RTD Sensor: How Do RTDs Work and Why They Excel

Explore the world of RTD sensor with DXM. Learn how do RTDs work and discover why they excel in precision temperature measurement. With advanced technology, our RTD sensor delivers unparalleled accuracy and reliability. Ideal for various industrial applications, trust DXM for your temperature sensing needs. Discover how RTDs can enhance your operations today.

- What is an RTD Sensor?

- How Do RTDs Work?

- Key Components of an RTD Sensor

- Advantages of Using RTD Sensor

- Applications of RTD Sensor

- Installation and Maintenance of RTD Sensor

- Why Choose RTD Sensor Over Other Temperature Sensor?

- Factors Affecting RTD Sensor Accuracy

- Conclusion

- FAQs

- How do RTDs differ from thermocouples?

- Why is platinum preferred for RTD elements?

- Can RTDs be used in extreme environments?

- What factors affect the accuracy of RTD sensor?

An RTD sensor (Resistance Temperature Detector) is widely used for precise temperature measurement across industries. It operates on the principle of electrical resistance changes with temperature, ensuring high accuracy and stability. Understanding how do RTDs work reveals why they are highly reliable and suitable for critical applications. This guide will explain their working mechanism and highlight their advantages over other temperature sensors.

What is an RTD Sensor?

An RTD sensor (Resistance Temperature Detector) measures temperature through electrical resistance variation. Platinum is commonly used due to its stable resistance-temperature relationship. This stability makes RTD sensor ideals for industries needing precision, such as pharmaceuticals and power generation.

How do RTDs work? RTD sensor links the resistance of their core (usually platinum) to temperature. This linear relationship simplifies calibration. Compared to thermocouples, RTDs offer greater stability and accuracy over long periods, ensuring reliable performance.

How Do RTDs Work?

RTD sensors operate on a simple yet effective principle: as the temperature changes, the electrical resistance of the RTD element also changes in a predictable way. Typically, the RTD element is made of platinum, which offers excellent stability and resistance to corrosion. The change in resistance is proportional to the temperature, and this predictable linear relationship allows for accurate temperature readings. But how do RTDs work in real-life industrial applications?

RTDs function by passing a small electrical current through the sensor element, usually made of platinum. As the temperature increases, the resistance of the platinum element also increases. This change in resistance is used to calculate the temperature. Because of the predictable nature of this resistance-temperature relationship, RTDs provide a very accurate means of temperature measurement. The high accuracy and stability of the rtd sensor make it the ideal solution for precision temperature monitoring in industries where even small temperature changes can significantly affect the product quality or process efficiency.

Key Components of an RTD Sensor

- RTD Element: Typically made of platinum, it serves as the core sensing component. The rtd sensor element plays a crucial role in determining the accuracy of the sensor. Platinum, in particular, is chosen for its reliable resistance-temperature characteristics.

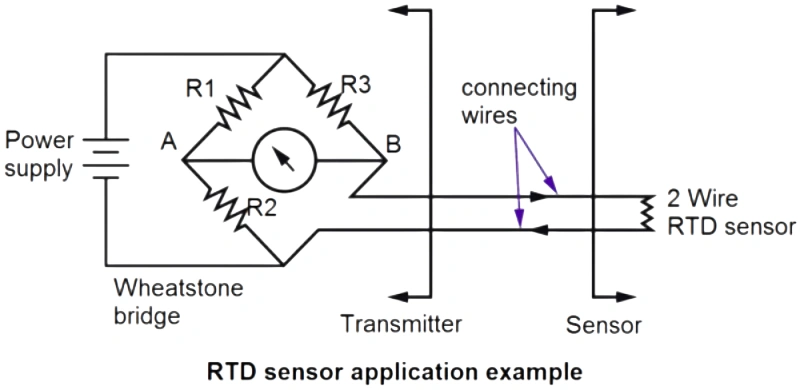

- Wiring Configuration: RTDs are configured in 2-wire, 3-wire, or 4-wire setups, each affecting measurement accuracy differently. Understanding how do RTDs work also involves understanding the different wiring configurations, as each configuration provides a different level of compensation for lead wire resistance.

- Protective Sheath: Made of materials like stainless steel to provide durability and protect against harsh environments. The protective sheath is an important component that allows the rtd sensor to withstand the demanding environments where it may be used.

Advantages of Using RTD Sensor

RTDs offer several advantages, making them suitable for demanding industrial environments:

| Advantages of Using RTD Sensors | Description |

| High Accuracy | RTD sensor provides greater precision across a broad temperature range compared to thermocouples. The accuracy of an RTD sensor is crucial for applications needing precision. |

| Stability and Repeatability | RTD sensor delivers consistent performance over prolonged use, critical for industrial settings. They offer high stability, ensuring consistent readings over time. This feature is key in environments needing precise temperature control. |

| Wide Temperature Range | RTD sensor can accurately measure from -200°C to 850°C. This versatility supports applications from cryogenics to high-temperature processes, making RTD sensors essential for many industries. |

Applications of RTD Sensor

RTD sensors are employed across various industries, including:

- Chemical Processing: For precise temperature control in chemical reactions. In chemical processing, accuracy is critical, and RTD sensors are trusted for their ability to provide exact temperature readings that help ensure consistent product quality.

- Food and Beverage: To monitor critical temperatures during production to ensure quality and safety. The use of rtd sensors in food production ensures that temperature-sensitive processes are monitored accurately, maintaining product quality and safety standards.

- HVAC Systems: To maintain efficient environmental control in buildings. HVAC systems rely on RTD sensors to monitor and regulate temperature precisely, ensuring both energy efficiency and comfort for occupants. Understanding how do RTDs work in HVAC applications reveals their effectiveness in maintaining optimal climate conditions.

- Power Generation: Used in monitoring key operational temperatures for safety and efficiency. Power generation facilities use RTDs to monitor the temperature of turbines, boilers, and other equipment, where temperature control is vital for safe and efficient operation. The rtd sensor plays a key role in ensuring that all systems operate within safe temperature limits.

-

Installation and Maintenance of RTD Sensor

Proper installation and maintenance of RTD sensors are crucial for ensuring accurate temperature readings. When installing an rtd sensor, it's important to place the sensor in an area with good thermal contact to the medium being measured. Incorrect installation can lead to inaccurate readings, which may impact the overall efficiency of the process. Proper insulation and protection from environmental factors such as moisture are also essential for ensuring the longevity of the sensor.

Regular calibration is also necessary to maintain the accuracy of the RTD sensor. Over time, the sensor's resistance may drift due to factors such as mechanical stress or contamination. By periodically calibrating the sensor, you can ensure that it continues to provide accurate and reliable temperature measurements. Understanding how do RTDs work and the factors that can affect their performance helps in establishing an effective maintenance schedule.

Why Choose RTD Sensor Over Other Temperature Sensor?

When selecting a temperature sensor for your application, you may be wondering why an rtd sensor might be preferable over other types of sensors, such as thermocouples or thermistors. The answer lies in the specific advantages that RTD sensors offer:

- Higher Accuracy: Compared to thermocouples, RTD sensors provide more accurate temperature readings, which is particularly important in applications where precision is critical.

- Long-Term Stability: RTDs are known for their long-term stability and resistance to drift, making them ideal for use in environments where consistent and repeatable measurements are required.

- Linear Response: The relationship between resistance and temperature is more linear in an RTD sensor, making it easier to interpret readings and reducing the complexity of calibration.

Factors Affecting RTD Sensor Accuracy

Several factors can affect the accuracy of an rtd sensor. These include:

- Lead Wire Resistance: The resistance of the lead wires can affect the accuracy of the temperature measurement, especially in 2-wire configurations. This is why understanding how do RTDs work with different wiring setups is crucial for choosing the right configuration.

- Mechanical Strain: Physical strain on the RTD element can alter its resistance, leading to inaccurate readings. Ensuring that the sensor is installed in a way that minimizes mechanical stress is important for maintaining accuracy.

- Environmental Factors: Factors such as moisture, contamination, or extreme temperature fluctuations can affect the sensor's performance. Properly sealing and protecting the rtd sensor is essential for ensuring accurate readings in harsh environments.

Conclusion

RTD sensors are an essential technology in modern temperature measurement, known for their accuracy, stability, and reliability. Whether it's for precise control in chemical processing or ensuring safety in food production, RTDs play a critical role. Understanding how RTDs work and their advantages helps in making informed decisions for applications that demand high precision. The rtd sensor is unmatched for its reliability in various demanding environments.

RTD sensors offer a combination of high accuracy, stability, and versatility that makes them ideal for numerous applications. Their ability to provide consistent and repeatable temperature measurements over a wide range makes them a preferred choice in industries where precision is paramount. From chemical processing to HVAC systems, the rtd sensor ensures that temperature control is achieved effectively, contributing to the overall efficiency and quality of various processes.

FAQs

How do RTDs differ from thermocouples?

RTDs offer greater precision, stability, and a more linear response compared to thermocouples, although thermocouples are generally less expensive and more robust in extreme conditions. When understanding how do RTDs work compared to thermocouples, it's clear that the increased accuracy and stability of RTDs make them preferable for many precision applications.

Why is platinum preferred for RTD elements?

Platinum is preferred due to its excellent stability, resistance to corrosion, and predictable resistance-temperature relationship, ensuring high precision. The rtd sensor element made of platinum provides unmatched accuracy and stability, making it the gold standard in temperature measurement.

Can RTDs be used in extreme environments?

Yes, RTDs are effective in extreme environments, especially when encased in a protective sheath that prevents damage from harsh conditions. The rtd sensor is designed to withstand harsh conditions, ensuring accurate temperature readings even in challenging environments.

What factors affect the accuracy of RTD sensor?

The wiring configuration, proper sensor placement, and the temperature coefficient of resistance are key factors that influence RTD accuracy. Understanding how do RTDs work and the factors that affect their accuracy helps in optimizing their performance for specific applications.

Looking to enhance your temperature measurement capabilities with RTD sensor? Explore our range of RTD solutions here and discover how we can help transform your projects with reliable temperature monitoring solutions.

© 2024 DXM Blog. All rights reserved.

Author: Ivan Huang

Recommended for you

Water Temperature Sensor: The Key to Engine Health and Efficiency

Lightning Surge Protection Varistor: Essential for Protecting Your Electrical Systems

Water Temp Sensor: How to Test it for Reliable Performance?

Capacitor Impedance: Calculation Guide & FAQs

Temperature Probe Sensor: A Comprehensive Guide

Termistor NTC: What Does a Thermistor Do?

Price and Payment

Do you offer bulk purchase discounts?

Yes, we offer bulk purchase discounts; the specific discount rate depends on the order quantity and cooperation method.

Payment Terms

There are a number of different payment methods that can be used when you deal with us. Two are mostly used: T/T payment in advance for small values and irrevocable L/C at sight for large values.

Logistics

How to track my order?

You can track your order through our official website or the order number provided and learn about the logistics status and delivery progress of your order at any time.

Is your logistics and distribution service reliable?

Yes, we cooperate with a number of well-known logistics companies to ensure the timeliness and reliability of logistics and distribution services and provide you with a satisfactory distribution experience.

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

You may also like

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd