PT1000 RTD Sensors: Your Guide to Precision Temperature Measurement

Explore precision temperature measurement with DXM's PT1000 RTD Sensors. Designed for accuracy and reliability, our PT1000 sensors offer exceptional performance in diverse applications. Discover how DXM leads the way in RTD sensor technology, ensuring optimal results in temperature monitoring and measurement. Enhance your operations with trusted RTD sensors solutions. Learn more today!

- What Are RTD Sensors?

- Why PT1000 Sensors Are Preferred for Temperature Measurement

- Key Advantages of PT1000 Sensors

- Applications of PT1000 and RTD Sensors

- How Do PT1000 Sensors Work?

- PT1000 Sensor Calibration

- Why Choose PT1000 Sensors Over Other Temperature Sensors?

- How to Select the Right RTD Sensor for Your Application

- Optimizing RTD sensors for Industrial Use

- SEO Strategies for PT1000 Sensors

- Conclusion

- FAQs: Frequently Asked Questions about PT1000 and RTD Sensors

PT1000 and RTD sensors are vital for accurate temperature measurement in industrial and scientific fields. These sensors ensure optimal performance, quality control, and safety. PT1000 sensors, a type of RTD, are highly reliable and precise. They work based on the resistance change of materials with temperature, offering excellent accuracy in various applications. Industries such as aerospace, food processing, and medical equipment rely on PT1000 sensors for precise readings. Their robust design and accuracy make them a preferred choice for temperature monitoring. Understanding their advantages can improve efficiency and reliability in critical processes.

What Are RTD Sensors?

RTD (Resistance Temperature Detector) sensors are a type of temperature sensor that work by measuring the change in electrical resistance of a material as its temperature changes. These sensors use metals, typically platinum, that exhibit a predictable change in resistance as a function of temperature. This property makes RTD sensors incredibly accurate and stable across a wide range of temperatures. Among various RTD sensors, the PT1000 model stands out for its performance, offering exceptional accuracy and reliability.

Why PT1000 Sensors Are Preferred for Temperature Measurement

PT1000 sensors are a specific type of RTD sensor with a resistance of 1000 ohms at 0°C. This higher base resistance compared to the PT100 sensor (which has 100 ohms at 0°C) provides several advantages in terms of accuracy, sensitivity, and stability. The rtd sensors are ideal for environments where precise temperature control is essential, such as industrial automation, HVAC systems, medical devices, and more. Let’s dive deeper into why PT1000 sensors are preferred across various industries.

Key Advantages of PT1000 Sensors

- High Accuracy: PT1000 sensors provide superior accuracy over a wide temperature range, making them ideal for high-precision applications.

- Long-Term Stability: These sensors maintain consistent readings over time, reducing the need for frequent recalibration and ensuring reliable performance.

- Wide Temperature Range: RTD sensors are capable of measuring temperatures from as low as -200°C to as high as 850°C, making them suitable for both low and high-temperature environments.

- Durability: RTD sensors are designed to withstand harsh environmental conditions such as humidity, vibration, and corrosive elements.

- Easy Integration: Due to their standardized resistance characteristics, PT1000 sensors can be easily integrated into various control systems and industrial setups.

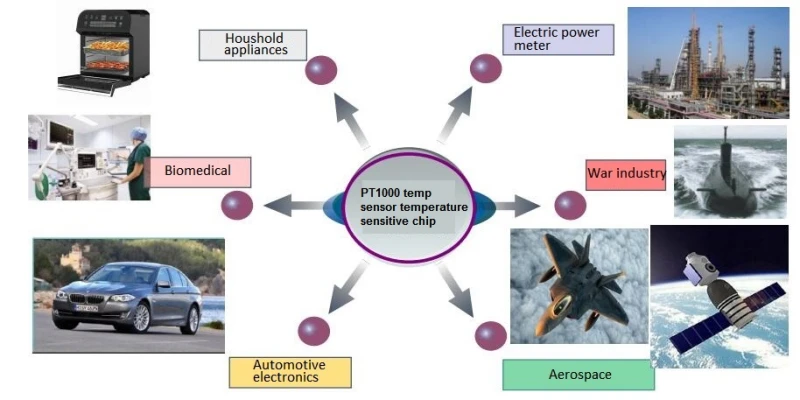

Applications of PT1000 and RTD Sensors

RTD sensors, particularly PT1000, are used across many industries that require precise temperature measurements. Below are some of the key sectors where RTD sensors are applied:

- Industrial Automation: In manufacturing and processing plants, RTD sensors monitor temperature in production lines, ensuring that machines and systems operate within the optimal temperature range.

- HVAC Systems: RTD sensors are integral to HVAC systems, helping maintain temperature control and energy efficiency in residential, commercial, and industrial buildings.

- Aerospace: Precision is crucial in the aerospace industry, where RTD sensors are used in engines and avionics to monitor and control the temperature of critical components.

- Food Processing: RTD sensors help maintain safe and consistent temperatures in food processing and storage, ensuring compliance with food safety regulations.

- Medical Equipment: PT1000 sensors are often found in medical devices such as incubators, sterilizers, and thermal imaging equipment, where precise temperature control is critical for patient safety.

-

How Do PT1000 Sensors Work?

The operation of PT1000 sensors is based on the principle of resistance temperature dependence. As the temperature of the platinum element changes, so does its electrical resistance. The relationship between resistance and temperature is nearly linear, which allows for accurate temperature readings. To measure temperature with a PT1000 sensor, an electronic circuit is used to measure the resistance and convert it into a corresponding temperature value using a calibration curve or a standard equation.

PT1000 Sensor Calibration

Calibration of PT1000 sensors is an essential step in ensuring accurate temperature measurements. Calibration is the process of comparing the sensor’s readings with a known reference temperature and adjusting the sensor’s output to match this reference. This ensures that the PT1000 sensor provides accurate readings throughout its temperature range. Calibration can be performed using precision temperature baths or dedicated calibration equipment designed for RTD sensors.

Why Choose PT1000 Sensors Over Other Temperature Sensors?

While there are many types of temperature sensors available on the market, PT1000 sensors offer distinct advantages. Here are some key reasons why RTD sensors are often the preferred choice:

- Higher Resistance: The 1000-ohm resistance at 0°C provides greater accuracy and a wider measurement range compared to other sensors like PT100.

- Better Stability: RTD sensors offer more stable readings over time, making them ideal for long-term applications where reliability is crucial.

- Higher Sensitivity: RTD sensors have improved sensitivity, which means they can detect smaller changes in temperature, leading to more precise measurements.

- Versatility: PT1000 sensors can be used in a wide variety of applications, from low-temperature measurements in cryogenics to high-temperature measurements in industrial furnaces.

How to Select the Right RTD Sensor for Your Application

When choosing an RTD sensor for your temperature measurement needs, several factors should be considered to ensure the best fit for your application:

- Temperature Range: Ensure that the sensor’s temperature range covers the operational temperatures required for your process.

- Accuracy Requirements: Different applications require different levels of accuracy. Choose a PT1000 sensor if high precision is necessary for your operations.

- Environmental Factors: Consider whether the sensor will be exposed to harsh environments such as moisture, vibration, or extreme temperatures. PT1000 sensors are highly durable and can withstand such conditions.

- Integration Needs: Ensure the sensor is compatible with your control and monitoring systems for easy integration.

Optimizing RTD sensors for Industrial Use

To get the most out of your PT1000 sensors, it's essential to integrate them correctly into your system and ensure they are well-calibrated. Additionally, considering factors like sensor placement, signal conditioning, and noise reduction can further enhance the performance of RTD sensors in industrial settings.

SEO Strategies for PT1000 Sensors

When marketing PT1000 sensors online, implementing effective SEO strategies can help increase visibility and drive traffic to your website. By focusing on high-quality, informative content that addresses the needs of your target audience, you can improve search engine rankings and attract more customers. Utilize relevant keywords such as “PT1000 sensors,” “RTD sensors,” and “temperature measurement,” ensuring that they are naturally integrated into your content.

Conclusion

PT1000 sensors offer exceptional accuracy, stability, and versatility for temperature measurement. Their precision and reliability make them ideal for critical applications across industries. From industrial processes to medical equipment, RTD sensors, particularly PT1000, ensure precise temperature control. By understanding the principles and benefits of these sensors, businesses can choose the best solution for their needs. As industries strive for higher efficiency, RTD sensor will continue to play a key role in achieving superior performance. Their ability to provide reliable data will remain vital in various fields.

FAQs: Frequently Asked Questions about PT1000 and RTD Sensors

The primary difference is the resistance at 0°C. PT100 sensors have a resistance of 100 ohms, while RTD sensors have 1000 ohms at 0°C. PT1000 sensors offer greater accuracy and higher resistance, making them ideal for applications requiring precision.

Calibration is done by comparing the sensor’s resistance at known temperatures with reference standards. This process ensures that the sensor gives accurate readings over its entire temperature range.

Yes, PT1000 sensors are highly durable and can be used in hazardous environments, provided they are equipped with the necessary protective enclosures or coatings to protect against corrosion, high humidity, or mechanical stress.

Recommended for you

Degausser and Degaussing TV Resistor: A Complete Guide

Temperature Probe: A Comprehensive Guide

Resistance Temperature Detector Price: A Comprehensive Guide

Electrical Components International: Top Electrical Component Manufacturer DXM

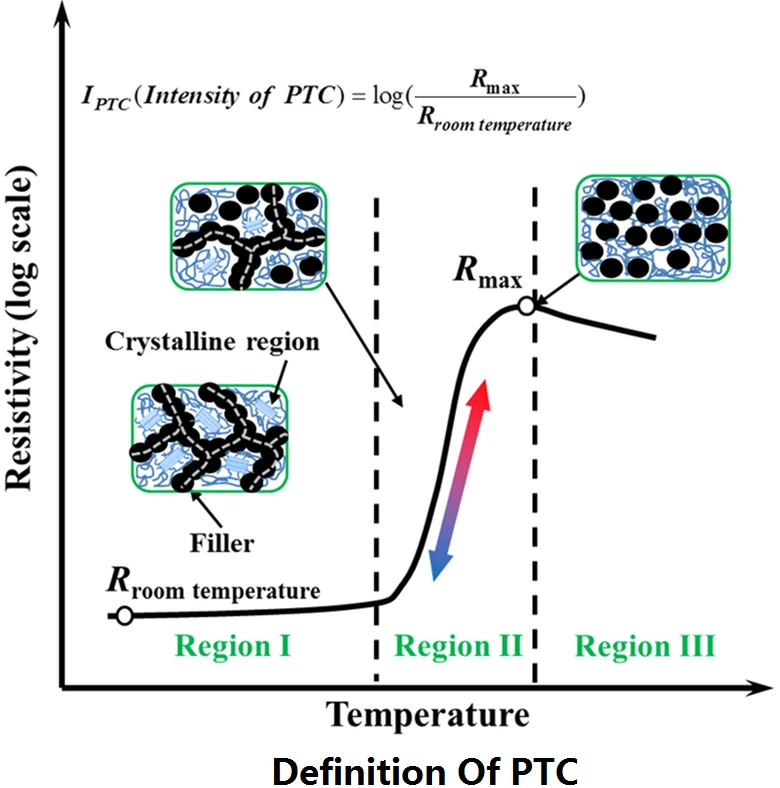

PTC Sensor: Understanding & Applications

Definition of PTC: Positive Temperature Coefficient Explained

Price and Payment

Price

The price will be quoted in US dollars.

1) For small order quantities and small packing, normally our quotation is based on the ex-works price. The cargo will be delivered by courier after being finished normally.

2) For bulk orders and large volumes, normally our quotation is based on the FOB price. Please inform us of your destination seaport and estimated quantity, and our representative will quote you the C&F or CIF price accordingly. If you feel our freight is higher than your expectation, you can recommend your shipping company to us. Our principal is looking for a shipping company with a good reputation that offers competitive freight costs and can deliver your cargo promptly.

Do you offer bulk purchase discounts?

Yes, we offer bulk purchase discounts; the specific discount rate depends on the order quantity and cooperation method.

Logistics

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

Can I change my shipping address?

Yes, you can contact our customer service team to modify the delivery address before order confirmation to ensure that the order can be accurately delivered to the address you specify.

Customized Services

Custom-made sample/order

SHENZHEN DXM TECHNOLOGY CO., LTD. are structured by high-tech talents from famous university

in China and accompanied with a batch of ceramic-sensitive components experts and technology

specialist, have powerful R&D and technology capabilities.DXM is one of a few manufacturers

master core production technology of ceramic-sensitive components in the world.

Samples and orders can be custom-made per customer’s requirements, as below:

1. Application environment of product

2. Required specifications or technical parameters

3. Reference sample

4. Reference drawing

You may also like

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd