PTC Ceramic Electronics for transformer overvoltage protection

The MZ31 series PTC Ceramic thermistor is a reliable solution for transformer overvoltage and overcurrent protection.

Key Features are as below:

● Cost-effective Protection: PTC Ceramic can replace traditional fuses with automatic recovery after faults cost-effectively.

● Self-Resetting: Self-resetting PTC Electronics offer superior performance.

● Versatile Use: PTC Transformer widely used in transformers and adapters.

● Durable and Safe: Contactless and noiseless, ensure circuit stability and safety.

● High Quality: Manufactured by DXM, meet rigorous standards, making them a top choice for various applications.

If you're seeking high-quality protection for your transformers, the MZ31 series PTC Ceramic from China provides the reliability and efficiency you need.

Introduction to PTC Ceramic Thermistors for Transformer Protection

Applications of PTC Ceramic Thermistors in Transformer Protection

The MZ31 series PTC Ceramic thermistor is widely used in transformers and adapters for:

- Primary PTC transformer for overvoltage protection

- Overload protection

- Overcurrent protection

These PTC Electronics components are essential in maintaining the integrity and safety of electrical circuits by minimizing residual current through rapid resistance increase and ensuring the overall system’s efficiency.

1.Automatic circuit protection: PTC Transformer can resume steadily after circuit protection.

2.Contactless,noiseless and flameless.

3.Has complete specification.

4.PTC Ceramic Thermistor Reacts fast.

5.Long stability.

6.With a better performance of overvoltage protection,

suitable for operating in 250/265V AC (high resistance state) continuously

7.Small steady resistance.

8.Low rated current.

9.PTC Electronics components are RoHS compliant.

Key Features of PTC Ceramic in Transformers

Working Principle

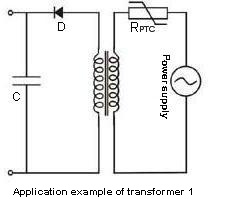

As indicated in Fig as below,when the circuit is operating normally, the current flowing through thePTC Ceramic is below the rated current, keeping the thermistor in a low resistance state. This allows the transformer’s primary and secondary loops to function without interruption. If a fault occurs, causing the current to exceed the rated level, the PTC Transformer quickly heats up, significantly increasing its resistance. This action effectively turns off the circuit to prevent damage. Once the fault is resolved, the PTC Electronics return to its low resistance state, allowing the circuit to resume normal operation.

Choosing Guidelines for PTC transformer for Overcurrent and Overload Protection

When selecting a PTC Ceramic for transformer overvoltage protection and overload protection, consider the following factors:

- Maximum Operating Current: Ensure it matches the non-trip current of the PTC Electronics.

- Maximum Operating Voltage: Must meet or exceed the circuit's requirements.

- Rated Zero Power Resistance: Crucial for ensuring proper protection.

- Physical Dimensions and Appearance: PTC Transformer should fit the design and layout of your circuit.

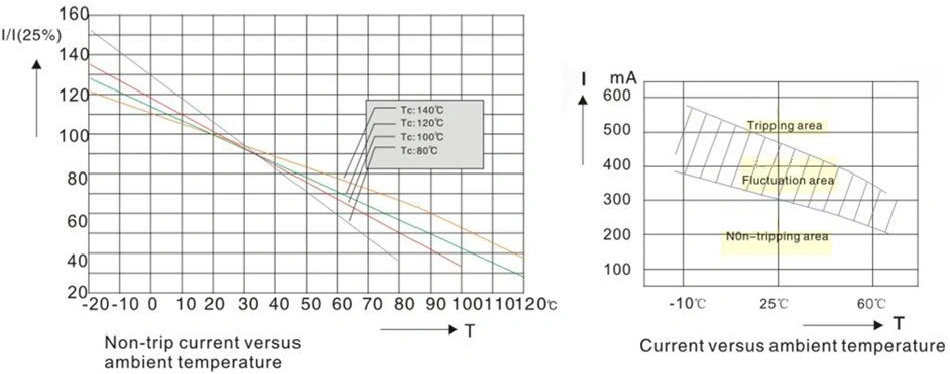

The relationship between operating temperature, operating current, and non-operating current is critical, as shown in the above figures. Generally, the operating current is 2-3 times the non-operating current, and both decrease as the operating temperature increases.

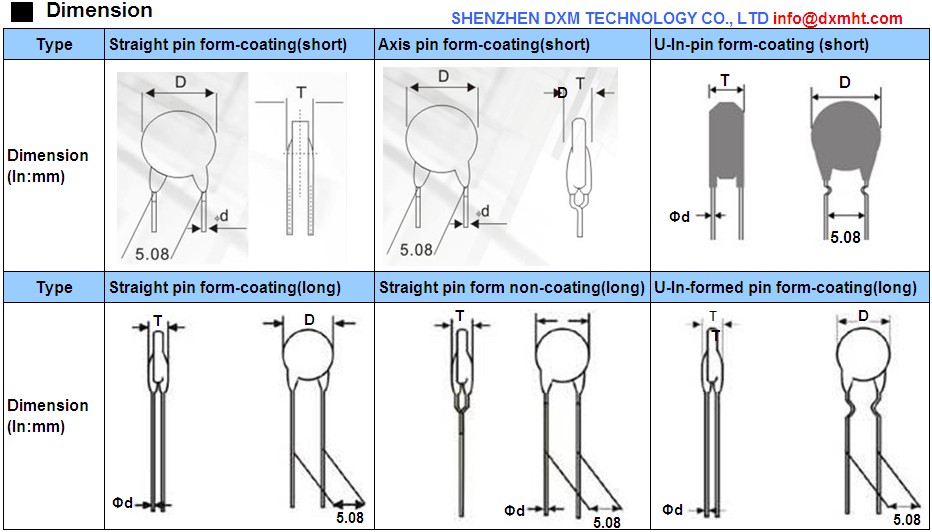

Dimesions of MZ31 Series PTC Ceramic (Unit: mm):

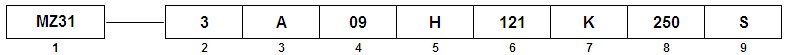

The part number for the MZ31 series PTC transformer includes the following details:

1.Series:PTC Electronics for transformer overvoltage protection

2.Type:1-disc,2-encased,3-pin form-coating,4-pin form non-coating,5-SMD

3.Type:A-general, B-compount, C-moduie

4.Chip size: 8-Φ8mm 9-Φ9mm 11-Φ11mm

5.Curie temperature: F-50℃ H-75℃ N-100℃ P-120℃ K-125℃

6.PTC Transformer R25 resistance: 6R0-6Ω 6R5-6.5Ω 70R-70Ω 121-120Ω

7.Resistance tolerance: K+/-10% M+/-20% H+/-25% N+/-30%

8.Greatly voltage:250-250V 265-265V

9.Wire shape: S-Straight, A-Axis formed, U-In-formed

-

Specifications and Part Numbers for PTC Ceramic Overload Protection in Transformer

PTC Electronics Embedded in Transformer Wire Coil

| Item | PTC Transformer Part No. | Resistance R 25(Ω) |

Non-trip current Int(mA) |

Tripcurrent @25℃ It(mA) |

Max. operating voltage V max (V) |

Max. current I m a x ( A ) |

Curie temperature T c (℃) |

Dimension (mm) |

|||

| @25℃ | @40℃ | D max | T max | Φd | |||||||

| 1 | MZ31-3A10N12RH265 | 12 | 170 | 95 | 340 | 265 | 1.5 | 100 | 11.0 | 5.0 | 0.6 |

| 2 | MZ31-3A12N12RH265 | 12 | 210 | 120 | 420 | 265 | 2.0 | 13.5 | 5.0 | 0.6 | |

| 3 | MZ31-3A10N18RH265 | 18 | 145 | 80 | 290 | 265 | 1.5 | 11.0 | 5.0 | 0.6 | |

| 4 | MZ31-3A12N18RH265 | 18 | 180 | 100 | 360 | 265 | 2.0 | 13.5 | 5.0 | 0.6 | |

| 5 | MZ31-3A10N22RH265 | 22 | 125 | 70 | 250 | 265 | 1.5 | 11.0 | 5.0 | 0.6 | |

| 6 | MZ31-3A07N22RH265 | 22 | 110 | 60 | 220 | 265 | 0.7 | 8.0 | 4.5 | 0.6 | |

| 7 | MZ31-3A08N25RH265 | 25 | 110 | 60 | 220 | 265 | 1.2 | 9.5 | 5.0 | 0.6 | |

| 8 | MZ31-3A08N30RH265 | 30 | 100 | 55 | 200 | 265 | 1.0 | 9.0 | 5.0 | 0.6 | |

| 9 | MZ31-3A07N32RH265 | 32 | 95 | 50 | 190 | 265 | 0.7 | 8.0 | 4.5 | 0.6 | |

| 10 | MZ31-3A08N35RH265 | 35 | 90 | 50 | 180 | 265 | 1.0 | 9.0 | 5.0 | 0.6 | |

| 11 | MZ31-3A08N39RH265 | 39 | 95 | 50 | 180 | 265 | 1.2 | 9.5 | 5.0 | 0.6 | |

| 12 | MZ31-3A08N40RH265 | 40 | 85 | 45 | 170 | 265 | 1.0 | 9.0 | 5.0 | 0.6 | |

| 13 | MZ31-3A07N55RH265 | 55 | 70 | 40 | 140 | 265 | 0.7 | 8.0 | 5.0 | 0.6 | |

| 14 | MZ31-3A05N121H265 | 120 | 45 | 25 | 90 | 265 | 0.4 | 6.5 | 5.0 | 0.6 | |

| 15 | MZ31-3A05N151H265 | 150 | 38 | 20 | 80 | 265 | 0.4 | 6.5 | 5.0 | 0.6 | |

PTC Ceramic Not Embedded in Transformer Wire Coil

| Item | Part No. | Resistance R 25(Ω) |

Non-trip current Int(mA) |

Tripcurrent @25℃ It(mA) |

Max. operating voltage V max (V) |

Max. current I m a x ( A ) |

Curie temperature T c (℃) |

Dimension (mm) |

|||

| @25℃ | @40℃ | D max | T max | Φd | |||||||

| 1 | MZ31-3A16P6R0H265 | 6.0 | 390 | 300 | 780.0 | 265 | 3.1 | 120 | 17.5 | 5.0 | 0.6 |

| 2 | MZ31-3A13P10RH265 | 10 | 260 | 200 | 520 | 265 | 1.8 | 14.0 | 5.0 | 0.6 | |

| 3 | MZ31-3A12P10RH265 | 10 | 250 | 200 | 500 | 265 | 1.8 | 13.5 | 5.0 | 0.6 | |

| 4 | MZ31-3A08P25RH265 | 25 | 130 | 100 | 250 | 265 | 0.8 | 9.0 | 5.0 | 0.6 | |

| 5 | MZ31-3A08P45RH265 | 45 | 105 | 80 | 200 | 265 | 0.8 | 9.0 | 5.0 | 0.6 | |

| 6 | MZ31-3A08P55RH265 | 55 | 90 | 70 | 180 | 265 | 0.8 | 6.5 | 5.0 | 0.6 | |

| 7 | MZ31-3A05P70RH265 | 70 | 65 | 50 | 130 | 250 | 0.3 | 6.5 | 5.0 | 0.6 | |

| 8 | MZ31-3A03P151H250 | 150 | 40 | 30 | 75 | 250 | 0.2 | 4.5 | 5.0 | 0.5 | |

Notes:

1.PTC Electronics wire shape form can be selected per using condition.

2.R 25 resistance tolerance can be selected per customer’s requirement.

3.Packing of the ptc transformer can be made per customer’s requirement.

Conclusion

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd