Temperature Coefficient Calculation for NTC Thermistors

Discover the essentials of Temperature Coefficient Calculation for NTC Thermistors with DXM. Our comprehensive guide dives into the pivotal role temperature coefficients play in thermistor performance, crucial for electronics and measurement precision. Learn how to enhance design efficiencies using our expert insights. DXM stands as a leader in the field, offering invaluable knowledge and solutions. Elevate your understanding and application of NTC thermistors today. Stay ahead with DXM for innovative, reliable temperature sensing technologies.

- What is a Temperature Coefficient?

- How to Calculate the Temperature Coefficient of an NTC Thermistor

- Formula for Calculating Temperature Coefficients

- Step-by-Step Temperature Coefficient Calculation Example

- Significance of Temperature Coefficient in Practical Applications

- Impact on Accuracy and Tolerance

- Real-World Use Cases of NTC Thermistors

- FAQs: Frequently Asked Questions

- Q: What is the main function of an NTC thermistor?

- Q: How does temperature coefficient affect a thermistor's performance?

- Q: Where are NTC thermistors commonly used?

- Conclusion: Why Calculating Temperature Coefficient is Crucial for NTC Thermistors

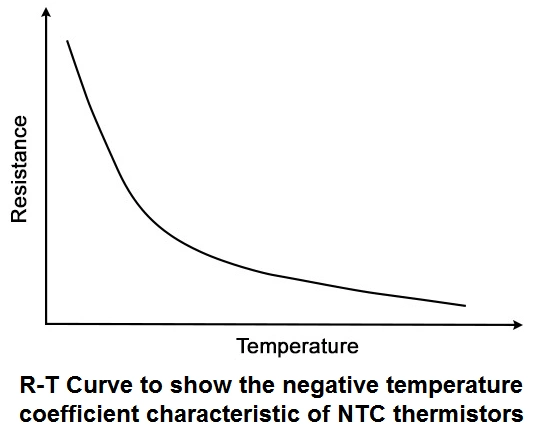

The Temperature Coefficient is crucial in NTC Thermistors, where resistance drops as temperature rises. Accurate calculation of temperature coefficients is essential for dependable thermistor performance in HVAC, automotive, and medical applications.

NTC Thermistors provide stable, precise temperature readings, making them ideal for systems that demand reliability and quick response. Control over the Temperature Coefficient enhances performance and ensures reliability across critical applications.

What is a Temperature Coefficient?

The Temperature Coefficient is a parameter that indicates how the resistance of an NTC thermistor changes in response to a change in temperature. It is typically measured in %/°C and allows engineers to calculate the corresponding resistance change under different temperatures, which is vital in applications requiring precise temperature monitoring.

How to Calculate the Temperature Coefficient of an NTC Thermistor

Formula for Calculating Temperature Coefficients

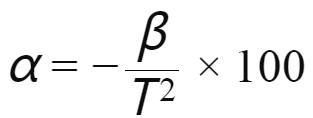

The Temperature Coefficient (α) of an NTC Thermistor is calculated using this formula:

Where:

- α (Temperature Coefficient): This is the value that represents the rate at which the thermistor’s resistance changes with temperature. It gives a negative result, as the resistance decreases with increasing temperature in NTC thermistors.

- β (Beta Constant): The β constant (Beta value) is a characteristic of NTC thermistors and relates the resistance of the thermistor to the temperature. The β value is typically provided by the manufacturer and describes how much the resistance decreases as the temperature rises. It is given in units of Kelvin (K).

- T² (Temperature in Kelvin squared): T is the temperature in Kelvin (K), which is the absolute temperature scale. In this formula, the temperature is squared.If the temperature is originally given in Celsius, you need to convert it to Kelvin by adding 273.15 to the Celsius temperature (i.e., T (K) = T (°C) + 273.15).

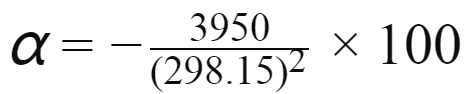

Step-by-Step Temperature Coefficient Calculation Example

Let’s say you are working at a temperature T of 298.15 K (25°C), and the β value is 3950 K, which is typical for many NTC thermistors. Plugging these values into the formula:

You would get a negative value for α, representing the percentage drop in resistance per degree rise in temperature, a key characteristic of NTC thermistors.

This formula is particularly useful when you need to calculate the rate of resistance change in thermistors for specific temperatures and then use that to adjust or design temperature-sensitive circuits.

To quickly calculate alpha values, try our Alpha Calculator for precise temperature coefficient results.

Significance of Temperature Coefficient in Practical Applications

Impact on Accuracy and Tolerance

Temperature Coefficients directly affect the accuracy of temperature readings in NTC Thermistors. In precision-critical systems, like medical and automotive applications, understanding temperature coefficient helps maintain measurement accuracy by compensating for resistance variations.

Real-World Use Cases of NTC Thermistors

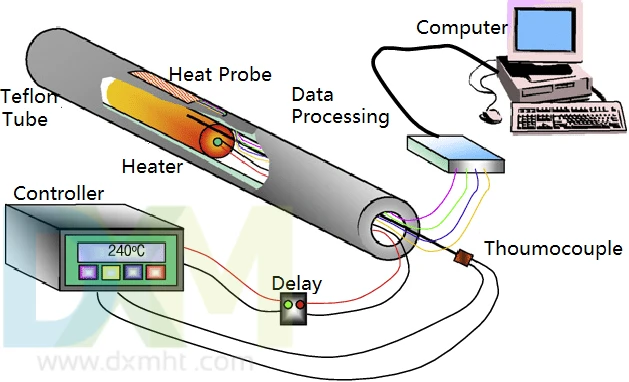

NTC Thermistors play a key role in HVAC systems, efficiently regulating heating and cooling. In automotive applications, they monitor coolant and air intake temperatures, optimizing engine performance. For medical devices, such as incubators, NTC Thermistor ensures temperature stability within a narrow range, enhancing safety and comfort.

FAQs: Frequently Asked Questions

Q: What is the main function of an NTC thermistor?

A: An NTC thermistor is used to measure and control temperature by decreasing its resistance as the temperature rises.

Q: How does temperature coefficient affect a thermistor's performance?

A: The temperature coefficients help determine how much the resistance will change with temperature, affecting the accuracy and responsiveness of the thermistor in temperature measurement systems.

Q: Where are NTC thermistors commonly used?

A: They are commonly used in HVAC systems, automotive temperature monitoring, and medical devices that require precise temperature control.

Conclusion: Why Calculating Temperature Coefficient is Crucial for NTC Thermistors

Understanding the Temperature Coefficient is vital for using NTC Thermistors in temperature-sensitive circuits. Calculating temperature coefficients accurately ensures precise measurements, essential for applications requiring high stability and control.

As technology advances, NTC Thermistors continue to be indispensable in fields needing precise temperature regulation, such as automotive, medical, and HVAC. A well-calculated Temperature Coefficient optimizes thermistor performance, providing reliability across critical applications.For guidance on selecting the right thermistor, refer to our Comprehensive Thermistors Guide to make informed, effective choices.

© 2024 DXM Blog. All rights reserved.

Author: Ivan Huang

Recommended for you

Probe For Temperature: The Ultimate Guide to Choosing and Using in Industrial Applications

Heat Probe & Heat Sensing: A Complete Guide

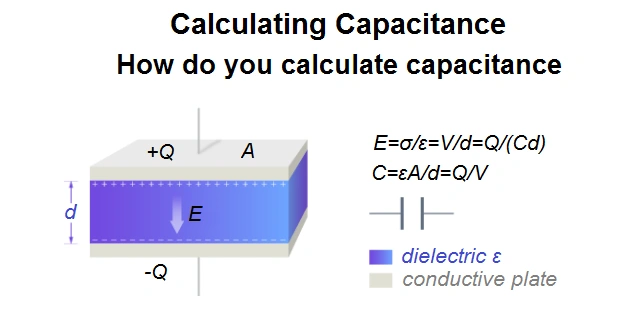

Mastering Calculating Capacitance | A Complete Guide

Capacitor Ceramico 103: The Ultimate Guide to Ceramic Disc Capacitors

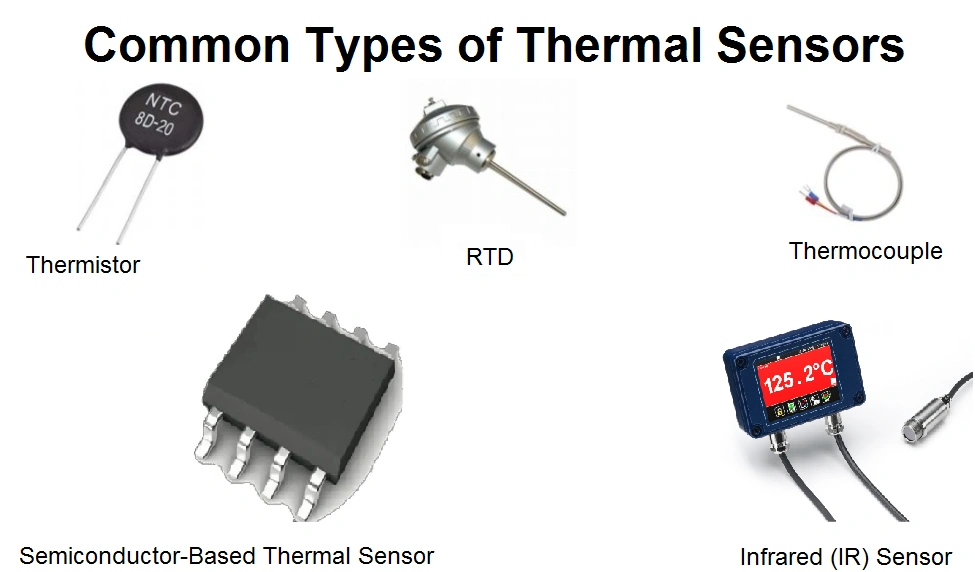

Understanding Sensor Thermal: Your Guide to Thermal Heat Sensors

Advanced Thermal Sensors: Precision and Reliability for Every Industry

Price and Payment

What’s the Minimum Order Quantity (MOQ) and Minimum Order Amount (MOA)

MOQ: 10000PCS

How are the prices of your products determined?

Our product prices are based on a variety of factors, including order quantity, customization requirements, and market competition.

Payment Terms

There are a number of different payment methods that can be used when you deal with us. Two are mostly used: T/T payment in advance for small values and irrevocable L/C at sight for large values.

Customized Services

Free sample availability

You can contact our representative via email, fax or phone to specify the sample you need and provide your courier's account number (such as UPS, FedEx, DHL, TNT, etc.).. And we’ll send you samples free of charge through your courier by freight collection.

Custom-made sample/order

SHENZHEN DXM TECHNOLOGY CO., LTD. are structured by high-tech talents from famous university

in China and accompanied with a batch of ceramic-sensitive components experts and technology

specialist, have powerful R&D and technology capabilities.DXM is one of a few manufacturers

master core production technology of ceramic-sensitive components in the world.

Samples and orders can be custom-made per customer’s requirements, as below:

1. Application environment of product

2. Required specifications or technical parameters

3. Reference sample

4. Reference drawing

You may also like

KTY83-110 Sensor with Silicon Glass Thermistor

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

Thermistor PTC MZ11 Series for Light Efficient Design

PTC Thermistors for Ballast Electronic and Energy Saving Lighting Intelligent Preheat Start MZ12 | DXM

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd