Mastering Calculating Capacitance | A Complete Guide

Unlock the secrets of calculating capacitance with DXM's complete guide. Dive into expert insights on how to accurately calculate capacitance for various applications. This essential guide provides you with everything you need to understand and master capacitance calculations, ensuring efficiency and precision in your projects. Trust DXM for reliable and practical information on capacitance.

- Introduction Of Calculating Capacitance

- Understanding Calculating Capacitance

- Basic Formula for Calculating Capacitance

- Factors Affecting Calculating Capacitance

- Practical Methods of Measuring Calculating Capacitance

- 1. Using Multimeters Calculating Capacitance

- 2. LCR Meters Calculating Capacitance

- 3. Resonant Frequency Method

- Common Challenges and Solutions

- Applications of Correct Capacitance Measurements

- Advanced Capacitance Calculation Methods

- 1. Parallel Plate Capacitor

- 2. Cylindrical Capacitor

- 3. Spherical Capacitor

- Technical Examples and Applications

- FAQs: Frequently Asked Questions

- 1. What is capacitance?

- 2. How can I measure capacitance without a multimeter?

- 3. Does the environment affect capacitance measurements?

- 4. Why is calculating capacitance important in circuit design?

- 5. Can I calculate capacitance for non-standard capacitor shapes?

- Conclusion of Calculating Capacitance

- Enhance Your Design Capabilities with Calculating Capacitance Today

- Blog Summary of Calculating Capacitance

Introduction Of Calculating Capacitance

Calculating capacitance is fundamental for optimizing electronic projects. But how do you calculate capacitance effectively? Mastering capacitance calculation ensures your circuits perform optimally, enhancing both design and troubleshooting processes. This comprehensive guide delves into the methods and principles essential for accurate capacitance measurement.

Understanding Calculating Capacitance

Capacitance measures a component's ability to store an electrical charge, expressed in farads. Most applications involve microfarads (μF) or picofarads (pF). Understanding capacitance is crucial for building and adjusting circuits, impacting frequency response and signal integrity.

In essence, capacitance determines how much charge a capacitor can hold at a given voltage. This property is vital in various electronic devices, from simple timers to complex signal processing systems.

Basic Formula for Calculating Capacitance

The fundamental formula for calculating capacitance is:

C = Q / V

Where

C is capacitance in farads,

Q is the charge in coulombs,

and V is the voltage.

This equation underscores the relationship between stored charge and voltage potential.

To understand how do you calculate capacitance in practical terms, consider a capacitor storing 10 coulombs of charge at a voltage of 5 volts. Using the formula, the capacitance would be:

C = 10 C / 5 V = 2 F

This simple calculation forms the basis for more complex capacitance measurements in various applications.

Factors Affecting Calculating Capacitance

Several factors influence how we calculate capacitance. Understanding these factors is key to accurate capacitance calculation:

- Surface Area of the Plates: Larger plate areas increase capacitance. The greater the area, the more charge a capacitor can store.

- Distance Between Plates: Shorter distances enhance capacitance. Reducing the gap between plates allows for more efficient charge storage.

- Dielectric Material: Different materials can either enhance or reduce capacitance. The dielectric constant of the material plays a significant role in capacitance calculation.

Additionally, environmental factors like temperature and humidity can affect capacitance, necessitating careful consideration during calculation.

Practical Methods of Measuring Calculating Capacitance

Knowing how do you calculate capacitance is essential, but measuring it accurately is equally important. Here are practical methods for calculating capacitance:

1. Using Multimeters Calculating Capacitance

Multimeters are versatile tools for capacitance measurement. To calculate capacitance using a multimeter:

- Set the multimeter to the capacitance setting.

- Connect the multimeter probes to the capacitor's terminals.

- Read the capacitance value displayed on the screen.

This method is straightforward and suitable for quick, approximate capacitance calculations.

2. LCR Meters Calculating Capacitance

LCR meters offer highly accurate capacitance measurements by evaluating inductance, capacitance, and resistance. They are ideal for applications requiring precision. When calculating capacitance with an LCR meter:

- Connect the capacitor to the LCR meter.

- Select the appropriate measurement mode.

- Read the precise capacitance value.

This method provides detailed insights, especially useful in complex electronic designs.

3. Resonant Frequency Method

This method involves incorporating a known inductor and measuring the oscillation frequency to derive capacitance using resonance formulas. To calculate capacitance using the resonant frequency method:

- Set up an LC circuit with a known inductance.

- Measure the resonant frequency of the circuit.

- Use the formula \( f = \frac{1}{2\pi\sqrt{LC}} \) to solve for capacitance.

This technique is particularly useful for non-standard capacitor types where traditional measurement methods may fall short.

Common Challenges and Solutions

When calculating capacitance, several challenges may arise. Addressing these challenges ensures accurate capacitance calculation:

- Parasitic Capacitance: Unintended capacitance can distort measurements. Mitigate this by using shielded cables and proper layout designs.

- Temperature Variations: Temperature changes can affect capacitance. Use temperature-stable capacitors or apply correction factors in your calculations.

- Component Tolerances: Variations in component specifications can impact accuracy. Employ precision components for critical circuits to ensure reliable capacitance calculation.

Additionally, electromagnetic interference (EMI) can introduce errors. Proper shielding and grounding techniques are essential to minimize such effects.

Applications of Correct Capacitance Measurements

Accurate capacitance calculations have significant implications across various fields. Here are key applications where calculating capacitance is crucial:

- Tuning Radios and Antennas: Ensures optimal frequency capture and signal clarity. Accurate capacitance calculation helps in adjusting the tuning circuits to desired frequencies.

- Power Supplies: Stabilizes voltage outputs, ensuring consistent device operation. Proper capacitance calculation prevents voltage fluctuations and enhances power supply reliability.

- Signal Filtering: Removes unwanted noise, enhancing data transmission fidelity. Calculating capacitance accurately allows for effective design of low-pass and high-pass filters.

- Energy Storage Systems: In renewable energy applications, precise capacitance calculation is vital for energy storage efficiency and reliability.

- Medical Devices: Ensures the safe and effective operation of sensitive electronic components in medical equipment through accurate capacitance measurement.

These applications demonstrate the importance of mastering how do you calculate capacitance to ensure high performance and reliability in electronic systems.

Advanced Capacitance Calculation Methods

For more complex systems, advanced methods of calculating capacitance are required. Here are some sophisticated techniques:

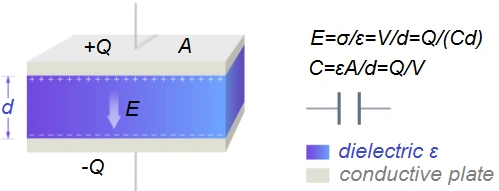

1. Parallel Plate Capacitor

For a parallel plate capacitor, capacitance is calculated using:

C = ε₀ × A / d

Where ε₀ is the permittivity of free space (8.854 × 10⁻¹² F/m), A is the area of one plate (m²), and d is the distance between the plates (m). This method is fundamental in understanding how do you calculate capacitance in simple geometries.

For example, if you have plates with an area of 0.1 m² separated by 0.001 m, the capacitance would be:

C = (8.854 × 10⁻¹² F/m) × 0.1 m² / 0.001 m = 8.854 × 10⁻⁹ F = 8.854 nF

2. Cylindrical Capacitor

The capacitance of a cylindrical capacitor is given by:

C = (2π × ε₀ × L) / ln(b/a)

Where L is the length of the cylinder (m), a is the inner radius (m), and b is the outer radius (m). This formula is essential when dealing with cylindrical geometries.

For instance, with a cylinder length of 2 m, inner radius of 0.01 m, and outer radius of 0.02 m:

C = (2π × 8.854 × 10⁻¹² F/m × 2 m) / ln(0.02 / 0.01) ≈ 1.11 × 10⁻⁹ F = 1.11 nF

3. Spherical Capacitor

For a spherical capacitor, the formula is:

C = 4π × ε₀ / (1/a - 1/b)

Where a is the radius of the inner sphere (m) and b is the radius of the outer sphere (m). This calculation is vital for spherical configurations.

For example, with an inner radius of 0.05 m and an outer radius of 0.1 m:

C = 4π × 8.854 × 10⁻¹² F/m / (1/0.05 - 1/0.1) ≈ 2.22 × 10⁻¹¹ F = 22.2 pF

Technical Examples and Applications

To illustrate calculating capacitance in real-world scenarios, consider designing a filter circuit. By accurately determining the capacitance, you can control the cutoff frequency, ensuring that only desired signals pass through. Another example is in power supply stabilization, where precise capacitance calculations prevent voltage fluctuations, safeguarding sensitive electronic components.

In high-frequency applications, how do you calculate capacitance to maintain signal integrity? Suppose you are designing a high-speed communication device. Accurate capacitance calculation ensures minimal signal loss and interference, leading to reliable data transmission.

Additionally, in energy storage systems like supercapacitors, calculating capacitance is crucial for determining energy density and discharge rates. This ensures that the system meets performance requirements for applications such as electric vehicles and renewable energy storage.

In medical devices, precise capacitance calculation is essential for devices like pacemakers and imaging equipment, where accuracy directly impacts patient safety and diagnostic reliability.

FAQs: Frequently Asked Questions

1. What is capacitance?

Capacitance is the ability of a component to store electric charge, measured in farads. It plays a crucial role in various electronic applications, from energy storage to signal processing.

2. How can I measure capacitance without a multimeter?

You can use an LCR meter for precise measurements or apply the resonant frequency method by incorporating a known inductor and measuring oscillation frequency.

3. Does the environment affect capacitance measurements?

Yes, environmental factors like temperature and humidity can influence capacitance readings. It's essential to use temperature-stable capacitors or apply correction factors to ensure accuracy.

4. Why is calculating capacitance important in circuit design?

Accurate capacitance calculation ensures that circuits function as intended, affecting performance aspects like signal filtering, energy storage, and timing.

5. Can I calculate capacitance for non-standard capacitor shapes?

Yes, using methods like the resonant frequency approach or finite element analysis, you can calculate capacitance for complex geometries.

Conclusion of Calculating Capacitance

Mastering capacitance calculation is foundational for optimizing electronic components and systems. By understanding how do you calculate capacitance effectively and overcoming common challenges, you enhance both efficiency and reliability in your designs. Dive deeper into these calculations to elevate your electronic projects and maintain a competitive edge in technological innovations.

Start implementing accurate capacitance measurement practices today to achieve unparalleled results in your electronic endeavors.

Enhance Your Design Capabilities with Calculating Capacitance Today

Understanding capacitance not only improves your current projects but also gives you a competitive edge in future technological innovations. Start implementing accurate measurement practices for unparalleled results.

Explore our range of capacitance measurement tools to enhance your design and troubleshooting capabilities.

Blog Summary of Calculating Capacitance

Calculating capacitance is crucial for optimizing electronic circuits. This guide covers methods, factors affecting capacitance, practical measurement techniques, and solutions to common challenges, empowering professionals with essential knowledge and skills.

Recommended for you

Water Temperature Sensor: The Key to Engine Health and Efficiency

Lightning Surge Protection Varistor: Essential for Protecting Your Electrical Systems

Water Temp Sensor: How to Test it for Reliable Performance?

Capacitor Impedance: Calculation Guide & FAQs

Temperature Probe Sensor: A Comprehensive Guide

Termistor NTC: What Does a Thermistor Do?

Logistics

Can I change my shipping address?

Yes, you can contact our customer service team to modify the delivery address before order confirmation to ensure that the order can be accurately delivered to the address you specify.

Does your product support global logistics and distribution?

Yes, our products support global logistics and distribution services, and you can receive our products anytime and anywhere.

Price and Payment

Payment Terms

There are a number of different payment methods that can be used when you deal with us. Two are mostly used: T/T payment in advance for small values and irrevocable L/C at sight for large values.

What’s the Minimum Order Quantity (MOQ) and Minimum Order Amount (MOA)

MOQ: 10000PCS

Price

The price will be quoted in US dollars.

1) For small order quantities and small packing, normally our quotation is based on the ex-works price. The cargo will be delivered by courier after being finished normally.

2) For bulk orders and large volumes, normally our quotation is based on the FOB price. Please inform us of your destination seaport and estimated quantity, and our representative will quote you the C&F or CIF price accordingly. If you feel our freight is higher than your expectation, you can recommend your shipping company to us. Our principal is looking for a shipping company with a good reputation that offers competitive freight costs and can deliver your cargo promptly.

You may also like

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd