electronics

- Industrial systems

- Renewable energy

- Medical devices

It safeguards circuits from transient voltage spikes.

5. Can Disk Varistor Be Used in AC and DC Systems?

Yes. Disk varistor is compatible with both AC and DC applications. Symmetric types work in AC circuits, while asymmetric ones are designed for DC systems.

6. What is the Typical Lifespan of a Disk Varistor?

Under normal conditions, high-quality disk varistor lasts several years. Its lifespan depends on surge frequency, operating temperature, and installation quality.

7. How Should I Maintain a Disk Varistor?

Maintenance tips include:

- Inspect for physical damage or wear.

- Monitor electrical performance regularly.

- Replace damaged varistors to ensure continued protection.

8. Are Your Disk Varistor MOV for Surge Protection Compliant with International Standards?

Yes. Our disk varistor complies with standards such as IEC, UL, RoHS, REACH, and CE marking, ensuring safety, performance, and environmental compatibility.

9. How Do I Integrate Disk Varistor into My System?

To integrate a disk varistor:

- Identify surge entry points.

- Select a varistor with the right specifications.

- Mount it near the power entry point.

- Connect it in parallel with the power line.

- Ensure secure soldering and installation.

10. Why Choose Your Disk Varistor?

Our disk varistor stands out due to:

- Superior energy absorption

- Wide voltage range

- Fast response time

- Minimal leakage current

- Compliance with global standards

We prioritize innovation and quality, ensuring unmatched protection for your systems.

© 2024 DXM Product. All rights reserved.

Author: Ivan Huang

Updated on 25th December 2024

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd