Linear PTC Thermistor Precision Temperature Sensing (KTY Series)

Introducing the DXM Linear Resistor Precision Temperature Sensing (KTY Series) – the perfect solution for accurate temperature monitoring. Our KTY Series offers reliable linear resistor performance, specifically engineered for precision and durability. With its rapid response and stable readings, this PTC thermistor ensures optimal operation in various applications. Choose DXM for your temperature sensing needs to enhance system reliability and efficiency. Experience the difference with our cutting-edge Linear PTC technology today.

In the realm of temperature sensing, the KTY series linear PTC thermistor stands out for its accuracy and reliability. This linear resistor, such as the KTY84-130, plays a crucial role in various industrial and consumer applications. Understanding their features and advantages can help engineers select the right components for their projects.

What Is a KTY Series Linear Resistor?

The KTY series Linear Resistor is a specialized PTC thermistor including KTY81, KTY82, KTY83, KTY84 designed for precise temperature measurement. Unlike traditional thermistors, this Linear Thermistor offers a more predictable and linear response to temperature changes, simplifying circuit design and improving accuracy.

Linear PTC thermistor is made of PTC material and physical process. It has superior stability, compound linearity, millions of repetitions with unchanged characteristic curve. The resistance value increases with the increase of temperature, and the change is linear, and the linearity is good.

Product Overview and Key Specifications of Linear Resistor PTC Thermistor

Linear Resistor increases resistance linearly with temperature, simplifying circuit design by eliminating the need for compensation. This makes the PTC Thermistor superior to traditional PTC polymer ceramic thermistors.

Simplified Circuit Design with KTY84-130

Unlike typical PTC Thermistor, which requires compensation due to non-linear resistance-temperature behavior, the KTY84-130 maintains a linear relationship from -40°C to 300°C. This reduces complexity in temperature detection and compensation circuits, setting it apart from general PTC Thermistor, which are commonly used for overcurrent protection with narrow linear regions.

Flexible Integration and Circuit Design

Linear Thermistor with the same temperature coefficient, such as KTY84-130, can be connected in series or parallel without affecting its temperature-resistance characteristics. For example, a 1K 2000PPM Linear Resistor can be configured in series to form 2K 2000PPM or in parallel to create 500Ω 2000PPM. This flexibility supports optimized circuit experiments, data acquisition, and mass production.

Advantages of Linear Resistor KTY Series

KTY series Linear Resistor offers several advantages that make it ideal for precise temperature sensing applications.

Precision and Accuracy

The Linear Resistor in the KTY series provides high-accuracy temperature measurement, with deviations typically within 1% to 5%. This level of precision is essential for applications requiring reliable temperature monitoring.

Excellent Stability

One of the main advantages of the KTY series PTC Thermistor is its long-term stability. It experiences minimal temperature drift over time, making it ideal for use in environments where consistent performance is critical.

Linear Resistance Response

Unlike standard thermistors, the KTY Linear Thermistor shows a linear increase in resistance as temperature rises. This characteristic simplifies the circuit design, ensuring a predictable response across various temperature ranges.

Durable and Robust Design

The KTY84-130 and other KTY series KTY Linear Resistor are designed to withstand harsh environmental conditions. Their robust construction ensures they remain reliable even under stress, making them suitable for a wide range of applications.

Compact and Easy to Integrate

The KTY series comes in small, standardized packages. This compact design allows for easy integration into a variety of systems without sacrificing performance.

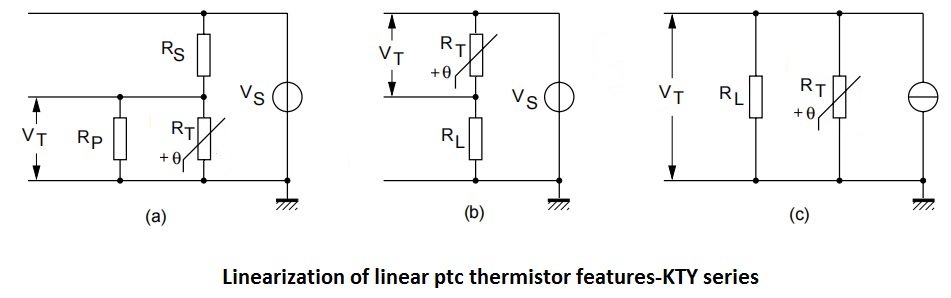

(a)There are series' RS 'and parallel thermistors' RP' and the system is powered by a constant voltage source.

(b) Thermistor RT in series with the linear ptc thermistor and system powered by constant voltage source.

(c) Parallel a thermistor 'RT' to the linear ptc thermistor.

Key Applications of KTY Series Linear Resistor

The KTY series Linear Resistor, including the KTY84-130, is essential for precise temperature measurement across various industries. Its Linear Thermistor design and PTC Thermistor properties make it a preferred choice for reliable temperature control.

Automotive Industry

In the automotive industry, the KTY84-130 Linear Resistor is commonly used for engine temperature monitoring, climate control systems, and battery management. This Linear Thermistor ensures accurate temperature regulation, enhancing vehicle performance and safety.

Industrial Automation

For industrial automation, the KTY series Linear Resistor is applied in HVAC systems, industrial process control, and equipment temperature monitoring. The Linear Thermistor design of the KTY84-130 PTC Thermistor provides consistent and precise temperature management for critical industrial applications.

Consumer Electronics

In consumer electronics, KTY series Linear Resistor is integrated into devices like refrigerators, air conditioners, and wearable health devices. Its accurate temperature sensing and Linear Thermistor properties helps ensure energy efficiency and performance in these devices.

Household Appliances

The KTY84-130 Linear Resistor plays a crucial role in household appliances such as coffee makers and hair dryers. This PTC Thermistor offers reliable thermal management, ensuring these appliances function safely over time.

Communication and Computing

In communication and computing devices, KTY Linear Thermistor is used for temperature compensation, surge suppression, and current limiting in circuits. The KTY84-130 Linear Resistor ensures that sensitive communication and computing components are protected from overheating or current surges.

Conclusion

The KTY series Linear Resistor, including the KTY84-130 PTC Thermistor, offers precise temperature control and Linear Thermistor functionality, making it ideal for a wide range of applications. Its accuracy, durability, and reliability ensure top performance in the automotive, industrial, consumer electronics, and communication sectors.

Difference between KTY81, KTY82, KTY83, KTY84

1.Different Drift of Silicon ptc thermistor

After 10000 hours of permanent operation at the maximum operating temperature with nominal operating current.

| KTY TYPE | TYPICAL DRIFT(K) | MAXIMUM DRIFT(K) |

| KTY81-1 ,KTY82-1 | 0.20 | 0.50 |

| KTY81-2 ,KTY82-2 | 0.20 | 0.80 |

| KTY83 | 0.15 | 0.40 |

Reliable Temperature Sensing with Linear Resistor and PTC Thermistor

Linear Resistor, offers stable and long-lasting temperature sensing. The performance of Linear Resistors is highly reliable due to the stable properties of silicon, the key element in Linear Thermistor. In particular, the KTY84-130 PTC Thermistor stands out for its minimal temperature drift over time.

Unmatched Stability in Long-Term Use

When testing the KTY84-130 under maximum operating temperatures, the Linear Resistor exhibited excellent stability. Over 10,000 hours of use (equivalent to 1.14 years), the temperature drift was as low as 0.2 K. Even under extreme conditions, the maximum drift observed was between 0.4 K and 0.8 K.

Superior Sensor Longevity

This minimal drift means your Linear Resistor sensor retains its accuracy, providing consistent performance. For industries requiring reliable temperature monitoring, PTC Thermistor KTY84-130 model is ideal choices. With extended operational life, the cost of sensor maintenance and replacement is greatly reduced.

Long-Term Stability of Linear Resistor and PTC Thermistor

Linear Resistor offers long-term stability even under extended use. When operating at half the specified maximum temperature, our silicon-based PTC Thermistor exhibits minimal drift. As shown in Table 1, this low drift persists for at least 450,000 hours (equal to 51 years). This is calculated using the Arrhenius equation with an activation energy of 0.7 eV.

Reliable Performance Over Decades

The KTY84-130 Linear Thermistor provides highly stable performance across its lifespan. Silicon’s inherent properties ensure that temperature drift is negligible, even after decades of operation. This makes Linear Resistor ideals for long-term applications where accuracy and reliability are critical.

Silicon-Based Batch Process Product for Stable Linear Resistor

Our Linear Resistor products are based on advanced silicon technology, benefiting from continuous improvements in microprocessors, computer memory, and other related fields. These advancements also positively impact packaging technology, leading to miniaturization and high-volume mass production.

Stable Performance of PTC Thermistor

The behavior of Linear Thermistor and PTC Thermistor remains exceptionally stable, just like the silicon they are built from. Recent tests confirm negligible temperature drifts even when sensors, such as the KTY84-130 Linear Resistor, is operating at their maximum limits. This ensures long-term reliability and consistent performance.

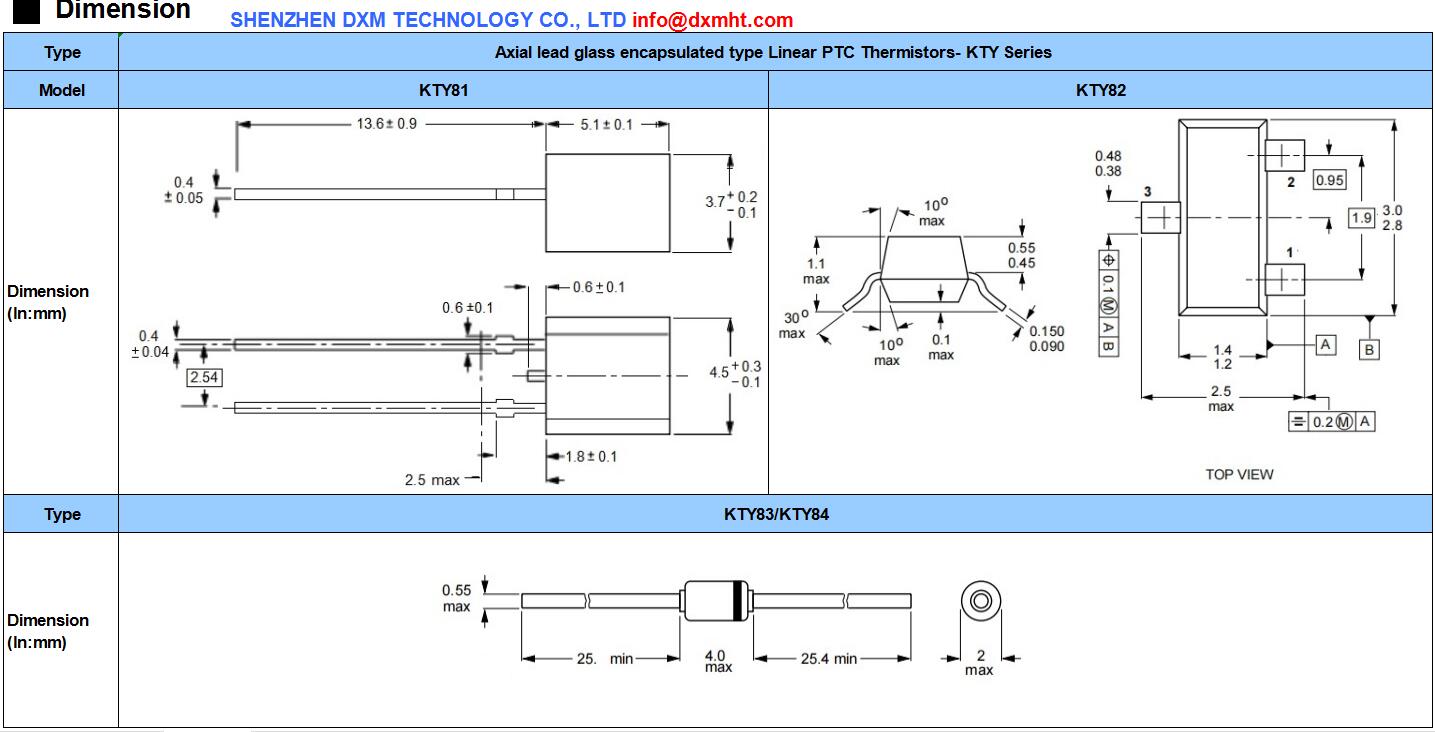

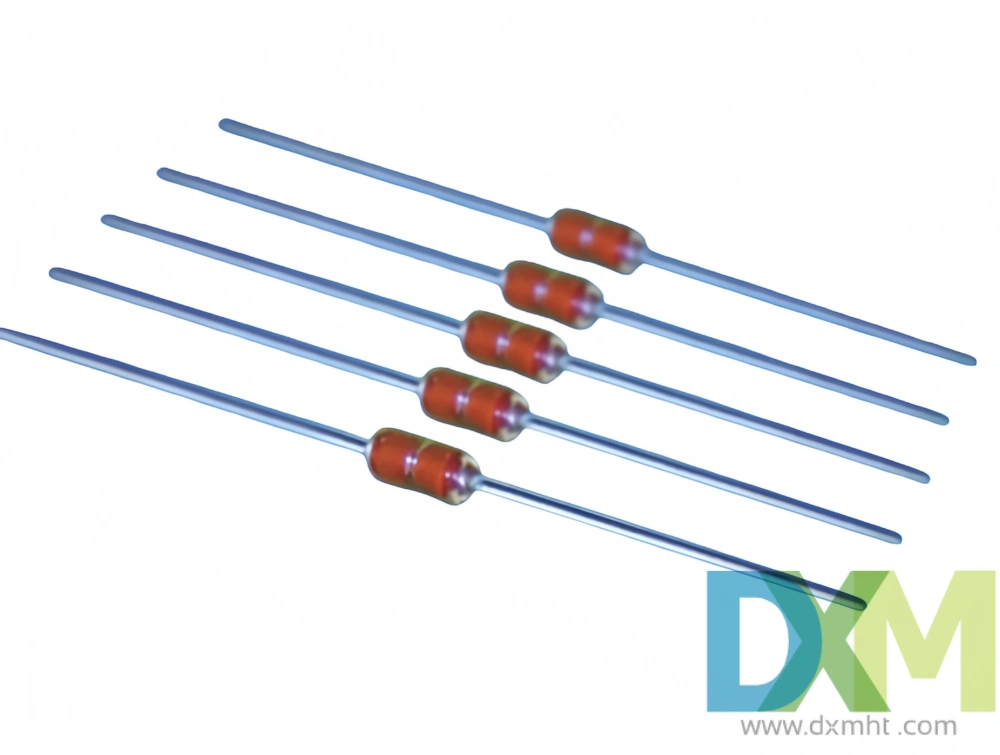

2.Different dimension:

(Unit: mm):

3.Different Key features of Linear Resistor shown as below

| KTY Type | Resistance(Ω)at 25℃ | Available Tolerance(ΔR) | Operation Temperature Range(°C) | Package Type |

| KTY81-1 | 1000 | ±1% up to ±5% | −55 to 150 | SOD70 |

| KTY81-2 | 2 000 | ±1% up to ±5% | −55 to 150 | SOD70 |

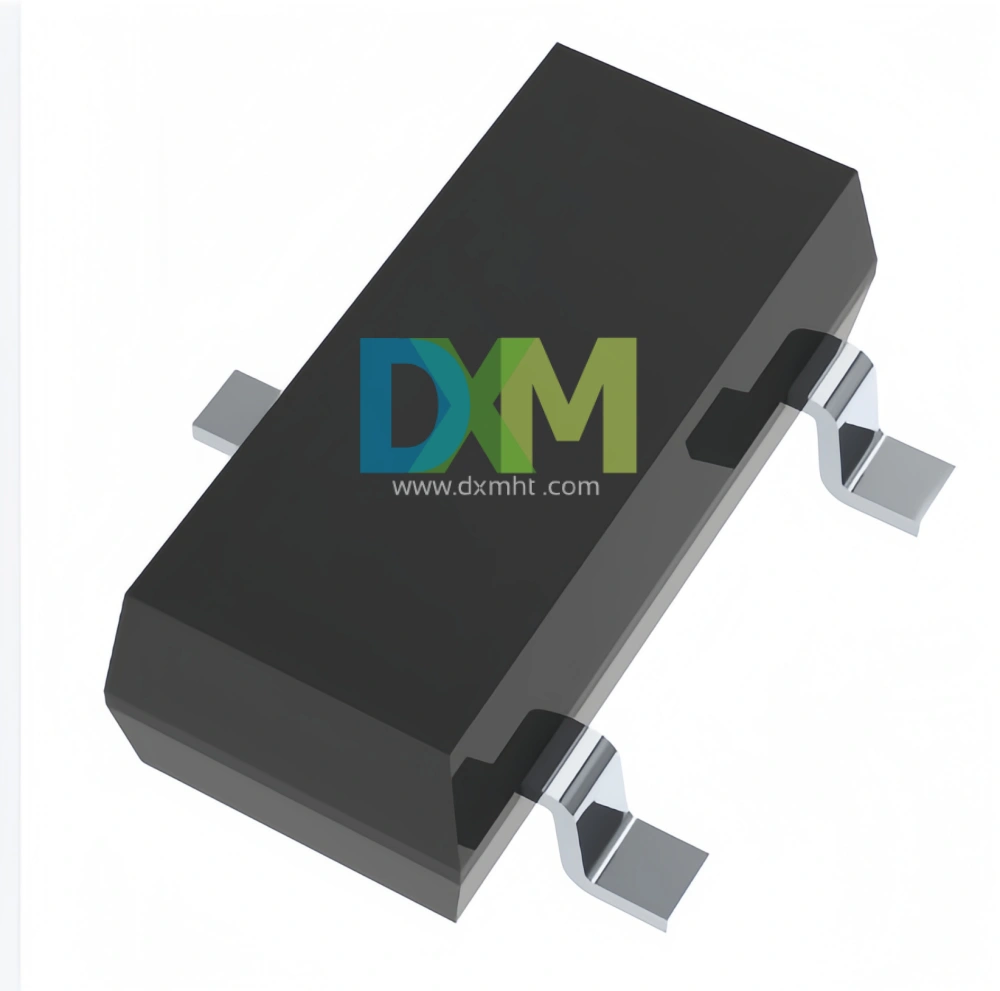

| KTY82-1 | 1000 | ±1% up to ±5% | −55 to 150 | SOT23 |

| KTY82-2 | 2000 | ±1% up to ±5% | −55 to 150 | SOT23 |

| KTY83-1 | 1000 | ±1% up to ±5% | −55 to 175 | SOD68 (DO-34) |

| KTY84-1 | 1000 (R100) | ±3% up to ±5% | −40 to 300 | SOD68 (DO-34) |

-

-

Key Characteristics of Linear Resistor and PTC Thermistor

Linear Resistor, particularly that from the KTY series, offers reliable performance with precise temperature measurement. This Linear Thermistor is glass-encapsulated and use semiconductor silicon single crystals, often referred to as Silicon PTC Thermistor.

Features of KTY84-130 Linear PTC Thermistor

- Material: The Linear Resistor KTY84-130 is made from silicon, offering high stability and reliability.

- Linear Resistance: As temperature rises, the resistance value increases linearly, earning it the name Linear PTC Thermistor.

- Accuracy: This Linear Thermistor offers high precision, with deviations as low as 1%,2%,3%,5%, meeting strict industrial standards.

- Dissipation Coefficient: Ranges between 2.5~5 mW/°C, ensuring efficient heat management.

- Operating Temperature: Depending on the model, the range typically spans from -55°C to +150°C, making it suitable for various applications.

- Encapsulation: Compact and robust designs (SOT-23, TO-92) ensure easy integration into different devices, capable of operating in high temperatures and humidity.

- Maximum Current: The maximum working current of Linear Resistor: Iopr=1.0mA.

- Stability: The annual drift rate of this PTC Thermistor is less than 0.01°C, ensuring long-term stability.

- Temperature Coefficient: With α25/50 ≥ 0.7%/°C, this equates to ≥7000 PPM, ensuring accurate temperature response.

- Rated Power of the Linear Thermistor: Typically 50 mW, suitable for various power requirements.

-

Working Principle of Linear Resistor PTC Thermistor

Linear Resistor thermistors, such as the KTY84-130, operate by increasing resistance as temperature rises. This change occurs in a straight line, ensuring a linear relationship between temperature and resistance. These Thermistors, including the KTY81-KTY84 series, maintain this linear resistance change within the temperature range of -40°C to 250°C.

Precision in Temperature Sensing

The Linear Thermistor design simplifies temperature sensing by eliminating the need for complex compensation circuits. With PTC Thermistor, the linearity of resistance makes them ideal for precise temperature monitoring in various industrial applications.

Selection Guide for Linear Resistor PTC Thermistors

When choosing a Linear Resistor, particularly the KTY84-130 PTC Thermistor, several factors must be considered to ensure optimal performance in your application.

Temperature Range

Select a Linear Thermistor with an operating range that covers the temperature extremes of your specific application. The KTY84-130 performs effectively across a wide range, from -40°C to 250°C.

Accuracy Requirements

Choose a PTC Thermistor that meets your accuracy needs. Linear Resistor typically offers tolerance levels of 1%, 2%, 3%, and 5%, making it suitable for precise temperature measurement.

Encapsulation Type

Consider the encapsulated size and type that best fits your mounting method and space requirements. Linear Thermistor like the KTY84-130 are available in compact, robust packages that ensure durability and ease of integration.

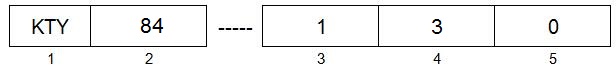

KTY Series Part Numbers

KTY Series Linear Resistor PTC Thermistor - Part Numbers and Specifications:

The KTY Series Linear Thermistor provides precise temperature sensing with a linear resistance-temperature relationship. Below are the part numbers and key specifications for the KTY series.

1.Series: KTY Series Linear PTC Thermistor

- 2.Types: KTY81, KTY82, KTY83, KTY84 (including KTY84-130)

3.Resistance (R25): 1-1KΩ, 2-2KΩ, for different application needs.

4.Tolerance Options: F (±1%), G (±2%), H (±3%), J (±5%)

- 5.Tolerance Limit: 0 (±Tolerance), 1 (-Tolerance), 2 (+Tolerance)

Specification & Part Numbers

Conclusion - Linear Resistor PTC Thermistor in Advanced Applications

The KTY Series Linear Resistor PTC Thermistor, including the KTY84-130, set the standard in temperature sensing. Their precision, reliability, and linear performance make them ideal for demanding applications in automotive, industrial automation, and consumer electronics.

This Linear Thermistor excels in environments requiring accurate temperature monitoring, making them the go-to solution for engineers seeking consistent and dependable performance.

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd