PTC Heaters: Efficient Heating with Ceramic Heating Elements

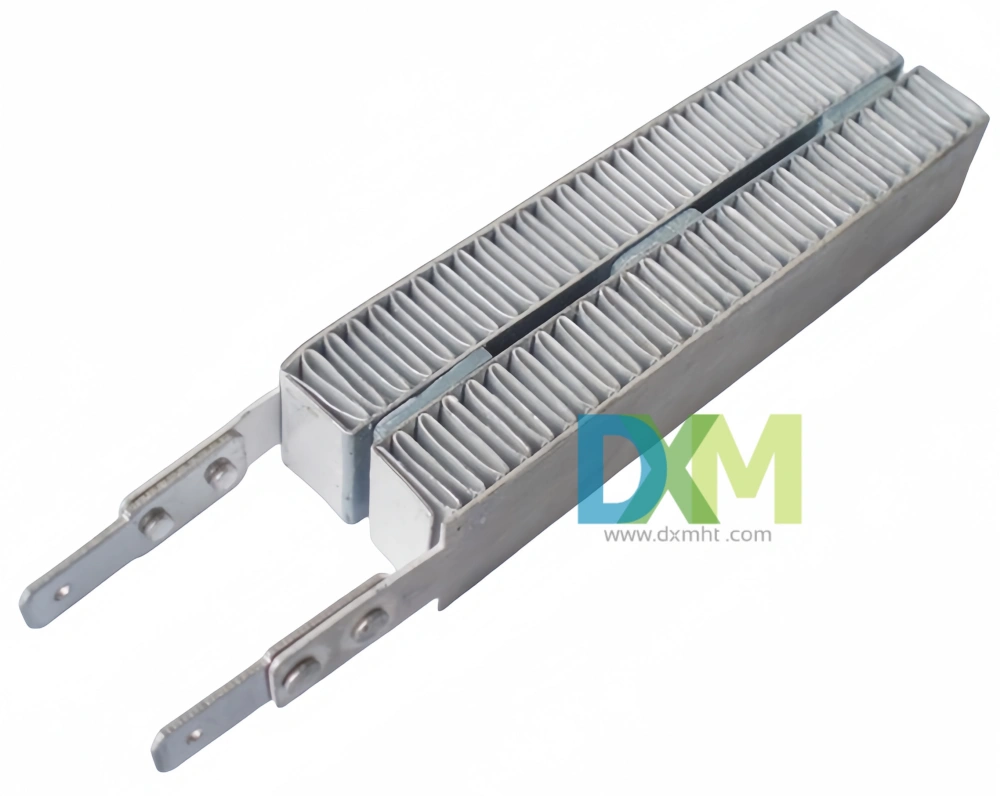

Introducing DXM's PTC Heaters: Experience efficient heating with advanced ceramic heating elements. Our resistance heaters ensure optimal performance and safety, perfect for various applications.

Why choose PTC heaters as Efficient Heating Solutions?

- Efficient Heating: Self-regulating Ceramic Heating Elements optimize energy use.

- Safety First:PTC resistance heater prevents overheating with automatic shut-off.

- Durability:Built from robust materials for long-lasting performance.

- Versatile Applications: Ideal for space heating, industrial use, and automotive systems.

- Customizable:Power, dimensions, and terminals can be tailored to specific needs.

- High Value, Competitive price: Delivers long-lasting performance at an Competitiveprice

Trust DXM for high-quality PTC heaters that deliver consistent warmth and energy efficiency. Discover the future of heating technology with DXM's innovative solutions today.

Optimized Overview of PTC Heaters

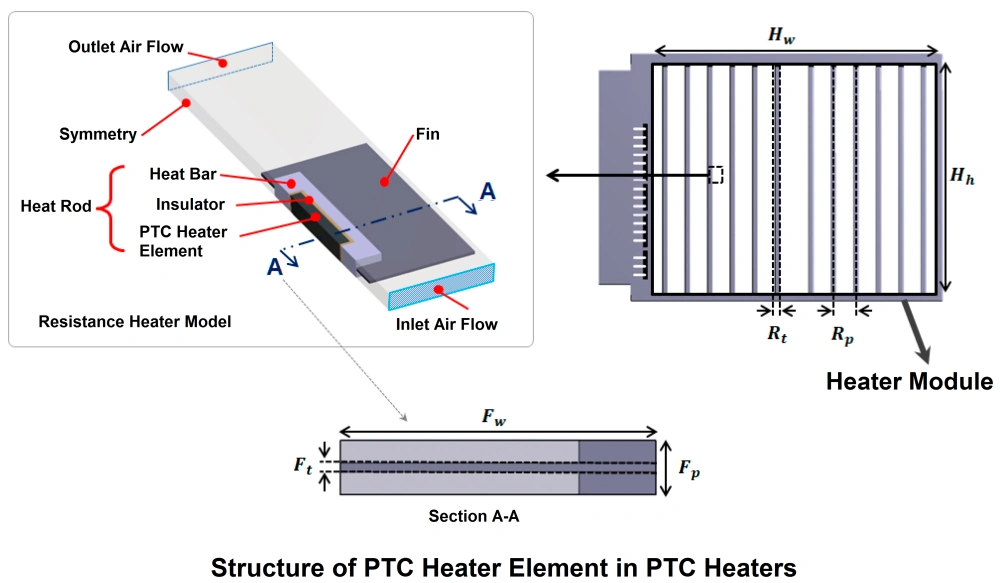

PTC heaters utilize ceramic heating elements for efficient, self-regulating performance. This PTC resistance heater evenly distributes heat and adapt to airflow changes. As the temperature increases, its resistance rises, ensuring safe, consistent operation. This self-regulation allows PTC heaters to maintain precise temperatures and conserve energy. Connections are secured through receptacle or welding, ensuring reliable functionality.

Below is an illustration of the internal structure of the resistance heater commonly used in these systems.

Key Advantages of PTC Heaters

-

Energy Efficiency

Ceramic Heating Elements optimize power usage in PTC Heaters. These elements consume more energy when cold and less as they reach target temperatures.

Safety

The self-regulating nature of resistance heater minimizes overheating risks. Many PTC Heaters feature automatic shut-off for added safety.

Durability

Ceramic Heating Elements, made from materials like barium titanate, ensure long-lasting and reliable performance.

Quick Heating

PTC Heater delivers rapid warmth, ideal for small to medium spaces. The automatic temperature control feature ensures consistent heating.

High Electric Conversion Efficiency

Resistance Heater in ceramic heating elements offer high electric conversion efficiency, complying with RoHS directives for environmental safety.

Customization and Versatility

Power, dimensions, and terminal connections of PTC heaters are customizable, fitting various designs and applications.

Automotive Applications

PTC Heater can preheat car engines in winter, preventing wear. Their efficiency is significantly higher than non-preheated winter starts.

Additional Benefits

- Stable and efficient performance with long life.

- Minimal effect from power supply voltage variations.

- Custom designs available to meet specific customer needs.

- DXM provides full technical support for resistance heater applications.

- Compliance with RoHS directive.

Considerations

- Limited Coverage: Ceramic Heating Elements are best for localized heating. Larger spaces may require multiple units.

- Noise: Fan-driven PTC resistance heater can produce noise, especially at higher speeds.

- Maintenance: Regular cleaning is needed to maintain performance and air quality.

Applications of PTC Heaters

- Space Heating: Ideal for personal and small room heating.

- Industrial Use: Suitable for drying, molding, and other controlled heating processes.

- Household Appliances: Common in devices like hair dryers and electric blankets.

PTC Heaters Features

PTC Heater, equipped with Ceramic Heating Elements, offer automated temperature control and energy efficiency. These ceramic heating elements are widely used in air-conditioners, dryers, and automotive heating systems. The design allows for efficient heat dissipation and continuous operation, with power adjustable based on wind speed.

How Ceramic Heating Elements Work in PTC Heaters

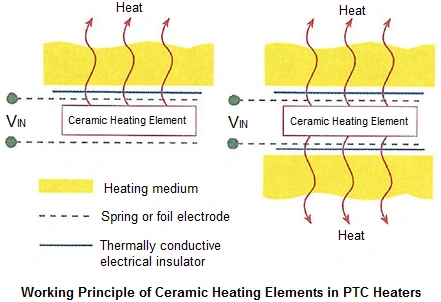

Current Flow through the Resistance Heater

When connecting with power,hot air blow generated by the high speed rotating motor fan resistance heater behind the PTC thermistor is out continuously,which will take away the surface heat of radiator to achieve the purpose of continuous heating air.The bending area of heat sink fins is very big for good heat dissipation and very high electric conversion efficiency.The design allows an automatic regulation of the heating power and temperature within certain ranges,and can work continuously.Due to its own PTC R-T characteristics,the heating power could be changed when the wind speed is changed.DXM is providing a wide range of designs.You can see working principle of the Resistance Heater in PTC Heater in picture as below:

Temperature Increase and Resistance Change

As the Resistance Heater heats up, its resistance increases sharply. This rise in resistance reduces current flow, thereby lowering heat output. This self-regulating feature prevents overheating.

Self-Regulating Mechanism

PTC Heater, with its Ceramic Heating Elements, operate without external thermostats. The Resistance Heater automatically adjusts heat output based on temperature, ensuring stable operation.

Heat Transfer and Air Heating

PTC ceramic heating elements are often in contact with aluminum fins, which help conduct heat. A fan blows air over these heated fins, warming the air and distributing it into the room.

Expert Technical Support for PTC Heaters Applications

PTC heaters leverage ceramic heating elements and resistance heaters for efficient, self-regulating heating. These components deliver even heat distribution and automatic temperature control. As resistance increases with rising temperature, PTC heaters ensure safe and consistent operation while reducing energy consumption. They are widely used in space heating, industrial processes, and automotive applications. Their customizable designs, high durability, and compliance with RoHS standards make them a reliable choice.

DXM provides specialized technical support for ceramic heating elements technology in PTC heaters. As a leading manufacturer of heating elements, DXM ensures seamless integration and optimal performance of PTC heaters systems across diverse industries.

© 2024 DXM Product. All rights reserved.

Author: Ivan Huang

Updated on 22th December 2024

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd