Inrush Current Calculation with NTC Thermistors: Reliable Inrush Current Calculator

Discover how DXM’s reliable Inrush Current Calculator simplifies inrush current calculation using NTC Thermistors. Inrush current, often seen as an electrical surge when devices power on, can challenge equipment durability. DXM’s advanced calculator ensures easy and accurate calculations, promoting device longevity and efficiency. Our focus on incorporating NTC Thermistors helps manage and mitigate these surges, offering a dependable solution for your electrical systems. Trust DXM for precision and reliability in inrush current management.

- 1. Accurate Inrush Current Calculation to Calculate Minimum Resistance

- Formula for Minimum Resistance in Inrush Current Calculation

- Calculation Explanation:

- Practical Example:

- Minimum Resistance Calculator

- 2. Optimize Inrush Current Calculation to Calculate Steady State Current

- Formula for Steady State Current Calculator

- Calculation Explanation:

- Practical Example:

- Steady State Current Calculator

- 3. Inrush Current Calculation to Calculate Joule-Capacitive

- Basic Formula for Joule Calculator:

- Calculation Explanation:

- Practical Example:

- Joule Calculator-Capacitive

- 4. Inrush Current Calculation: Prevent Circuit Breaker Trips

- Understanding Inrush Current and Prevention

- NTC Thermistors for Inrush Current Control

- Sample Problem and Solution

- Current issue:

- Solution:

- 5. Inrush Current Calculation: Choosing the Right NTC Thermistors

- How can I Use Inrush Current Calculation to Choose the Right NTC Thermistors?

- Key Benefits of Accurate Inrush Current Calculation

- 6. Inrush Current Calculation Without Capacitors

- How to Find Total Energy Requirements

- Key Assumptions

- Energy Calculation Formula

- 7. Importance of Inrush Current Calculation for System Safety and Longevity

- 8. Using NTC Thermistors for Effective Inrush Current Calculation and Management

- 9. FAQs on Inrush Current Calculation and Circuit Design

- What is Inrush Current, and Why is Controlling It Important?

- How to Calculate Minimum Resistance for Inrush Current?

- What Role Does Efficiency Play in Steady State Current Calculation?

- Can NTC Thermistors Be Used to Control Inrush Current?

- 10. Summary: Optimize Inrush Current Calculation for NTC Thermistors

Our Inrush Current Calculator for NTC Thermistors ensures accurate inrush current calculation, calculating Minimum Resistance, Steady State Current, and Storage Energy for stable power flow.These tools provide reliable, industry-standard results, helping engineers streamline workflows, prevent equipment damage, and boost performance across applications.

Effective inrush current calculation manages surges during startup, protecting equipment. Calculate minimum resistance, steady state current, and joule-capacitive energy for optimal NTC Thermistor selection.This article shows you three-step inrush current calculation for optimal power protection.

1. Accurate Inrush Current Calculation to Calculate Minimum Resistance

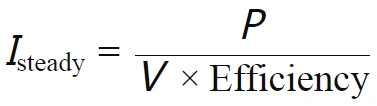

Our Minimum Resistance Calculator is essential for precise inrush current calculation in NTC Thermistors. Enter your Peak Voltage (Vpeak) and Maximum Allowable Inrush Current (A) to quickly determine the minimum resistance needed for safe operation.

This calculator, combined with our Inrush Current Calculator, helps manage current surges, protect equipment, and ensure reliable performance across applications.

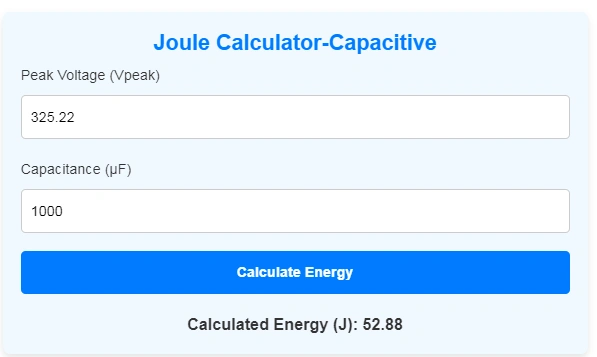

Formula for Minimum Resistance in Inrush Current Calculation

The Minimum Resistance Calculator is a critical tool for precise inrush current calculation, designed to protect electrical components in NTC Thermistors applications. By calculating the minimum resistance, engineers can effectively limit inrush current, preventing potential component damage from sudden surges and ensuring safe power-up.

The formula for calculating minimum resistance is:

- Explanation of Terms:

- Rmin: Minimum resistance (in ohms, Ω), required to control inrush current.

- Vpeak: Peak voltage, derived from Rated Voltage VAC × √2(1.414), representing the maximum voltage in the system.

- Iinrush: Maximum allowable inrush current (in amperes, A).

Accurate inrush current calculation, using this formula within our Inrush Current Calculator, enable engineers to protect components effectively, supporting reliable performance and extending the lifespan of electronic systems.

Calculation Explanation:

This formula calculates the minimum resistance needed to control inrush current effectively, based on peak voltage and maximum allowable inrush current of NTC Thermistors.

Practical Example:

For a Rated Voltage VAC

peak voltage of 325.22 V ,

For example,for a Rated Voltage VAC = 230 V, then peak voltage=230 x 1.414=325.22 V, and maximum inrush current of 20 A, the minimum resistance can be calculated as:

Rmin= 325.22 / 20 = 16.26 ohms.

Minimum Resistance Calculator

2. Optimize Inrush Current Calculation to Calculate Steady State Current

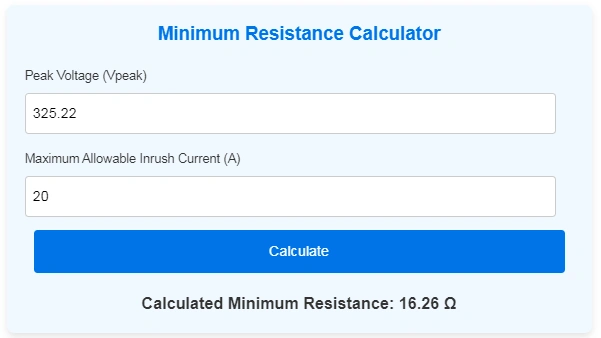

Our inrush current calculation also functions as a precise Steady State Current Calculator, providing essential insights into both startup and continuous current requirements for NTC Thermistors. By managing both inrush and steady state currents, this tool enhances safety, optimizes performance, and simplifies power system design.

Formula for Steady State Current Calculator

For steady state current calculation, input the output power, input voltage, and efficiency percentage (as a decimal) to instantly receive results. This calculation helps ensure that circuits can handle continuous operation without risking overheating or overload.

The formula for calculating steady state current is:

Where:

- Isteady: Steady state current (in amperes, A)

- P: Power rating of the device (in watts, W)

- Vac: Input voltage across the device (in volts, V)

- Efficiency: Efficiency factor, typically expressed as a decimal (e.g., 0.85 for 85%)

For accurate inrush current calculation, input output power, input voltage, and efficiency in the Steady State Current Calculator. This ensures circuits operate smoothly, preventing overheating or overload.

Calculation Explanation:

The formula calculates steady state current by dividing output power by the product of input voltage and efficiency, enabling optimal circuit operation.

Practical Example:

For example, for a device with 1000 W output power, 230 V Input voltage, and 0.9 efficiency, the steady state current can be calculated as:

Isteady= 1000/ (230 x 0.9) = 4.83 A

Steady State Current Calculator

3. Inrush Current Calculation to Calculate Joule-Capacitive

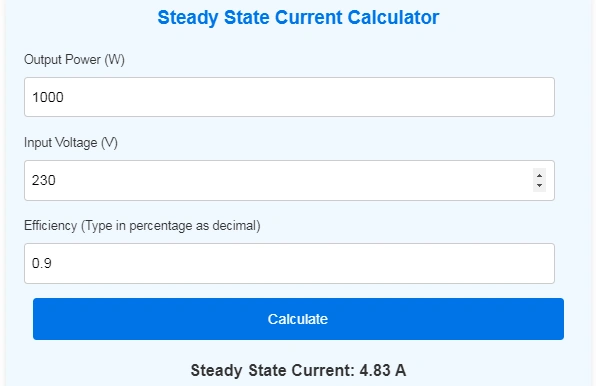

Our Joule Calculator simplifies inrush current calculation for NTC Thermistors. Accurately determine energy storage, ensuring system protection and optimal performance.To calculate the energy when peak voltage and capacitance values are known, the following formula can be used:

Basic Formula for Joule Calculator:

E = (1/2) * C * Vpeak²

Where

- E: Energy stored (in Joules, J)

- C: Capacitance (in Farads, F)

- Vpeak: Peak voltage applied across the capacitor (in Volts, V)

Calculation Explanation:

This formula calculates the energy stored in the capacitor, which is proportional to both capacitance and the square of the applied voltage. This relationship exists because, during charging, energy is required to move charges across the capacitor plates.

Practical Example:

For example, if the capacitance is 1000 µF (1000 x 10⁻⁶ F) and the peak voltage is 325.22 V, the stored energy can be calculated as:

E = (1/2) * (1000 x 10⁻⁶) * (325.22)² = 52.88 J

Thus, the stored energy is 52880 millijoules (mJ).

Using this formula, you can easily calculate the energy storage of NTC Thermistors or other filter capacitors based on known peak voltage and capacitance values. This is essential for effective inrush current calculation to know the storage energy, ensuring component protection and system stability.

Enter peak voltage, capacitance and press the "Calculate" button to calculate energy.Total energy will display once all fields are filled the "Calculate" button is pressed.Joule Calculator-Capacitive

4. Inrush Current Calculation: Prevent Circuit Breaker Trips

Use our inrush current calculation to select proper NTC Thermistors and avoid tripping circuit breakers. The Inrush Current Calculator determines key parameters such as peak voltage, resistance, and efficiency. These tools, including the Minimum Resistance Calculator, Steady State Current Calculator, and joule calculator support precise design choices to limit inrush current effectively.

Understanding Inrush Current and Prevention

The inrush current calculation aims to estimate the initial surge that occurs when turning on electrical equipment. This sudden current can damage circuits or lead to tripping of breakers. Calculators like the Inrush Current Calculator and Minimum Resistance Calculator help in predicting these values.

NTC Thermistors for Inrush Current Control

NTC Thermistors are a common solution to reduce inrush current. By adding an NTC Thermistor to your circuit, you can limit the high surge current, making it less likely for the breaker to trip.

Sample Problem and Solution

Current issue:

High inrush current trips a 20-amp circuit breaker on a 1000W power supply.

Given a 230 VAC input voltage,

- the peak voltage is:

- Peak Voltage: 230 VAC * 1.414 = 325.22V.

- And 1000W output power rating,

- Filter Capacitance: 1000µF

- Efficiency: 90%

Solution:

To reduce inrush, add an NTC Thermistor inrush current limitter to your circuit and ensuring safe operation. This approach effectively limits high inrush current and prevents the circuit breaker from tripping.

High inrush current can cause circuit breakers to trip unexpectedly. Inrush current calculation helps to determine the right methods to mitigate this issue. Using NTC Thermistors is an effective way to limit the inrush current during power-up. In this guide, we explore different Inrush Current Calculator tools like the Minimum Resistance Calculator, Steady State Current Calculator, and joule calculator to manage current surges effectively.

5. Inrush Current Calculation: Choosing the Right NTC Thermistors

Our inrush current calculation simplifies calculating both minimum resistance, steady state current and energy in circuits of NTC Thermistors. Just enter key parameters like peak voltage, power rating, and efficiency. The calculators provides precise values to support safe, efficient circuit designs, helping you make well-informed decisions quickly.

How can I Use Inrush Current Calculation to Choose the Right NTC Thermistors?

Input key parameters such as peak voltage, power rating, and efficiency. The Inrush Current Calculator then provides precise results, ensuring your circuit is optimized for safe and efficient operation. Using tools like the Minimum Resistance Calculator, Steady State Current Calculator and joule calculator makes the process smooth.Inrush current calculation details are as below:

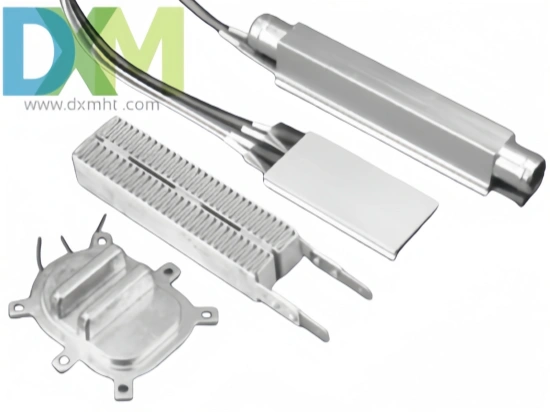

Based inrush current calculation results shown as above,the inrush current limiter NTC Thermistor MF72-20D22 is recommended:

. 20 ohms

. 7 amps Max Steady State Current

Key Benefits of Accurate Inrush Current Calculation

Accurate inrush current calculations are essential to protect your components from surges and maintain optimal performance. Save time and enhance safety by using our calculator to manage critical inrush current requirements in your designs.

Using our Inrush Current Calculator tools provides confidence in selecting the right NTC Thermistors and preventing excessive inrush. Accurate calculations are key to enhancing circuit reliability and efficiency.

6. Inrush Current Calculation Without Capacitors

Use our inrush current calculation guide to determine energy requirements for selecting surge limiters. Our Inrush Current Calculator is crucial for scenarios where capacitors or scope traces are unavailable. It provides reliable calculations, using tools like NTC Thermistors, Minimum Resistance Calculator, and Steady State Current Calculator.

How to Find Total Energy Requirements

Without capacitors, energy estimates are essential for selecting the right inrush current limiter. Below are key assumptions to make accurate calculations.

Key Assumptions

- If the filter capacitor is unavailable, assume inrush lasts one cycle (60 Hz = 0.0167 seconds).

- If the scope trace is unavailable, estimate inrush current as 30 times the steady state current.

Energy Calculation Formula

The formula to calculate energy in this scenario:

Energy = 30 × Steady State Current × 0.0167 × Input Voltage

Use this inrush current calculation to prevent damage and ensure optimal system stability.

7. Importance of Inrush Current Calculation for System Safety and Longevity

Effective inrush current calculation is essential for protecting electronic devices and extending their lifespan. High inrush currents can damage components, shorten the life of power supplies, and cause circuit breakers to trip. By accurately calculating minimum resistance and steady state current, engineers can design circuits that safely manage initial high currents, ensuring stable long-term operation.

Proper inrush current management minimizes the risk of overloads, crucial for both consumer electronics and industrial systems where initial current surges are common. With precise inrush current calculations, NTC Thermistors and other components are protected from sudden spikes, supporting improved performance and durability across applications.

8. Using NTC Thermistors for Effective Inrush Current Calculation and Management

NTC thermistors are a practical solution for managing inrush current. These components initially provide high resistance, which gradually decreases as they heat up, effectively limiting inrush current during power-up. This approach is ideal for applications with significant inrush current calculations, such as transformers, motors, and power supplies, where controlling initial surges is essential for protecting components and ensuring reliable operation.

9. FAQs on Inrush Current Calculation and Circuit Design

What is Inrush Current, and Why is Controlling It Important?

Inrush current is the initial surge of current that occurs when a device is powered on. Managing this surge is crucial to prevent damage to electronic components and ensure smooth, reliable operation. Using an effective Inrush Current Calculator is key to achieving safe, stable circuit performance.

How to Calculate Minimum Resistance for Inrush Current?

The minimum resistance required to limit inrush current can be calculated with the formula This formula helps set inrush current to safe levels. Using an accurate inrush current calculation ensures effective circuit protection and reliability.

What Role Does Efficiency Play in Steady State Current Calculation?

Efficiency impacts how effectively power is converted in a circuit, directly influencing steady state current. Higher efficiency results in a lower current for a given power output. Including efficiency in inrush current calculations is essential for reliable and optimal circuit design.

Can NTC Thermistors Be Used to Control Inrush Current?

Yes, NTC Thermistors are commonly used to limit inrush current. They offer high initial resistance, which decreases as they warm up, effectively reducing inrush current during power-up. This approach is widely used to protect circuits from sudden current surges.

10. Summary: Optimize Inrush Current Calculation for NTC Thermistors

Our advanced tool for inrush current calculation helps control surges efficiently. Use our Inrush Current Calculator for precise measurements and system safety. This calculator integrates features like the Minimum Resistance Calculator, Steady State Current Calculator and Joule Calculator for complete support.

Input key parameters like rated voltage, peak voltage, and inrush limits. The Inrush Current Calculator delivers accurate data, crucial for safe power performance. Effective inrush management with NTC Thermistors prevents startup damage and enhances operational stability.

Designed to industry standards, this tool ensures reliability. Accurate inrush current calculation strengthens power systems and maintains efficient circuits.

2024 DXM Blog. All rights reserved.

Author: Ivan Huang

Recommended for you

10k PTC Thermistors: Enhancing Efficiency & Reliability

The Complete Guide to Ceramic Heater and Heating Element

104 Capacitor: Mastering the Features, Applications, and Advantages

Heater Sensors: Pioneering Intelligent Thermal Management Technologies

Essential Guide to AC Capacitors

PT1000 RTD Sensors: Your Guide to Precision Temperature Measurement

Logistics

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

Does your product support global logistics and distribution?

Yes, our products support global logistics and distribution services, and you can receive our products anytime and anywhere.

Is your logistics and distribution service reliable?

Yes, we cooperate with a number of well-known logistics companies to ensure the timeliness and reliability of logistics and distribution services and provide you with a satisfactory distribution experience.

Does it support express delivery?

Yes, we support express delivery services. You can choose different delivery methods according to your needs, including ordinary express delivery and expedited express delivery.

Price and Payment

Do you offer bulk purchase discounts?

Yes, we offer bulk purchase discounts; the specific discount rate depends on the order quantity and cooperation method.

You may also like

Bracket Type NTC Thermal Sensor MF52X for Precise Temperature Measurement

Glass Thermistors MF58E for High-Precision Applications

KTY83-110 Sensor with Silicon Glass Thermistor

High Precise NTC Sensors for Temperature Measurement and Control

WMZ12A 75S PTC Thermistors for Over-Current and Over-Load Protection

SMD Sensors: Advanced Temperature Sensing Excellence

PTC SMD Thermistor: Cutting-Edge Temperature Sensing Technology

KTY81-210 Sensor: Reliable and Precise Temperature Monitoring for Various Applications

Get in Touch

Discover premium thermistors, sensors, and resistors tailored to your needs.Our dedicated team of experts is available to assist with product selection, technical queries, and after-sales service. Contact us for custom solutions and experience exceptional customer support.

© 2024 DXM | Designed by gooeyun

Scan QR Code

Scan QR Code

Scan QR Code

Whatsapp: +8618927361658

Shenzhen DXM Technology Co., Ltd.

DXM PTCNTC

Shenzhen DXM Technology Co., Ltd