Capacitor Ceramico 103: The Ultimate Guide to Ceramic Disc Capacitors

Explore the comprehensive guide on Capacitor Ceramico 103 by DXM, your go-to resource for ceramic disc capacitors. Learn about their specifications, applications, and benefits in electronic circuits. Discover why DXM’s capacitors are the ideal choice for stability and performance. Enhance your projects with reliable components from a trusted brand.

- What is Capacitor Ceramico 103?

- Decoding the "103" Marking

- Electrical Characteristics of Capacitor Ceramico 103

- Key Specifications

- Performance Features

- Applications of Ceramic Disc Capacitors

- Technical Insights and Practical Examples

- Choosing the Right Capacitor Ceramico 103

- Installation Best Practices

- Advantages of Ceramic Disc Capacitors

- Challenges and Considerations

- Future Trends in Ceramic Disc Capacitors

- Comparing Capacitor Ceramico 103 with Other Capacitors

- Ensuring Quality and Reliability

- Cost Considerations

- Environmental Impact and Sustainability

- Advanced Manufacturing Techniques

- Capacitor Ceramico 103 in Renewable Energy Systems

- Capacitor Ceramico 103 in Telecommunications

- Design Considerations for Using Ceramic Disc Capacitors

- Testing and Quality Assurance

- Capacitor Ceramico 103 in Automotive Electronics

- Environmental and Safety Standards

- Capacitor Ceramico 103 in Medical Devices

- Innovations in Capacitor Ceramico 103

- Case Study: Capacitor Ceramico 103 in a Power Supply Circuit

- Maintenance and Troubleshooting

- Capacitor Ceramico 103 in Audio Electronics

- Capacitor Ceramico 103 in Consumer Electronics

- Capacitor Ceramico 103 in Aerospace

- Environmental Testing for Capacitor Ceramico 103

- Capacitor Ceramico 103 in Industrial Automation

- Capacitor Ceramico 103 in Renewable Energy Storage

- Capacitor Ceramico 103 in High-Speed Digital Circuits

- Capacitor Ceramico 103 and IoT Devices

- Capacitor Ceramico 103 in LED Lighting

- Capacitor Ceramico 103 in Power Electronics

- Capacitor Ceramico 103 in Military Applications

- Capacitor Ceramico 103 in Home Appliances

- Capacitor Ceramico 103 in Renewable Energy Integration

- Capacitor Ceramico 103 in Robotics

- Capacitor Ceramico 103 in Smart Grids

- Capacitor Ceramico 103 in Telecommunications Infrastructure

- Capacitor Ceramico 103 in High-Power Applications

- Capacitor Ceramico 103 in Renewable Energy Vehicles

- Capacitor Ceramico 103 in High-Reliability Systems

- Capacitor Ceramico 103 in Smart Appliances

- Capacitor Ceramico 103 in High-Performance Computing

- FAQs: Frequently Asked Questions

- Enhance Your Projects with Quality Ceramic Disc Capacitors

In modern electronics, the capacitor ceramico 103 plays a pivotal role. These ceramic disc capacitors are renowned for their reliability and versatility in various applications. Understanding the specifications and applications of capacitor ceramico 103 is essential for engineers and hobbyists alike.

What is Capacitor Ceramico 103?

The term capacitor ceramico 103 refers to a specific type of ceramic disc capacitor marked with "103." These capacitors are integral components in many electronic circuits due to their precise capacitance values and stability.

Decoding the "103" Marking

The "103" marking on a ceramic capacitor signifies its capacitance. This is a standardized three-digit code where:

- First two digits (10): Represent the significant figures.

- Third digit (3): Indicates the number of zeros to follow.

Thus, "103" translates to $$10 \times 10^3$$ picofarads (pF), which equals 10,000 pF or 10 nF.

Electrical Characteristics of Capacitor Ceramico 103

Key Specifications

- Capacitance: 10 nF (10,000 pF)

- Voltage Ratings: Available in 50V, 100V, and up to 3KV, depending on the manufacturer.

- Temperature Range: Typically operates from -55°C to +85°C.

- Dielectric Types: Commonly Y5V or X7R, influencing stability and tolerance.

Performance Features

- Low Loss: Exhibits low dissipation factors, ideal for high-frequency applications.

- High Stability: Maintains capacitance across varying temperatures and voltages.

- Compact Size: Small form factor suitable for space-constrained designs.

- Reliability: Durable and consistent performance over time.

Applications of Ceramic Disc Capacitors

Capacitor ceramico 103 is utilized in numerous electronic circuits due to its versatile nature:

- Coupling and Bypass Circuits: Essential in high-voltage bypass applications and coupling circuits in audio and RF systems.

- Tuning Circuits: Utilized where precise capacitance is crucial for tuning purposes.

- Energy Storage: Employed in circuits that require energy storage, such as memory circuits.

- Filtering Applications: Used in power supply filters to smooth out voltage fluctuations.

- Decoupling: Helps in decoupling noise from power lines in digital circuits.

Technical Insights and Practical Examples

In high-frequency RF applications, ceramic disc capacitors ensure signal integrity due to their low loss characteristics. For example, in radio transmitters, capacitor ceramico 103 filters out unwanted noise, maintaining clear signal transmission.

Another instance is in power supply units where capacitor ceramico 103 is used in bypass circuits to stabilize voltage levels, preventing fluctuations that could damage sensitive components.

In consumer electronics, these capacitors are found in smartphones and tablets, providing stable power to various components, ensuring optimal performance and longevity.

Moreover, in industrial machinery, ceramic disc capacitors play a role in motor control circuits, enhancing efficiency and reliability.

Choosing the Right Capacitor Ceramico 103

Selecting the appropriate capacitor ceramico 103 is crucial for the success of your electronic projects. Here are key factors to consider:

- Capacitance Value: Ensure the capacitance matches the circuit requirements.

- Voltage Rating: Choose a voltage rating that exceeds the maximum operating voltage.

- Temperature Stability: Select dielectric types that offer stability in your operating temperature range.

- Size Constraints: Verify that the physical size fits within your circuit design.

- Manufacturer Reputation: Opt for capacitors from reputable manufacturers to guarantee quality and reliability.

Installation Best Practices

Proper installation of ceramic disc capacitors ensures optimal performance:

- Placement: Position capacitors close to the components they support to minimize inductance and resistance.

- Orientation: Ensure correct orientation to avoid polarity issues, especially in polarized applications.

- Environmental Protection: Protect capacitors from extreme temperatures and humidity to maintain performance.

- Soldering: Use appropriate soldering techniques to avoid damaging the capacitor.

- Testing: After installation, test the circuit to ensure the capacitor functions correctly.

Advantages of Ceramic Disc Capacitors

Ceramic disc capacitors offer several benefits that make them a preferred choice in electronics:

- High Frequency Performance: Suitable for applications requiring high-frequency operation.

- Low Cost: Economical compared to other capacitor types.

- Durability: Resistant to mechanical stress and environmental factors.

- Wide Availability: Easily obtainable from various suppliers.

- Ease of Integration: Simple to incorporate into existing circuit designs.

Challenges and Considerations

While capacitor ceramico 103 offers numerous advantages, there are some challenges to consider:

- Temperature Sensitivity: Some dielectric types may exhibit capacitance variation with temperature changes.

- Voltage Dependence: Capacitance can decrease with increasing voltage in certain types.

- Physical Fragility: Although durable, they can be damaged by excessive mechanical stress.

- Tolerance: Ceramic capacitors may have wider tolerance ranges compared to other types.

- ESR Considerations: Equivalent Series Resistance (ESR) needs to be managed in high-frequency applications.

Future Trends in Ceramic Disc Capacitors

The market for ceramic disc capacitors is evolving with technological advancements:

- Miniaturization: Continued reduction in size for use in compact electronic devices.

- Enhanced Performance: Development of capacitors with higher capacitance and voltage ratings.

- Advanced Materials: Use of new dielectric materials to improve stability and performance.

- Environmental Sustainability: Focus on eco-friendly manufacturing processes and materials.

- Integration with Smart Technologies: Capacitors designed for use in IoT and smart devices.

Comparing Capacitor Ceramico 103 with Other Capacitors

When selecting capacitors, it's essential to compare capacitor ceramico 103 with other types:

- Electrolytic Capacitors: Higher capacitance but larger size and lower frequency performance.

- Tantalum Capacitors: Stable capacitance but more expensive and sensitive to overvoltage.

- Film Capacitors: Excellent stability and low ESR but larger in size.

- MLCCs (Multi-Layer Ceramic Capacitors): Similar to ceramic disc capacitors but offer higher capacitance in smaller packages.

Choosing between these depends on specific application requirements such as size, cost, and performance.

Ensuring Quality and Reliability

Quality ceramic disc capacitors are essential for reliable electronic designs:

- Certification: Look for certifications like ISO and RoHS to ensure quality and environmental compliance.

- Manufacturer Reputation: Opt for capacitors from trusted manufacturers to guarantee performance.

- Testing Procedures: Ensure capacitors undergo rigorous testing for capacitance, voltage, and temperature stability.

- Warranty: Prefer suppliers offering warranties to protect against defects and failures.

- Sample Testing: Test samples in your specific application to verify suitability before bulk purchasing.

Cost Considerations

Cost is a significant factor when selecting capacitor ceramico 103:

- Bulk Purchasing: Buying in bulk can reduce the per-unit cost.

- Supplier Negotiation: Negotiate with suppliers for better pricing based on volume and long-term partnerships.

- Quality vs. Cost: Balance between cost and quality to ensure reliability without overspending.

- Alternative Suppliers: Explore various suppliers to find competitive pricing without compromising quality.

- Lifecycle Costs: Consider the total cost of ownership, including potential failures and replacements.

Environmental Impact and Sustainability

Environmental considerations are increasingly important in electronics manufacturing:

- Eco-Friendly Materials: Use capacitors with environmentally friendly dielectric materials.

- Recycling Programs: Participate in recycling programs to dispose of old capacitors responsibly.

- Energy-Efficient Manufacturing: Choose suppliers who prioritize energy-efficient manufacturing processes.

- Compliance: Ensure capacitors comply with environmental regulations like RoHS and REACH.

- Reducing Waste: Optimize designs to minimize capacitor waste and encourage reuse where possible.

Advanced Manufacturing Techniques

Modern manufacturing techniques enhance the performance and reliability of ceramic disc capacitors:

- Precision Manufacturing: High-precision manufacturing ensures consistent capacitance and performance.

- Layering Technology: Multi-layer ceramic capacitors (MLCCs) offer higher capacitance in smaller sizes.

- Automated Assembly: Automation improves manufacturing efficiency and reduces defects.

- Quality Control: Advanced quality control measures ensure each capacitor meets stringent standards.

- Innovative Materials: Use of advanced dielectric materials enhances performance characteristics.

Capacitor Ceramico 103 in Renewable Energy Systems

The rise of renewable energy systems has increased the demand for reliable capacitors:

- Solar Power: Used in solar inverters and power conditioning units to stabilize voltage.

- Wind Energy: Integral in wind turbine control systems for energy storage and voltage regulation.

- Energy Storage Systems: Employed in battery management systems for efficient energy storage.

- Grid Stabilization: Help in maintaining grid stability by smoothing out power fluctuations.

- Electric Vehicles: Used in electric vehicle power electronics for efficient energy management.

Capacitor Ceramico 103 in Telecommunications

Telecommunications rely heavily on ceramic disc capacitors for various functions:

- Signal Filtering: Essential in filtering unwanted signals to ensure clear communication.

- Power Supply Stabilization: Maintain stable power supplies in telecom equipment.

- Frequency Tuning: Used in tuning circuits for frequency selection and modulation.

- RF Circuits: Integral in RF amplifiers and oscillators for maintaining signal integrity.

- Data Transmission: Ensure reliable data transmission by minimizing noise and interference.

Design Considerations for Using Ceramic Disc Capacitors

Effective design integration of capacitor ceramico 103 involves several considerations:

- Space Allocation: Ensure adequate space for the physical size of the capacitor.

- Thermal Management: Manage heat dissipation to maintain capacitor performance.

- Electrical Layout: Optimize the electrical layout to minimize inductance and resistance.

- Component Placement: Position capacitors near power and signal lines for optimal performance.

- EMI Shielding: Implement EMI shielding to protect capacitors from electromagnetic interference.

Testing and Quality Assurance

Ensuring the quality of ceramic disc capacitors involves rigorous testing:

- Capacitance Testing: Verify the capacitance value against specifications.

- Voltage Testing: Ensure capacitors can withstand rated voltages without failure.

- Temperature Cycling: Test performance across the specified temperature range.

- Reliability Testing: Assess long-term reliability under operational stresses.

- Insulation Resistance: Measure insulation resistance to prevent leakage currents.

Capacitor Ceramico 103 in Automotive Electronics

The automotive industry extensively uses capacitor ceramico 103 in various applications:

- Engine Control Units (ECUs): Stabilize power supplies and filter noise in ECUs.

- Infotainment Systems: Ensure reliable performance in car audio and navigation systems.

- Safety Systems: Used in airbag and braking systems for dependable operation.

- Lighting Systems: Enhance performance in LED and other lighting applications.

- Powertrain Electronics: Support efficient power management in hybrid and electric vehicles.

Environmental and Safety Standards

Compliance with environmental and safety standards is crucial for ceramic disc capacitors:

- RoHS Compliance: Ensures capacitors are free from hazardous substances.

- REACH Compliance: Addresses the registration, evaluation, authorization, and restriction of chemicals used in capacitors.

- UL Certification: Indicates adherence to safety standards.

- ISO Standards: Guarantees quality management systems in capacitor manufacturing.

- CE Marking: Signifies conformity with health, safety, and environmental protection standards in the EU.

Capacitor Ceramico 103 in Medical Devices

The medical industry relies on ceramic disc capacitors for critical applications:

- Diagnostic Equipment: Stabilize power supplies in MRI and CT machines.

- Monitoring Devices: Ensure reliable operation in patient monitoring systems.

- Implantable Devices: Provide stable power in implantable medical devices.

- Therapeutic Equipment: Support energy storage and delivery in therapeutic devices.

- Safety Systems: Enhance the reliability of safety-critical medical systems.

Innovations in Capacitor Ceramico 103

Continuous innovation enhances the performance of capacitor ceramico 103:

- Advanced Dielectrics: Development of new dielectric materials improves capacitance and stability.

- Miniaturization: Smaller capacitors with higher performance meet the demands of compact electronics.

- Enhanced Tolerance: Improved manufacturing techniques achieve tighter capacitance tolerances.

- Higher Voltage Ratings: Capacitors capable of handling higher voltages expand application possibilities.

- Integration with Other Components: Combining capacitors with inductors and resistors for multi-functional components.

Case Study: Capacitor Ceramico 103 in a Power Supply Circuit

Consider a power supply circuit in a desktop computer. The capacitor ceramico 103 is used in the bypass configuration to filter out noise from the power lines. Its low ESR and high stability ensure that the voltage remains steady, protecting sensitive components like the CPU and GPU from voltage spikes.

By strategically placing multiple ceramic disc capacitors near the power pins of integrated circuits, the overall performance and reliability of the power supply are significantly enhanced.

Maintenance and Troubleshooting

Proper maintenance ensures the longevity of capacitor ceramico 103 in electronic circuits:

- Regular Inspections: Check for physical damage or signs of wear.

- Performance Monitoring: Use oscilloscopes and multimeters to monitor capacitance and voltage levels.

- Replacement: Replace capacitors showing signs of degradation to prevent circuit failures.

- Cleaning: Keep circuit boards clean to avoid contamination that could affect capacitor performance.

- Environmental Control: Maintain optimal environmental conditions to prolong capacitor life.

Capacitor Ceramico 103 in Audio Electronics

In audio electronics, ceramic disc capacitors are vital for maintaining sound quality:

- Signal Coupling: Transfer audio signals between stages without distortion.

- Decoupling: Remove noise from power supplies, ensuring clean audio output.

- Tone Control: Adjust frequency responses in tone control circuits.

- Feedback Loops: Stabilize feedback loops in amplifiers for consistent performance.

- Power Supply Filtering: Smooth out power supply variations to prevent audio artifacts.

Capacitor Ceramico 103 in Consumer Electronics

Consumer electronics heavily rely on capacitor ceramico 103 for various functions:

- Smartphones: Stabilize power supplies and filter signals in smartphones.

- Tablets: Ensure reliable performance in tablet power management systems.

- Televisions: Enhance image and sound quality by filtering power and signal lines.

- Gaming Consoles: Maintain stable power in high-performance gaming systems.

- Wearable Devices: Provide compact and reliable capacitance in smartwatches and fitness trackers.

Capacitor Ceramico 103 in Aerospace

The aerospace industry demands high-performance components, including ceramic disc capacitors:

- Avionics Systems: Ensure reliable power and signal filtering in avionics.

- Satellite Electronics: Provide stable capacitance in satellite communication systems.

- Navigation Systems: Maintain accurate navigation signals by filtering out noise.

- Control Systems: Support precise control in flight and engine management systems.

- Spacecraft Power Systems: Stabilize power supplies in harsh space environments.

Environmental Testing for Capacitor Ceramico 103

Environmental testing ensures ceramic disc capacitors can withstand various conditions:

- Thermal Cycling: Test performance across extreme temperature ranges.

- Humidity Resistance: Ensure capacitors operate reliably in high-humidity environments.

- Vibration Testing: Assess durability under mechanical stress and vibrations.

- Shock Testing: Verify resistance to sudden shocks and impacts.

- Corrosion Testing: Ensure capacitors resist corrosion from environmental exposure.

Capacitor Ceramico 103 in Industrial Automation

Industrial automation systems benefit from capacitor ceramico 103 in several ways:

- PLC Systems: Stabilize power supplies in Programmable Logic Controllers (PLCs).

- Motor Drives: Enhance performance and efficiency in motor drive circuits.

- Sensors: Provide stable power to various industrial sensors.

- Control Panels: Ensure reliable operation of control panels and interfaces.

- Robotics: Support power management in robotic control systems.

Capacitor Ceramico 103 in Renewable Energy Storage

Energy storage systems require reliable capacitors like ceramic disc capacitors:

- Battery Management: Stabilize voltage in battery management systems.

- Energy Harvesting: Efficiently store energy harvested from renewable sources.

- Inverter Circuits: Ensure smooth operation of inverter circuits in solar and wind systems.

- Power Conditioning: Maintain power quality in energy storage applications.

- Grid-Tied Systems: Support grid-tied energy storage systems for reliable power supply.

Capacitor Ceramico 103 in High-Speed Digital Circuits

High-speed digital circuits demand precise and stable capacitors:

- Signal Integrity: Maintain signal integrity by filtering out noise.

- Power Supply Decoupling: Stabilize power supplies in high-speed digital systems.

- Clock Circuits: Ensure accurate timing in clock circuits.

- Data Transmission: Support reliable data transmission by minimizing interference.

- Memory Modules: Enhance performance in memory modules through stable capacitance.

Capacitor Ceramico 103 and IoT Devices

The Internet of Things (IoT) relies on capacitor ceramico 103 for efficient operation:

- Sensor Nodes: Provide stable power to sensor nodes in IoT networks.

- Communication Modules: Ensure reliable communication in IoT devices.

- Power Management: Manage power consumption in battery-operated IoT devices.

- Data Processing: Support efficient data processing in IoT gateways.

- Connectivity: Enhance connectivity by stabilizing power supplies in connected devices.

Capacitor Ceramico 103 in LED Lighting

LED lighting systems benefit from ceramic disc capacitors in various ways:

- Power Supply Filtering: Smooth out power supply variations to ensure consistent LED performance.

- Driver Circuits: Stabilize voltage in LED driver circuits.

- Energy Efficiency: Enhance energy efficiency by reducing power loss in LED systems.

- Heat Management: Manage heat dissipation in high-power LED applications.

- Longevity: Increase the lifespan of LED systems by maintaining stable power.

Capacitor Ceramico 103 in Power Electronics

Power electronics circuits utilize capacitor ceramico 103 for efficient power management:

- DC-DC Converters: Stabilize output voltages in DC-DC converter circuits.

- AC-DC Converters: Filter and stabilize power in AC-DC conversion processes.

- Inverters: Enhance inverter performance by smoothing out voltage fluctuations.

- Rectifiers: Improve rectifier efficiency by filtering out ripple currents.

- Switching Power Supplies: Ensure stable operation in switching power supply units.

Capacitor Ceramico 103 in Military Applications

The military sector relies on ceramic disc capacitors for robust and reliable performance:

- Communication Systems: Ensure reliable communication in combat and strategic operations.

- Radar Systems: Maintain signal integrity in radar and detection systems.

- Weapon Systems: Support power management in advanced weaponry.

- Navigation Systems: Enhance accuracy in military navigation equipment.

- Surveillance Equipment: Provide stable power in surveillance and reconnaissance devices.

Capacitor Ceramico 103 in Home Appliances

Home appliances integrate capacitor ceramico 103 for improved functionality:

- Refrigerators: Stabilize power in compressor circuits.

- Washing Machines: Enhance motor control and performance.

- Microwave Ovens: Ensure reliable operation of high-frequency circuits.

- Air Conditioners: Maintain stable power in cooling systems.

- Smart Home Devices: Support efficient power management in smart home technologies.

Capacitor Ceramico 103 in Renewable Energy Integration

Integrating renewable energy sources involves the use of ceramic disc capacitors:

- Solar Inverters: Stabilize output in solar inverter circuits.

- Wind Turbines: Enhance performance in wind turbine power electronics.

- Energy Storage Systems: Support efficient energy storage and retrieval.

- Grid Integration: Facilitate smooth integration of renewable energy into the grid.

- Power Conditioning: Improve power quality in renewable energy systems.

Capacitor Ceramico 103 in Robotics

Robotics systems utilize capacitor ceramico 103 for reliable performance:

- Control Boards: Stabilize power in control boards and processors.

- Motor Drivers: Enhance performance of motor drivers in robotic actuators.

- Sensors: Provide stable power to various sensors used in robotics.

- Communication Modules: Ensure reliable communication between robotic components.

- Power Management: Efficiently manage power distribution in robotic systems.

Capacitor Ceramico 103 in Smart Grids

Smart grids leverage ceramic disc capacitors for advanced power management:

- Voltage Regulation: Maintain stable voltage levels across the grid.

- Power Quality: Improve power quality by filtering out harmonics and noise.

- Energy Storage: Enhance energy storage capabilities in smart grid systems.

- Demand Response: Support demand response strategies through efficient power management.

- Renewable Integration: Facilitate the integration of renewable energy sources into the grid.

Capacitor Ceramico 103 in Telecommunications Infrastructure

Telecommunications infrastructure relies on capacitor ceramico 103 for stable operations:

- Base Stations: Stabilize power and filter signals in base station equipment.

- Fiber Optic Systems: Ensure reliable power in fiber optic transmission systems.

- Switching Centers: Enhance performance in switching and routing centers.

- Data Centers: Maintain stable power supplies in data center operations.

- Telecom Towers: Support power management in telecom towers and antennas.

Capacitor Ceramico 103 in High-Power Applications

High-power applications demand robust capacitors like ceramic disc capacitors:

- Industrial Motors: Enhance performance and efficiency of industrial motors.

- Power Supplies: Stabilize high-power supply units in industrial settings.

- HVAC Systems: Support reliable operation of heating, ventilation, and air conditioning systems.

- Electric Heaters: Ensure stable power in electric heating elements.

- Heavy Machinery: Maintain power stability in heavy machinery operations.

Capacitor Ceramico 103 in Renewable Energy Vehicles

Electric and hybrid vehicles utilize capacitor ceramico 103 for efficient energy management:

- Battery Systems: Stabilize power in battery management systems.

- Inverters: Enhance inverter performance in electric drivetrains.

- Charging Systems: Ensure reliable operation of vehicle charging systems.

- Power Distribution: Manage power distribution across vehicle systems.

- Energy Recovery: Support energy recovery systems in regenerative braking.

Capacitor Ceramico 103 in High-Reliability Systems

High-reliability systems require dependable capacitors like ceramic disc capacitors:

- Aerospace Systems: Ensure reliable power and signal management in aerospace applications.

- Medical Equipment: Maintain stable operation in critical medical devices.

- Military Systems: Support robust performance in military electronics.

- Data Centers: Enhance reliability in data center power management.

- Telecommunications: Ensure uninterrupted performance in telecom infrastructure.

Capacitor Ceramico 103 in Smart Appliances

Smart appliances incorporate capacitor ceramico 103 for enhanced functionality:

- Smart Refrigerators: Stabilize power in smart refrigeration systems.

- Smart Ovens: Ensure reliable operation of smart cooking appliances.

- Smart Washers: Enhance performance in smart washing machines.

- Smart Thermostats: Support stable power in smart heating and cooling controls.

- Smart Lighting: Improve power management in smart lighting systems.

Capacitor Ceramico 103 in High-Performance Computing

High-performance computing systems depend on ceramic disc capacitors for stable operations:

- Server Power Supplies: Stabilize power in server and data center power supplies.

- High-Speed Memory: Ensure reliable performance in high-speed memory modules.

- Processor Cooling: Support efficient cooling systems in high-performance CPUs.

- GPU Systems: Enhance power stability in GPU-based computing systems.

- Networking Equipment: Maintain reliable power in high-speed networking devices.

FAQs: Frequently Asked Questions

- What does the "103" marking on a ceramic capacitor signify?

- The "103" marking indicates a capacitance value of 10,000 pF or 10 nF, where the first two digits are significant figures and the third digit represents the number of zeros.

- What are the common applications of capacitor ceramico 103?

- They are commonly used in coupling and bypass circuits, tuning circuits, energy storage, filtering applications, and decoupling in various electronic devices.

- How do ceramic disc capacitors maintain stability across different temperatures?

- They are made with dielectric materials like Y5V or X7R, which provide temperature stability and capacitance tolerance.

- Can capacitor ceramico 103 be used in high-frequency applications?

- Yes, their low dissipation factors make them suitable for high-frequency applications such as RF circuits.

- What voltage ratings are available for capacitor ceramico 103?

- They are available in various voltage ratings, including 50V, 100V, and up to 3KV, depending on the manufacturer.

- Are ceramic disc capacitors suitable for energy storage applications?

- Yes, capacitor ceramico 103 can be used in energy storage applications, providing reliable performance and stability.

- What dielectric types are used in capacitor ceramico 103?

- Common dielectric types include Y5V and X7R, which affect the capacitor's temperature stability and capacitance tolerance.

- How do I choose the right capacitor ceramico 103 for my project?

- Consider factors like capacitance value, voltage rating, temperature range, dielectric type, size constraints, and manufacturer reputation.

- What are the advantages of using ceramic disc capacitors over other types?

- Ceramic disc capacitors offer high frequency performance, low cost, durability, wide availability, and ease of integration into circuit designs.

- Can capacitor ceramico 103 withstand high temperatures?

- Yes, they typically operate within a temperature range of -55°C to +85°C, depending on the dielectric type.

Enhance Your Projects with Quality Ceramic Disc Capacitors

Investing in high-quality capacitor ceramico 103 ensures the reliability and efficiency of your electronic projects. Whether you're a hobbyist or a professional engineer, these ceramic disc capacitors are a dependable choice for achieving optimal performance.

For more information and to browse our extensive range of ceramic disc capacitors, visit our Products Page.

© 2025 DXM Blog. All rights reserved.

Author: Ivan Huang

Recommended for you

Degausser and Degaussing TV Resistor: A Complete Guide

Temperature Probe: A Comprehensive Guide

Resistance Temperature Detector Price: A Comprehensive Guide

Electrical Components International: Top Electrical Component Manufacturer DXM

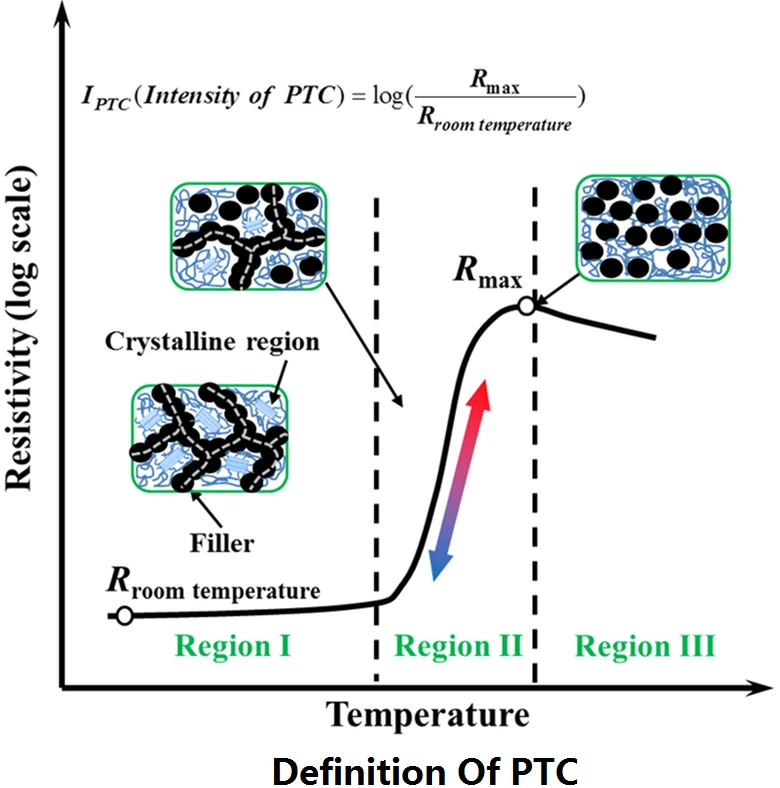

PTC Sensor: Understanding & Applications

Definition of PTC: Positive Temperature Coefficient Explained

Customized Services

Can I customize (OEM) the product?

Yes. You can customize the product with DXM. Our R&D and production technology have already reached an advanced world level, and we can provide qualified OEM service for global customers.Please specify your requirements to our representative or send samples to our factory office, and we will confirm your details.

Logistics

Is your logistics and distribution service reliable?

Yes, we cooperate with a number of well-known logistics companies to ensure the timeliness and reliability of logistics and distribution services and provide you with a satisfactory distribution experience.

Price and Payment

How are the prices of your products determined?

Our product prices are based on a variety of factors, including order quantity, customization requirements, and market competition.

Payment Terms

There are a number of different payment methods that can be used when you deal with us. Two are mostly used: T/T payment in advance for small values and irrevocable L/C at sight for large values.

What’s the Minimum Order Quantity (MOQ) and Minimum Order Amount (MOA)

MOQ: 10000PCS

You may also like

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd