What is the difference between ntc and ptc thermistors

Discover the essential differences between NTC and PTC thermistors with DXM's comprehensive guide. Negative Temperature Coefficient and Positive Temperature Coefficient thermistors play critical roles in temperature sensing and protection. Understanding their unique properties helps ensure optimal performance across various applications. Explore how DXM's high-quality solutions cater to your specific needs, offering reliability and precision. Stay informed and make smarter choices in thermal management with our expert insights. Trust DXM for all your PTC and NTC requirements.

- Understanding PTC NTC - Thermistors Explained

- What Are Thermistors?

- NTC Thermistors Defined

- PTC Thermistors Defined

- Key Differences Between NTC and PTC

- Temperature Coefficient

- Response Time

- Applications

- NTC Thermistor Applications

- Temperature Sensors

- Circuit Protection

- Inrush Current Limiters

- PTC Thermistor Applications

- Safety Devices

- Self-Regulating Heaters

- Motor Protection

- Selecting the Right Thermistor

- Consider Temperature Requirements

- Evaluate Response Time

- Assess Environmental Factors

- FAQs About NTC and PTC Thermistors

- What do NTC and PTC stand for in thermistors?

- Where are NTC thermistors commonly used?

- What is the primary use of PTC thermistors?

- How do I choose between NTC and PTC thermistors?

- Are PTC thermistors suitable for temperature sensing?

- Conclusion

Understanding PTC NTC - Thermistors Explained

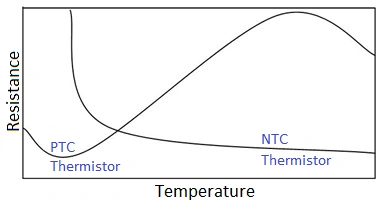

In the realm of electronic components, PTC NTC thermistors play a crucial role. But exactly what is the difference between ntc and ptc thermistors? and how do they differ? Let's delve into the details of ntc and ptc.

What Are Thermistors?

Thermistors are temperature-sensitive resistors. They change resistance with temperature variations. They are essential in many temperature measurement and control applications.

NTC Thermistors Defined

NTC stands for Negative Temperature Coefficient. In NTC thermistors, resistance decreases as temperatures rise. They are suitable for precise temperature measurements. Industries use them extensively in sensors and circuits.

PTC Thermistors Defined

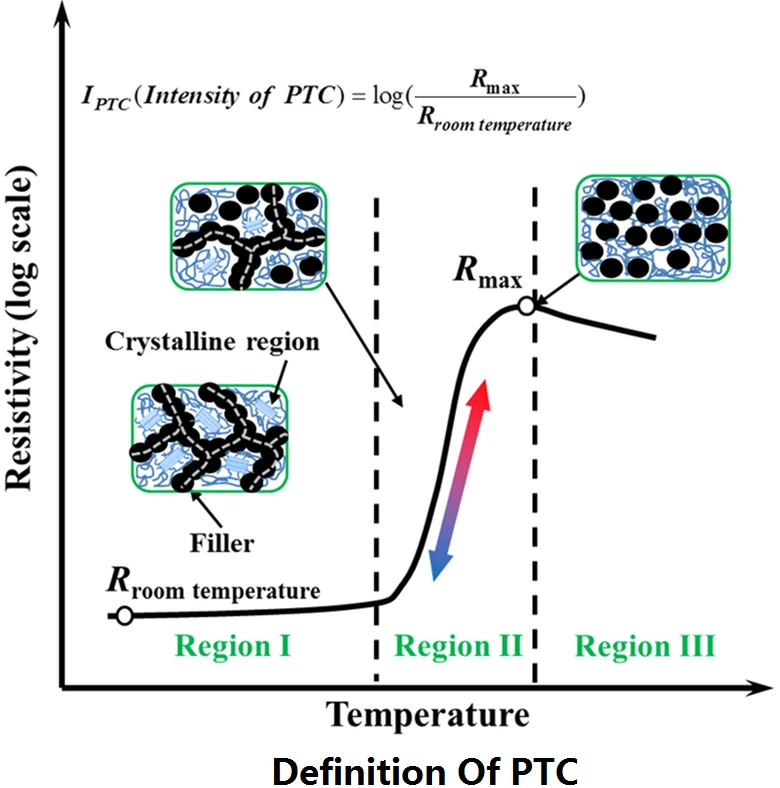

PTC stands for Positive Temperature Coefficient. Here, resistance increases with rising temperatures. PTC thermistors act as self-regulating heating elements. They are common in overcurrent and short-circuit protection applications.

Key Differences Between NTC and PTC

Understanding the differences helps decide the right thermistor for your needs.

Temperature Coefficient

- NTC Thermistors: Resistance decreases with temperature rise.

- PTC Thermistors: Resistance increases with an increase in temperature.

Response Time

NTC thermistors respond quickly to temperature changes. PTC thermistors, however, react slower but provide thermal protection.

Applications

- NTC: Ideal for temperature sensing.

- PTC: Suited for overcurrent protection.

NTC Thermistor Applications

NTC thermistors are versatile. Here's where they shine:

Temperature Sensors

Used in household appliances and automotive engineering. They ensure temperature remains within safe limits.

Circuit Protection

NTC thermistors act as protection devices. They prevent overheating in electronic circuits.

Inrush Current Limiters

They limit inrush currents, preventing circuit damage. This is crucial during start-up processes.

PTC Thermistor Applications

PTC thermistors are equally important. Here’s how they make a difference:

Safety Devices

PTC thermistors are used in safety devices. They prevent overcurrent by altering their resistance.

Self-Regulating Heaters

They stabilize temperatures in devices like heaters. It ensures efficient energy usage.

Motor Protection

PTC thermistors shield motors from overheating. This enhances motor lifespan and efficiency.

Selecting the Right Thermistor

Choosing between NTC and PTC depends on application needs.

Consider Temperature Requirements

Understand your temperature range and stability needs. NTC is better for precision, PTC for gradual control.

Evaluate Response Time

Determine how quickly you need the system to respond. Consider the balance between speed and safety.

Assess Environmental Factors

Account for external conditions. High temperature or humidity might affect thermistor performance.

FAQs About NTC and PTC Thermistors

What do NTC and PTC stand for in thermistors?

NTC stands for Negative Temperature Coefficient. PTC stands for Positive Temperature Coefficient.

Where are NTC thermistors commonly used?

They are used in temperature sensors, circuit protection, and inrush current limiters.

What is the primary use of PTC thermistors?

PTC thermistors are used for overcurrent protection and as self-regulating heaters.

How do I choose between NTC and PTC thermistors?

Consider application requirements, temperature range, response time, and environmental conditions.

Are PTC thermistors suitable for temperature sensing?

While they can be used for basic sensing, NTC thermistors offer more precision.

Conclusion

Understanding NTC and PTC thermistors' definitions, applications, and differences is crucial. They hold significant roles in electronic and industrial fields. Whether for precise temperature sensing or safety applications, the choice depends on specific needs. Evaluate your requirements carefully to choose the right thermistor for optimal performance and safety. The right decision can lead to more efficient and secure electronic systems.

By mastering NTC and PTC principles, you enhance your systems' resilience and functionality. Thermistors are more than components; they're the backbone of modern electronics. Navigate your electronic endeavors with this knowledge, ensuring safety and efficiency in your applications.

Author: Ivan Huang

© 2024 DXM Blog. All rights reserved.

Recommended for you

Degausser and Degaussing TV Resistor: A Complete Guide

Temperature Probe: A Comprehensive Guide

Resistance Temperature Detector Price: A Comprehensive Guide

Electrical Components International: Top Electrical Component Manufacturer DXM

PTC Sensor: Understanding & Applications

Definition of PTC: Positive Temperature Coefficient Explained

Logistics

Does it support express delivery?

Yes, we support express delivery services. You can choose different delivery methods according to your needs, including ordinary express delivery and expedited express delivery.

How to track my order?

You can track your order through our official website or the order number provided and learn about the logistics status and delivery progress of your order at any time.

Price and Payment

Are invoices provided?

Yes, we provide legal invoices that can be used for reimbursement and accounting records.

How are the prices of your products determined?

Our product prices are based on a variety of factors, including order quantity, customization requirements, and market competition.

Customized Services

Can I customize (OEM) the product?

Yes. You can customize the product with DXM. Our R&D and production technology have already reached an advanced world level, and we can provide qualified OEM service for global customers.Please specify your requirements to our representative or send samples to our factory office, and we will confirm your details.

You may also like

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd