What is MOV? Understanding the Metal Oxide Varistor and Its Definition

Discover the essentials of MOV with DXM. A Metal Oxide Varistor (MOV) is a semiconductor device used to protect electrical equipment from voltage spikes and surges. By clamping excessive voltage, it ensures smooth electrical operation and prevents potential damage. Understanding MOV is crucial for maintaining the longevity and efficiency of electrical components. Dive into the comprehensive MOV definition with DXM to safeguard your valuable assets. Enhance your knowledge on "what is MOV" today with our expert insights.

- MOV Definition: The Basics of Metal Oxide Varistor

- Delving Deeper: Metal Oxide Varistor Definition and Composition

- Key Characteristics of MOVs: What is MOV in Detail

- How MOVs Work: The Science Behind Metal Oxide Varistor Protection

- The MOV in Action: A Step-by-Step Process of Voltage Protection

- Applications of Metal Oxide Varistor: Where MOV Definition Fits

- Consumer Electronics: Understanding MOV's Role

- Industrial Equipment: MOV Definition in Industrial Use

- Telecommunications: Metal Oxide Varistor in Telecoms

- Selecting the Right MOV: Factors Based on MOV Definition

- Installation and Maintenance of MOVs

- Installation Best Practices

- Maintenance and Replacement

- Advantages of Using MOVs in Circuit Protection

- Potential Drawbacks and Considerations

- Recent Advancements in MOV Technology

- MOVs vs. Other Surge Protection Devices

- Future Trends in MOV Technology

- Best Practices for MOV Implementation

- FAQs: Frequently Asked Questions About MOVs

If you're wondering what is MOV or seeking a comprehensive MOV definition, you've come to the right place. MOV, short for Metal Oxide Varistor, is a crucial component in modern electronics. This guide explores the metal oxide varistor definition, its applications, and why it's essential for protecting your devices.

MOV Definition: The Basics of Metal Oxide Varistor

The MOV definition describes a voltage-dependent resistor used to protect electrical circuits from voltage spikes. Understanding what is MOV is crucial for grasping its role in safeguarding sensitive electronics from power surges, ensuring longer device lifespans and stable operations.

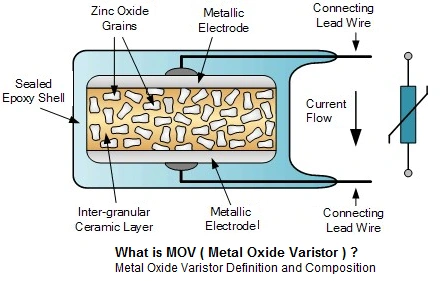

Delving Deeper: Metal Oxide Varistor Definition and Composition

The metal oxide varistor definition expands on the MOV definition by specifying its composition. MOVs are primarily made from zinc oxide, which gives them their unique protective properties. This metal oxide varistor definition is key to understanding how MOVs function in various applications.

Key Characteristics of MOVs: What is MOV in Detail

- Non-linear resistance, a crucial aspect of what is MOV

- High energy absorption capacity, central to the MOV definition

- Fast response time, essential in understanding what is MOV

- Bidirectional protection, a key feature in the metal oxide varistor definition

How MOVs Work: The Science Behind Metal Oxide Varistor Protection

To truly grasp what is MOV, we need to delve into its operation. The MOV definition includes its function of clamping voltage at a predetermined level. When voltage exceeds this threshold, the MOV's resistance drops sharply, allowing it to divert excess energy away from the protected circuit.

The MOV in Action: A Step-by-Step Process of Voltage Protection

- Normal operation: High resistance, minimal current flow

- Voltage spike occurs: Resistance drops rapidly

- Energy diversion: Excess current is shunted to ground

- Voltage stabilization: Circuit is protected from damage

- Return to normal: MOV reverts to high-resistance state

This process is central to understanding what is MOV and how it protects your devices.

Applications of Metal Oxide Varistor: Where MOV Definition Fits

The versatility described in the metal oxide varistor definition makes MOVs indispensable in various industries. Let's explore where you might find these protective components:

Consumer Electronics: Understanding MOV's Role

From smartphones to televisions, MOVs play a crucial role in protecting our everyday devices. Knowing what is MOV helps us appreciate their presence in:

- Power strips and surge protectors

- Computer motherboards

- Gaming consoles

Industrial Equipment: MOV Definition in Industrial Use

In industrial settings, the MOV definition takes on added importance as these components safeguard expensive machinery and critical systems:

- Motor control centers

- Programmable logic controllers (PLCs)

- Industrial power supplies

Telecommunications: Metal Oxide Varistor in Telecoms

The telecommunications sector relies heavily on the properties outlined in the metal oxide varistor definition to protect sensitive equipment:

- Cell tower components

- Telephone exchange systems

- Fiber optic terminals

Selecting the Right MOV: Factors Based on MOV Definition

Choosing the appropriate MOV for your application is crucial. Here are key factors to keep in mind when applying the MOV definition to your needs:

Voltage Rating: The MOV's voltage rating should match your system's normal operating voltage. This ensures protection without interfering with regular operation, a key aspect of what is MOV functionality.

Energy Absorption Capacity: Consider the potential energy of voltage spikes in your system. Choose an MOV with sufficient energy handling capability to withstand expected surges, as described in the metal oxide varistor definition.

Clamping Voltage: The clamping voltage is the maximum voltage the MOV will allow during a surge. Select a value that protects your equipment without being too restrictive, aligning with the MOV definition.

Physical Size and Mounting Options: Ensure the MOV fits within your device or system. Consider available space and mounting requirements when making your selection, keeping in mind what is MOV in terms of physical characteristics.

Installation and Maintenance of MOVs

Proper installation and regular maintenance are crucial for optimal MOV performance. Follow these guidelines based on the metal oxide varistor definition:

Installation Best Practices

- Ensure secure connections to minimize resistance

- Place MOVs as close as possible to the protected device

- Use appropriate wire gauge for current capacity

- Implement proper grounding techniques

Maintenance and Replacement

MOVs degrade over time and with each voltage event. Regular inspections and timely replacements are essential:

- Conduct visual inspections for signs of damage or discoloration

- Test MOV functionality periodically using specialized equipment

- Replace MOVs after significant surge events or every 2-3 years

- Keep spare MOVs on hand for quick replacements

Advantages of Using MOVs in Circuit Protection

Understanding the benefits of MOVs helps appreciate their value in electronic systems and reinforces what is MOV in practical terms:

1. Fast Response Time:

MOVs react to voltage spikes in nanoseconds, providing near-instantaneous protection, a key feature in the MOV definition.

2. High Energy Absorption:

These components can absorb substantial amounts of energy, making them ideal for handling large surges, as outlined in the metal oxide varistor definition.

3. Cost-Effective Solution:

MOVs offer excellent protection at a relatively low cost compared to other surge protection devices, making them a popular choice in various applications.

4. Compact Design:

Their small size allows for easy integration into various devices and systems, a practical aspect of what is MOV in design considerations.

5. Bidirectional Protection:

MOVs provide protection against surges in both positive and negative voltage directions, a crucial feature in the MOV definition.

Potential Drawbacks and Considerations

While MOVs offer significant benefits, it's important to be aware of their limitations when considering what is MOV for your application:

1. Degradation Over Time:

Each surge event slightly degrades the MOV, eventually leading to failure, a factor to consider in long-term applications.

2. Limited Lifespan:

MOVs have a finite number of surge events they can handle before requiring replacement, as noted in the metal oxide varistor definition.

3. Potential for Catastrophic Failure:

In rare cases, MOVs can fail dramatically, potentially causing fires if not properly protected, highlighting the importance of proper implementation.

4. Temperature Sensitivity:

Extreme temperatures can affect MOV performance and longevity, a consideration when applying the MOV definition in various environments.

Recent Advancements in MOV Technology

The field of MOV technology is continuously evolving, expanding our understanding of what is MOV and its capabilities:

1. Enhanced Energy Absorption:

New manufacturing techniques have increased the energy handling capacity of MOVs, pushing the boundaries of the traditional metal oxide varistor definition.

2. Improved Thermal Management:

Advanced designs help dissipate heat more effectively, extending MOV lifespan and enhancing their protective capabilities.

3. Self-Healing Properties:

Some newer MOVs can partially recover from minor surge events, prolonging their useful life and redefining what is MOV in terms of durability.

4. Integration with Smart Systems:

MOVs are being incorporated into intelligent surge protection systems for real-time monitoring and predictive maintenance, expanding the MOV definition to include smart features.

MOVs vs. Other Surge Protection Devices

While MOVs are widely used, they're not the only option for surge protection. Let's compare them to other common devices to better understand what is MOV in context:

MOVs vs. TVS Diodes:

Transient Voltage Suppressor (TVS) diodes offer faster response times but lower energy absorption capacity compared to MOVs. They're often used in sensitive electronic circuits where speed is crucial.

MOVs vs. Gas Discharge Tubes

Gas Discharge Tubes (GDTs) can handle higher surge currents than MOVs but have slower response times. They're commonly used in telecommunications and outdoor applications, complementing the metal oxide varistor definition in specific scenarios.

MOVs vs. Surge Protection ICs

Integrated Circuit (IC) surge protectors offer more precise protection and additional features but at a higher cost. They're typically used in high-end electronics and critical systems, showcasing different approaches to surge protection beyond the standard MOV definition.

Future Trends in MOV Technology

As we look to the future, several trends are shaping the evolution of MOV technology and expanding our understanding of what is MOV:

1. Nanotechnology Integration:

Researchers are exploring the use of nanomaterials to enhance MOV performance and longevity, potentially redefining the metal oxide varistor definition.

2. Smart MOV Systems:

The integration of MOVs with IoT technology for real-time monitoring and predictive maintenance is on the horizon, adding new dimensions to the MOV definition.

3. Environmentally Friendly Materials:

There's a push towards developing MOVs with more sustainable and eco-friendly materials, aligning with global environmental concerns.

4. Hybrid Protection Solutions:

Combining MOVs with other protection devices to create more robust and versatile surge protection systems, expanding on what is MOV in comprehensive protection strategies.

Best Practices for MOV Implementation

To maximize the effectiveness of MOVs in your systems, consider these best practices based on the metal oxide varistor definition:

1. Proper Sizing and Selection:

Choose MOVs with appropriate voltage ratings and energy absorption capacities for your specific application, aligning with the MOV definition.

2. Strategic Placement:

Position MOVs at critical points in your circuit to provide optimal protection, considering what is MOV.

FAQs: Frequently Asked Questions About MOVs

Q: What is MOV in electrical terms?

MOV stands for Metal Oxide Varistor. It's a voltage-dependent resistor used to protect electrical circuits from voltage spikes and surges.

Q: How does an MOV work?

An MOV works by changing its resistance in response to voltage changes. When voltage exceeds a certain threshold, the MOV's resistance drops sharply, diverting excess energy away from the protected circuit.

Q: What are the main applications of MOVs?

MOVs are widely used in surge protectors, power supplies, and various electronic devices to safeguard against voltage spikes. They're common in consumer electronics, industrial equipment, and telecommunications systems.

Q: How long do MOVs last?

The lifespan of an MOV depends on its exposure to voltage surges. Under normal conditions, they can last several years. However, after significant surge events or repeated small surges, they may need replacement.

Q: Can MOVs fail?

Yes, MOVs can fail, especially after absorbing multiple surges or one large surge beyond their capacity. Failed MOVs should be replaced promptly to maintain protection.

Recommended for you

Water Temperature Sensor: The Key to Engine Health and Efficiency

Lightning Surge Protection Varistor: Essential for Protecting Your Electrical Systems

Water Temp Sensor: How to Test it for Reliable Performance?

Capacitor Impedance: Calculation Guide & FAQs

Temperature Probe Sensor: A Comprehensive Guide

Termistor NTC: What Does a Thermistor Do?

Logistics

Can I change my shipping address?

Yes, you can contact our customer service team to modify the delivery address before order confirmation to ensure that the order can be accurately delivered to the address you specify.

How to track my order?

You can track your order through our official website or the order number provided and learn about the logistics status and delivery progress of your order at any time.

Does it support express delivery?

Yes, we support express delivery services. You can choose different delivery methods according to your needs, including ordinary express delivery and expedited express delivery.

Does your product support global logistics and distribution?

Yes, our products support global logistics and distribution services, and you can receive our products anytime and anywhere.

Customized Services

Free sample availability

You can contact our representative via email, fax or phone to specify the sample you need and provide your courier's account number (such as UPS, FedEx, DHL, TNT, etc.).. And we’ll send you samples free of charge through your courier by freight collection.

You may also like

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd