Unlocking the Secrets of Negative Temperature Coefficient, NTC Thermistor

Explore the fascinating world of Negative Temperature Coefficient (NTC) Thermistors with DXM. Dive into their unique properties and applications that make them essential in temperature sensing and control. Discover how NTC Thermistors can transform your technological solutions by enhancing accuracy and performance. Unleash the potential of precise thermal management today.

- What is a Negative Temperature Coefficient (NTC) Thermistor?

- How Does a Negative Temperature Coefficient Thermistor Work?

- Applications of Negative Temperature Coefficient (NTC) Thermistor

- Benefits of Negative Temperature Coefficient Thermistor

- Key Considerations When Using Negative Temperature Coefficient Thermistors

- How to Choose the Right Negative Temperature Coefficient Thermistor

- Negative Temperature Coefficient Thermistors in Power Supply Systems

- NTC Thermistor in Battery Management Systems

- Negative Temperature Coefficient Thermistors in Automotive Applications

- Future Trends in NTC Thermistor Technology

- Conclusion

- Frequently Asked Questions (FAQs)

Negative Temperature Coefficient (NTC Thermistor) is a key component in modern electronics. It has a unique feature: its resistance decreases as the temperature rises. This property makes the NTC Thermistor ideal for applications like temperature sensing, overcurrent protection, and power regulation. In this guide, we will explore how Negative Temperature Coefficient thermistors work, their benefits, and their applications. Understanding these principles ensures their proper use in various electronic systems, making them invaluable for accurate temperature control and circuit protection.

What is a Negative Temperature Coefficient (NTC) Thermistor?

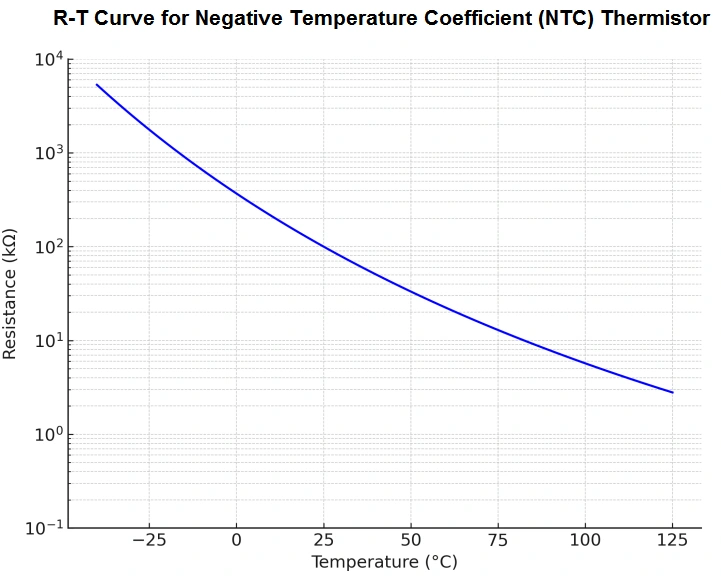

An NTC Thermistor is a thermistor with a unique property: its resistance decreases as the temperature increases. This phenomenon is called the Negative Temperature Coefficient. Because of this property, NTC Thermistors are ideal for precise temperature measurement and control. The relationship between resistance and temperature is non-linear. This characteristic ensures higher accuracy, making them suitable for both industrial and consumer applications.

How Does a Negative Temperature Coefficient Thermistor Work?

An NTC Thermistor is usually made from metal oxides or ceramics. As the temperature rises, the charge carriers within the thermistor gain energy. This allows them to move more freely, reducing the resistance. The resistance of an NTC Thermistor decreases exponentially as the temperature increases. This non-linear behavior makes NTC thermistors highly sensitive to even small temperature changes. Their ability to detect these small variations is why NTC Thermistor is widely used in applications that require precise temperature measurement.

Applications of Negative Temperature Coefficient (NTC) Thermistor

NTC Thermistors are used in various fields. Some of the most common applications include:

- Temperature Sensing: NTC Thermistor is integral to temperature sensor. You can find it in digital thermometers, medical devices, HVAC systems, and industrial machines. Their high sensitivity to temperature changes makes it ideal for precise temperature measurements.

- Overcurrent Protection: Negative Temperature Coefficient thermistors protect circuits from excessive current. When too much current flows, the thermistor heats up. This causes its resistance to drop, limiting the current and preventing damage to the circuit.

- Power Regulation: In power supply circuits, NTC Thermistor regulates the current flowing to sensitive components. It helps ensure stable performance by adjusting the current as needed, providing consistent power to devices.

- Battery Protection: NTC Thermistor is used in battery management systems to monitor battery temperature. It helps prevent overheating, thus extending the battery's lifespan and avoiding thermal runaway.

Benefits of Negative Temperature Coefficient Thermistor

Negative Temperature Coefficient Thermistor offers several benefits, making it ideal for many applications:

- High Sensitivity: NTC Thermistor is highly sensitive to temperature changes. Even small variations in temperature cause significant changes in resistance. This sensitivity makes it perfect for precision applications, like medical devices and industrial machines.

- Cost-Effective: NTC thermistors are affordable compared to other temperature sensors. This makes them a cost-effective solution for consumer electronics, industrial, and automotive applications.

- Compact Size: NTC Thermistor comes in small sizes, making it suitable for devices with limited space. It easily fits into small form factors without compromising performance.

- Quick Response Time: NTC Thermistors respond rapidly to temperature changes. This quick response makes them ideal for real-time temperature sensing and control applications.

Key Considerations When Using Negative Temperature Coefficient Thermistors

While Negative Temperature Coefficien thermistors provide many advantages, there are several key factors to consider:

- Nonlinear Resistance-Temperature Relationship: The relationship between resistance and temperature in an NTC thermistor is nonlinear. This non-linearity can make it difficult to predict the thermistor’s behavior without proper calibration. However, engineers can compensate for this behavior using appropriate mathematical models, such as the Steinhart-Hart equation.

- Temperature Range: Negative Temperature Coefficient thermistors have a limited temperature range. It's essential to select a thermistor that can operate within the required temperature range for your specific application. If the thermistor is exposed to temperatures beyond its rated range, it may fail or provide inaccurate readings.

- Self-Heating: When a high current is applied to an NTC thermistor, it can heat up. This self-heating effect can affect the thermistor’s resistance and result in inaccurate readings. To mitigate this, proper circuit design and thermal management are necessary.

How to Choose the Right Negative Temperature Coefficient Thermistor

Choosing the right NTC thermistor involves considering a few key factors:

- Resistance Value: The resistance of the thermistor at a reference temperature, usually 25°C, is an important parameter. Ensure that the resistance value matches the needs of your application to ensure accurate temperature readings.

- Beta Value: The beta value defines the thermistor’s sensitivity to temperature changes. A higher beta value means the thermistor is more sensitive to temperature changes but may have a narrower operational range. Choose a thermistor with the appropriate beta value for your needs.

- Thermal Time Constant: The thermal time constant describes how quickly the thermistor responds to temperature changes. For applications requiring fast response times, such as power supplies or battery management systems, a lower thermal time constant is ideal.

Negative Temperature Coefficient Thermistors in Power Supply Systems

NTC thermistors are widely used to limit inrush currents in power supply systems. When an electronic device is powered on, the initial current can be very high, which could damage sensitive components. NTC thermistors limit the inrush current by initially providing high resistance. As the thermistor heats up, its resistance decreases, allowing normal current to flow and ensuring safe operation.

NTC Thermistor in Battery Management Systems

In battery management systems, NTC thermistors monitor the temperature of batteries during charging and discharging. By preventing the battery from overheating, these thermistors help protect the battery from damage, ensuring longer life and preventing thermal runaway.

Negative Temperature Coefficient Thermistors in Automotive Applications

Negative Temperature Coefficient thermistors are also used in automotive systems to monitor the temperature of the engine, battery, and air intake. The temperature data is used by the vehicle’s control system to optimize engine performance, protect critical components, and enhance overall safety.

Future Trends in NTC Thermistor Technology

As technology advances, the demand for high-performance temperature sensors is growing. Negative Temperature Coefficient thermistors are evolving to meet this demand, with new materials and designs that improve sensitivity, expand temperature ranges, and offer faster response times. The rise of technologies like the Internet of Things (IoT) and electric vehicles will drive continued innovation in NTC thermistor technology.

Conclusion

Negative Temperature Coefficient (NTC) thermistors are crucial components in modern electronics. Their ability to change resistance with temperature makes them ideal for temperature sensing, overcurrent protection, and power regulation. By understanding how they work and selecting the right NTC thermistor for your application, you can ensure that your systems perform efficiently and reliably.

Frequently Asked Questions (FAQs)

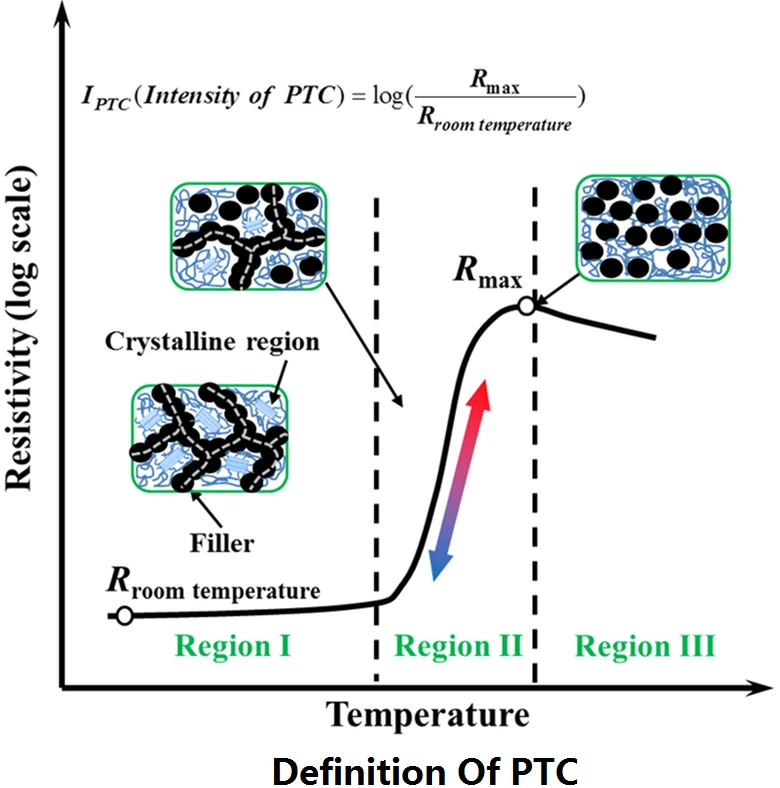

1. What is the difference between NTC and PTC thermistors?

Negative Temperature Coefficient thermistors have a resistance that decreases as the temperature increases, while PTC thermistors have a resistance that increases as the temperature rises.

2. Can Negative Temperature Coefficient thermistors be used for precise temperature control?

Yes, Negative Temperature Coefficient thermistors are widely used for precise temperature sensing in applications such as medical devices, HVAC systems, and battery management systems.

3. What are some common uses of NTC thermistors?

NTC thermistors are used in a variety of devices, including household appliances, automotive systems, power supplies, and temperature sensors for industrial applications.

Learn More About Negative Temperature Coefficient Thermistors

© 2024 DXM Blog. All rights reserved.

Author: Ivan Huang

Recommended for you

Degausser and Degaussing TV Resistor: A Complete Guide

Temperature Probe: A Comprehensive Guide

Resistance Temperature Detector Price: A Comprehensive Guide

Electrical Components International: Top Electrical Component Manufacturer DXM

PTC Sensor: Understanding & Applications

Definition of PTC: Positive Temperature Coefficient Explained

Logistics

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

Does it support express delivery?

Yes, we support express delivery services. You can choose different delivery methods according to your needs, including ordinary express delivery and expedited express delivery.

Does your product support global logistics and distribution?

Yes, our products support global logistics and distribution services, and you can receive our products anytime and anywhere.

Price and Payment

How are the prices of your products determined?

Our product prices are based on a variety of factors, including order quantity, customization requirements, and market competition.

Are invoices provided?

Yes, we provide legal invoices that can be used for reimbursement and accounting records.

You may also like

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd